New here - just looking for some tips from experienced people!

Posted by jp911

|

New here - just looking for some tips from experienced people! February 17, 2014 01:25PM |

Registered: 10 years ago Posts: 1 |

Hi!

New here,

I just purchased and set up my Prusa i3 from Makerfarm.

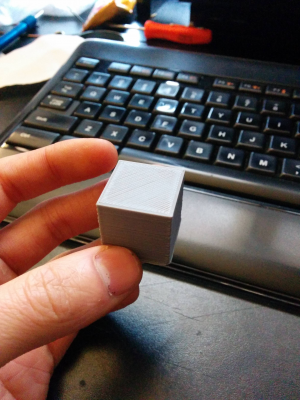

I have a few prints under my belt. But I had some questions.

1. The LCD interface during the print - it allows me to change the speed of the print in % on the fly. Is there a way I can utilize this to give me better prints? Or should I just leave it at 100?

2. Is there a good bed leveling guide out there? Ive had some luck doing it with just a piece of paper and moving the head around but if there is a better way Id love to know.

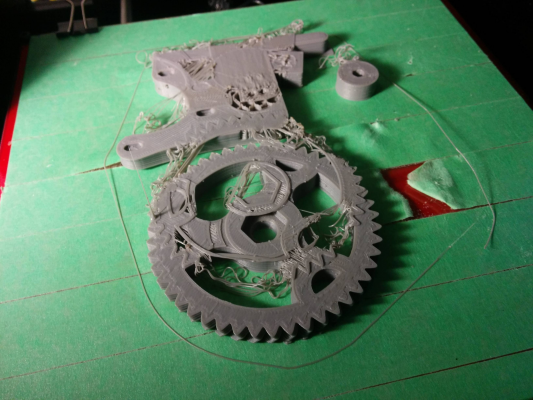

3. I recently had a print fail like this twice. The print itself shifted. Any comments?

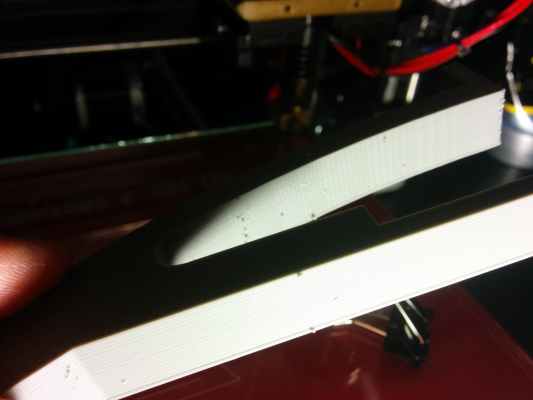

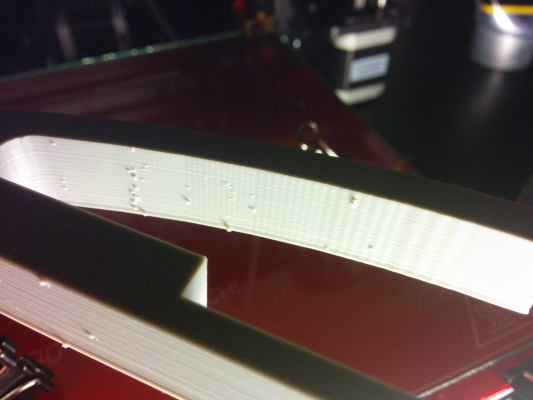

4. How can I improve the print quality and reduce the little bubbles that come out? Over hang on the dome I printed? I know what I am getting is pretty good but it can always be better right?

Thanks,

Jeff

New here,

I just purchased and set up my Prusa i3 from Makerfarm.

I have a few prints under my belt. But I had some questions.

1. The LCD interface during the print - it allows me to change the speed of the print in % on the fly. Is there a way I can utilize this to give me better prints? Or should I just leave it at 100?

2. Is there a good bed leveling guide out there? Ive had some luck doing it with just a piece of paper and moving the head around but if there is a better way Id love to know.

3. I recently had a print fail like this twice. The print itself shifted. Any comments?

4. How can I improve the print quality and reduce the little bubbles that come out? Over hang on the dome I printed? I know what I am getting is pretty good but it can always be better right?

Thanks,

Jeff

|

Re: New here - just looking for some tips from experienced people! February 19, 2014 01:06PM |

Registered: 13 years ago Posts: 485 |

1- I don't have one of those, so I don't know for sure. I believe people normally leave them at 100% unless there is a need to slow down or speed up to deal with a difficult portion of a particular print. For example, you may want to slow it down to give small layers more time to cool, or speed it up to keep really small layers from melting.

2- Apart from implementing auto-leveling, it sounds like you're on the right track. It looks like you have glass on the print bet too, which is good for making sure you have a flat surface. The last thing to remember is to level the bed with everything hot and in an equilibrium state. Since things swell slightly when hot, that's where you want to level and set Z axis home. In general, calibrate anything using conditions as close as possible to ordinary operating conditions.

3- Lost steps. Either current on the stepper driver is too low, or acceleration is too high. Current too high can cause similar symptoms, because the stepper driver will turn itself off to cool if it overheats.

4- Bubbles are caused by moisture in the filament, or pockets of gas in low quality filament. Keep your filament dry with a dessicant. I hear you can dry filament at low temperature in the oven, but you run the risk of melting a whole spool if you get it too hot. Correct temperature for drying will depend on the filament material, and I don't know what to recommend for what. I just store mind in big zip-lock bags with dessicant. Also, PLA is more prone to moisture contamination than ABS.

For steeper overhangs, try lower layer heights. This allows less overhang as a percentage of the trace width, so the trace is anchored better on the previous layer.

2- Apart from implementing auto-leveling, it sounds like you're on the right track. It looks like you have glass on the print bet too, which is good for making sure you have a flat surface. The last thing to remember is to level the bed with everything hot and in an equilibrium state. Since things swell slightly when hot, that's where you want to level and set Z axis home. In general, calibrate anything using conditions as close as possible to ordinary operating conditions.

3- Lost steps. Either current on the stepper driver is too low, or acceleration is too high. Current too high can cause similar symptoms, because the stepper driver will turn itself off to cool if it overheats.

4- Bubbles are caused by moisture in the filament, or pockets of gas in low quality filament. Keep your filament dry with a dessicant. I hear you can dry filament at low temperature in the oven, but you run the risk of melting a whole spool if you get it too hot. Correct temperature for drying will depend on the filament material, and I don't know what to recommend for what. I just store mind in big zip-lock bags with dessicant. Also, PLA is more prone to moisture contamination than ABS.

For steeper overhangs, try lower layer heights. This allows less overhang as a percentage of the trace width, so the trace is anchored better on the previous layer.

|

Re: New here - just looking for some tips from experienced people! February 19, 2014 03:33PM |

Registered: 11 years ago Posts: 57 |

Hi jp911,

Overall your prints look good.

But, looking at the two last pictures (white printed strip with bumps), let me guess your using Slic3r...

(your artifacts/bumps/blobs problems look like typically garbage from Slic3r output).

_______

So here's my little copy and paste rant on using a competent slicer...

Have a quick glance at the Slic3r Forum... [forums.reprap.org]

Nothing more than a extensive bug list that goes on forever and grows with every new release of Slic3r.

I used to read this Slic3r blog daily, then I got a clue... You can't circumvent crappy slicing software by manipulating your slicer profiles, modifying your firmware or blaming your machine.

FYI... NOT sure why anybody is still using Slic3R beyond v7.02b (v7.02b is a great simple and competent slicer).

I sadly laugh when I see people trying to fix problems with this continual problematic slicer >Slic3R v7.02b.

I finally gave up after Slic3R v9.8; recouped my life, and no more wasted time and plastic, and moved forward away from Slic3R.

Every new Slic3R upgrade version has a new set of unresolved problems. I tried EVERY Slic3R version v7.02b - v9.8 extensively and utilized every smart so called fix for the problems... result garbage can full of melted plastic, hundred of frustrating hours endured/wasted, and saw my life passing me by. I'M DONE, DONE, DONE and DONE with Slic3R !!!

I used Skeinforge v41-v50 as my primary slicer for the last 2 years, but it has a memory limit which restricts you from printing more than simple trinkets and objects.

Over the last year, I print very complex and close tolerance engineering prototypes (0.1mm Layer Height @ +- 0.05mm tolerance) all day long everyday using KISSlicer, IMO it is the best slicer solution out there. NO more Slic3r wasting my time and memory limitations using Skeinforge, I have my life back now and time to do other things other than melt plastic in to useless shapes and fill the garbage can.

Note : KISSlicer is seemingly and sadly going defunct it appears, and is no longer maintained by it's creator/owner, but is still the best overall slicer ATM.

Download from here:

www.kisslicer.com

Information here:

- Kisslicer Refugee Camp - Google Groups

[groups.google.com]

_____________________

Stop chasing your tail around using Slic3r.

You problems could quickly go away by using a competent slicer and NOT Slic3R.

Edited 4 time(s). Last edit at 02/20/2014 01:36PM by ShawnT98027.

Overall your prints look good.

But, looking at the two last pictures (white printed strip with bumps), let me guess your using Slic3r...

(your artifacts/bumps/blobs problems look like typically garbage from Slic3r output).

_______

So here's my little copy and paste rant on using a competent slicer...

Have a quick glance at the Slic3r Forum... [forums.reprap.org]

Nothing more than a extensive bug list that goes on forever and grows with every new release of Slic3r.

I used to read this Slic3r blog daily, then I got a clue... You can't circumvent crappy slicing software by manipulating your slicer profiles, modifying your firmware or blaming your machine.

FYI... NOT sure why anybody is still using Slic3R beyond v7.02b (v7.02b is a great simple and competent slicer).

I sadly laugh when I see people trying to fix problems with this continual problematic slicer >Slic3R v7.02b.

I finally gave up after Slic3R v9.8; recouped my life, and no more wasted time and plastic, and moved forward away from Slic3R.

Every new Slic3R upgrade version has a new set of unresolved problems. I tried EVERY Slic3R version v7.02b - v9.8 extensively and utilized every smart so called fix for the problems... result garbage can full of melted plastic, hundred of frustrating hours endured/wasted, and saw my life passing me by. I'M DONE, DONE, DONE and DONE with Slic3R !!!

I used Skeinforge v41-v50 as my primary slicer for the last 2 years, but it has a memory limit which restricts you from printing more than simple trinkets and objects.

Over the last year, I print very complex and close tolerance engineering prototypes (0.1mm Layer Height @ +- 0.05mm tolerance) all day long everyday using KISSlicer, IMO it is the best slicer solution out there. NO more Slic3r wasting my time and memory limitations using Skeinforge, I have my life back now and time to do other things other than melt plastic in to useless shapes and fill the garbage can.

Note : KISSlicer is seemingly and sadly going defunct it appears, and is no longer maintained by it's creator/owner, but is still the best overall slicer ATM.

Download from here:

www.kisslicer.com

Information here:

- Kisslicer Refugee Camp - Google Groups

[groups.google.com]

_____________________

Stop chasing your tail around using Slic3r.

You problems could quickly go away by using a competent slicer and NOT Slic3R.

Edited 4 time(s). Last edit at 02/20/2014 01:36PM by ShawnT98027.

Sorry, only registered users may post in this forum.