Plastic comes out of the hotend sideways?

Posted by barakori

|

Plastic comes out of the hotend sideways? November 24, 2014 02:56PM |

Registered: 9 years ago Posts: 56 |

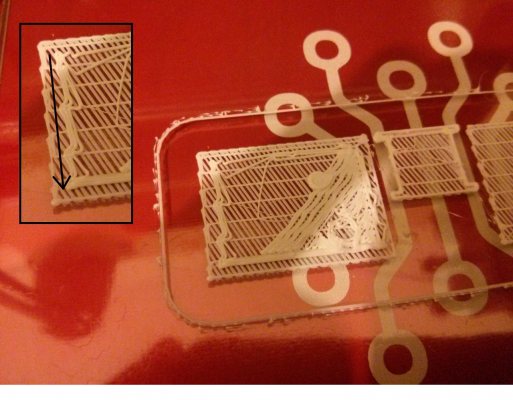

Take a look at this image, taken after the first model layer was printed (above 2 raft layers):

The bottom raft layer is fine - the diagonal lines that make the base stick to the hotbed.

The 2nd layer (top raft layer) also seems fine, that't the more sparse lines that go sideways.

With the 3rd layer (first layer of the model) things got really messy. I stopped the print during this print and took a picture.

The most noticeable strangeness are the saw-teeth lines that are also enlarged. The print head did a straight Y-only move in the direction of the arrow, but the end result was these crooked lines. These are the 3 perimeter lines.

I know slic3r makes sure there's some gap between the raft (or support material) and the printed model, it looks like when this gap exists the filament "drifts" to the right and doesn't keep it's position.

Any suggestions on how to tackle this?

Thanks.

Note: Similar issues were discussed in http://forums.reprap.org/read.php?262,433333, but I really wanted to pinpoint this issue and see if it can be solved.

The bottom raft layer is fine - the diagonal lines that make the base stick to the hotbed.

The 2nd layer (top raft layer) also seems fine, that't the more sparse lines that go sideways.

With the 3rd layer (first layer of the model) things got really messy. I stopped the print during this print and took a picture.

The most noticeable strangeness are the saw-teeth lines that are also enlarged. The print head did a straight Y-only move in the direction of the arrow, but the end result was these crooked lines. These are the 3 perimeter lines.

I know slic3r makes sure there's some gap between the raft (or support material) and the printed model, it looks like when this gap exists the filament "drifts" to the right and doesn't keep it's position.

Any suggestions on how to tackle this?

Thanks.

Note: Similar issues were discussed in http://forums.reprap.org/read.php?262,433333, but I really wanted to pinpoint this issue and see if it can be solved.

|

Re: Plastic comes out of the hotend sideways? November 28, 2014 06:25PM |

Registered: 11 years ago Posts: 1,592 |

I rarely use rafts so not too sure about this but that 2nd raft layer seems odd to me - the horizontal spacing seems exceptionally wide. I was wondering if that was "mechanically" reacting somehow with the first print layer proper, causing it to distort?

_______________________________________

Waitaki 3D Printer

_______________________________________

Waitaki 3D Printer

|

Re: Plastic comes out of the hotend sideways? November 29, 2014 12:40AM |

Registered: 9 years ago Posts: 56 |

On the 2nd layer, the lines are 2.5mm apart, which is set in Slic3r's Print Settings > Support Material > Options for support material and raft > Pattern spacing.

This is the default setting, I assume it's rather large so that it would be easier to remove the raft. I can try a smaller spacing.

This is the default setting, I assume it's rather large so that it would be easier to remove the raft. I can try a smaller spacing.

|

Re: Plastic comes out of the hotend sideways? November 29, 2014 03:42AM |

Registered: 9 years ago Posts: 56 |

I took apart the J-head hotend, Just to be sure, I cleaned with a steel guitar string (plastic passes through anyway, I though maybe something partially blocking the way - couldn't find anything).

I then held the hotend on its side, heated it up to 185 degrees and manually pushed some PLA into it. The plastic coming out of the nozzle didn't come out straight, and actually went up and right, defying gravity.

It's easier to show than describe in words, so I uploaded a video of this to YouTube: https://www.youtube.com/watch?v=sx2beJy_SYM

Any reason why this happens and if this can be fixed?

Alternatively, is it possible to replace only the nozzle, and not the entire hotend? I tried looking for places online, but only saw full hotends for sale.

Thanks.

I then held the hotend on its side, heated it up to 185 degrees and manually pushed some PLA into it. The plastic coming out of the nozzle didn't come out straight, and actually went up and right, defying gravity.

It's easier to show than describe in words, so I uploaded a video of this to YouTube: https://www.youtube.com/watch?v=sx2beJy_SYM

Any reason why this happens and if this can be fixed?

Alternatively, is it possible to replace only the nozzle, and not the entire hotend? I tried looking for places online, but only saw full hotends for sale.

Thanks.

|

Re: Plastic comes out of the hotend sideways? November 29, 2014 01:57PM |

Registered: 11 years ago Posts: 560 |

Your video looks fairly normal for extrusion. I would take a very fine sand paper to the tip. With the end mounted bring the nozzle down to .1 to .15mm on the sand paper, very light pressure, and give the sand paper a couple drags across the nozzle tip, you could have a small burr in the brass at the tip.

Have you had successful prints with this nozzle? layer heights you are trying to print and nozzle size?

Have you had successful prints with this nozzle? layer heights you are trying to print and nozzle size?

|

Re: Plastic comes out of the hotend sideways? November 29, 2014 02:36PM |

Registered: 9 years ago Posts: 56 |

|

Re: Plastic comes out of the hotend sideways? November 30, 2014 07:04PM |

Registered: 9 years ago Posts: 19 |

|

Re: Plastic comes out of the hotend sideways? November 30, 2014 11:14PM |

Registered: 12 years ago Posts: 174 |

I would not be too concerned on the free space extrusion bending to one side or the other since that is not how the nozzle was made to be used. When satisfactory settings are used the extruded filament should be confined between the nozzle surface and the print bed or the prior printed layer.

If you sanded the nozzle, make sure that you re-dress it with a fine abrasive so to smooth it out again and ensure a flat surface, use like 1500 grit or finer like crocus cloth. You can verify with a microscope or a large magnifier that scratches are removed.

Some deposits of heat decomposed plastic have been reported to reduce nozzle effective diameter after a year of service PTPG, but again this does not seem to be your issue.

What would cause the deflection of the filament to the side during a print run would be that the nozzle is higher than the diameter of the extruded filament. This would make sense since the raft which usually prints at lower layer heights than nominal to cause more squeeze out of the filament printed fine although they do not appear to be as squeezed out as would be expected. My guess is that your raft settings are at the right height for the nominal layer height and your raft settings for layer height are a little big. Re-evaluate your layer height settings for your nozzle diameter. Layer height should not be larger than extrudate diameter which with die swell will be just a few percent larger than nozzle hole size.

If you sanded the nozzle, make sure that you re-dress it with a fine abrasive so to smooth it out again and ensure a flat surface, use like 1500 grit or finer like crocus cloth. You can verify with a microscope or a large magnifier that scratches are removed.

Some deposits of heat decomposed plastic have been reported to reduce nozzle effective diameter after a year of service PTPG, but again this does not seem to be your issue.

What would cause the deflection of the filament to the side during a print run would be that the nozzle is higher than the diameter of the extruded filament. This would make sense since the raft which usually prints at lower layer heights than nominal to cause more squeeze out of the filament printed fine although they do not appear to be as squeezed out as would be expected. My guess is that your raft settings are at the right height for the nominal layer height and your raft settings for layer height are a little big. Re-evaluate your layer height settings for your nozzle diameter. Layer height should not be larger than extrudate diameter which with die swell will be just a few percent larger than nozzle hole size.

Sorry, only registered users may post in this forum.