ABS overhang printing issues

Posted by sodonnell

|

ABS overhang printing issues January 28, 2015 10:36PM |

Registered: 9 years ago Posts: 53 |

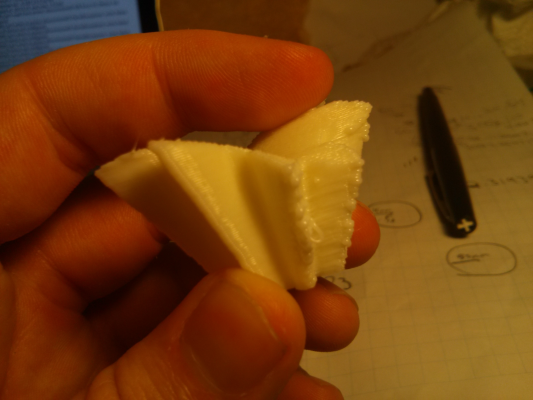

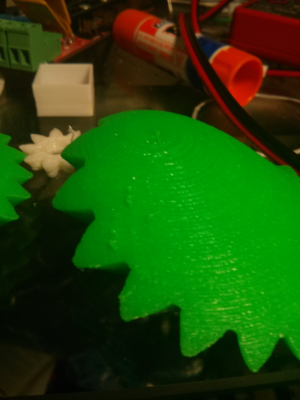

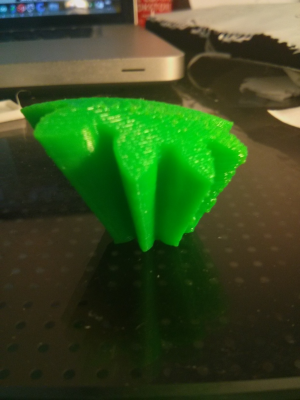

Thanks to the extremely helpful reprap community I was able to concur the evil curling overhangs with a 1.5 w/t and a printing temperature of 250C. However I now have another issue, while attempting to print the heart gear some of the teeth come out less than perfect specifically in

, however some teeth come out nicely. I am slicing with Cura and I set my outer shell speed to 20mm/s. is this due to the layer always starting or ending there? Do I need more retraction? Any help would be awesome....I can almost taste completion.

Thanks!!!!!

Thanks!!!!!

|

Re: ABS overhang printing issues January 29, 2015 05:32PM |

Registered: 9 years ago Posts: 125 |

250C is very hot if your thermistor is Ok. I have used max. 235C on ABS. Your part looks too melted. Use a fan or lower your hotend temp or draw a perfect support structure. My little parts got better with a fan and a duct (ABS). And I mean a fan blowing to the plastic, not a hotend cooler.

P.S. Slic3r has a random layer starting point option I think....

Edited 1 time(s). Last edit at 01/29/2015 05:35PM by Plasteroid.

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

P.S. Slic3r has a random layer starting point option I think....

Edited 1 time(s). Last edit at 01/29/2015 05:35PM by Plasteroid.

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

|

Re: ABS overhang printing issues January 29, 2015 07:32PM |

Registered: 9 years ago Posts: 53 |

|

Re: ABS overhang printing issues January 29, 2015 09:56PM |

Registered: 9 years ago Posts: 53 |

|

Re: ABS overhang printing issues January 30, 2015 04:46AM |

Registered: 9 years ago Posts: 125 |

How hot your bed is? I have 110C and I start the fan after the first layer and I use ABS juice. My ABS curling has gone better with a 40mm fan which has a tiny tip duct. Perhaps your blows too much?

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

|

Re: ABS overhang printing issues January 30, 2015 11:28AM |

Registered: 9 years ago Posts: 6 |

|

Re: ABS overhang printing issues January 30, 2015 12:39PM |

Registered: 9 years ago Posts: 53 |

|

Re: ABS overhang printing issues January 30, 2015 03:39PM |

Registered: 10 years ago Posts: 770 |

|

Re: ABS overhang printing issues January 30, 2015 04:13PM |

Registered: 9 years ago Posts: 125 |

Hey! I thought that a fan is bad for ABS. But then there was this on the forum: [forums.reprap.org] . I think that a fan can "freeze" ABS before it starts curling up. It can also prevent ABS sticking so perhaps it is some kind of "correct balance" what it needs? On big parts I don't usually use the fan, but look what I achieved to print with a fan on: [youtu.be]

...and it was ABS plastic.

P.S. Is it good ABS if you need 250C? Perhaps your printer wobbles when doing some direction changes?

Edited 1 time(s). Last edit at 01/30/2015 04:14PM by Plasteroid.

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

...and it was ABS plastic.

P.S. Is it good ABS if you need 250C? Perhaps your printer wobbles when doing some direction changes?

Edited 1 time(s). Last edit at 01/30/2015 04:14PM by Plasteroid.

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

|

Re: ABS overhang printing issues January 31, 2015 05:24AM |

Registered: 11 years ago Posts: 1,171 |

|

Re: ABS overhang printing issues January 31, 2015 12:42PM |

Registered: 9 years ago Posts: 53 |

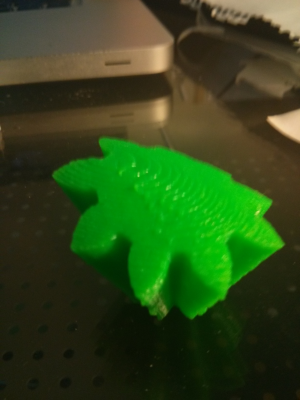

I lowered my hot end temp to about 240C....that is the lowest I can go without curling. I also set up retraction at 35mm/s and .5mm with some positive results. My bed is currently at 110C. Now I get small blobs on the parts only on 1 or 2 teeth of the gear (still trying to print the heart gear) and then along the tops when it is creating the rounded sides. Would this be a sign that I need more retraction distance or speed or is this something that just happens and cannot be fixed. I will post reference photos after I take them.

Thanks for all your help.

Thanks for all your help.

|

Re: ABS overhang printing issues January 31, 2015 12:51PM |

Registered: 9 years ago Posts: 53 |

|

Re: ABS overhang printing issues January 31, 2015 08:20PM |

Registered: 11 years ago Posts: 1,171 |

|

Re: ABS overhang printing issues February 02, 2015 09:32AM |

Registered: 9 years ago Posts: 53 |

|

Re: ABS overhang printing issues February 03, 2015 04:12PM |

Registered: 11 years ago Posts: 1,171 |

When the heat from the bed is high matches up with the heater block (same side) the part can get overly hot on that side and cause shrinkage and the same effect your photo shows.

[reprap.org]

Scroll down to "Part Temperature" that black block is mine and the problem went away with turning the bed temp down. It was highly prominant on the side where the heater block on the hotend was.

[reprap.org]

Scroll down to "Part Temperature" that black block is mine and the problem went away with turning the bed temp down. It was highly prominant on the side where the heater block on the hotend was.

|

Re: ABS overhang printing issues February 04, 2015 02:33PM |

Registered: 10 years ago Posts: 329 |

My tuppence worth.

My settings for ABS are:

Hotend temp of 230 or max 235 deg C for ABS. No fan.

Increase acceleration to get sharper corners. Set Slic3R on perimeters first, then infil.

No lift on layer change. Retract on layer change, 2.5mm retraction. Seam position aligned.

External perimeters first - leave this unticked, so most layer change blobs are on the inside.

My settings for ABS are:

Hotend temp of 230 or max 235 deg C for ABS. No fan.

Increase acceleration to get sharper corners. Set Slic3R on perimeters first, then infil.

No lift on layer change. Retract on layer change, 2.5mm retraction. Seam position aligned.

External perimeters first - leave this unticked, so most layer change blobs are on the inside.

Sorry, only registered users may post in this forum.