Adhesion problems with larger nozzle size.

Posted by Frans_Printa

|

Adhesion problems with larger nozzle size. May 03, 2015 11:21AM |

Registered: 9 years ago Posts: 7 |

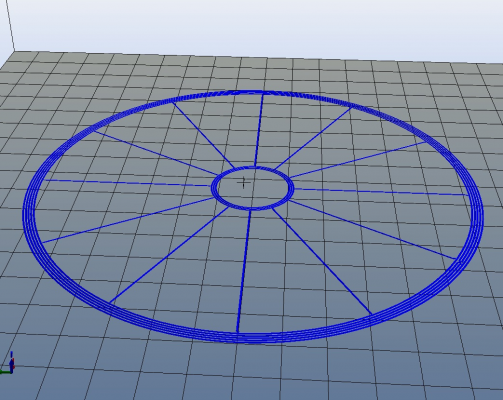

I recently changed my nozzle from size 0.4 to 0.8, to be able to print larger objects in reasonable time. Now I'm having some difficulties to get the layers to stick to the layer below it seems. The gaps as you can see are created when the nozzle leaves the edge and going in or out while printing the thin walls. I'm using a prusa i3, slic3r, 0.4 layer height. Does anyone have any suggestions how to solve this issue? Thanks, Frans.

|

Re: Adhesion problems with larger nozzle size. May 03, 2015 11:58AM |

Registered: 9 years ago Posts: 1,873 |

That's an interesting object. What materiel are you printing with? In the second photo it looks like filament has pulled away from the complete width of the the 3 perimeter inner cylinder. Is it possible that the thin walled radials are cooling more quickly than the thicker inner and outer walls, shrinking and pulling away? If so, you might need a heated chamber to control the cooling more evenly, or to make the radials thicker so that they cool at a similar rate to the cylinders.

|

Re: Adhesion problems with larger nozzle size. May 03, 2015 12:51PM |

Registered: 9 years ago Posts: 7 |

PLA. It seems like on the first 2-3mm after starting to print after a retraction/jump the filament doesn't stick and is dragged a few millimeters. It's hard to explain, but it is only at points where the extruder has retracted and starts to print again i get gaps.

Edited 1 time(s). Last edit at 05/03/2015 01:21PM by Frans_Printa.

Edited 1 time(s). Last edit at 05/03/2015 01:21PM by Frans_Printa.

|

Re: Adhesion problems with larger nozzle size. May 03, 2015 01:44PM |

Registered: 9 years ago Posts: 286 |

Being a much bigger nozzle maybe your extruder cant quite keep up all the time pumping through the filament?

So its retracted but then needs to very quickly extrude again to fill the melt chamber ready to print but not getting quite enough in time?

Gordon

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

So its retracted but then needs to very quickly extrude again to fill the melt chamber ready to print but not getting quite enough in time?

Gordon

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

|

Re: Adhesion problems with larger nozzle size. May 05, 2015 11:31PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: Adhesion problems with larger nozzle size. May 11, 2015 04:36AM |

Registered: 9 years ago Posts: 7 |

|

Re: Adhesion problems with larger nozzle size. May 11, 2015 10:08AM |

Registered: 10 years ago Posts: 1,401 |

Sorry, only registered users may post in this forum.