Varied gaps in ABS prints

Posted by zaa

|

Varied gaps in ABS prints February 07, 2015 10:09AM |

Registered: 9 years ago Posts: 8 |

Hello all,

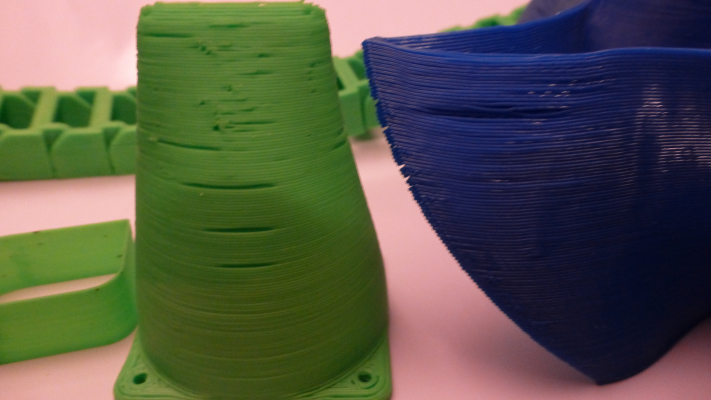

In the images below, you can see my issue. I've printed many of the little D shaped calibration objects, and have tuned my settings accordingly. This seems like under extrusion to me, but with all the calibration set what seems perfect, I hate to go changing it.

Here's the info:

Prusa i3V 12" heated bed with Rambo board.

Hexagon hot end with 40mm fan and supplied shroud.

Slic3r version 0.9.9, as suggested by Makerfarm.

X, Y, Z object measurements are mostly within 0.05mm on my most recent prints.

ABS Print temps 230 - 250c, bed temps are 110c, then dropping to 70c after the first layer, I believe this is the Makerfarm default.

I've done the extrusion calibration first by measuring the filament, then checking after extrusion. After that, I used the D shaped calibration print, measured and averaged, then put the resulting percentage into slic3r. The measurements are now pretty near perfect. As you can see, I've done it on both the blue, and green filament. The blue is from Makerfarm, the green is from IC3D.

At first glance, it seems to be worse as it gets further away from the table, but that's not the only place it happens. With the small cable chain prints, the layer adhesion isn't great, they're brittle along the layers.

The blue coupler on the left was printed before calibration, and while it looks better, the dimensions weren't accurate compared to the model.

Thanks for looking!

Here's a gcode header, this was for the green nozzle shroud:

In the images below, you can see my issue. I've printed many of the little D shaped calibration objects, and have tuned my settings accordingly. This seems like under extrusion to me, but with all the calibration set what seems perfect, I hate to go changing it.

Here's the info:

Prusa i3V 12" heated bed with Rambo board.

Hexagon hot end with 40mm fan and supplied shroud.

Slic3r version 0.9.9, as suggested by Makerfarm.

X, Y, Z object measurements are mostly within 0.05mm on my most recent prints.

ABS Print temps 230 - 250c, bed temps are 110c, then dropping to 70c after the first layer, I believe this is the Makerfarm default.

I've done the extrusion calibration first by measuring the filament, then checking after extrusion. After that, I used the D shaped calibration print, measured and averaged, then put the resulting percentage into slic3r. The measurements are now pretty near perfect. As you can see, I've done it on both the blue, and green filament. The blue is from Makerfarm, the green is from IC3D.

At first glance, it seems to be worse as it gets further away from the table, but that's not the only place it happens. With the small cable chain prints, the layer adhesion isn't great, they're brittle along the layers.

The blue coupler on the left was printed before calibration, and while it looks better, the dimensions weren't accurate compared to the model.

Thanks for looking!

Here's a gcode header, this was for the green nozzle shroud:

; generated by Slic3r 0.9.9 on 2015-02-06 at 19:46:42 ; layer_height = 0.35 ; perimeters = 3 ; top_solid_layers = 3 ; bottom_solid_layers = 3 ; fill_density = 0.4 ; perimeter_speed = 75 ; infill_speed = 100 ; travel_speed = 130 ; nozzle_diameter = 0.4 ; filament_diameter = 3 ; extrusion_multiplier = .913 ; perimeters extrusion width = 0.42mm ; infill extrusion width = 0.42mm ; solid infill extrusion width = 0.42mm ; top infill extrusion width = 0.42mm ; first layer extrusion width = 0.60mm

|

Re: Varied gaps in ABS prints February 07, 2015 10:31AM |

Registered: 11 years ago Posts: 560 |

|

Re: Varied gaps in ABS prints February 07, 2015 10:43AM |

Registered: 9 years ago Posts: 8 |

|

Re: Varied gaps in ABS prints February 07, 2015 10:52AM |

Registered: 11 years ago Posts: 5,780 |

Filament diameter is never exactly 3mm. Try measuring the filament with a caliper at about 20 places and use the avergae value for the filament diameter Slic3r. Then you leave your flow control set to 100%. Make sure when you measure the filament that you rotate the orientation of the caliper on the filament- it is usually slightly oval and if you keep measuring in the same orientation you won't get a good sampling of the diameter values.

It looks a little like gaps produced after retraction, when the extruder is supposed to start extruding again, but doesn't quite start up immediately. Maybe you need to tweak the retraction settings to have it extrude a little more plastic AFTER a retraction.

It looks a little like gaps produced after retraction, when the extruder is supposed to start extruding again, but doesn't quite start up immediately. Maybe you need to tweak the retraction settings to have it extrude a little more plastic AFTER a retraction.

|

Re: Varied gaps in ABS prints February 07, 2015 11:01AM |

Registered: 9 years ago Posts: 8 |

Sorry, only registered users may post in this forum.