Trying to get a smoother top layer without stitching and gaps

Posted by barakori

|

Trying to get a smoother top layer without stitching and gaps October 25, 2014 02:46AM |

Registered: 9 years ago Posts: 56 |

I'm trying to get my top layer to be as smooth as possible.

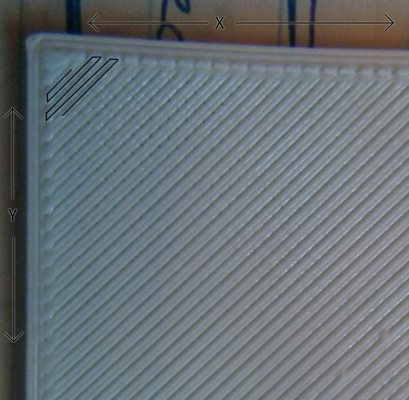

For starters, I printed a 40mm x 40mm x 1mm cube to see how the top layer looks like. Here's the result:

(please ignore the distorted X/Y angle - this was shot through a magnifying glass)

The top layer is not smooth. There are diagonal gaps and some raised plastics (looks like stitching) where the diagonal top fill touches the perimeter.

Looking closely (consider the black "snake" line I drew to follow the print pattern), it seems that the diagonal lines have gap every other line - during the diagonal draw pattern, when advancing on the one axis (X or Y when touching the perimeter), the movement is a little too far, creating a gap. Next time, when moving on the other axis, the movement is correct, so now there's no gap.

I don't know which axis is right, since I don't know the print direction, but if you follow my snake line starting at the upper part, then X is right and Y is wrong. If you start at the lower part, it's reversed. Note that I measured the total size of the cube with a caliper, and it's 39.86mm x 39.9mm, so the X/Y calibration is pretty good.

Another issue I see is stitching patterns where the diagonal fill touches the perimeter. I printed this with 3 perimeter lines and it looks like the diagonal pattern gets "too close" to the perimeter, thus creating small blobs of plastic. When touching the surface with my finger, I can definitely sense these little raised blobs.

Printing settings: Used slic3r 1.1.7 with a 0.35mm head, 0.2mm layer height and 0.4mm print width. Printer PLA at 185/60C. Anything else I should mention?

Thanks.

Any suggestion on how to improve the quality of the top layer? These issues don't feel that important on non-surfaces, but I intend to print a surface with some engraved letters in it, and this really reduces quality.

For starters, I printed a 40mm x 40mm x 1mm cube to see how the top layer looks like. Here's the result:

(please ignore the distorted X/Y angle - this was shot through a magnifying glass)

The top layer is not smooth. There are diagonal gaps and some raised plastics (looks like stitching) where the diagonal top fill touches the perimeter.

Looking closely (consider the black "snake" line I drew to follow the print pattern), it seems that the diagonal lines have gap every other line - during the diagonal draw pattern, when advancing on the one axis (X or Y when touching the perimeter), the movement is a little too far, creating a gap. Next time, when moving on the other axis, the movement is correct, so now there's no gap.

I don't know which axis is right, since I don't know the print direction, but if you follow my snake line starting at the upper part, then X is right and Y is wrong. If you start at the lower part, it's reversed. Note that I measured the total size of the cube with a caliper, and it's 39.86mm x 39.9mm, so the X/Y calibration is pretty good.

Another issue I see is stitching patterns where the diagonal fill touches the perimeter. I printed this with 3 perimeter lines and it looks like the diagonal pattern gets "too close" to the perimeter, thus creating small blobs of plastic. When touching the surface with my finger, I can definitely sense these little raised blobs.

Printing settings: Used slic3r 1.1.7 with a 0.35mm head, 0.2mm layer height and 0.4mm print width. Printer PLA at 185/60C. Anything else I should mention?

Thanks.

Any suggestion on how to improve the quality of the top layer? These issues don't feel that important on non-surfaces, but I intend to print a surface with some engraved letters in it, and this really reduces quality.

|

Re: Trying to get a smoother top layer without stitching and gaps October 25, 2014 04:55AM |

Registered: 10 years ago Posts: 14,672 |

I see similar stitching patterns and I have a theory about the cause. I think the inherent elasticity in the Bowden extruders on my machine gives rise to excess extrusion at the end of a run when the head slows down and turns around. I have produced a simple mathematical model of this effect, and I intend to try pre-compensating for it in the firmware.

Does your printer use a Bowden extruder too?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Does your printer use a Bowden extruder too?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Trying to get a smoother top layer without stitching and gaps October 25, 2014 09:33AM |

Registered: 9 years ago Posts: 56 |

|

Re: Trying to get a smoother top layer without stitching and gaps October 25, 2014 11:30PM |

Registered: 10 years ago Posts: 1,401 |

The way the slicer creates the extrusion might be the reason for the gaps, if you can do the following: change the width to 0.42 and reduce the infill to perimeter overlap, also check your infill speed, might be going to fast for the extrusion, just make it around 80% of print speed, one last thing, check again the steps per mm on your extruder, it might be just a little off (believe me, a 1/4 of mm makes a big difference) . other test that you can do is to increased the temperature a few degrees, that will help the filament to swell a little more and cover the gaps.

Edited 2 time(s). Last edit at 10/25/2014 11:31PM by ggherbaz.

Edited 2 time(s). Last edit at 10/25/2014 11:31PM by ggherbaz.

|

Re: Trying to get a smoother top layer without stitching and gaps October 26, 2014 02:16PM |

Registered: 9 years ago Posts: 56 |

@ffherbaz - thanks for the info. I looked up "infill to perimeter overlap", and it seems like it's a Skeinforge option.

Anyone knows if there's an equivalent option in slic3r?

Don't want to add another tool to my chain at the moment. This only increases the chances of something going wrong...

Thanks.

Anyone knows if there's an equivalent option in slic3r?

Don't want to add another tool to my chain at the moment. This only increases the chances of something going wrong...

Thanks.

|

Re: Trying to get a smoother top layer without stitching and gaps October 26, 2014 02:29PM |

Registered: 11 years ago Posts: 560 |

In slic3r, under Print Settings\Advanced set your Default extrusion width to 0.35mm, the same as your nozzle size. People will say this isn't the fix, but for me and others it is.

For some printers, slic3r's calculation for auto extrusion width is too wide for what the nozzle is physically doing, which can cause the gaps between passes of the extruder.

For some printers, slic3r's calculation for auto extrusion width is too wide for what the nozzle is physically doing, which can cause the gaps between passes of the extruder.

|

Re: Trying to get a smoother top layer without stitching and gaps October 26, 2014 06:18PM |

Registered: 10 years ago Posts: 1,401 |

Dirty Steve,

You are actually "almost correct " to fill the area completely you need to set it to 0.36mm. That setting will cover the most of the square.

Total distance 56.56mm

0.35mm will cover: 56.35

0.42mm will cover: 56.28

0.36mm will cover: 56.52

Accounting for filament swell, a nozzle setting of 0.36 will cover all the area in 157 passes (3 on each side for perimeters) .

Thanks for the correction.

Edited 1 time(s). Last edit at 10/26/2014 06:25PM by ggherbaz.

You are actually "almost correct " to fill the area completely you need to set it to 0.36mm. That setting will cover the most of the square.

Total distance 56.56mm

0.35mm will cover: 56.35

0.42mm will cover: 56.28

0.36mm will cover: 56.52

Accounting for filament swell, a nozzle setting of 0.36 will cover all the area in 157 passes (3 on each side for perimeters) .

Thanks for the correction.

Edited 1 time(s). Last edit at 10/26/2014 06:25PM by ggherbaz.

Sorry, only registered users may post in this forum.