Universal 3D printing filament spool standard 2014

Posted by richrap

|

Universal 3D printing filament spool standard 2014 March 13, 2014 09:59AM |

Registered: 13 years ago Posts: 818 |

Hello Everyone,

This thread is intended to be a place where comments and ideas can be gathered by anyone and everyone for a 'Universal 3D printing filament spool standard'

The idea is for the 3D printing community to help define a standard and ask filament manufacturers to consider supporting this so it's easier for all to use different filaments from various suppliers and also so designers can start to integrate filament spools into machine designs.

The outline goals should come from the questions below, but remember this is supposed to be an open standard made by and for the community, so feel free to suggest ideas and other goals if they are important to you.

Would it be possible for manufacturers to have a set filament standard for spool size, shape and mounting?

Can the 3D printing community help develop that standard?

Can we make it Eco-friendly and recyclable?

Does anyone want it? (What is it worth - to the customer, filament manufacturer, 3D printer manufacturer, 3D printing community)

I have posted a lot more information on My Blog here, just to get some ides going and the campaign underway.

The 3D Printing Association are providing support for this campaign, if it goes well maybe we can strive for more standards or collaborative specifications for designers and manufacturers to support and build on.

I hope this is something you want and need, if it is, show some support, get involved, lets see what we can do together.

Rich.

Twitter - @RichRap3D

[richrap.blogspot.com]

This thread is intended to be a place where comments and ideas can be gathered by anyone and everyone for a 'Universal 3D printing filament spool standard'

The idea is for the 3D printing community to help define a standard and ask filament manufacturers to consider supporting this so it's easier for all to use different filaments from various suppliers and also so designers can start to integrate filament spools into machine designs.

The outline goals should come from the questions below, but remember this is supposed to be an open standard made by and for the community, so feel free to suggest ideas and other goals if they are important to you.

Would it be possible for manufacturers to have a set filament standard for spool size, shape and mounting?

Can the 3D printing community help develop that standard?

Can we make it Eco-friendly and recyclable?

Does anyone want it? (What is it worth - to the customer, filament manufacturer, 3D printer manufacturer, 3D printing community)

I have posted a lot more information on My Blog here, just to get some ides going and the campaign underway.

The 3D Printing Association are providing support for this campaign, if it goes well maybe we can strive for more standards or collaborative specifications for designers and manufacturers to support and build on.

I hope this is something you want and need, if it is, show some support, get involved, lets see what we can do together.

Rich.

Twitter - @RichRap3D

[richrap.blogspot.com]

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 10:37AM |

Registered: 10 years ago Posts: 11 |

This is a great idea Rich! Only last night I was trying to untangle at 750g roll of 1.75mm PLA after it tied a knot around itself! It would be great to be able to purchase filament and simply locate it on the printer, feed it into the extruder and away you go.

I’ve been using a company for a couple of years who supply the material in loose coils; in general I have no problems as I’ve made myself an adjustable spool which caters for the variation in loose coil inner diameter. I’ve noticed that some loose coils are zip tied together to hold its shape – I find these ones tend to tangle much less than the non zip tied coils. Either way this isn’t a great solution because I can never quite trust that the filament will tangle itself during an unattended print. Nothing worse than coming back to a 10 hour long print only to find its been skywriting for 9.5 hours!!

I think the concept of a cardboard spool is a great idea and I was given the choice to spend a little more money I would buy a spooled coil over a loose coil every time.

Also on a slightly different note, reding your blog I agree that filament suppliers seem to be offering less per coil. For someone like me who only prints in one colour at a time I find it quite tiresome as the coils (especially 1.75mm) do not last long enough. Minor quibble though!

Thanks for getting the ball rolling Rich. I’ll watch the progress with a keen interest and I’ll do what I can to help along the way.

I’ve been using a company for a couple of years who supply the material in loose coils; in general I have no problems as I’ve made myself an adjustable spool which caters for the variation in loose coil inner diameter. I’ve noticed that some loose coils are zip tied together to hold its shape – I find these ones tend to tangle much less than the non zip tied coils. Either way this isn’t a great solution because I can never quite trust that the filament will tangle itself during an unattended print. Nothing worse than coming back to a 10 hour long print only to find its been skywriting for 9.5 hours!!

I think the concept of a cardboard spool is a great idea and I was given the choice to spend a little more money I would buy a spooled coil over a loose coil every time.

Also on a slightly different note, reding your blog I agree that filament suppliers seem to be offering less per coil. For someone like me who only prints in one colour at a time I find it quite tiresome as the coils (especially 1.75mm) do not last long enough. Minor quibble though!

Thanks for getting the ball rolling Rich. I’ll watch the progress with a keen interest and I’ll do what I can to help along the way.

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 12:04PM |

Registered: 10 years ago Posts: 903 |

Why does everyone hate on Cube 3D for making their own filament cartridge standard?

Seriously though, let me play devil's advocate. With all of the varying qualities of filament on the market, some of us would like the hope of being able to figure out who the manufacturer of re-branded filament is by looking at pictures of the spools before we order. If three different vendors are selling the same filament from the same manufacturer for vastly different markups, this would make shopping based on price much less risky if one can map the manufacturer to their unique spools. Although it sounds like a great idea from a mechanical perspective, put me down as voting no for standardized spools.....

Seriously though, let me play devil's advocate. With all of the varying qualities of filament on the market, some of us would like the hope of being able to figure out who the manufacturer of re-branded filament is by looking at pictures of the spools before we order. If three different vendors are selling the same filament from the same manufacturer for vastly different markups, this would make shopping based on price much less risky if one can map the manufacturer to their unique spools. Although it sounds like a great idea from a mechanical perspective, put me down as voting no for standardized spools.....

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 12:13PM |

Registered: 12 years ago Posts: 50 |

This would match up very well with the Universal Filament Identification System that is currently developed:

[plus.google.com]

[plus.google.com]

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 12:25PM |

Registered: 10 years ago Posts: 241 |

It would be nice to have a STANDARD. Although, there are many things to consider when asking the manufacturers to conform.

1. They may have a contract with a spool company and are obligated to use them.

2. They are specified to a machine that will now require that spool size and shape.

3. THEIR spool making machine can only make one kind.

I'd rather re-spool onto another. Such as filling a sewing machine bobbin or re-spooling fishing line on a reel.

1. They may have a contract with a spool company and are obligated to use them.

2. They are specified to a machine that will now require that spool size and shape.

3. THEIR spool making machine can only make one kind.

I'd rather re-spool onto another. Such as filling a sewing machine bobbin or re-spooling fishing line on a reel.

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 01:17PM |

Registered: 13 years ago Posts: 818 |

Thanks for the early feedback everyone, much appreciated.

@strelly - thanks, I replied on my blog comments about this. Thank you for getting involved.

@vreihen - Anyone can make their own standard, this is more about an 'open mechanical standard' hopefully without using lots of plastic casings that are not designed to be refilled and only contain ~300g of plastic filament costing $80+

This 'standard' should not stop people branding up the spools however they like, labels, printed cardboard with logo's or coloured with the manufacturers 'brand' It should be quite possible to identify a manufacturer and have a universal mechanical standard. In fact you could argue many more options for branding appear with a cardboard spool than a plastic one. Any re-branded filament should not be too hard to track-down - are you still a NO to the idea of a standard?

@jreinhardt - Indeed, and maybe it even helps the UFIS project if we have a 'standard place' to put the details etc.

@KingRahl - All challenges, but possible to change and work with. Re-spooling filament is almost the last thing you ever want to try doing, that can cause many more problems than the ones already identified.

Cheers,

Rich.

[richrap.blogspot.com]

@strelly - thanks, I replied on my blog comments about this. Thank you for getting involved.

@vreihen - Anyone can make their own standard, this is more about an 'open mechanical standard' hopefully without using lots of plastic casings that are not designed to be refilled and only contain ~300g of plastic filament costing $80+

This 'standard' should not stop people branding up the spools however they like, labels, printed cardboard with logo's or coloured with the manufacturers 'brand' It should be quite possible to identify a manufacturer and have a universal mechanical standard. In fact you could argue many more options for branding appear with a cardboard spool than a plastic one. Any re-branded filament should not be too hard to track-down - are you still a NO to the idea of a standard?

@jreinhardt - Indeed, and maybe it even helps the UFIS project if we have a 'standard place' to put the details etc.

@KingRahl - All challenges, but possible to change and work with. Re-spooling filament is almost the last thing you ever want to try doing, that can cause many more problems than the ones already identified.

Cheers,

Rich.

[richrap.blogspot.com]

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 01:19PM |

Registered: 12 years ago Posts: 5 |

@vreihen -- Keep in mind that spools are often NOT made by the same company that is producing the filament. There is a US-based company that makes spools for this market, and their spool is used by at least two different extrusion companies.

Perhaps instead of defining *one* standard to rule them all, there might be several standardized form-factors? Much like the various sizes of ATX/ITX variants, SPWG panel standards, and storage devices (HDD/SSD) that specify key mechanical features...

By imposing a too-rigid requirement on the standard, you'll drive the price of the spools up. There may be production/workflow issues that also guides the selection of spooling methods for a particular producer.

Perhaps instead of defining *one* standard to rule them all, there might be several standardized form-factors? Much like the various sizes of ATX/ITX variants, SPWG panel standards, and storage devices (HDD/SSD) that specify key mechanical features...

By imposing a too-rigid requirement on the standard, you'll drive the price of the spools up. There may be production/workflow issues that also guides the selection of spooling methods for a particular producer.

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 01:28PM |

Registered: 12 years ago Posts: 12 |

Hi Guys.

Down here in sunny South Africa, it's been really costly to import filament. Of late we have been turning to China and have found some excellent quality suppliers, but it's only viable bringing in about 1 ton at a time and the by ocean freight. This takes up to 3 months sometimes to arrive and we have often been left red faced when we have run out of stock and cannot supply to customers.

The solution - we have started to extrude our own ABS and PTA - and we have been very successful.

Now would be a great time to standardise on a spool.

Has any consensus been made as to the ideal spool dimensions. We currently use a cardboard spool.

Something else to take into consideration is standardising on colour choices. I think these should be controlled ' like Pantone colours.

1 suppliers blue is not the same as another's. I've even found 1 blue and another blue from the same supplier is different. This causes huge problems in large jobs and production jobs.

www.3d-printer.co.za

www.cad-house.co.za

Edited 1 time(s). Last edit at 03/13/2014 01:29PM by FuzzyDuck.

Down here in sunny South Africa, it's been really costly to import filament. Of late we have been turning to China and have found some excellent quality suppliers, but it's only viable bringing in about 1 ton at a time and the by ocean freight. This takes up to 3 months sometimes to arrive and we have often been left red faced when we have run out of stock and cannot supply to customers.

The solution - we have started to extrude our own ABS and PTA - and we have been very successful.

Now would be a great time to standardise on a spool.

Has any consensus been made as to the ideal spool dimensions. We currently use a cardboard spool.

Something else to take into consideration is standardising on colour choices. I think these should be controlled ' like Pantone colours.

1 suppliers blue is not the same as another's. I've even found 1 blue and another blue from the same supplier is different. This causes huge problems in large jobs and production jobs.

www.3d-printer.co.za

www.cad-house.co.za

Edited 1 time(s). Last edit at 03/13/2014 01:29PM by FuzzyDuck.

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 02:00PM |

Registered: 10 years ago Posts: 241 |

Quote

richrap

All challenges, but possible to change and work with. Re-spooling filament is almost the last thing you ever want to try doing, that can cause many more problems than the ones already identified.

Rich.

Spooling or re-spooling can help prevent those pesky knots created from not having a spool. I've had a spool that was so tightly wound, one of the end caps came off. I was able to re-spool without any problems. It took forever though. I thought about designing a motorized winder to get it done quicker but only needed it once. It sounds like if there would be a standard that more machines "required" and suppliers kept sending non-compatible spool or no spool at all, I may make one.

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 02:13PM |

Registered: 13 years ago Posts: 2,947 |

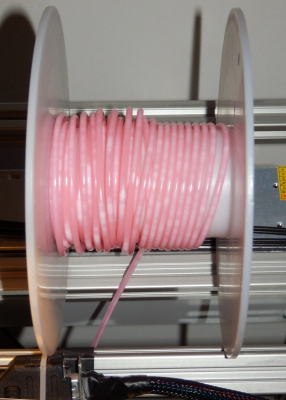

I like that you can tell who manufactured the filament from the spool style. It is true a few companies use the same spools but they do not use the same spools as the bad suppliers like Esun. If manufacturers want to standardize the spools I think they need to agree to mark the spool with the manufacturers name so we as consumers can tell them apart regardless of what the re-sellers want or think. As it is the re-sellers are unknowingly letting us know who made their filament by the spool type and giving them a way to hide their supplier does not sit well with me. Also I like the tightly wound spools since they take up less space and cause ZERO issues if you use a Bowden cable or a feed tube. I think the only part that could be standardized is the hole in the middle so they fit on the same holder. I also like the idea of them being cardboard so they can easily be recycled and save money on shipping cost due to the lower weight.

Edited 1 time(s). Last edit at 03/13/2014 02:30PM by Sublime.

Edited 1 time(s). Last edit at 03/13/2014 02:30PM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 02:41PM |

Registered: 13 years ago Posts: 818 |

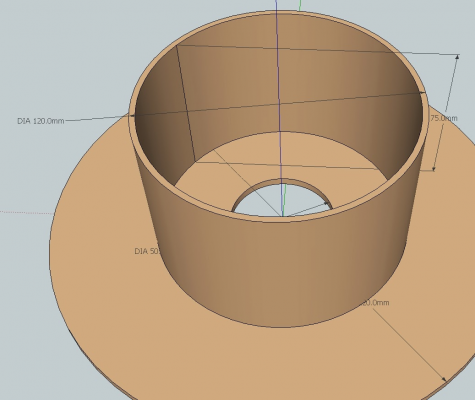

@toybuilder - Agreed, the main critical 'standard' dimensions are mounting hole and I believe a minimum inner coil diameter suitable for the type of filament being wound/unwound.

I was trying to illustrate on my Blog post that manufacturers could comply to the standard but have compatible critical dimensions, in this sketch -

[richrap.blogspot.com]

I was trying to illustrate on my Blog post that manufacturers could comply to the standard but have compatible critical dimensions, in this sketch -

[richrap.blogspot.com]

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 02:46PM |

Registered: 13 years ago Posts: 818 |

@FuzzyDuck - that's good to know, and congratulations on making your own filament locally. I doubt any manufacturer will want to be told what colour to use, branding, colours and packaging should play a big part in flexibility of the standard as long as key mechanical aspects are met.

@KingRahl - I agree you can sometimes help things by re-spooling, but I never want to have to re-spool any filament ever again. I have also had experiences of filament fracturing and breaking by re-spooling a tighter coil into a bigger one, over time the PLA fractured then shattered. When Filament is made it's directly spooled onto the reels, not done after being manufactured,so it set's in that shape. Without impact modifiers it can break under stress.

[richrap.blogspot.com]

@KingRahl - I agree you can sometimes help things by re-spooling, but I never want to have to re-spool any filament ever again. I have also had experiences of filament fracturing and breaking by re-spooling a tighter coil into a bigger one, over time the PLA fractured then shattered. When Filament is made it's directly spooled onto the reels, not done after being manufactured,so it set's in that shape. Without impact modifiers it can break under stress.

[richrap.blogspot.com]

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 03:03PM |

Registered: 13 years ago Posts: 818 |

@Sublime - Hi Brad, thanks for getting involved. I can't imagine many good manufacturer will want to keep their spools blank and non-marked. at the moment with plastic spools a label can be removed from the spool, if it was on a printed cardboard spool it would be much harder to hide the manufacturer, I hope that's another incentive for actual manufacturers to do something like this.

Colorfabb have a custom ABS spool stamped with their website, a recycle logo and date, resellers can't hide that and why would they want to.

I have seen many more then ZERO issues on various machines using tightly wound 3mm filament, even ones using bowden feeds. But much of that also depends on how the filament has been treated going onto the spool, some get wound quickly when still warm, squashed oval, strained, kinked or twisted.

I would not want to bet a machine like the Ultimaker 2 with a direct drive bowden would not have issues with a coil like this, I would be very happy to be proved wrong, but tightly wound coils of PLA have caused me and others plenty of issues in use.

The less changes we need to make the more likely manufacturers are to implement something, I agree cardboard and a 'standard' mounting hole has to be a good starting point, but I will also look out for bigger inner coils too.

Cheers,

Rich.

[richrap.blogspot.com]

Colorfabb have a custom ABS spool stamped with their website, a recycle logo and date, resellers can't hide that and why would they want to.

I have seen many more then ZERO issues on various machines using tightly wound 3mm filament, even ones using bowden feeds. But much of that also depends on how the filament has been treated going onto the spool, some get wound quickly when still warm, squashed oval, strained, kinked or twisted.

I would not want to bet a machine like the Ultimaker 2 with a direct drive bowden would not have issues with a coil like this, I would be very happy to be proved wrong, but tightly wound coils of PLA have caused me and others plenty of issues in use.

The less changes we need to make the more likely manufacturers are to implement something, I agree cardboard and a 'standard' mounting hole has to be a good starting point, but I will also look out for bigger inner coils too.

Cheers,

Rich.

[richrap.blogspot.com]

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 03:24PM |

Registered: 13 years ago Posts: 2,947 |

Quote

richrap

@Sublime -

I have seen many more then ZERO issues on various machines using tightly wound 3mm filament, even ones using bowden feeds. But much of that also depends on how the filament has been treated going onto the spool, some get wound quickly when still warm, squashed oval, strained, kinked or twisted.

I would not want to bet a machine like the Ultimaker 2 with a direct drive bowden would not have issues with a coil like this, I would be very happy to be proved wrong, but tightly wound coils of PLA have caused me and others plenty of issues in use.

Although this is true you can also just say it is a machine issue not a spool issue. I could say all 3mm is made wrong if I have a1.75mm hotend but that is not really the truth.

So sometimes we need to stop and say, do we want the supplier to be able to stock more in a smaller space thus costing less per sq foot to stock and larger variety available, which would in turn could/should repeatedly reduce the cost to the end user at the one time expensive of building a better extruder. Or should be have higher prices on the consumables we buy all the time for the one time cheaper extruder.

Also if the tightly rolled filament is an issue it would be really easy to print a straightener.

This is a stainless tubing/rod straightener.

In the last year and a half I have only used PLA that comes on spools like you pictured and every single one looks like that in the middle (except for the unspooled I still have from 2years ago that I use for testing sometimes).

I keep 12 active rolls of filament on bars in a rubbermaid tub and have feed tubes coming out to the front of the machines into the bowden and with the Esun style spools I could only get about 8 in the same box because it could not be two layers.

The cost of living space is so high I think space saving is really important.

Do not get me wrong I do agree that the larger inner diameter could help if the extruder is weak or a bad hobb. But a feed tube would stop most of the other issues like the carriage getting pulled sideways or the rack getting pulled down.

Quote

The less changes we need to make the more likely manufacturers are to implement something, I agree cardboard and a 'standard' mounting hole has to be a good starting point, but I will also look out for bigger inner coils too.

Agreed.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 04:35PM |

Registered: 10 years ago Posts: 903 |

Quote

richrap

@vreihen - Anyone can make their own standard, this is more about an 'open mechanical standard' hopefully without using lots of plastic casings that are not designed to be refilled and only contain ~300g of plastic filament costing $80+

This 'standard' should not stop people branding up the spools however they like, labels, printed cardboard with logo's or coloured with the manufacturers 'brand' It should be quite possible to identify a manufacturer and have a universal mechanical standard. In fact you could argue many more options for branding appear with a cardboard spool than a plastic one. Any re-branded filament should not be too hard to track-down - are you still a NO to the idea of a standard?

Rich,

Every open-source hardware vendor and their brother seems to be selling a "store brand" of filament. Some have good prices, and others not so good. They are not manufacturing their filament, but rather buying it pre-spooled in larger orders from a manufacturer, slapping their own branding label on it, and selling it as their own product. These resellers don't want to share who the manufacturer of their filament is, because it allows for people to price shop knowing that they are getting the same exact filament from another reseller at a better price. The only other alternative is to buy it, have it shipped, and return it once you peel the reseller's branding label off to see who made it.

By publishing a spool standard, you may be driving the manufacturers of the filament to all buy the same mass-produced spools, which will come down in cost (good thing!) but take away our ability to fingerprint the manufacturer of a particular filament (bad thing).

Yes, I can see the good things that would come from a standard spool size...especially in filament storage containers with seals for humidity control. Is a spool even the best way to store/transport filament to keep it dry and free of contamination? Would a donut-shaped cylinder where you pull filament out of the center be a better standard if we're only pursuing one?

Quote

Sublime

I like that you can tell who manufactured the filament from the spool style. It is true a few companies use the same spools but they do not use the same spools as the bad suppliers like Esun. If manufacturers want to standardize the spools I think they need to agree to mark the spool with the manufacturers name so we as consumers can tell them apart regardless of what the re-sellers want or think. As it is the re-sellers are unknowingly letting us know who made their filament by the spool type and giving them a way to hide their supplier does not sit well with me.

I guess that our secret is out of the bag now, huh?

Quote

toybuilder

@vreihen -- Keep in mind that spools are often NOT made by the same company that is producing the filament. There is a US-based company that makes spools for this market, and their spool is used by at least two different extrusion companies.

American Standard doesn't just manufacture toilets!

However, I'm willing to bet that those US-manufactured empty spools don't cross an ocean traveling west due to the shipping cost, so seeing that one spool can potentially eliminate an entire hemisphere's worth of filament manufacturers when you're trying to figure out the source of a filament when shopping by pictures.....

However, I'm willing to bet that those US-manufactured empty spools don't cross an ocean traveling west due to the shipping cost, so seeing that one spool can potentially eliminate an entire hemisphere's worth of filament manufacturers when you're trying to figure out the source of a filament when shopping by pictures.....

|

Re: Universal 3D printing filament spool standard 2014 March 13, 2014 05:36PM |

Registered: 10 years ago Posts: 6 |

I like the reel-less packaging that some network cabling comes in.

It pays out from the center of a folded figure-8 through a tube in the side of the box.

No loops, snags, or reel inertia. I've yet to have one tangle on me.

It'd be the ideal filament "spool". All post-consumer cardboard and such

They've also done some interesting srinkwrap packages.

Check out Reelex

Alternatively we could do flat figure-8 loops in a rectangular box or bag and pay it out from the center of the "8"

It pays out from the center of a folded figure-8 through a tube in the side of the box.

No loops, snags, or reel inertia. I've yet to have one tangle on me.

It'd be the ideal filament "spool". All post-consumer cardboard and such

They've also done some interesting srinkwrap packages.

Check out Reelex

Alternatively we could do flat figure-8 loops in a rectangular box or bag and pay it out from the center of the "8"

|

Re: Universal 3D printing filament spool standard 2014 March 14, 2014 07:08AM |

Registered: 10 years ago Posts: 23 |

|

Re: Universal 3D printing filament spool standard 2014 March 14, 2014 07:23AM |

Registered: 10 years ago Posts: 14 |

@Rich -- excellent idea, and I was actually going to propose the same (although honestly think it will be hard to make manufacturers change spools).

I am in the process of setting up filament manufacturing business and last week was debating around the same issue. What spool to go for...

Small/big, plastic/cardboard, small core or large core...

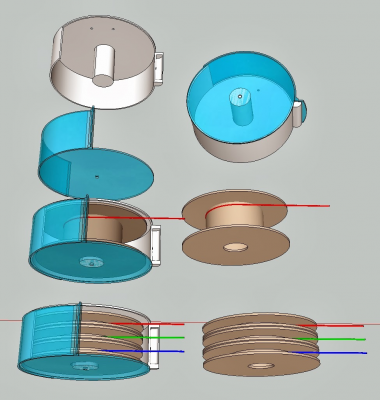

What I came up with so far is this:

- bigger spool is always better than small, as tightly wound filament deforms, springs, and can also break if doesn't contain modifiers -- especially true when it comes to ABS. but you can't stick to big core spool only, because there are many small printers that won't have space to mount these... So I think we need two standard spool sizes.

- material -- plastic vs cardboard -- I came to a conclusion that it does not matter, as long as it's hard cardboard and you don't get loose paper fibres all over your filament -- I've been to a few spool manufacturers and found some that make "solid" cardboard spool, that don't have any loose fibres. Conclusion: spool material does not matter. Paper is probably cheaper and easily recyclable everywhere.

- spool core -- this is the most important one I think -- I suggest as big core as possible, and then... 3D print adapters for smaller cores! I think this would be the easiest from the transition point of view.

Thoughts?

Regards,

Marcin

I am in the process of setting up filament manufacturing business and last week was debating around the same issue. What spool to go for...

Small/big, plastic/cardboard, small core or large core...

What I came up with so far is this:

- bigger spool is always better than small, as tightly wound filament deforms, springs, and can also break if doesn't contain modifiers -- especially true when it comes to ABS. but you can't stick to big core spool only, because there are many small printers that won't have space to mount these... So I think we need two standard spool sizes.

- material -- plastic vs cardboard -- I came to a conclusion that it does not matter, as long as it's hard cardboard and you don't get loose paper fibres all over your filament -- I've been to a few spool manufacturers and found some that make "solid" cardboard spool, that don't have any loose fibres. Conclusion: spool material does not matter. Paper is probably cheaper and easily recyclable everywhere.

- spool core -- this is the most important one I think -- I suggest as big core as possible, and then... 3D print adapters for smaller cores! I think this would be the easiest from the transition point of view.

Thoughts?

Regards,

Marcin

|

Re: Universal 3D printing filament spool standard 2014 March 14, 2014 10:01AM |

Registered: 13 years ago Posts: 818 |

@vreihen - Thanks for the thoughts, I'm very aware 'generic filament' is re-sold all over for various prices. Manufacturers making good quality filament are proud to brand it, re-sellers who sell good quality filament are proud to name the manufacture, if they don't then my advice is Do Not Buy It. It's always the very first question I ask any filament seller - Do you make it, if not who manufacturers the filament / where. And what exactly does it contain, including impact modifiers etc.

@MarksAlot - very interesting idea, I'm not sure if it would work for all 3D printing plastic, maybe nylon and PET? - I will try to find out by asking some of the manufacturers. It's rather disappointing that Reelex is a patented process...

@ralphferro - Excellent ! - thank you

@nothinman - That's about where I was at when writing the initial blog post. Maybe Nylon and soft materials can have a smaller core ~50mm and PLA's filled materials like Laywood, Laybrick and Woodfill should really have a bigger inner core ~120mm

Good luck with setting up manufacture, you are the second person to be doing that in this short thread alone!

I agree, you do not want cardboard fibers on the filament, that's not good news at all, but with clean cut solid cardboard or paper reels this should not be a problem. Or why not make the spools from PLA, one day we may finally be able to grind them down and make our own filament out of them - that's actually not a good idea, I'm not sure PLA is all that good for real recycling, it's bio-degradable but Cardboard would always be my first option.

- that's actually not a good idea, I'm not sure PLA is all that good for real recycling, it's bio-degradable but Cardboard would always be my first option.

@sublime - yes, space is a very important issue, (volume and weight too) I have spent a lot of time thinking about that, and it's not an easy one to balance. For the user I did wonder if you could make a bowden style extruder that sits inside the filament core, acts as both a mount for the coil and a direct feed (from the center) - very tricky to implement, but an interesting use of 3D space for two items that need to be together anyway.

[richrap.blogspot.com]

@MarksAlot - very interesting idea, I'm not sure if it would work for all 3D printing plastic, maybe nylon and PET? - I will try to find out by asking some of the manufacturers. It's rather disappointing that Reelex is a patented process...

@ralphferro - Excellent ! - thank you

@nothinman - That's about where I was at when writing the initial blog post. Maybe Nylon and soft materials can have a smaller core ~50mm and PLA's filled materials like Laywood, Laybrick and Woodfill should really have a bigger inner core ~120mm

Good luck with setting up manufacture, you are the second person to be doing that in this short thread alone!

I agree, you do not want cardboard fibers on the filament, that's not good news at all, but with clean cut solid cardboard or paper reels this should not be a problem. Or why not make the spools from PLA, one day we may finally be able to grind them down and make our own filament out of them

- that's actually not a good idea, I'm not sure PLA is all that good for real recycling, it's bio-degradable but Cardboard would always be my first option.

- that's actually not a good idea, I'm not sure PLA is all that good for real recycling, it's bio-degradable but Cardboard would always be my first option.@sublime - yes, space is a very important issue, (volume and weight too) I have spent a lot of time thinking about that, and it's not an easy one to balance. For the user I did wonder if you could make a bowden style extruder that sits inside the filament core, acts as both a mount for the coil and a direct feed (from the center) - very tricky to implement, but an interesting use of 3D space for two items that need to be together anyway.

[richrap.blogspot.com]

|

Re: Universal 3D printing filament spool standard 2014 March 14, 2014 12:39PM |

Registered: 11 years ago Posts: 334 |

@vreihen I label my plastic with my brand name and I am very proud of the quality of my filament. I am also an avid 3D printer and have shopped around to try other brands. The spool has been sort of an indicator of some manufacturers but it shouldn't be your only indicator of the quality and manufacturer of the plastic. Personally I recommend that 3D printer owners find a good supplier and stick with it. A good supplier will be able to tell you about the resins used in their plastics but sometimes you have to ask nicely. I have found that a lot of guys who buy solely on the lowest price learn the hard way that you get what you pay for. It doesn't take many failed prints before your supposed savings has now cost your more then buying good plastic in the first place. This is a real problem for people new to 3D printing, poor plastic can cause problems that newbies mistake for machine problems.

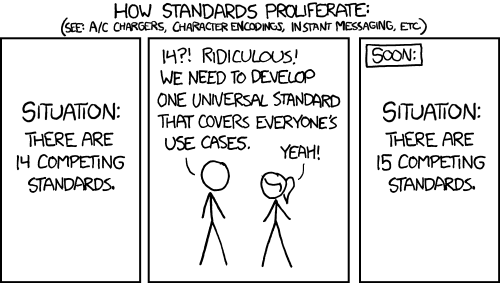

Richrap Although a standard would be nice We are going to have this problem almost immediately

I think that we need to think about this problem a different way, rather then trying to dictate a single standard for the marketplace. Spool centers seem to be the main problem with spool width a distant second. I have rarely found spool size to be a problem and it is easy to build a spool holder that accepts a range of spool sizes. My guess is that 90% of spools fall within a very similar set of parameters and we really only need to get the other 10% up to speed. We need to set a range of acceptable spool parameters or more specifically, a minimum standard. Rather then say that the spool has to have a 5" center diameter, we say that the the minimum center diameter is 5"+.

Getting standards to work is a very hard thing to do because companies are really not compelled to use a standard unless the market dictates it. The only other way to force a standard to work is to create it and then sell so much of a standardized product that it becomes the de facto standard. I don't see that happening with spools.

I don't want you to think that I am against the idea, the idea is great. It's the reality of setting standards that really make this into a difficult preposition.

Edited 1 time(s). Last edit at 03/14/2014 12:42PM by jzatopa.

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

Richrap Although a standard would be nice We are going to have this problem almost immediately

I think that we need to think about this problem a different way, rather then trying to dictate a single standard for the marketplace. Spool centers seem to be the main problem with spool width a distant second. I have rarely found spool size to be a problem and it is easy to build a spool holder that accepts a range of spool sizes. My guess is that 90% of spools fall within a very similar set of parameters and we really only need to get the other 10% up to speed. We need to set a range of acceptable spool parameters or more specifically, a minimum standard. Rather then say that the spool has to have a 5" center diameter, we say that the the minimum center diameter is 5"+.

Getting standards to work is a very hard thing to do because companies are really not compelled to use a standard unless the market dictates it. The only other way to force a standard to work is to create it and then sell so much of a standardized product that it becomes the de facto standard. I don't see that happening with spools.

I don't want you to think that I am against the idea, the idea is great. It's the reality of setting standards that really make this into a difficult preposition.

Edited 1 time(s). Last edit at 03/14/2014 12:42PM by jzatopa.

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

|

Re: Universal 3D printing filament spool standard 2014 March 14, 2014 12:55PM |

Registered: 10 years ago Posts: 553 |

|

Re: Universal 3D printing filament spool standard 2014 March 14, 2014 08:51PM |

Registered: 10 years ago Posts: 903 |

Quote

richrap

@vreihen - Thanks for the thoughts, I'm very aware 'generic filament' is re-sold all over for various prices. Manufacturers making good quality filament are proud to brand it, re-sellers who sell good quality filament are proud to name the manufacture, if they don't then my advice is Do Not Buy It. It's always the very first question I ask any filament seller - Do you make it, if not who manufacturers the filament / where. And what exactly does it contain, including impact modifiers etc.

Rich - Perhaps a more noble effort would be to form a voluntary filament manufacturer conformity standard organization, sort of like what the WiFi Alliance has done for wireless LAN hardware? If your wireless hardware passes the compatibility tests, you can use the WiFi logo on the packaging. If a filament has a diameter that varies less than X%, contains at least Y% new plastic and Z% filler when submitted for original testing (or post-certification random testing) plus whatever else is important for quality filament, then the manufacturer can use the organization's logo with a vendor/certification number so that interested parties can visit one web site and see the test results and manufacturer's name.

Actually, a better model might be what the Snell Foundation has done for motorcycle/bicycle/motorsport helmet safety. They publish an improved standard every 5 years, and manufacturers have to meet the new standard to use the latest certification number and logo. With filament, maybe a one year standard would be better until the technology and manufacturing process stabilize? This would give the better manufacturers who actually care about QC an incentive to create a premium product, because they could charge a higher price for it knowing that consumers interested in quality will be looking for the latest logo.

If your standardized spool proposal also included rigid specs for the filament quality and some sort of voluntary certification process, then I would change my vote to yes.....

|

Re: Universal 3D printing filament spool standard 2014 March 15, 2014 10:33AM |

Registered: 10 years ago Posts: 14 |

@vreihen

I'd like to remind you that the discussion is about the spools, not the filaments.

Also, you need to descend from the clouds back to Earth buddy; whereas I completely agree with you when it comes to quality of the filament, you need to understand that there will always be crap on the market. And it's entirely up to you to choose the filament you like. If you always go for the cheapest -- you have a problem. If you don't - demand the best. Any form of a 'certification' is pure nonsense. I really don't fancy paying someone for a sticker (and pay who exactly?) if I do better measurements that then can do, to verify mine. Also, there is nothing wrong with fillers. "Laywood" has 60% filler and nobody complains about it :-) Colour is also a filler. 2-3% of it.

But now, can we go back to talking about the spools please...

Marcin

I'd like to remind you that the discussion is about the spools, not the filaments.

Also, you need to descend from the clouds back to Earth buddy; whereas I completely agree with you when it comes to quality of the filament, you need to understand that there will always be crap on the market. And it's entirely up to you to choose the filament you like. If you always go for the cheapest -- you have a problem. If you don't - demand the best. Any form of a 'certification' is pure nonsense. I really don't fancy paying someone for a sticker (and pay who exactly?) if I do better measurements that then can do, to verify mine. Also, there is nothing wrong with fillers. "Laywood" has 60% filler and nobody complains about it :-) Colour is also a filler. 2-3% of it.

But now, can we go back to talking about the spools please...

Marcin

|

Re: Universal 3D printing filament spool standard 2014 March 17, 2014 04:59AM |

Registered: 14 years ago Posts: 36 |

I'm not sure how the cardboard spools are meant to be held together, but here's an idea I had. Two pieces of cardboard and a short piece of plastic or cardboard tube (length <= radius). You can wrap some packing tape around the center before spooling the plastic to hold the two halves in place.

It doesn't have the inner rim that Richrap's design has, but that could be added (strengthening the walls in the process) by laminating another layer of cardboard on each side, which would also prevent the core tube from working its way out. The extra wall pieces would be a good place for manufacturers to print their branding and UFID code.

Edited 1 time(s). Last edit at 03/17/2014 05:00AM by whosawhatsis.

[whosawhatsis.com]

It doesn't have the inner rim that Richrap's design has, but that could be added (strengthening the walls in the process) by laminating another layer of cardboard on each side, which would also prevent the core tube from working its way out. The extra wall pieces would be a good place for manufacturers to print their branding and UFID code.

Edited 1 time(s). Last edit at 03/17/2014 05:00AM by whosawhatsis.

[whosawhatsis.com]

|

Re: Universal 3D printing filament spool standard 2014 March 17, 2014 08:09AM |

Registered: 13 years ago Posts: 818 |

@jzatopa - I like the graphic, but I don't see 'any' real standards competing, just some spools that work well for people and plenty that don't. Many manufacturers were not even aware of these sorts of issues for users. They are skilled in plastic extrusion, some don't 3D print themselves and so are not aware how users desire their product. Many spools were just what the manufacturer could get hold of, not what's good for the consumer, and that's the whole point in this exercise.

@jzatopa - I put a big list of the ones I had on my blog post, highlighting some common aspects.

@vreihen - more noble maybe, but I and most others don't have time to run an organisation, that's exactly what i'm 'using' the 3D printing Association for - so lets' gather the data and ideas from the community and not worry about if manufacturers want to take it on, whatever happens this will be good feedback (for them and us) to improve things and hopefully help standardize one aspect of home 3D printing.

- so lets' gather the data and ideas from the community and not worry about if manufacturers want to take it on, whatever happens this will be good feedback (for them and us) to improve things and hopefully help standardize one aspect of home 3D printing.

@nothinman - agreed, filaments are another conversation. price v quality usually resolves itself in the marketplace. This campaign aims to make good printable filament more usable on most/many/all machines if at all possible.

[richrap.blogspot.com]

@jzatopa - I put a big list of the ones I had on my blog post, highlighting some common aspects.

@vreihen - more noble maybe, but I and most others don't have time to run an organisation, that's exactly what i'm 'using' the 3D printing Association for

- so lets' gather the data and ideas from the community and not worry about if manufacturers want to take it on, whatever happens this will be good feedback (for them and us) to improve things and hopefully help standardize one aspect of home 3D printing.

- so lets' gather the data and ideas from the community and not worry about if manufacturers want to take it on, whatever happens this will be good feedback (for them and us) to improve things and hopefully help standardize one aspect of home 3D printing.@nothinman - agreed, filaments are another conversation. price v quality usually resolves itself in the marketplace. This campaign aims to make good printable filament more usable on most/many/all machines if at all possible.

[richrap.blogspot.com]

|

Re: Universal 3D printing filament spool standard 2014 March 17, 2014 08:19AM |

Registered: 13 years ago Posts: 818 |

Quote

whosawhatsis

I'm not sure how the cardboard spools are meant to be held together, but here's an idea I had. Two pieces of cardboard and a short piece of plastic or cardboard tube (length <= radius). You can wrap some packing tape around the center before spooling the plastic to hold the two halves in place.

It doesn't have the inner rim that Richrap's design has, but that could be added (strengthening the walls in the process) by laminating another layer of cardboard on each side, which would also prevent the core tube from working its way out. The extra wall pieces would be a good place for manufacturers to print their branding and UFID code.

That is basically fantastic! - not only can I see that working well, but it could be die-cut and automatically assembled, glue and all.

I really like the idea of two further disc's on the outside being stuck to form the inner smaller mounting hole

And the process could be scaled up and down for both width and spool size.

If I was at home now, I would be cutting one out by hand to test strength

Great stuff. Do we have any cardboard experts in the community who could comment on this design idea? And I bet we have someone here who could even design the machine to automatically make them.

[richrap.blogspot.com]

|

Re: Universal 3D printing filament spool standard 2014 March 17, 2014 09:21AM |

Registered: 10 years ago Posts: 14 |

Thanks for your input whosawhatsis. Insteresting, but overcomplicated :-)

Also, that many cut lines would produce more loose fibres, and that won't be very good.

Normally, cardboard spools are either glued or "riveted". You literally rivet the core when wet. You can also rivet a metal insert, or you use a plastic insert.

Either way, I'd leave this up to manufacturers and focus on the actual dimensions.

So:

1) mounting hole size,

2) minimum core diameter,

3) max. outside diameter,

4) max spool width / "thickness"

And my suggestions:

1) 52mm. So that it can be mounted on 50mm mounting thingy. If someone wants a smaller diameter we can design, and then 3D-print adapters. Easy.

Now, re 2) 3) and 4) there are many options. Here are my calculations. I've added ~10% to the capacity, I _think_ this should be enough. Calculations are for 2.95mm filament. Due to nature of the wire the capacity will be slightly higher for 1.75mm.

Rim diameter x core diameter on the outside (minimum radius of the bent filament) x spool width

250mm x 150mm x 50mm

220mm x 100mm x 50mm

250mm x 170mm x 60mm

220mm x 130mm x 60mm

200mm x 90mm x 60mm

200mm x 90mm x 60mm

250mm x195 x 80mm

200mm x125 x 80mm

Thoughts?

Marcin

Edited 1 time(s). Last edit at 03/17/2014 12:59PM by nothinman.

Also, that many cut lines would produce more loose fibres, and that won't be very good.

Normally, cardboard spools are either glued or "riveted". You literally rivet the core when wet. You can also rivet a metal insert, or you use a plastic insert.

Either way, I'd leave this up to manufacturers and focus on the actual dimensions.

So:

1) mounting hole size,

2) minimum core diameter,

3) max. outside diameter,

4) max spool width / "thickness"

And my suggestions:

1) 52mm. So that it can be mounted on 50mm mounting thingy. If someone wants a smaller diameter we can design, and then 3D-print adapters. Easy.

Now, re 2) 3) and 4) there are many options. Here are my calculations. I've added ~10% to the capacity, I _think_ this should be enough. Calculations are for 2.95mm filament. Due to nature of the wire the capacity will be slightly higher for 1.75mm.

Rim diameter x core diameter on the outside (minimum radius of the bent filament) x spool width

250mm x 150mm x 50mm

ABS Nylon PLA PVA

Min density (g/cm3) 1.00 1.13 1.21 1.19

Max density (g/cm3) 1.05 1.41 1.43 1.31

Avg density (g/cm3) 1.03 1.27 1.32 1.25

Kilograms on spool 1.09 1.36 1.41 1.33

220mm x 100mm x 50mm

ABS Nylon PLA PVA

Min density (g/cm3) 1.00 1.13 1.21 1.19

Max density (g/cm3) 1.05 1.41 1.43 1.31

Avg density (g/cm3) 1.03 1.27 1.32 1.25

Kilograms on spool 1.10 1.36 1.42 1.34

250mm x 170mm x 60mm

ABS Nylon PLA PVA

Min density (g/cm3) 1.00 1.13 1.21 1.19

Max density (g/cm3) 1.05 1.41 1.43 1.31

Avg density (g/cm3) 1.03 1.27 1.32 1.25

Kilograms on spool 1.18 1.46 1.51 1.43

220mm x 130mm x 60mm

ABS Nylon PLA PVA

Min density (g/cm3) 1.00 1.13 1.21 1.19

Max density (g/cm3) 1.05 1.41 1.43 1.31

Avg density (g/cm3) 1.03 1.27 1.32 1.25

Kilograms on spool 1.13 1.40 1.46 1.38

200mm x 90mm x 60mm

ABS Nylon PLA PVA

Min density (g/cm3) 1.00 1.13 1.21 1.19

Max density (g/cm3) 1.05 1.41 1.43 1.31

Avg density (g/cm3) 1.03 1.27 1.32 1.25

Kilograms on spool 1.11 1.38 1.43 1.35

200mm x 90mm x 60mm

ABS Nylon PLA PVA

Min density (g/cm3) 1.00 1.13 1.21 1.19

Max density (g/cm3) 1.05 1.41 1.43 1.31

Avg density (g/cm3) 1.03 1.27 1.32 1.25

Kilograms on spool 1.11 1.38 1.43 1.35

250mm x195 x 80mm

ABS Nylon PLA PVA

Min density (g/cm3) 1.00 1.13 1.21 1.19

Max density (g/cm3) 1.05 1.41 1.43 1.31

Avg density (g/cm3) 1.03 1.27 1.32 1.25

Kilograms on spool 1.17 1.45 1.51 1.43

200mm x125 x 80mm

ABS Nylon PLA PVA

Min density (g/cm3) 1.00 1.13 1.21 1.19

Max density (g/cm3) 1.05 1.41 1.43 1.31

Avg density (g/cm3) 1.03 1.27 1.32 1.25

Kilograms on spool 1.12 1.39 1.45 1.37

Thoughts?

Marcin

Edited 1 time(s). Last edit at 03/17/2014 12:59PM by nothinman.

|

Re: Universal 3D printing filament spool standard 2014 March 17, 2014 01:21PM |

Registered: 10 years ago Posts: 14 |

I'm not a cardboard expert  but been working on a spool design with a company who are.

but been working on a spool design with a company who are.

So idea whosawhatsis had has a few issues:

- spool width is directly linked to diameter, because 'teeth' of a given length would create a hole of the same diameter (d = h)

- a lot of knifes required for cutting - more expensive to make tooling

- not-so-clean gluing due to many teeth

Plus... why do YOU want to design a spool?

If it's to be made out of cardboard it's a pretty simple design -- I'll try to post it here tonight or tomorrow.

Again -- let's focus on dimensions, because this is the problem. Not the spool itself, but its dimensions.

It's rather obvious that core diameter and mounting hole diameter have to be different -- core has to be big, hole would usually be smaller (52mm +/- 1mm is my suggestion)

Design would consist of a tube, two inserts that would go into both sides of the tube with a mounting hole cut out, and two disc rims that would go on the sides. At least this is what my design is going to look like :-)

Like I said, I'll post it shortly in case it's hard to visualise.

Cheers,

Marcin

but been working on a spool design with a company who are.

but been working on a spool design with a company who are.So idea whosawhatsis had has a few issues:

- spool width is directly linked to diameter, because 'teeth' of a given length would create a hole of the same diameter (d = h)

- a lot of knifes required for cutting - more expensive to make tooling

- not-so-clean gluing due to many teeth

Plus... why do YOU want to design a spool?

If it's to be made out of cardboard it's a pretty simple design -- I'll try to post it here tonight or tomorrow.

Again -- let's focus on dimensions, because this is the problem. Not the spool itself, but its dimensions.

It's rather obvious that core diameter and mounting hole diameter have to be different -- core has to be big, hole would usually be smaller (52mm +/- 1mm is my suggestion)

Design would consist of a tube, two inserts that would go into both sides of the tube with a mounting hole cut out, and two disc rims that would go on the sides. At least this is what my design is going to look like :-)

Like I said, I'll post it shortly in case it's hard to visualise.

Cheers,

Marcin

|

Re: Universal 3D printing filament spool standard 2014 March 17, 2014 06:03PM |

Registered: 14 years ago Posts: 36 |

Does someone have links to some better cardboard spools? All of the ones I've seen are worse designs than what I posted.

Even if there are better designs (and I hope there are), it doesn't hurt to have a version that can be made by anyone with a lasercutter and a way to cut lengths of tube.

[whosawhatsis.com]

Even if there are better designs (and I hope there are), it doesn't hurt to have a version that can be made by anyone with a lasercutter and a way to cut lengths of tube.

[whosawhatsis.com]

|

Re: Universal 3D printing filament spool standard 2014 March 18, 2014 06:40AM |

Registered: 10 years ago Posts: 14 |

Quote

whosawhatsis

Does someone have links to some better cardboard spools? All of the ones I've seen are worse designs than what I posted.

Even if there are better designs (and I hope there are), it doesn't hurt to have a version that can be made by anyone with a lasercutter and a way to cut lengths of tube.

Don't get me wrong, I'm not criticising your design, it's actually pretty interesting. It's just that it's actually hard to make tooling for it and it requires a lot of assembly.

If you're making one spool then it's fine. If you cut it with a laser -- even better.

But again: why would YOU want/need to make spools?

Marcin

Sorry, only registered users may post in this forum.