PLA curling up on angled objects.

Posted by ttttrigg3r

|

PLA curling up on angled objects. July 29, 2014 01:41AM |

Registered: 10 years ago Posts: 29 |

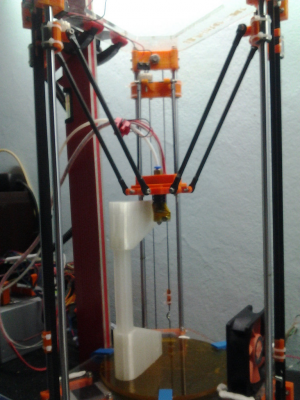

I'm trying to print a donut shaped object. The PLA sticks just fine to the bed, but it curls as the hot nozzle makes pass over pass of the perimeters of the object. This causes deformities as shown in the picture due to the edges curling up.

Steps I took to fix:

I've tried adjusting temperatures ranging from 195-205C. I've also used this fan duct to cool the extruded plastic as recommended but it's not working so far.

Any ideas?

My machine:

Reprap Prusa i3 rework. PLA 200C. HPB 80C. Makergear nozzle.

Edited 1 time(s). Last edit at 07/29/2014 01:47AM by ttttrigg3r.

Steps I took to fix:

I've tried adjusting temperatures ranging from 195-205C. I've also used this fan duct to cool the extruded plastic as recommended but it's not working so far.

Any ideas?

My machine:

Reprap Prusa i3 rework. PLA 200C. HPB 80C. Makergear nozzle.

Edited 1 time(s). Last edit at 07/29/2014 01:47AM by ttttrigg3r.

|

Re: PLA curling up on angled objects. July 29, 2014 06:23AM |

Registered: 10 years ago Posts: 69 |

|

Re: PLA curling up on angled objects. July 29, 2014 11:18AM |

Registered: 10 years ago Posts: 790 |

Fan fan fan. Most common [not sure how you haven't seen that yet, but everybody's experience is different] and simplest and typically the most effective fix. You need a fan blowing under/around the nozzle so that the plastic cools as quickly as possible once it leaves the nozzle.

Just a few examples.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Just a few examples.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: PLA curling up on angled objects. August 04, 2014 06:47PM |

Registered: 9 years ago Posts: 189 |

I have 3x 50mm fans running at full speed, PLA extruding at 185° and it still occurs...

even on just a calibration cube, the edges curl up after 10 or 15 layers!

I think nophead might be onto something here:

I will try fiddling with the with over height settings more tomorrow, as I have quite a batch to run through the next days.

thsi does not happen to me on larger objects, so might really still have to do with cooling.

but with 3 fans?!

They have no fan duct by the way...so maybe the hotend just heats more and more "against" the cooling of the fans?

Alex

even on just a calibration cube, the edges curl up after 10 or 15 layers!

I think nophead might be onto something here:

Quote

nophead: Yes the height doesn't affect the stretching if you keep the width constant because lower heights get proportionally lower flow. It is the width that counts. SF is better than SFACT and I think Slice3r because it relates the width to the height. If W/T is constant then thinner layers does stretch it more. 0.35 width is very thin for ABS and a 0.35 nozzle. If you measure the plastic extruded into free air it will be substantially bigger diameter than the nozzle, maybe 0.45. That is before you squash it flat by having the layer height lower than the width. Typically I would use 0.30 layers with a 0.35 nozzle with W/T of 1.5 giving a width of 0.45. Or 0.35 layers giving 0.525 for even less stretch. The most stretch I would use would be 0.25 layers with a width of 0.375, still more than yours. For lower layer heights I would increase W/T, so W would never be less than 0.375.

I will try fiddling with the with over height settings more tomorrow, as I have quite a batch to run through the next days.

thsi does not happen to me on larger objects, so might really still have to do with cooling.

but with 3 fans?!

They have no fan duct by the way...so maybe the hotend just heats more and more "against" the cooling of the fans?

Alex

|

Re: PLA curling up on angled objects. August 05, 2014 01:55PM |

Registered: 9 years ago Posts: 56 |

I don't use small fans mounted around the nozzle anymore since I realized that they are like a fart in a huricane compared to a 80mm fan I am using now.

I used to have multiple 40mm fans mounted on the effector and was experimenting with additional 80mm fan to solve warping.

It actually solved many other problems also and I realized that the small fans from China are useless for my needs. I also have some 80mm fans that don't

have the same airflow as the one I am using now.

So its not the size or quantity that matters, its the airflow that the fan can deliver.

All about delta 3d printers in one place [www.deltarap.org]

I used to have multiple 40mm fans mounted on the effector and was experimenting with additional 80mm fan to solve warping.

It actually solved many other problems also and I realized that the small fans from China are useless for my needs. I also have some 80mm fans that don't

have the same airflow as the one I am using now.

So its not the size or quantity that matters, its the airflow that the fan can deliver.

All about delta 3d printers in one place [www.deltarap.org]

|

Re: PLA curling up on angled objects. August 05, 2014 04:56PM |

Registered: 10 years ago Posts: 87 |

|

Re: PLA curling up on angled objects. August 05, 2014 06:36PM |

Registered: 9 years ago Posts: 56 |

Quote

victorjung

you could also try to swich your heated bed off. even after the first layers if you need it to stick at the begining.

I second that, i somehow missed that you are using HPB 80C. You don't need heated bed for PLA.

All about delta 3d printers in one place [www.deltarap.org]

|

Re: PLA curling up on angled objects. August 08, 2014 09:51PM |

Registered: 9 years ago Posts: 189 |

wow!

that is some quite steep overhang there!

amazing!

Mind sharing your settings?

What temperature are you printing at?

And What speed and layer-Width?

Alex

|

Re: PLA curling up on angled objects. August 09, 2014 12:10AM |

Registered: 9 years ago Posts: 56 |

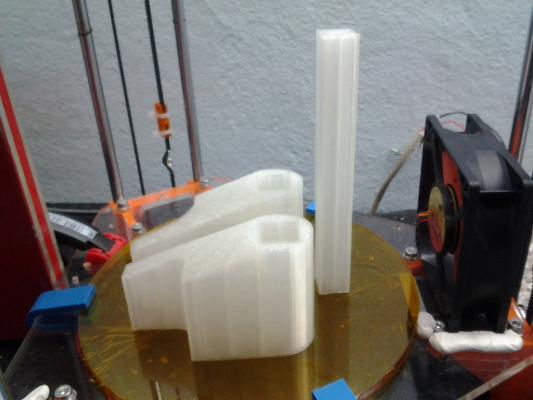

Sorry, that picture is very misleading. That object is composed of three parts and the end result is taller then my Z-height.

Look closer and you will notice that the head is at maximum height and is still lower than the object.That is better picture:

All about delta 3d printers in one place [www.deltarap.org]

Look closer and you will notice that the head is at maximum height and is still lower than the object.That is better picture:

All about delta 3d printers in one place [www.deltarap.org]

|

Re: PLA curling up on angled objects. August 09, 2014 07:37PM |

Registered: 10 years ago Posts: 29 |

Thanks yall. Took your advice and went back to no heat+blue tape+hairspray. Works like a charm, Not perfect but pretty well.

DinoK nice Delta printer, is it pretty straight forward to build one of those? I want to build one. I really like the Prusa i3 because it's very popular and well documented. What model do you recommend when it comes to Delta printer.

Also I have a question about your 80mm fan. It just sits there stationary blowing at the bottom layers of the bed right? Is there a thread for that? Will that not cause temperature fluctuation issues with your hotend if it hits your hotend directly?

DinoK nice Delta printer, is it pretty straight forward to build one of those? I want to build one. I really like the Prusa i3 because it's very popular and well documented. What model do you recommend when it comes to Delta printer.

Also I have a question about your 80mm fan. It just sits there stationary blowing at the bottom layers of the bed right? Is there a thread for that? Will that not cause temperature fluctuation issues with your hotend if it hits your hotend directly?

|

Re: PLA curling up on angled objects. August 11, 2014 03:57AM |

Registered: 9 years ago Posts: 56 |

Quote

ttttrigg3r

Thanks yall. Took your advice and went back to no heat+blue tape+hairspray. Works like a charm, Not perfect but pretty well.

DinoK nice Delta printer, is it pretty straight forward to build one of those? I want to build one. I really like the Prusa i3 because it's very popular and well documented. What model do you recommend when it comes to Delta printer.

This is my first printer and bought it mainly because of the price. The build is simple but configuration is not so.

But then I dived my head into configuration of deltas for weeks and finally cracked it. I can't really advise you on that as it's the only printer I ever used, but found some topics about similar dillema :

Rostock Mini or Kossel: Sensible for a first-time builder?

First Printer Build: Prusa, Mendel, or Rostock

Quote

ttttrigg3r

Also I have a question about your 80mm fan. It just sits there stationary blowing at the bottom layers of the bed right? Is there a thread for that? Will that not cause temperature fluctuation issues with your hotend if it hits your hotend directly?

As I am constantly experimenting I use UHU Patafix glue pads to attach various things to the printer.

You can see white putty-like material on the picture which holds the fan in place.

This is just a quick way to test what is the best position for the fan(or fans) and plan on printing a fan holder later, something like that:

Mini Kossel 120mm Fan Mount

Vitamin Free RepRapPro Huxley 120mm Fan Mounts

The fan is stationary and is blowing on the hotend so it should cause temperature fluctuation issues BUT it doesn't - my prints never looked better.

All about delta 3d printers in one place [www.deltarap.org]

|

Re: PLA curling up on angled objects. August 17, 2014 06:23PM |

Registered: 9 years ago Posts: 189 |

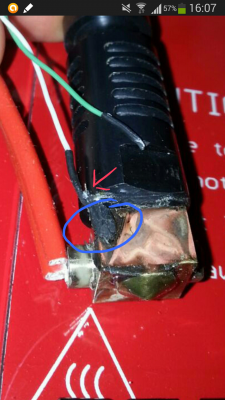

yeah, about that fan, that blows onto the hotend...

the rubber insulating the thermistor is supposed to withstand temperatures of up to 280-300 degrees I was told.

the brazz nozzle/heaterblock got discoloured...

I NEVER had temperature higher then 194° set....

but there used to be 3 fans one blowing at an angle at the peek insulator, so I would not get PLA Jams,

the other two angled at the printbed, but at a very steep angle, so they pretty much blew onto the hotend/heaterblock I guess...

Since that disastrous over-heating I purchased 2 E3D V6 Hotends

and had to find out, they were even more prone to PLA curling on edges and overhangs...

Not even 7 or 8 Layers into a simple 1x1x1cm or 2x2x2cm cube would print without the edges forming to horns and me having to abort the print!

I then tried the "hollow-cube" object

and held ONE of my 3 50mm fans with my hand pointed towards the freshly printed layers.

It was some sort of "manual assist" for the printer during the whole print!

and what can I say,

it turned out better then ever!

since I was able to slightly blow under the extruded filament with my hand, the overhangs printed flawlessly and I got some nice results for a first ever try of that object on a brand new uncalibrated hotend^^

Right now i have gathere a collection of "fan-ducts" and fan-adapters as .stl files^^

I think i downloaded all the designs I thought were best suited for the purpose.

I will try several out during the next few days and report back.

If you guys want to, I can easily pack them in a .rar or .zip file and upload them somewhere.

Oh and one more thing:

I remember as a little boy - when packing presents for christmas - one could easily curl up the ribbons by pressing the ribbon against the blade of a sharp scissors!

and then move it along the scissors.

now i took a very close look at both the J-head nozzle and the E3D Nozzle.

while the j-head is kind of flatter in total - also the transition from the orifice (is that correct term for opening?)

of the nozzle to the outer regions is very smooth!

not so on the E3D, it has very sharp edges - one can easily feel the sharpness with one`s finger.

So maybe the same goes here?!

and it is like with that ribbon?

the nozzle "scratching" over the hot plastic, making the hot extruded filament wanting to curl up even more badly!

One aspect which would support my theory:

With the E3D the effect of PLA curling is way worse, then it was with the J-head nozzle.

Plus the finer the layers, the worse the effect!

with 0.1mm Layer it curls up soooo damn bad, feels somehow exactly like a curled up ribbon ;-)

like a small plastic-bag/foil piece...

with 0.2mm layers the problem is not as pronounced.

Although one would expect it to be other way round, since smaller layers mean less overhang!

Also - for me - speed helps!

If I go faster everything works better with the E3D - from sticking of first Layer, up to the curling...funny, huh?!

Ok, those are my findings, based on my own experience of the problem.

i will try to evaluate it more and repost here.

Alex

the rubber insulating the thermistor is supposed to withstand temperatures of up to 280-300 degrees I was told.

the brazz nozzle/heaterblock got discoloured...

I NEVER had temperature higher then 194° set....

but there used to be 3 fans one blowing at an angle at the peek insulator, so I would not get PLA Jams,

the other two angled at the printbed, but at a very steep angle, so they pretty much blew onto the hotend/heaterblock I guess...

Since that disastrous over-heating I purchased 2 E3D V6 Hotends

and had to find out, they were even more prone to PLA curling on edges and overhangs...

Not even 7 or 8 Layers into a simple 1x1x1cm or 2x2x2cm cube would print without the edges forming to horns and me having to abort the print!

I then tried the "hollow-cube" object

and held ONE of my 3 50mm fans with my hand pointed towards the freshly printed layers.

It was some sort of "manual assist" for the printer during the whole print!

and what can I say,

it turned out better then ever!

since I was able to slightly blow under the extruded filament with my hand, the overhangs printed flawlessly and I got some nice results for a first ever try of that object on a brand new uncalibrated hotend^^

Right now i have gathere a collection of "fan-ducts" and fan-adapters as .stl files^^

I think i downloaded all the designs I thought were best suited for the purpose.

I will try several out during the next few days and report back.

If you guys want to, I can easily pack them in a .rar or .zip file and upload them somewhere.

Oh and one more thing:

I remember as a little boy - when packing presents for christmas - one could easily curl up the ribbons by pressing the ribbon against the blade of a sharp scissors!

and then move it along the scissors.

now i took a very close look at both the J-head nozzle and the E3D Nozzle.

while the j-head is kind of flatter in total - also the transition from the orifice (is that correct term for opening?)

of the nozzle to the outer regions is very smooth!

not so on the E3D, it has very sharp edges - one can easily feel the sharpness with one`s finger.

So maybe the same goes here?!

and it is like with that ribbon?

the nozzle "scratching" over the hot plastic, making the hot extruded filament wanting to curl up even more badly!

One aspect which would support my theory:

With the E3D the effect of PLA curling is way worse, then it was with the J-head nozzle.

Plus the finer the layers, the worse the effect!

with 0.1mm Layer it curls up soooo damn bad, feels somehow exactly like a curled up ribbon ;-)

like a small plastic-bag/foil piece...

with 0.2mm layers the problem is not as pronounced.

Although one would expect it to be other way round, since smaller layers mean less overhang!

Also - for me - speed helps!

If I go faster everything works better with the E3D - from sticking of first Layer, up to the curling...funny, huh?!

Ok, those are my findings, based on my own experience of the problem.

i will try to evaluate it more and repost here.

Alex

|

Re: PLA curling up on angled objects. August 17, 2014 06:37PM |

Registered: 10 years ago Posts: 790 |

Quote

MrDoctorDIV

Fan fan fan. Most common [not sure how you haven't seen that yet, but everybody's experience is different] and simplest and typically the most effective fix. You need a fan blowing under/around the nozzle so that the plastic cools as quickly as possible once it leaves the nozzle.

Just a few examples.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: PLA curling up on angled objects. August 17, 2014 08:43PM |

Registered: 9 years ago Posts: 189 |

the insulation on the bukschnozzle form your first link looks nice!

I am planning on doing some insulation of my heaterblock for 2 reasons:

1: I can then apply fan without worrying it will cool the heaterblock too much and have the same thermal disaster again with overheating on one side etc.

2: It will use less energy, since it is kinda like boiling water, once withput the lid on the pot, then with the lid on the pot closed (way faster, less energy required)

Any idea where I can get that self-adhesive Glas-fibre insulatoin tape?!

I found a source online in the uk, heat resistent up to 520° Celsius!

So way more then any hotend would do, but they did not reply to my email about where to buy...

Alex,

who just installed a ducted fan on the backside of his prusa i3`s X-carriage, blowing slightly at and under the nozzle.

Will try out tomorrow.

I am planning on doing some insulation of my heaterblock for 2 reasons:

1: I can then apply fan without worrying it will cool the heaterblock too much and have the same thermal disaster again with overheating on one side etc.

2: It will use less energy, since it is kinda like boiling water, once withput the lid on the pot, then with the lid on the pot closed (way faster, less energy required)

Any idea where I can get that self-adhesive Glas-fibre insulatoin tape?!

I found a source online in the uk, heat resistent up to 520° Celsius!

So way more then any hotend would do, but they did not reply to my email about where to buy...

Alex,

who just installed a ducted fan on the backside of his prusa i3`s X-carriage, blowing slightly at and under the nozzle.

Will try out tomorrow.

Sorry, only registered users may post in this forum.