ABS problems: delamination, cracks, warping [SOLVED]

Posted by abuharsky

|

ABS problems: delamination, cracks, warping [SOLVED] November 19, 2014 05:54AM |

Registered: 9 years ago Posts: 25 |

Hello All.

I spent a couple of weeks, even months in a vain attempt to print anything from ABS plastic.

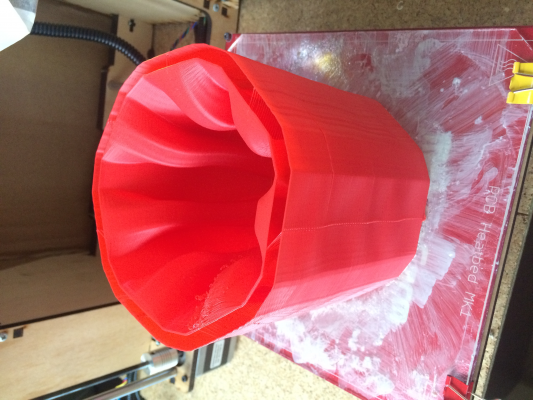

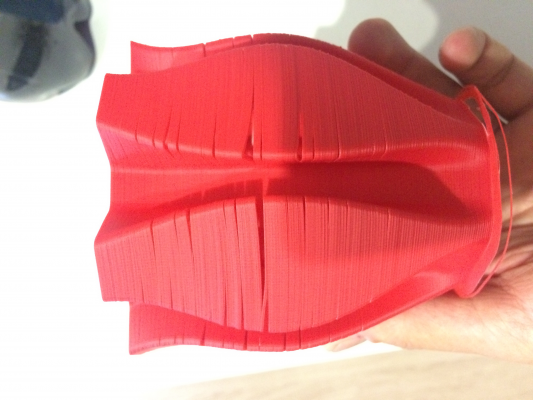

There are no problems with printing small models, but with large models having constant problems: you just can not print any big vase without cracks and delaminations!

First, I tried few experiments with slicer(KISSlicer) settings for better adhesion between layers (slightly more flow rate, slightly more hotend temp - 240C, 250C instead of 230C, very low speed - 20-30 mm/s).

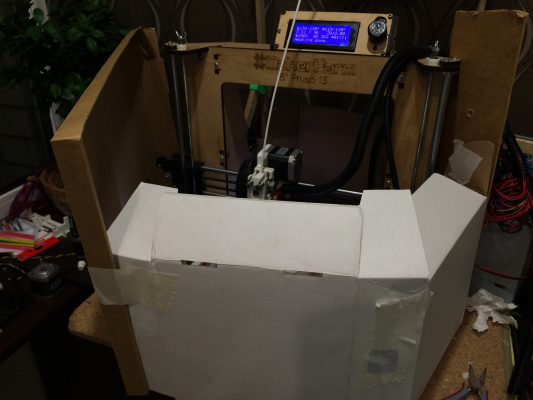

Second, I tried to make simple enclosure for printer using cardboard.

Third, I tried to print model inside thin wall to make thermos effect to get uniform cooling of the plastic.

although it did not work out all the details of cracked

I wanted to understand why this is happening.

At high temperatures, the plastic expands when low narrows, it creates internal tension. It is necessary to calculate or determine experimentally the value of narrowing:

1) look for the coefficient of thermal expansion ABS: 73.8 * 10 ^ -6 ° C-1 ( [temperatures.ru] )

2) remember physics 6th grade ( [goo.gl] )

( [goo.gl] )

3) calculate how much less will be the length of the extruded rod 100mm at the bed temperature of 100C and 230C of the nozzle

ΔL = a * L * Δt = 73.8 * 10 ^ -6 * 100mm * (230C - 100C) = 0,96mm - which is almost 1% of the original length.

Upon reaching room temperature, 25 ° C - it is 1,5% (ΔL = a * L * Δt = 73.8 * 10 ^ -6 * 100mm * (230C - 25C) = 1,51mm)

1% - It is very small.

---------------

Accordingly, with this small change in length of the plastic (1%) occurs corresponding to the internal pressure value of which is not too high.

The fact is, if the bonding strength is higher than the internal stresses - problem solved.

Then I tested the strength of bonding layers.

Testing methodology is simple: on the printed cylinder with 2 perimeters I evenly apply pressure with finger on the wall as long as it is not cracked between layers. By the depth pressing I detected the magnitude of the applied strength.

== Print speed affects the adhesion, but not much: I got about the same results for speeds 30-50mm/s;

== Much greater affect temperature of the extrusion: at 220C-260С I got the same bad result (plastic cracked from the slightest finger pressure), but the situation changed dramatically at temperature 270C-280C.

(Also, I have 2 different ABS filaments from different manufacturers, for the second filament I determined the optimal temperature in 260C.)

At this moment I have few succeeded prints (big models up to 150mm in diameter and up to 180mm in height) at 280C without any enclosure and for some models with enabled extrusion cooling fan(!!!):

1) single perimeter, 30mm/s, 0.4 nozzle, 280C, extrusion cooling fan OFF

(top no cracks, it is because of the fact that one of the perimeter for this detail is not enough or need support)

2) 2 perimeters, 70mm/s, 0.4 nozzle, 280C, extrusion cooling fan ON (full speed)

Finally, a few rules for successful work with ABS:

1) maximum heat for your particular filament (note that not all filaments are the same, they have different properties: viscosity, shrinkage, bonding and etc.)

2) the average print speed (I recommend 30-60mm/s)

3) calibrated heated bed and ABS juice for good adhesion of the first layer; ( [www.makerbot.com] )

4) a bit of luck!

UPDATE #1

Most often china thermistors can't show you real temp of your nozzle, when you think its 250C, in real it may only be 220C(or 280C). Don't forget to fine tune your temp sensors.

Edited 6 time(s). Last edit at 11/20/2014 09:58AM by abuharsky.

I spent a couple of weeks, even months in a vain attempt to print anything from ABS plastic.

There are no problems with printing small models, but with large models having constant problems: you just can not print any big vase without cracks and delaminations!

First, I tried few experiments with slicer(KISSlicer) settings for better adhesion between layers (slightly more flow rate, slightly more hotend temp - 240C, 250C instead of 230C, very low speed - 20-30 mm/s).

Second, I tried to make simple enclosure for printer using cardboard.

Third, I tried to print model inside thin wall to make thermos effect to get uniform cooling of the plastic.

although it did not work out all the details of cracked

I wanted to understand why this is happening.

At high temperatures, the plastic expands when low narrows, it creates internal tension. It is necessary to calculate or determine experimentally the value of narrowing:

1) look for the coefficient of thermal expansion ABS: 73.8 * 10 ^ -6 ° C-1 ( [temperatures.ru] )

2) remember physics 6th grade

( [goo.gl] )

( [goo.gl] )3) calculate how much less will be the length of the extruded rod 100mm at the bed temperature of 100C and 230C of the nozzle

ΔL = a * L * Δt = 73.8 * 10 ^ -6 * 100mm * (230C - 100C) = 0,96mm - which is almost 1% of the original length.

Upon reaching room temperature, 25 ° C - it is 1,5% (ΔL = a * L * Δt = 73.8 * 10 ^ -6 * 100mm * (230C - 25C) = 1,51mm)

1% - It is very small.

---------------

Accordingly, with this small change in length of the plastic (1%) occurs corresponding to the internal pressure value of which is not too high.

The fact is, if the bonding strength is higher than the internal stresses - problem solved.

Then I tested the strength of bonding layers.

Testing methodology is simple: on the printed cylinder with 2 perimeters I evenly apply pressure with finger on the wall as long as it is not cracked between layers. By the depth pressing I detected the magnitude of the applied strength.

== Print speed affects the adhesion, but not much: I got about the same results for speeds 30-50mm/s;

== Much greater affect temperature of the extrusion: at 220C-260С I got the same bad result (plastic cracked from the slightest finger pressure), but the situation changed dramatically at temperature 270C-280C.

(Also, I have 2 different ABS filaments from different manufacturers, for the second filament I determined the optimal temperature in 260C.)

At this moment I have few succeeded prints (big models up to 150mm in diameter and up to 180mm in height) at 280C without any enclosure and for some models with enabled extrusion cooling fan(!!!):

1) single perimeter, 30mm/s, 0.4 nozzle, 280C, extrusion cooling fan OFF

(top no cracks, it is because of the fact that one of the perimeter for this detail is not enough or need support)

2) 2 perimeters, 70mm/s, 0.4 nozzle, 280C, extrusion cooling fan ON (full speed)

Finally, a few rules for successful work with ABS:

1) maximum heat for your particular filament (note that not all filaments are the same, they have different properties: viscosity, shrinkage, bonding and etc.)

2) the average print speed (I recommend 30-60mm/s)

3) calibrated heated bed and ABS juice for good adhesion of the first layer; ( [www.makerbot.com] )

4) a bit of luck!

UPDATE #1

Most often china thermistors can't show you real temp of your nozzle, when you think its 250C, in real it may only be 220C(or 280C). Don't forget to fine tune your temp sensors.

Edited 6 time(s). Last edit at 11/20/2014 09:58AM by abuharsky.

|

Re: ABS problems: delamination, cracks, warping [SOLVED] November 20, 2014 06:10AM |

Registered: 10 years ago Posts: 100 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] November 20, 2014 09:30AM |

Registered: 10 years ago Posts: 770 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] November 25, 2014 07:01AM |

Registered: 9 years ago Posts: 25 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] November 25, 2014 09:18AM |

Registered: 10 years ago Posts: 770 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] December 12, 2014 09:39AM |

Registered: 9 years ago Posts: 25 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] December 12, 2014 10:23PM |

Registered: 11 years ago Posts: 1,592 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] December 15, 2014 08:07PM |

Registered: 11 years ago Posts: 160 |

I usually take my prints up in temp until they start to look funny from being too hot, then back off 10C. That's where I have found best lamination. But what I am finding now is the quality of the ABS really matters. Some of the cheaper stuff no matter how I print, it just likes to delaminate, or be brittle.

|

Re: ABS problems: delamination, cracks, warping [SOLVED] December 15, 2014 09:10PM |

Registered: 10 years ago Posts: 118 |

I found out that any material -> higher temp == better result

But ABS is so hard to work with, so much warp. Nylon is much much better.

I might get a filastruder and try to make a ABS-Nylon mix to have their good characteristics combined.

I also found out that more walls = better lamination Thicker the better.

Thicker the better.

But ABS is so hard to work with, so much warp. Nylon is much much better.

I might get a filastruder and try to make a ABS-Nylon mix to have their good characteristics combined.

I also found out that more walls = better lamination

Thicker the better.

Thicker the better.

|

Re: ABS problems: delamination, cracks, warping [SOLVED] December 16, 2014 12:33AM |

Registered: 11 years ago Posts: 160 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] December 16, 2014 03:21AM |

Registered: 11 years ago Posts: 1,592 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] December 17, 2014 04:14PM |

Registered: 10 years ago Posts: 118 |

I'm using cheapest nylon i could find: Trimmer line!

Sure there is some warping issues with nylon, but they are usually rather small issues.

Nylon requires the extra step of drying it, and damn it picks up moisture fast, but when it's dry it's a dream to work with compared to ABS. Sticks like hell on PVA glue or ABS juice too.

Sure there is some warping issues with nylon, but they are usually rather small issues.

Nylon requires the extra step of drying it, and damn it picks up moisture fast, but when it's dry it's a dream to work with compared to ABS. Sticks like hell on PVA glue or ABS juice too.

|

Re: ABS problems: delamination, cracks, warping [SOLVED] January 23, 2015 09:23AM |

Registered: 9 years ago Posts: 25 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] January 24, 2015 09:46AM |

Registered: 10 years ago Posts: 118 |

For ABS i have my cooling fan on slow, start with 255-265C, and bed ~100C.

After a layer or too i raise the temp to 285-295, and eventually bed rises to 120C.

PVA glue or ABS juice bottom. I like PVA glue that it's easier to get the parts of at the end, but some models are just so warp prone you need thick ABS juiced one not to warp a corner. Example of such print would be a big rectangle, sharp corners tend to lift

Print speed i use is 100-120mm/s with 25mm/s jerk and 4000mm/s2 acceleration.

After a layer or too i raise the temp to 285-295, and eventually bed rises to 120C.

PVA glue or ABS juice bottom. I like PVA glue that it's easier to get the parts of at the end, but some models are just so warp prone you need thick ABS juiced one not to warp a corner. Example of such print would be a big rectangle, sharp corners tend to lift

Print speed i use is 100-120mm/s with 25mm/s jerk and 4000mm/s2 acceleration.

|

Re: ABS problems: delamination, cracks, warping [SOLVED] January 24, 2015 09:55AM |

Registered: 11 years ago Posts: 560 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] January 24, 2015 09:14PM |

Registered: 9 years ago Posts: 47 |

I been also printing a lot with abs and printed 6 of those types of vases, I use to do the crappy abs juice thing now I use that over priced hair spray called 3DLAC its expensive 20 dollars a can but it does along way and since then I have Zero warping and everything sticks really well and once the bed temp lowers to 40 c everything simply lets go with out a fight . and as for those vases I found my 0.8 and my 0.6 nozzles do the best jobs with faster print times then my 0.4

e3d hotend temp 230c

heatbed 100c

print speed@ 55 to 70 mms

I also use cure and after 1mm I bring the flow rate to 98%

No cooling

Edited 1 time(s). Last edit at 01/24/2015 09:15PM by Tibuck.

e3d hotend temp 230c

heatbed 100c

print speed@ 55 to 70 mms

I also use cure and after 1mm I bring the flow rate to 98%

No cooling

Edited 1 time(s). Last edit at 01/24/2015 09:15PM by Tibuck.

|

Re: ABS problems: delamination, cracks, warping [SOLVED] January 27, 2015 08:23PM |

Registered: 10 years ago Posts: 118 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] January 27, 2015 09:54PM |

Registered: 10 years ago Posts: 770 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] April 11, 2015 08:58AM |

Registered: 9 years ago Posts: 1 |

Until recently I had exact the same problems as abuharsky:cracked layers, layers not sticking well.

Previously I used a j-head compatible and it seems all ok. I printed on 235 degrees, but after a while (3 months of printing) the nozzle "came out". After reading this post I suppose the thermistor was probably off and the actual temperature (but I have no way to confirm it) was more like 260 degrees.

So after the 3rd meltdown I threw away the j-head compatible and bought a brand-new E3D v6. All was stable and working well at 235 degrees, except the layers didn't seem to bind well. I printed the Bear Puzzle and even with small layers there were cracks everywhere. I tried different layer thicknesses, slightly different temperatures, different infills, 2 different ABS brands... nothing seemed to help. THEN I came to this page, raised the temperature to 260 degrees, later 265 and the problem was solved! So easy if you think about it... So thanks alot abuharsky!

Bear Puzzle:

printed at probably 235 degrees, 0.2mm layer

[www.thingiverse.com]

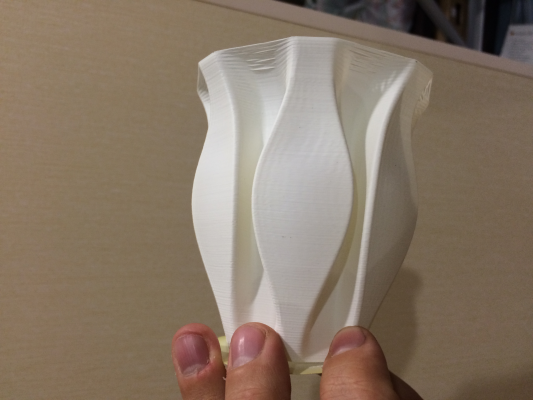

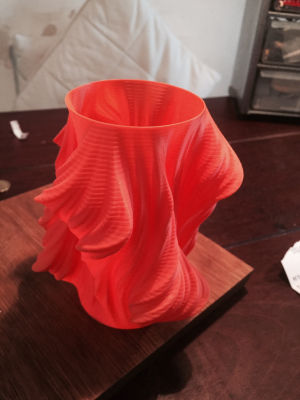

Julia Vase:

printed 265 degrees, 0.25mm layer in a spiral. sliced with Slic3r.

[www.thingiverse.com]

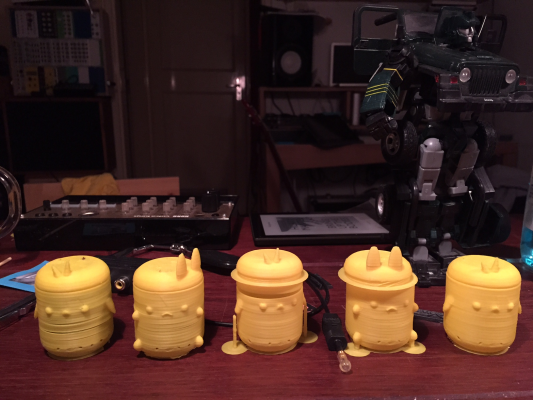

Egg Pods:

From left to right:

220, 225, 235, 260 and 265 degrees.

[www.thingiverse.com]

Previously I used a j-head compatible and it seems all ok. I printed on 235 degrees, but after a while (3 months of printing) the nozzle "came out". After reading this post I suppose the thermistor was probably off and the actual temperature (but I have no way to confirm it) was more like 260 degrees.

So after the 3rd meltdown I threw away the j-head compatible and bought a brand-new E3D v6. All was stable and working well at 235 degrees, except the layers didn't seem to bind well. I printed the Bear Puzzle and even with small layers there were cracks everywhere. I tried different layer thicknesses, slightly different temperatures, different infills, 2 different ABS brands... nothing seemed to help. THEN I came to this page, raised the temperature to 260 degrees, later 265 and the problem was solved! So easy if you think about it... So thanks alot abuharsky!

Bear Puzzle:

printed at probably 235 degrees, 0.2mm layer

[www.thingiverse.com]

Julia Vase:

printed 265 degrees, 0.25mm layer in a spiral. sliced with Slic3r.

[www.thingiverse.com]

Egg Pods:

From left to right:

220, 225, 235, 260 and 265 degrees.

[www.thingiverse.com]

|

Re: ABS problems: delamination, cracks, warping [SOLVED] May 18, 2015 11:10AM |

Registered: 8 years ago Posts: 47 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] May 18, 2015 11:33AM |

Registered: 9 years ago Posts: 25 |

Quote

amplivibs

THEN I came to this page, raised the temperature to 260 degrees, later 265 and the problem was solved! So easy if you think about it... So thanks alot abuharsky!

Quote

aFrazatto

I can confirm this is a VERY good solution.

Thanks a lot.

I'm happy to read this!

enjoy

Edited 1 time(s). Last edit at 05/18/2015 11:34AM by abuharsky.

|

Re: ABS problems: delamination, cracks, warping [SOLVED] May 19, 2015 10:21AM |

Registered: 9 years ago Posts: 251 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] May 21, 2015 09:41PM |

Registered: 9 years ago Posts: 476 |

Hi, I am using mk8 extruder type, I wonder if I'm able to reach up to 270c? Since you guys all using e3d type hotend, is there anyone uses other than e3d type to reach up to 270c?

Just got my cracks last night though and I am running on sangui board so there were no way to control the fan except it is always on, but i do have a fan duct, I took it out last night when printing the back case of my lcd due to cracking occurs when printing it at 240c, .2mm, 3 walls and 4 bottom/top layer

Just got my cracks last night though and I am running on sangui board so there were no way to control the fan except it is always on, but i do have a fan duct, I took it out last night when printing the back case of my lcd due to cracking occurs when printing it at 240c, .2mm, 3 walls and 4 bottom/top layer

|

Re: ABS problems: delamination, cracks, warping [SOLVED] May 21, 2015 10:37PM |

Registered: 8 years ago Posts: 47 |

|

Re: ABS problems: delamination, cracks, warping [SOLVED] May 25, 2015 12:56PM |

Registered: 9 years ago Posts: 25 |

Sorry, only registered users may post in this forum.