Printing issues with ABS and advices to solve it

Posted by BenBCN

|

Printing issues with ABS and advices to solve it February 05, 2015 11:30AM |

Registered: 9 years ago Posts: 2 |

Hello everyone,

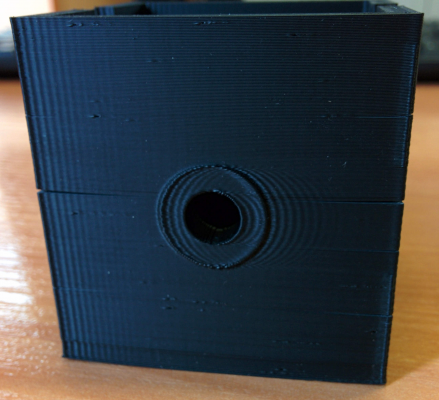

I did a print with ABS to make an empty box on a BCN3D+ printer. I can clearly see some issues on the resulting print (you can see them on the photo). Could you please give me some advices on the way to solve each of them ?

Thanks before for any advice !

Ben

I did a print with ABS to make an empty box on a BCN3D+ printer. I can clearly see some issues on the resulting print (you can see them on the photo). Could you please give me some advices on the way to solve each of them ?

- bottom wrapping : the printed item have wrapped and was only maintained by a central portion area on the bottom. My heat bed was set at 95°C and I use fixative spray. Any other advice ?

- inter-layer adhesion : the layer fan was off, extrusion temperature was 250°C, but the room where it have been printed is cold (~15°C). Do you think the room temperature can be important for that issue ?

- resonance on the corners and central hole (it's not a photo artefact !) : I have a dual extruder setup ; do you think a bowden will solve that issue ?

- Small residue on the face : we can see some ABS residue on the front face, and some inner small holes on the other faces. What do you think it comes from ?

- inferior width on the bottom : you can see that the 3-4 first millimeters of the print are less width than the rest of the part. This section correspond to the bottom of the part, which is plain ; it seems to have retracted. Why does it do that ?

Thanks before for any advice !

Ben

|

Re: Printing issues with ABS and advices to solve it February 06, 2015 02:45PM |

Registered: 9 years ago Posts: 2 |

|

Re: Printing issues with ABS and advices to solve it February 06, 2015 03:01PM |

Registered: 9 years ago Posts: 2 |

I might be able to help you with your layers. The room temperature is important. Especially when it's -15. The plastic will cool too quickly won't have enough time to adhere to the other layers. If it's going to be kept in such a cold room consider putting it in a heat chamber of some sort to keep it warm inside. Your layers also look to be on the large side. What do you have layer height set to compared to your nozzle diameter? I use a .4mm nozzle and my layer height is usually .2mm.

As for the other problems, I don't have any experience with those.

As for the other problems, I don't have any experience with those.

|

Re: Printing issues with ABS and advices to solve it February 06, 2015 03:35PM |

Registered: 10 years ago Posts: 580 |

Ben,

I hesitated to respond as I do not have that model of printer...

I agree with everything Kieth said.

I see the resonances at the corners also. A clue to determine what is shaking might be - does it happen in both the X and Y direction?

Also, is there a loose belt? You could also try lowering the accelerations and/or print speed in firmware.

That's a fairly high extrusion temp. The hotter you print, the more the plastic will shrink (but the cool environment is worse). The holes may be blow-outs due to absorbed water in the filament turning to steam, Iv'e seen that. There are ways you can dry the filament, you can search for that. (I put my filament into my heated chamber when I'm done and it seems to stay good that way.)

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I hesitated to respond as I do not have that model of printer...

I agree with everything Kieth said.

I see the resonances at the corners also. A clue to determine what is shaking might be - does it happen in both the X and Y direction?

Also, is there a loose belt? You could also try lowering the accelerations and/or print speed in firmware.

That's a fairly high extrusion temp. The hotter you print, the more the plastic will shrink (but the cool environment is worse). The holes may be blow-outs due to absorbed water in the filament turning to steam, Iv'e seen that. There are ways you can dry the filament, you can search for that. (I put my filament into my heated chamber when I'm done and it seems to stay good that way.)

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Printing issues with ABS and advices to solve it February 06, 2015 07:28PM |

Registered: 11 years ago Posts: 5,780 |

The ghosting of the hole in the center and the corners is related to the current in the motor. If you increase the current that effect will decrease. If you can increase the voltage to the motors it will also help.

The pinched appearance of the corners is due to low acceleration. Try increasing it if your machine can handle it. After you've increased the motor current you should be able to push the acceleration a little higher.

The bottom layers looking wider than those higher up is due to the first layer being squished out and more plastic being extruded for the first layer, and the high temperature of the print bed. You might try reducing the bed temperature a little. You may have the nozzle set a little close to the bed, making the first layer squish out more than it should.

The delamination is due to layers cooling as the print progresses. It is especially bad in objects with smooth flat sides because all the force created by the shrinking gets concentrated at the corners. The best solution is to enclose the printer and print in a high temperature environment. I have found that 45C or so eliminates most of the delamination. If you can avoid smooth sides it will also help. Printing slower may also help.

The pinched appearance of the corners is due to low acceleration. Try increasing it if your machine can handle it. After you've increased the motor current you should be able to push the acceleration a little higher.

The bottom layers looking wider than those higher up is due to the first layer being squished out and more plastic being extruded for the first layer, and the high temperature of the print bed. You might try reducing the bed temperature a little. You may have the nozzle set a little close to the bed, making the first layer squish out more than it should.

The delamination is due to layers cooling as the print progresses. It is especially bad in objects with smooth flat sides because all the force created by the shrinking gets concentrated at the corners. The best solution is to enclose the printer and print in a high temperature environment. I have found that 45C or so eliminates most of the delamination. If you can avoid smooth sides it will also help. Printing slower may also help.

Sorry, only registered users may post in this forum.