Undersized circles - Has this been solved yet?

Posted by redhatman

|

Undersized circles - Has this been solved yet? September 14, 2014 01:04PM |

Registered: 9 years ago Posts: 57 |

Hi everyone!

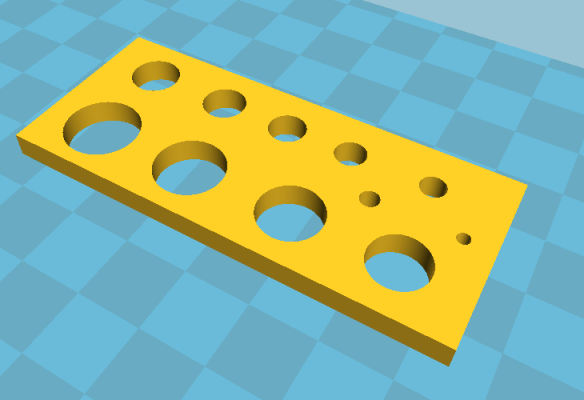

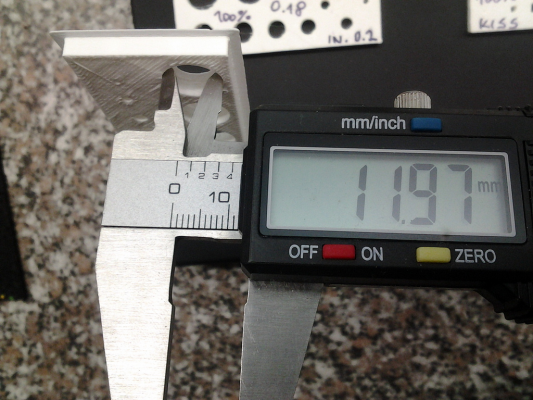

I've managed to get my Prusa i2 printing pretty smoothly, however one issue still exists. I cannot get circles to print out to be the correct size. I created a circle test plate with holes ranging from 12mm to 3mm, and all holes are coming out small by a pretty fairly consistent measurement of 0.7mm under.

i.e. (12mm = 11.3mm actual ID, 11mm = 10.3mm actual ID...etc)

My current setup is:

-Prusa i2

-Slic3r

-Repetier

-MK2 Heatbed

-Sanguinololu Board (I believe 1.2 or 1.3)

-Marlin Firmware

-Geared Extruder

-Prusa Nozzle Hotend, 0.4mm

-3mm PLA Filament

The issue only seems to happen when drawing a circle on the X-Y plane. Outer diameter dimensions of circles and parts seem to be pretty well spot on.

I have come across the issue in searches, however most people seem to just say "drill it out" to whoever asked.... I would like to know if there's a way I can just make the part print the way it was designed?

Attempted Solutions/What I've tried

-Recalibrating the steppers by measurement, also by the online calculator

-Tightened down hardware, gears, etc

-Played with Slic3r's extrusion width values for perimeters (I tried 70%, 50%, and 30%).

-Designed a part with a 15.8mm hole, and it indeed printed out to just about 15mm actual I.D.

My thought is that simply there is too much filament being dumped on the outer perimeter, which is causing the circle to "cave in" on itself. I think this is going on because of the consistency of the error when measuring. All other aspects of the print seem to be working great.

Has anyone else had this issue? How has it been solved?

All input is appreciated, thank you!

-Pat

- "Project Locus" - Mostly all printed parts, Corexy, Bowden Setup, 12x12 heatbed, ~1 cubic foot build volume

- SeeMeCNC Rostock Max V2

I've managed to get my Prusa i2 printing pretty smoothly, however one issue still exists. I cannot get circles to print out to be the correct size. I created a circle test plate with holes ranging from 12mm to 3mm, and all holes are coming out small by a pretty fairly consistent measurement of 0.7mm under.

i.e. (12mm = 11.3mm actual ID, 11mm = 10.3mm actual ID...etc)

My current setup is:

-Prusa i2

-Slic3r

-Repetier

-MK2 Heatbed

-Sanguinololu Board (I believe 1.2 or 1.3)

-Marlin Firmware

-Geared Extruder

-Prusa Nozzle Hotend, 0.4mm

-3mm PLA Filament

The issue only seems to happen when drawing a circle on the X-Y plane. Outer diameter dimensions of circles and parts seem to be pretty well spot on.

I have come across the issue in searches, however most people seem to just say "drill it out" to whoever asked.... I would like to know if there's a way I can just make the part print the way it was designed?

Attempted Solutions/What I've tried

-Recalibrating the steppers by measurement, also by the online calculator

-Tightened down hardware, gears, etc

-Played with Slic3r's extrusion width values for perimeters (I tried 70%, 50%, and 30%).

-Designed a part with a 15.8mm hole, and it indeed printed out to just about 15mm actual I.D.

My thought is that simply there is too much filament being dumped on the outer perimeter, which is causing the circle to "cave in" on itself. I think this is going on because of the consistency of the error when measuring. All other aspects of the print seem to be working great.

Has anyone else had this issue? How has it been solved?

All input is appreciated, thank you!

-Pat

- "Project Locus" - Mostly all printed parts, Corexy, Bowden Setup, 12x12 heatbed, ~1 cubic foot build volume

- SeeMeCNC Rostock Max V2

|

Re: Undersized circles - Has this been solved yet? September 14, 2014 02:13PM |

Registered: 11 years ago Posts: 939 |

Assuming your dimensions are correct for simple polygons, Nophead discussed this on his blog a couple of years ago. I think the major issue is corner cutting by the filament, but there are several contributing factors.

[hydraraptor.blogspot.com]

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

[hydraraptor.blogspot.com]

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

|

Re: Undersized circles - Has this been solved yet? September 14, 2014 02:46PM |

Registered: 10 years ago Posts: 790 |

It's common issue most given to Slic3r, I think they fixed/improved it in newer versions but I don't know for sure.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Undersized circles - Has this been solved yet? September 14, 2014 11:28PM |

Registered: 11 years ago Posts: 1,320 |

|

Re: Undersized circles - Has this been solved yet? September 16, 2014 01:22AM |

Registered: 11 years ago Posts: 1,171 |

|

Re: Undersized circles - Has this been solved yet? September 18, 2014 12:39PM |

Registered: 10 years ago Posts: 62 |

I think this is inherent in the way the plastic is deposited. I had it explained to me like this: think about runners on a race track. The runners on the inside of the circle have less distance to travel, the runners on the outside have more distance to travel, to arrive at the same point in the circle. For plastic coming out of a nozzle, moving in an arc, it's similar. The plastic on the inside of the arc has less distance to travel, but the same surface area of plastic is dumped on the inside as the outside. Same amount of plastic, less total length, more total width.

I would imagine this could be taken care of with slicing software - if they haven't already done it, they may soon. Anyone know if Slic3r has done this yet?

I would imagine this could be taken care of with slicing software - if they haven't already done it, they may soon. Anyone know if Slic3r has done this yet?

|

Re: Undersized circles - Has this been solved yet? September 21, 2014 05:21PM |

Registered: 9 years ago Posts: 57 |

Assuming that shrinkage is negligible, and all print temp/flow settings are perfect for straight edge parts, wouldn't the only issue left be the one Wissing mentioned?

I have now tried Slic3r, Kisslicer, and Cura all with the same results. I have managed to get better looking parts with all of this messing around, however I still do not have accurate inner dimensions for circles.

I would be interested in helping solve this issue if I knew a little bit more about the way slicing software works. I understand the basics of how flow width, height, etc is calculated, however, I'm referring to how the software actually interprets the .stl file and outputs the g-code.

Again, thank you to everyone chiming in here. This forum has been great and continues to be a great benefit. I appreciate it,

-Pat

- "Project Locus" - Mostly all printed parts, Corexy, Bowden Setup, 12x12 heatbed, ~1 cubic foot build volume

- SeeMeCNC Rostock Max V2

I have now tried Slic3r, Kisslicer, and Cura all with the same results. I have managed to get better looking parts with all of this messing around, however I still do not have accurate inner dimensions for circles.

I would be interested in helping solve this issue if I knew a little bit more about the way slicing software works. I understand the basics of how flow width, height, etc is calculated, however, I'm referring to how the software actually interprets the .stl file and outputs the g-code.

Again, thank you to everyone chiming in here. This forum has been great and continues to be a great benefit. I appreciate it,

-Pat

- "Project Locus" - Mostly all printed parts, Corexy, Bowden Setup, 12x12 heatbed, ~1 cubic foot build volume

- SeeMeCNC Rostock Max V2

|

Re: Undersized circles - Has this been solved yet? September 22, 2014 03:34PM |

Registered: 9 years ago Posts: 56 |

@redhatman Can you please give some STL or(and) GCode examples of your failed prints ?

I would like to try and print them myself as I have been researching this issue myself.

All about delta 3d printers in one place [www.deltarap.org]

I would like to try and print them myself as I have been researching this issue myself.

All about delta 3d printers in one place [www.deltarap.org]

|

Re: Undersized circles - Has this been solved yet? September 22, 2014 06:21PM |

Registered: 9 years ago Posts: 57 |

Quote

DinoK

@redhatman Can you please give some STL or(and) GCode examples of your failed prints ?

I would like to try and print them myself as I have been researching this issue myself.

Essentially, if a part involves a circle hole, it will come out undersized. I made a circle test plate to use as a calibration/practice part which is used solely for messing around with this stuff.

I have attached the .STL file, the holes should be 12mm down to 2mm, in step sizes of 1mm. Please let me know if you're able to get anywhere with it, the closest I have come to getting the accurate dimensions are 0.4mm undersized.

circlestestplate.stl

- "Project Locus" - Mostly all printed parts, Corexy, Bowden Setup, 12x12 heatbed, ~1 cubic foot build volume

- SeeMeCNC Rostock Max V2

|

Re: Undersized circles - Has this been solved yet? October 05, 2014 09:06PM |

Registered: 9 years ago Posts: 56 |

Ok , I finally found some time to dive into this and managed to get the perfect prints  .

.

I am getting the prints within 0.05mm of the target size which seemed imposible before. I wrote more detailed article about it on the blog.

Redhatman, I used your STL file and published it on Youmagine, hope you don't mind. I also made my own test STL files with squares and circles.

To sum it up, everybody can do it, you just have to fine tune the printer

All about delta 3d printers in one place [www.deltarap.org]

.

.I am getting the prints within 0.05mm of the target size which seemed imposible before. I wrote more detailed article about it on the blog.

Redhatman, I used your STL file and published it on Youmagine, hope you don't mind. I also made my own test STL files with squares and circles.

To sum it up, everybody can do it, you just have to fine tune the printer

All about delta 3d printers in one place [www.deltarap.org]

|

Re: Undersized circles - Has this been solved yet? October 05, 2014 09:11PM |

Registered: 9 years ago Posts: 269 |

|

Re: Undersized circles - Has this been solved yet? February 22, 2015 11:52AM |

Registered: 9 years ago Posts: 1 |

Quote

DinoK

I wrote more detailed article about it on the blog.

...

To sum it up, everybody can do it, you just have to fine tune the printer

I've read your post dozens of times, but still don't understand what to do to make my Kossel print holes with exact internal diameters.

I'm printing with PLA now, 200C, 60mm/s. Shell thickness is a double of nozzle diameter (2*0.4mm=0.8mm) and layer height is 0.2mm.

I've tried bigger shell thickness and 0.1mm layers and other temperatures, but regardless of the settings my holes (either round or square) are printed smaller than needed by ~0.5mm.

This is blocker for me. I'm trying to print engineering parts and precise dimensions are required for assembly.

Any help how to teach my Kossel mini to print holes with exact diameters would be appreciated .

|

Re: Undersized circles - Has this been solved yet? February 22, 2015 05:40PM |

Registered: 11 years ago Posts: 1,171 |

Quote

pistolero

Quote

DinoK

I wrote more detailed article about it on the blog.

...

To sum it up, everybody can do it, you just have to fine tune the printer

I've read your post dozens of times, but still don't understand what to do to make my Kossel print holes with exact internal diameters.

I'm printing with PLA now, 200C, 60mm/s. Shell thickness is a double of nozzle diameter (2*0.4mm=0.8mm) and layer height is 0.2mm.

I've tried bigger shell thickness and 0.1mm layers and other temperatures, but regardless of the settings my holes (either round or square) are printed smaller than needed by ~0.5mm.

This is blocker for me. I'm trying to print engineering parts and precise dimensions are required for assembly.

Any help how to teach my Kossel mini to print holes with exact diameters would be appreciated .

With an FDM machine it's just not going to happen. At least not yet. It's not your machines fault but the nature of the plastic and how it expands and shrinks. The best we can hope for is a slic3r that figures out how to compensate for the problem but even then it's going to be different on every printer and every filament type / brand.

So, the best you can currently do is either design the parts with slightly larger holes (print a reference hole chart then measure) or drill out holes after printing. Or, wait until the technology matures quite a bit and a solution is found.

|

Re: Undersized circles - Has this been solved yet? February 22, 2015 05:43PM |

Registered: 11 years ago Posts: 1,171 |

Here, this is a link to the hole size chart I designed and it's what I use to design my parts. [www.thingiverse.com]

|

Re: Undersized circles - Has this been solved yet? February 23, 2015 09:15PM |

Registered: 11 years ago Posts: 5,780 |

Part of the problem is the fact that holes are polygons, not circles. The STL file is made up of triangles, so you don't print a round hole, you print a polygonal hole.

You might get better results if you start with a higher resolution STL file. If you're going to calibrate yourself for adjusting designed hole sizes to compensate for the printer's errors, you should probably standardize on one STL file resolution,otherwise you're going to be getting different results from different CAD files.

This is one of the reasons why 3D printers are not consumer products yet. It takes a lot of arcane knowledge to get a printer to produce quality prints.

You might get better results if you start with a higher resolution STL file. If you're going to calibrate yourself for adjusting designed hole sizes to compensate for the printer's errors, you should probably standardize on one STL file resolution,otherwise you're going to be getting different results from different CAD files.

This is one of the reasons why 3D printers are not consumer products yet. It takes a lot of arcane knowledge to get a printer to produce quality prints.

|

Re: Undersized circles - Has this been solved yet? January 11, 2016 02:09AM |

Registered: 9 years ago Posts: 3 |

Someone did add a fix to the "Track Width/Area" problem for slic3r way back in 2012 however it was removed due to non-circular holes printing out too large. I think it would have been a better option to just have that setting as an option that we can tweak. Perhaps if we make enough noise we can get the slic3r developers to put it back in as an optional setting.

|

Re: Undersized circles - Has this been solved yet? January 11, 2016 02:28AM |

Registered: 10 years ago Posts: 444 |

|

Re: Undersized circles - Has this been solved yet? July 04, 2016 07:45AM |

Registered: 8 years ago Posts: 74 |

|

Re: Undersized circles - Has this been solved yet? July 04, 2016 09:03PM |

Registered: 8 years ago Posts: 177 |

Everyone seems to ignore the actual filament extruded width.

To even get a handle on hole size issues once you have the rest of the machine calibrated you need to measure the diameter of the filament extruded into free air.

I have found for ABS on a range of nominally 0.4mm nozzles that I constantly get 0.58-0.60mm. This is 0. to 0.12 larger than the slicer set width.

As slicers set their paths based on the set extrusion width any actual width will be reflected in the internal sizing of things like holes.

Other people may get different results from their nozzles and this is why you should measure.

To even get a handle on hole size issues once you have the rest of the machine calibrated you need to measure the diameter of the filament extruded into free air.

I have found for ABS on a range of nominally 0.4mm nozzles that I constantly get 0.58-0.60mm. This is 0. to 0.12 larger than the slicer set width.

As slicers set their paths based on the set extrusion width any actual width will be reflected in the internal sizing of things like holes.

Other people may get different results from their nozzles and this is why you should measure.

|

Re: Undersized circles - Has this been solved yet? July 05, 2016 10:03PM |

Registered: 7 years ago Posts: 558 |

Wouldn't the width be different depending on how much filament is hanging from your hotend, as it gets longer, I'd imagine gravity will pull it down more so than if it was fresh out of the nozzle. I've also seen right as it starts to extruder in mid air it begins to overlap itself at first and then finally begin to fall slowly which in turn would also affect the width of the extruded filament.

I wonder if it wouldn't be better to have a given gcode string to extrude a known line on the bed and measure that rather than extruding in mid air.

I wonder if it wouldn't be better to have a given gcode string to extrude a known line on the bed and measure that rather than extruding in mid air.

|

Re: Undersized circles - Has this been solved yet? July 06, 2016 03:07AM |

Registered: 8 years ago Posts: 177 |

Quote

PDBeal

Wouldn't the width be different depending on how much filament is hanging from your hotend, as it gets longer, I'd imagine gravity will pull it down more so than if it was fresh out of the nozzle. I've also seen right as it starts to extruder in mid air it begins to overlap itself at first and then finally begin to fall slowly which in turn would also affect the width of the extruded filament.

I wonder if it wouldn't be better to have a given gcode string to extrude a known line on the bed and measure that rather than extruding in mid air.

Honestly just try it, extrude 300mm to 500mm (extruded length) and measure a few spots, it will be remarkable consistent. This is the die swell factor.

Rather than a single line on the bed you would be better to print a single wall cube and measure the wall thickness for each layer thickness you commonly use, this factors in the "squish" spread. This doesn't take into account path overlap that slicers will have when doing multiple perimeters.

I only suggested checking the free air die swell as this has been remarkable consistent in determining how much smaller the inside diameter will be (for me).... the whole polygonal hole is also a factor.

|

Re: Undersized circles - Has this been solved yet? July 29, 2016 10:44AM |

Registered: 7 years ago Posts: 558 |

I've noticed on one machine I'm running a 0.3 nozzle vs the 0.4 nozzle on my other machine, and the 0.3 nozzle seems to be capable of doing my exact hole dimensions. If I draw a 4.3mm hole in my object, I'm measuring 4.34 on my calipers. Ofcourse, with the 0.3 nozzle, I am running about 10mm/s slower which is probably a contributing factor.

At work we have a Stratasys uPrint SE Plus, and it does exact dimensions so it is possible for the FDM machine to be capable of printing exact dimensions on holes and parts, but I have not been able to figure out without disassembly of what nozzle size this machine is using.

At work we have a Stratasys uPrint SE Plus, and it does exact dimensions so it is possible for the FDM machine to be capable of printing exact dimensions on holes and parts, but I have not been able to figure out without disassembly of what nozzle size this machine is using.

|

Re: Undersized circles - Has this been solved yet? January 08, 2017 01:23PM |

Registered: 7 years ago Posts: 4 |

|

Re: Undersized circles - Has this been solved yet? January 08, 2017 01:31PM |

Registered: 7 years ago Posts: 558 |

I've had much better luck producing accurate holes when printing with files sliced by Cura 2.3.1. My hole dimensions are still on the small side, but the tolerances in my parts are more than enough for this to work. I've not had to drill out any holes since switching to Cura 2.3.1 from slic3r.

On a side note, I have noticed my holes are more accurate on the machines with a direct drive than they are with the bowden tube setup. I'm assuming this is probably due to the flex of the filament inside the bowden tube.

On a side note, I have noticed my holes are more accurate on the machines with a direct drive than they are with the bowden tube setup. I'm assuming this is probably due to the flex of the filament inside the bowden tube.

|

Re: Undersized circles - Has this been solved yet? January 08, 2017 03:49PM |

Registered: 7 years ago Posts: 181 |

The problem has been acknowledged for some time now, and I have two formulae that I acquired from a professional 3d printing firm. I can't remember who they were now, as I didn't make a note at the time.

They suggested that where X mm was the required diameter of the hole then Y mm was the dimension needed to achieve it and that:

a) for vertical holes Y = 1.0155X + 0.2795 mm

b) for horizontal holes Y = 0.9927X + 0.3602 mm

These figures were for PLA, and as I understand it, they take into account various factors including the fact that the inside of the hole is unrestrained against shrinkage.

Have a look and see how they compare with what you have found. I have had success with these in sizing non-circular holes to accept metal rods as a tight fit.

They suggested that where X mm was the required diameter of the hole then Y mm was the dimension needed to achieve it and that:

a) for vertical holes Y = 1.0155X + 0.2795 mm

b) for horizontal holes Y = 0.9927X + 0.3602 mm

These figures were for PLA, and as I understand it, they take into account various factors including the fact that the inside of the hole is unrestrained against shrinkage.

Have a look and see how they compare with what you have found. I have had success with these in sizing non-circular holes to accept metal rods as a tight fit.

|

Re: Undersized circles - Has this been solved yet? January 10, 2017 10:32AM |

Registered: 7 years ago Posts: 4 |

|

Re: Undersized circles - Has this been solved yet? January 10, 2017 11:59AM |

Registered: 7 years ago Posts: 181 |

|

Re: Undersized circles - Has this been solved yet? January 10, 2017 01:43PM |

Registered: 7 years ago Posts: 5 |

I don't know if somebody already suggested this, but if the holes are constantly too small (for example always .5mm), there's a setting called "Dimensional Accuracy" or "horizontal size compensation" or smth. like that in most of the slicers. If your holes are always .5mm too small, try typing in -0.25mm (so just half of the amount that they are too small) If your holes are too big then do the same but with positive values.

|

Re: Undersized circles - Has this been solved yet? January 10, 2017 04:24PM |

Registered: 7 years ago Posts: 558 |

Quote

Farnomat

I don't know if somebody already suggested this, but if the holes are constantly too small (for example always .5mm), there's a setting called "Dimensional Accuracy" or "horizontal size compensation" or smth. like that in most of the slicers. If your holes are always .5mm too small, try typing in -0.25mm (so just half of the amount that they are too small) If your holes are too big then do the same but with positive values.

You have to be careful with that setting as it affects the entire part and not just the holes.

|

Re: Undersized circles - Has this been solved yet? January 10, 2017 05:51PM |

Registered: 9 years ago Posts: 978 |

What's really needed is a file format like AMF [en.wikipedia.org] which allows curved triangles to be supported by CAD design software and by slicers. Current slicers work with mesh files (e.g. .STL) which describe objects as flat surfaces, so any curve must be represented as a series of straight lines. Some slicers (e.g. Slic3r) can convert straight lines (back) to arcs, and there is a post-processor that can do that too [github.com]. However, the quality of the resultant arc will depend on the fineness of the mesh and the errors allowed by the slicer software in deciding whether a point is on an arc or not. Only some firmware can print arcs directly using the G2/G3 codes [reprap.org].

Edited 1 time(s). Last edit at 01/10/2017 06:31PM by frankvdh.

Edited 1 time(s). Last edit at 01/10/2017 06:31PM by frankvdh.

Sorry, only registered users may post in this forum.