Big gaps and no good fills

Posted by alfadex

|

Big gaps and no good fills November 15, 2014 08:27AM |

Registered: 11 years ago Posts: 119 |

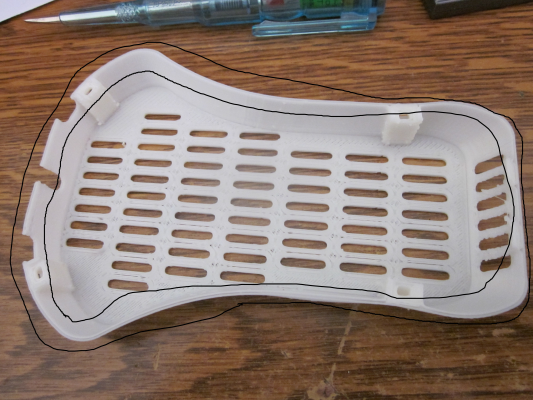

I thing i have big space as photo shows. That result everything i make ,not to be sturdy.When a line is printed is not always connected with side lines

I have pursa mendel 2 ,0.5 nozzle, teachup firmware,abs plastic 2.75.i am using Using Slic3r and Pronterface

I am printing 0.3 or0.4 layer the same problem

Also, at the perimeter or this thing ,there are two perimeters but are not connected together ,why is this happening?

Edited 1 time(s). Last edit at 11/15/2014 08:28AM by alfadex.

I have pursa mendel 2 ,0.5 nozzle, teachup firmware,abs plastic 2.75.i am using Using Slic3r and Pronterface

I am printing 0.3 or0.4 layer the same problem

Also, at the perimeter or this thing ,there are two perimeters but are not connected together ,why is this happening?

Edited 1 time(s). Last edit at 11/15/2014 08:28AM by alfadex.

|

Re: Big gaps and no good fills November 15, 2014 11:37AM |

Registered: 10 years ago Posts: 1,401 |

The problem isn't the layer height but the extrusion width.

Using a 0.5 nozzle standard extrusion width will be 0.6 if the width of the part you are printing can be divided by that number then your part will come out right, if any difference then a gap will be visible.

A 2.4mm will be covered with 4 0.6mm lines, but anything from 2.5 to 2.9 will display gaps that will get bigger the closer they get to the next divider width 3.0

You can play with the extrusion width or the nozzle size to compensate for the part width.

The other way you have to work it around is with the number of perimeters, a 2.5mm wall cannot be filled with 3 perimeters at 0.6 because there is not enough space, the slicer will just lay 4 lines leaving a gap, but if you lower it to 2 perimeters then you have a 1mm gap that can be fill.(the slicer should be intelligent enough to do this by itself, but it doesn't, you have to do it)

Edited 4 time(s). Last edit at 11/15/2014 11:53AM by ggherbaz.

Using a 0.5 nozzle standard extrusion width will be 0.6 if the width of the part you are printing can be divided by that number then your part will come out right, if any difference then a gap will be visible.

A 2.4mm will be covered with 4 0.6mm lines, but anything from 2.5 to 2.9 will display gaps that will get bigger the closer they get to the next divider width 3.0

You can play with the extrusion width or the nozzle size to compensate for the part width.

The other way you have to work it around is with the number of perimeters, a 2.5mm wall cannot be filled with 3 perimeters at 0.6 because there is not enough space, the slicer will just lay 4 lines leaving a gap, but if you lower it to 2 perimeters then you have a 1mm gap that can be fill.(the slicer should be intelligent enough to do this by itself, but it doesn't, you have to do it)

Edited 4 time(s). Last edit at 11/15/2014 11:53AM by ggherbaz.

|

Re: Big gaps and no good fills November 15, 2014 12:10PM |

Registered: 11 years ago Posts: 119 |

mmm you are right, i have never thign of this.

I print that part again but i make two change simitaneusly , i have very good result but whick one is the reason

I check default extrusion width at advance settings as my noozle 0.5, it was empty before

And the other one is filament diameter was 2.4 and i go it at 2mm. As i measure with calliper i found it 2.6-2.8.

Do you think it was because of default extrusion width? Should it be 0.6 or 0.5mm???

thank you very much

I print that part again but i make two change simitaneusly , i have very good result but whick one is the reason

I check default extrusion width at advance settings as my noozle 0.5, it was empty before

And the other one is filament diameter was 2.4 and i go it at 2mm. As i measure with calliper i found it 2.6-2.8.

Do you think it was because of default extrusion width? Should it be 0.6 or 0.5mm???

thank you very much

|

Re: Big gaps and no good fills November 15, 2014 12:21PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: Big gaps and no good fills November 15, 2014 12:23PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: Big gaps and no good fills November 15, 2014 12:45PM |

Registered: 11 years ago Posts: 119 |

|

Re: Big gaps and no good fills November 15, 2014 01:38PM |

Registered: 10 years ago Posts: 1,401 |

Sorry, only registered users may post in this forum.