printing Taulman bridge nylon - delaminating vertically

Posted by gordonendersby

|

printing Taulman bridge nylon - delaminating vertically March 24, 2015 05:53PM |

Registered: 9 years ago Posts: 286 |

Ive just started printing with Tailman bridge.

Ive done a few small prints without any problems and got really good results.

Nice smooth finish, sharp edges, strong and nearly unbreakable.

All with a nozzle temp of 240degC Which is lower than recomended but it was stringing a lot when hotter.

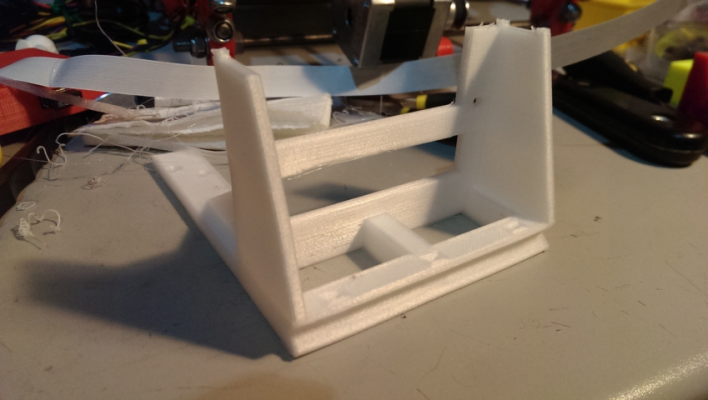

So i decided to print something a bit bigger.

This power supply tray for my printer.

[www.thingiverse.com]

Sliced in cura.

Nozzle temp 240degC, bed started at 90 then increased to 105degC after first few layers.

0.5mm nozzle, 0.25mm layers.

2mm perimeter, 2mm top and bottom layer.

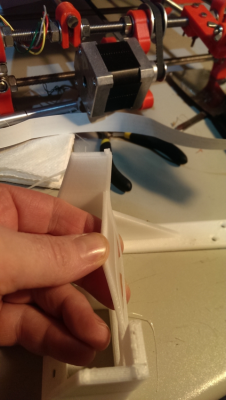

It looked good at first but then i noticed it was delaminating in a strange way.

I stopped the print.

Heres the vertical delamination. Its between each and every perimeter theres no infill in that section due to the number of perimiters..

Is it just the temp being too low?

Or anything else i have missed.

Gordon

Edited 4 time(s). Last edit at 03/24/2015 06:04PM by gordonendersby.

Ive done a few small prints without any problems and got really good results.

Nice smooth finish, sharp edges, strong and nearly unbreakable.

All with a nozzle temp of 240degC Which is lower than recomended but it was stringing a lot when hotter.

So i decided to print something a bit bigger.

This power supply tray for my printer.

[www.thingiverse.com]

Sliced in cura.

Nozzle temp 240degC, bed started at 90 then increased to 105degC after first few layers.

0.5mm nozzle, 0.25mm layers.

2mm perimeter, 2mm top and bottom layer.

It looked good at first but then i noticed it was delaminating in a strange way.

I stopped the print.

Heres the vertical delamination. Its between each and every perimeter theres no infill in that section due to the number of perimiters..

Is it just the temp being too low?

Or anything else i have missed.

Gordon

Edited 4 time(s). Last edit at 03/24/2015 06:04PM by gordonendersby.

|

Re: printing Taulman bridge nylon - delaminating vertically March 24, 2015 07:09PM |

Registered: 10 years ago Posts: 1,401 |

Bed at 80, 240 for the hotend but 3 things are really important:

1. Dry the filament before printing. If you haven't storage it in a special setting, its most likely full of moisture. You will damage the spool but only effective way I have found to dry it its in the oven (1 hour at 225)

2. Lower the speed. I mean print SLOW if you don't want to have that kind of delamination.

3. Change nozzle size or extrusion width in the slicer to smaller than real size (if 0.4 go 0.35~.38) that way infill will be packed together.

1. Dry the filament before printing. If you haven't storage it in a special setting, its most likely full of moisture. You will damage the spool but only effective way I have found to dry it its in the oven (1 hour at 225)

2. Lower the speed. I mean print SLOW if you don't want to have that kind of delamination.

3. Change nozzle size or extrusion width in the slicer to smaller than real size (if 0.4 go 0.35~.38) that way infill will be packed together.

|

Re: printing Taulman bridge nylon - delaminating vertically March 24, 2015 07:17PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: printing Taulman bridge nylon - delaminating vertically March 24, 2015 07:45PM |

Registered: 9 years ago Posts: 286 |

Ggherbaz,

1,

Its brand new practically straight out of the bag stored with crystals to take out the moisture.

I didnt think it had time to get wet.

The 2 earlier smaller prints looked fine.

It does crackle a little in the nozxle but no steam but id heard it does crackle a little as there will be some moisture in the skin of the filament no matter what you do.

Also they claim Taulman bridge is better at keeping the moisture out but can get a little in the skin of the filament.

2, speed, goid point. I had it set at 50mm/s as i would for abs. I printed the earlier stuff at 30mm/s. 50 must be too fast.

3, the parts of the print withh infill were fine except the perimeter peeled from the infill. so overextruding isnt neccesary as the infill itself is well packed together.

Wouldnt you just increase the extruder multiplier to do this rather than change the nozzle size value?

Ill give it a go at drying out thefilament more by cutting of a length and drying it in the oven as i need it. Should save the spool that way.

Ill try printing slower as well and give it another go.

Have you got any pics of your succsesful prints and surface finish you could show me?

Im having trouble finding pics of good prints.

Thanks

Gordon

Edited 1 time(s). Last edit at 03/24/2015 07:46PM by gordonendersby.

1,

Its brand new practically straight out of the bag stored with crystals to take out the moisture.

I didnt think it had time to get wet.

The 2 earlier smaller prints looked fine.

It does crackle a little in the nozxle but no steam but id heard it does crackle a little as there will be some moisture in the skin of the filament no matter what you do.

Also they claim Taulman bridge is better at keeping the moisture out but can get a little in the skin of the filament.

2, speed, goid point. I had it set at 50mm/s as i would for abs. I printed the earlier stuff at 30mm/s. 50 must be too fast.

3, the parts of the print withh infill were fine except the perimeter peeled from the infill. so overextruding isnt neccesary as the infill itself is well packed together.

Wouldnt you just increase the extruder multiplier to do this rather than change the nozzle size value?

Ill give it a go at drying out thefilament more by cutting of a length and drying it in the oven as i need it. Should save the spool that way.

Ill try printing slower as well and give it another go.

Have you got any pics of your succsesful prints and surface finish you could show me?

Im having trouble finding pics of good prints.

Thanks

Gordon

Edited 1 time(s). Last edit at 03/24/2015 07:46PM by gordonendersby.

|

Re: printing Taulman bridge nylon - delaminating vertically March 24, 2015 08:06PM |

Registered: 9 years ago Posts: 286 |

Just been looking at what images i have found and my earler slower prints surfaces look pretty similar.

[taulman3d.com]

They also keep stating how much better it is supposed to be at keeping moisture at bay.

Maybe the biggest factor could be the speed and im just going too quick.

Ill have to have another play tomorrow with some test cubes rather than the larger stuff i was trying to print today.

Gordon

[taulman3d.com]

They also keep stating how much better it is supposed to be at keeping moisture at bay.

Maybe the biggest factor could be the speed and im just going too quick.

Ill have to have another play tomorrow with some test cubes rather than the larger stuff i was trying to print today.

Gordon

|

Re: printing Taulman bridge nylon - delaminating vertically March 25, 2015 12:29AM |

Registered: 10 years ago Posts: 1,401 |

Sorry no images, they belong to the customers.

You can increase extrusion multiplier, but with smaller nozzle, the slicer generates more infill lines tight together and that helps a lot. Also nylon tends to bulge up so extruding more will exaggerate that.

If you can hear the popping then its best to dry it some, you will see a huge difference. If the roll is quite new then put the oven as low as it can get and put the spool for at least 30 minutes or until you see the spool starting to deform.

You are right about speed, 50mm/sec is way to fast for nylon, I usually never exceed 20.

One last thing, about the infill to perimeter bonding, you can adjust the overlap to a higher value. I usually print nylon with up to 60% overlap.

One little trick I use (since my spool became useless) since nylon would not entangle itself, you can "carefully" put it inside a big mayo jar and fill it with rice (grind the rice with a blender for few seconds) cut a little hole in the lid, glue a piece of sponge inside and pull the filament through the hole. Tape the piece of filament that its outside of the jar and then tape the union of the jar and lid. Since I did it, I have never had to oven it again.

You can increase extrusion multiplier, but with smaller nozzle, the slicer generates more infill lines tight together and that helps a lot. Also nylon tends to bulge up so extruding more will exaggerate that.

If you can hear the popping then its best to dry it some, you will see a huge difference. If the roll is quite new then put the oven as low as it can get and put the spool for at least 30 minutes or until you see the spool starting to deform.

You are right about speed, 50mm/sec is way to fast for nylon, I usually never exceed 20.

One last thing, about the infill to perimeter bonding, you can adjust the overlap to a higher value. I usually print nylon with up to 60% overlap.

One little trick I use (since my spool became useless) since nylon would not entangle itself, you can "carefully" put it inside a big mayo jar and fill it with rice (grind the rice with a blender for few seconds) cut a little hole in the lid, glue a piece of sponge inside and pull the filament through the hole. Tape the piece of filament that its outside of the jar and then tape the union of the jar and lid. Since I did it, I have never had to oven it again.

|

Re: printing Taulman bridge nylon - delaminating vertically March 25, 2015 05:11AM |

Registered: 9 years ago Posts: 286 |

Thanks for that lot.

Plenty for me to try. Especially the jar trick

Id previously lowered my overlap to 5% for abs as the default 15% was causing patterns in the walls.

Ill try increasing that. Do you find it can effect the surface finish or is the nylon thst much more fluid it doesnt effect them?

Gordon

Plenty for me to try. Especially the jar trick

Id previously lowered my overlap to 5% for abs as the default 15% was causing patterns in the walls.

Ill try increasing that. Do you find it can effect the surface finish or is the nylon thst much more fluid it doesnt effect them?

Gordon

|

Re: printing Taulman bridge nylon - delaminating vertically March 25, 2015 01:59PM |

Registered: 9 years ago Posts: 286 |

Tried drying it at 150 it turned opaque, swollen and bubbled along most of its length after about 1/2 an hour.

Totally unusable.

Luckily i cut of 2 metres so didnt loose the reel.

ggherbaz Are you sure that was Taulman bridge you put in the oven at 150c?

Now trying at lowest setting of the oven for 1/2 an hour.

Gordon

Edited 1 time(s). Last edit at 03/25/2015 02:00PM by gordonendersby.

Totally unusable.

Luckily i cut of 2 metres so didnt loose the reel.

ggherbaz Are you sure that was Taulman bridge you put in the oven at 150c?

Now trying at lowest setting of the oven for 1/2 an hour.

Gordon

Edited 1 time(s). Last edit at 03/25/2015 02:00PM by gordonendersby.

|

Re: printing Taulman bridge nylon - delaminating vertically March 25, 2015 04:49PM |

Registered: 9 years ago Posts: 286 |

I seem to have it printing really well now.

Once id dried the filament for an hour in the oven at a low temp it was totally different to print with.

The brim and first layer went down much more evenly and no popping sound.

So even though it was a new roll it had some moisture in there.

I upped the temp to 245 and retraction to 5mm and it seemed to string a lot less. My nozzle is .5mm it seems to need 1mm for every .1mm for the nozzle.

Speed all the way down to 20mm/s incredibly slow for my printer.

Filament diameter is all over the place ive ended up at an average of 2.7mm with no multiplier.

Relatively thick first layer of 0.3mm

Bed temp is critical on kapton tape any higher than 70 and your taking the tape of with the print.

Any lower and it can lift. Be patient to let the bed cool to remove the print and it cracks off nicely.

Infill percentage effects the stiffness so you can increase the infill to increase thevstiffness quite nicely.

If only it came in red i would replace a lot of my printer parts with this.

Im going to use the jar tip and dry the lot out and feed it to the printer from the jar to keep it dry.

Thanks for the help.

Gordon

Once id dried the filament for an hour in the oven at a low temp it was totally different to print with.

The brim and first layer went down much more evenly and no popping sound.

So even though it was a new roll it had some moisture in there.

I upped the temp to 245 and retraction to 5mm and it seemed to string a lot less. My nozzle is .5mm it seems to need 1mm for every .1mm for the nozzle.

Speed all the way down to 20mm/s incredibly slow for my printer.

Filament diameter is all over the place ive ended up at an average of 2.7mm with no multiplier.

Relatively thick first layer of 0.3mm

Bed temp is critical on kapton tape any higher than 70 and your taking the tape of with the print.

Any lower and it can lift. Be patient to let the bed cool to remove the print and it cracks off nicely.

Infill percentage effects the stiffness so you can increase the infill to increase thevstiffness quite nicely.

If only it came in red i would replace a lot of my printer parts with this.

Im going to use the jar tip and dry the lot out and feed it to the printer from the jar to keep it dry.

Thanks for the help.

Gordon

|

Re: printing Taulman bridge nylon - delaminating vertically March 25, 2015 05:40PM |

Registered: 9 years ago Posts: 286 |

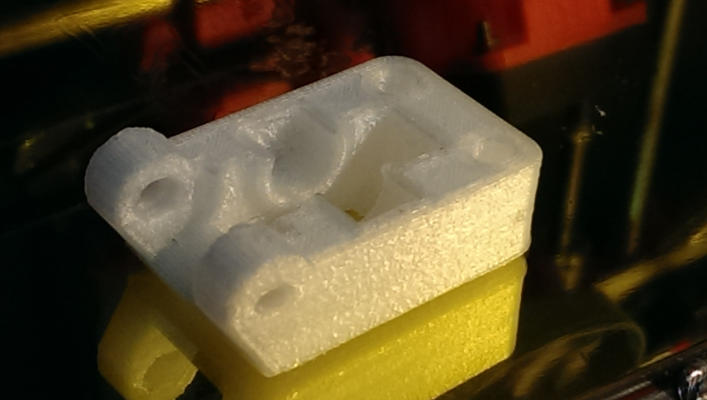

Here we go first useful print.

Wades extruder guide and pinch bearing holder.

Fairly pleased with that.

Gordon

Wades extruder guide and pinch bearing holder.

Fairly pleased with that.

Gordon

|

Re: printing Taulman bridge nylon - delaminating vertically March 25, 2015 05:47PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: printing Taulman bridge nylon - delaminating vertically March 25, 2015 05:52PM |

Registered: 10 years ago Posts: 1,401 |

Sorry, only registered users may post in this forum.