Excessive globbing at corner

Posted by Razorconcepts

|

Excessive globbing at corner July 12, 2014 03:22PM |

Registered: 10 years ago Posts: 9 |

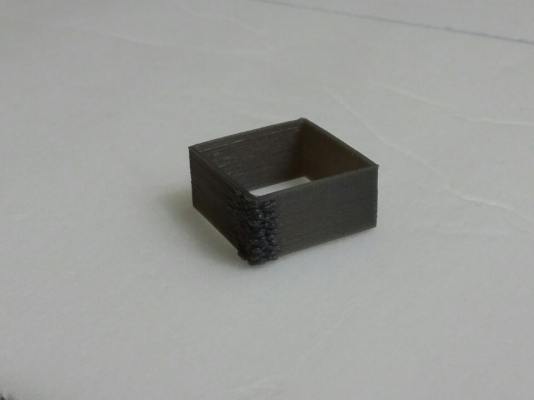

Hello, I'm doing the 0.4mm thin wall calibration. It looks OK, except at the corner at which the extruder retracts, goes up a layer, then extrudes again. It seems like it extrudes excessively at this location:

I'm using Skeinforge. What setting do I have to adjust? Thanks!

Edited 1 time(s). Last edit at 07/12/2014 03:23PM by Razorconcepts.

I'm using Skeinforge. What setting do I have to adjust? Thanks!

Edited 1 time(s). Last edit at 07/12/2014 03:23PM by Razorconcepts.

|

Re: Excessive globbing at corner July 14, 2014 09:52AM |

Registered: 9 years ago Posts: 156 |

|

Re: Excessive globbing at corner July 15, 2014 12:21AM |

Registered: 10 years ago Posts: 9 |

Quote

duranza

Your flow rate is too high. It looks like it's over extruding, too many steps per mm in the extruder calibration.

Thanks for the tip. The feed rate and flow rate setting were both 50, so I tried lowering the flow rate setting to 46, but it made the problem worse - I got 1mm thick walls on the 0.4mm thin wall object.

Should I actually be changing the E-steps-per-mm? The manual for the mendel90 states:

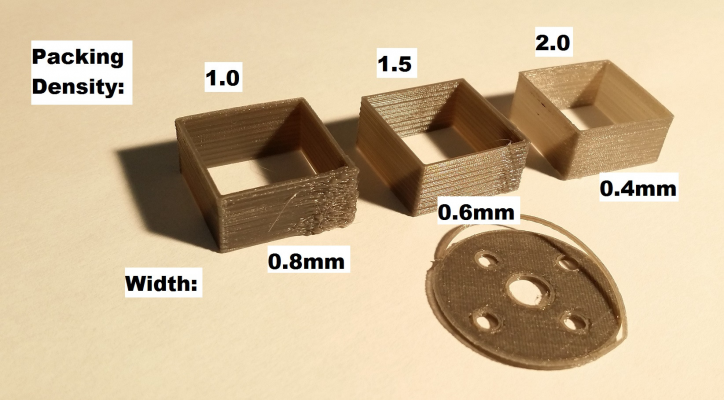

My E Steps Per MM is properly calibrated to feed the exact amount, and the Skeinforge knows I'm using 3.0mm filament. I tried changing the packing density, and here are my results:Quote

Extruder Calibration

The E steps per mm should be adjusted so that when commanded to extrude 100mm it actually

feeds 100mm. This is done by placing a mark (a piece of tape for instance) on the filament 120mm

above the extruder and telling it to feed 100mm at say 60mm/min. Then measure the distance to the

mark to work out how much it actually extruded. It depends on the diameter of the bolt hobbing and

how far the plastic is pressed into it, i.e. how soft it is and the spring tension. Harder plastics will

feed faster.

Multiply the E_STEPS_PER_MM in the firmware by 100 / actual extrusion and reload it.

With packing density set to 2, the 0.4mm thin wall looks great with 0.4mm thick walls, however when I try to print anything out, its as if the lines are too thin, and the first layer doesn't stick with each other. I printed a circular part with the packing density at 1.5, and there I can just peel off the outer ring, since the filler on the inside isnt even touching the ring, since the lines are so thin.

This is really puzzling me, the 0.4mm thin wall prints properly with a packing density of 2, but the lines are too thin to print anything else.

The 0.4mm thin wall prints with 0.8mm thick walls with the original packing density of 1, and I can print other objects with it, but things such as holes are undersized.

Edited 1 time(s). Last edit at 07/15/2014 12:22AM by Razorconcepts.

Sorry, only registered users may post in this forum.