Worm Gear / Cura Support Structure / Slic3r ?

Posted by Plasteroid

|

Worm Gear / Cura Support Structure / Slic3r ? October 30, 2014 03:18PM |

Registered: 9 years ago Posts: 125 |

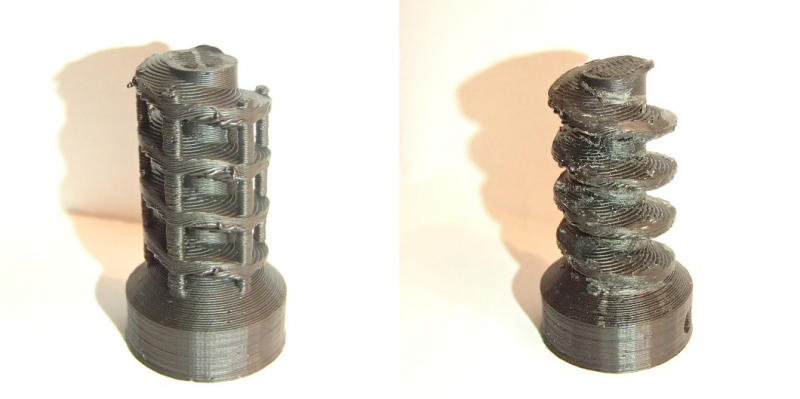

I was trying to print a worm gear ( [www.thingiverse.com] ). Slic3r 1.0 RC2 made too much support (image). Cura was missing top part support and my print was knocked down by the hotend ( upper part edge curling). I have overhang angle 60 on Cura. Does it help to put it to about 40 (upper part slope)? Some Slic3r setting so the whole gear would not be covered by the hard shell? Or more Cura settings?

P.S.

I was thinking to draw my own support pillars.

ABS

225C / 110C

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

P.S.

I was thinking to draw my own support pillars.

ABS

225C / 110C

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

|

Re: Worm Gear / Cura Support Structure / Slic3r ? October 30, 2014 05:52PM |

Registered: 11 years ago Posts: 1,171 |

|

Re: Worm Gear / Cura Support Structure / Slic3r ? October 31, 2014 03:49PM |

Registered: 9 years ago Posts: 125 |

I flipped the gear. I don't know why it was designed to stand on it's tip? I drew the support by myself and printed it much better. Perhaps a little bit more and thinner pillars could do it better?

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

|

Re: Worm Gear / Cura Support Structure / Slic3r ? November 01, 2014 09:48PM |

Registered: 11 years ago Posts: 1,171 |

Just to give you some possible ideas, here is a screenshot of my project showing the support I drew, notice I even went around the barbs sticking out as they don't need support (I removed a section of support pieces so you could see inside).

I always may my support as thin as my slicing software can handle, a single perimeter is ideal. Then I make sure there is one layer height between the top of the support and the part, this means you can easily remove it after printing as the upper piece will be resting on it but not fused to it.

You can also think outside the box. Your screw, I myself would cut it into to parts down the center, lay them both flat on the cut edge print then use acetone (assuming you print in ABS) to glue them back together.

BTW mine needed support not just for looks but this is actually 2 pieces that make up a swivel for a vacuum system. The top half has to spin on the bottom and there is a cavity inside with ball like joint.

I always may my support as thin as my slicing software can handle, a single perimeter is ideal. Then I make sure there is one layer height between the top of the support and the part, this means you can easily remove it after printing as the upper piece will be resting on it but not fused to it.

You can also think outside the box. Your screw, I myself would cut it into to parts down the center, lay them both flat on the cut edge print then use acetone (assuming you print in ABS) to glue them back together.

BTW mine needed support not just for looks but this is actually 2 pieces that make up a swivel for a vacuum system. The top half has to spin on the bottom and there is a cavity inside with ball like joint.

|

Re: Worm Gear / Cura Support Structure / Slic3r ? November 02, 2014 05:46AM |

Registered: 9 years ago Posts: 125 |

Nice! Single perimeter thin. I have to try. I was afraid to use very thin pillars thinking they could bend. One layer space between the object and the support; I don't know because my ABS tends to curl up not down...or perhaps it gets a grip? I 've been thinking to print two halves also. I haven't got experience yet, ABS + acetone joining. Perhaps some mortise and tenon joint inside makes it better.

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

Sorry, only registered users may post in this forum.