Mystery Jam

Posted by mrmuffin

|

Mystery Jam September 11, 2015 09:43AM |

Registered: 8 years ago Posts: 41 |

Ever since the beginning of this week I have had nothing but failure from my printer. My printer no longer makes 3d objects, it only makes frustration now. After cleaning out the nozzle calibrating e-steps changing out the fan and messing with slicer for days I'm still right where I started. After about a half hour all of my prints begin to jam for no reason. The heat break is cold where it should be and hot where it should. I am using a E3d V6 with bowden at 1.75mm. I am trying to print black Hatchbox pla at 215c onto painter's tape. My bed is level and the layer height is set at .2mm. I have been at it for days now and i'm at the end of my rope on what to check. Please help me out.

|

Re: Mystery Jam September 11, 2015 10:41AM |

Registered: 8 years ago Posts: 25 |

Are you sure it is a jam or is it just that the extruder stops extruding?

If the former, how does the filament near the cold end of your extruder look like before and after the jam? Is it aligned with the hole into the extruder? Is it bent after jamming?

If it is not a jam and the extruder just stops, is the extruder motor turning after the extruder has stopped extruding? It could just be that after the motor gets hot, half an hour through the print, the small gear gets loose and stops turning while the motor shaft keeps turning normally. This happens often with motors with round shaft and a single grubscrew.

Can you check?

If the former, how does the filament near the cold end of your extruder look like before and after the jam? Is it aligned with the hole into the extruder? Is it bent after jamming?

If it is not a jam and the extruder just stops, is the extruder motor turning after the extruder has stopped extruding? It could just be that after the motor gets hot, half an hour through the print, the small gear gets loose and stops turning while the motor shaft keeps turning normally. This happens often with motors with round shaft and a single grubscrew.

Can you check?

|

Re: Mystery Jam September 11, 2015 08:10PM |

Registered: 8 years ago Posts: 41 |

The extruder gear keeps turning but the filament won't budge it pushes a little then slips back along the gear. I tried to push it manually but even then it was still not moving. I have the stepper potentiometer set fairly high and I have a fan that keeps the ramps board cool. I am currently using the marlin firmware. I have checked and the nozzle is the correct size for the settings I have on Slic3r. The weirdest part is how new this problem is. I used to be able to print just fine a few days ago but now I can't print anything.

|

Re: Mystery Jam September 11, 2015 11:15PM |

Registered: 8 years ago Posts: 778 |

I am assuming you have clone and not the original E3D ?

If so my "fix" for the cheap clone I bought for a test might help you:

The upper hole in the cold end is supposed to seal but with the marks from the extruder it poses more of a break than a seal.

I did not have the right tools to increase the diameter by just 0.1mm without causing damage, so I used glue and wrapped a few turns of fine sand paper around a section of bike spokes.

Using a cordless drill I sanded this bottle neck for quite a while to slightly increase the diameter and round the edges at the same time.

After that I added some fine metal polish to the worn down sand paper and polished the aluminium hole.

Part two is for the heat break and takes more time.

You can use fine steel wool, sand paper or to finnish off even electro polishing to get a smooth surface on the inside.

I noticed that the fine marks from the drilling caused a lot of friction on the filament, especially near the end of a roll and with PLA.

Before the polishing it was to push the filament through the heat break by hand (if it had marks from the extruder) but after it was quite easy.

The final touch is make sure the hole in the cold end is the same diameter as the heat breaks inner diameter, if in doubt sand and polish again - you don't want ANY edge in this area as it either messes with the extrusion or the retraction!

As I had the bowden version but a direct extruder I also made an extension so it fits my extruder and carrier.

Here I noticed another potential problem.

The supplied tube connector was not going all the way, leaving a gap.

I fixed that with my extension but in a bowden system I would add a piece of teflon to match this gap from insde the connector to the cold end inlet.

If so my "fix" for the cheap clone I bought for a test might help you:

The upper hole in the cold end is supposed to seal but with the marks from the extruder it poses more of a break than a seal.

I did not have the right tools to increase the diameter by just 0.1mm without causing damage, so I used glue and wrapped a few turns of fine sand paper around a section of bike spokes.

Using a cordless drill I sanded this bottle neck for quite a while to slightly increase the diameter and round the edges at the same time.

After that I added some fine metal polish to the worn down sand paper and polished the aluminium hole.

Part two is for the heat break and takes more time.

You can use fine steel wool, sand paper or to finnish off even electro polishing to get a smooth surface on the inside.

I noticed that the fine marks from the drilling caused a lot of friction on the filament, especially near the end of a roll and with PLA.

Before the polishing it was to push the filament through the heat break by hand (if it had marks from the extruder) but after it was quite easy.

The final touch is make sure the hole in the cold end is the same diameter as the heat breaks inner diameter, if in doubt sand and polish again - you don't want ANY edge in this area as it either messes with the extrusion or the retraction!

As I had the bowden version but a direct extruder I also made an extension so it fits my extruder and carrier.

Here I noticed another potential problem.

The supplied tube connector was not going all the way, leaving a gap.

I fixed that with my extension but in a bowden system I would add a piece of teflon to match this gap from insde the connector to the cold end inlet.

|

Re: Mystery Jam September 12, 2015 12:45AM |

Registered: 8 years ago Posts: 41 |

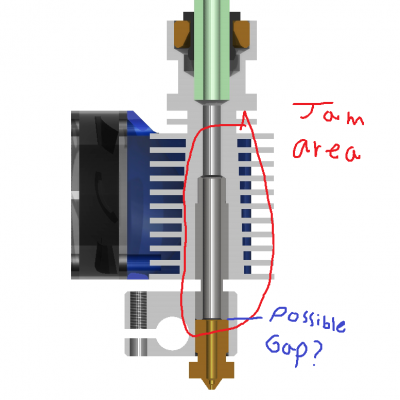

I bought this V6. After messing around with it I can only extrude about 35-40 mm of filament before the extruder jams. I can push it through with my hand but it's not easy nor a long term solution. It always seems to get stuck in the lower part of the heat break, where it meets the heater block. I am wondering if something might be getting in between the ends of the heat break cylinder and the nozzle.

I made an art for you.

I made an art for you.

|

Re: Mystery Jam September 12, 2015 01:13AM |

Registered: 9 years ago Posts: 978 |

Check for wear in the guide holes in the extruder... if these are out of round, then filament can jam in them.

However, there are several forum threads of people who have all-metal E3DV6 hotends who are having problems with jams.

Minimizing retraction seems to be a partial answer.

FWIW, after I switched to a hotend with a PTFE liner in the top of the heat break, the problem went away. You can buy these for next to nothing on AliExpress.

However, there are several forum threads of people who have all-metal E3DV6 hotends who are having problems with jams.

Minimizing retraction seems to be a partial answer.

FWIW, after I switched to a hotend with a PTFE liner in the top of the heat break, the problem went away. You can buy these for next to nothing on AliExpress.

|

Re: Mystery Jam September 12, 2015 07:26AM |

Registered: 8 years ago Posts: 778 |

You identified the problem area good in the pic!

Take the heat break out and check the hole against a light - you will see marks from the drilling or even circles on the surface.

Take a piece of PLA that went through the extruder and has marks on it - it should go through with not to much pressure.

If you have trouble moving it back and forth by hand you have to polish the heat break.

There should be no gap between heat break and nozzle, it there is you will find the the thing oozing.

Where the green ends is the other problem area for the retraction.

Make sure the filament moves freely through the aluminium bit of the cold end . if not sand the top part a bit wider until it does.

If you have a gap between bowden tube and metal of the cold end add a teflon tube on the inside or remove the locking notch inside the bowden connector with a dremel tool so you can push the tube all the way through.

After that your hotend should print almost like the original, at least mine does

Take the heat break out and check the hole against a light - you will see marks from the drilling or even circles on the surface.

Take a piece of PLA that went through the extruder and has marks on it - it should go through with not to much pressure.

If you have trouble moving it back and forth by hand you have to polish the heat break.

There should be no gap between heat break and nozzle, it there is you will find the the thing oozing.

Where the green ends is the other problem area for the retraction.

Make sure the filament moves freely through the aluminium bit of the cold end . if not sand the top part a bit wider until it does.

If you have a gap between bowden tube and metal of the cold end add a teflon tube on the inside or remove the locking notch inside the bowden connector with a dremel tool so you can push the tube all the way through.

After that your hotend should print almost like the original, at least mine does

|

Re: Mystery Jam September 12, 2015 02:01PM |

Registered: 8 years ago Posts: 41 |

Even after it's been through the extruder the filament moves through the aluminum heat tube just fine. Pushing it by hand without the tube attached was a little tough but I don't think the heat break has anything to do with it physically. When I use the lcd controller to move the filament it's fairly smooth but still gets a little stuck. I've applied canola oil to the start of the filament before putting it into the extruder and hotend. Whenever I start a simple print though it can't go 10 seconds without jamming.

Here are my Print settings

.2 Layer height

2 Perimeters , 3 top and bottom layers

1.75mm Filament Diameter, 1.0 Extrusion multiplier

0 retract and lift z

225 first layer, 220 afterwards

25mm/s for perimeters and infill

175mm/s in-between movements

Here are my Print settings

.2 Layer height

2 Perimeters , 3 top and bottom layers

1.75mm Filament Diameter, 1.0 Extrusion multiplier

0 retract and lift z

225 first layer, 220 afterwards

25mm/s for perimeters and infill

175mm/s in-between movements

|

Re: Mystery Jam September 12, 2015 02:45PM |

Registered: 8 years ago Posts: 778 |

|

Re: Mystery Jam September 12, 2015 03:08PM |

Registered: 8 years ago Posts: 41 |

I just stopped a benchy halfway to show you guys what's happening.

Here is how it printed before I began having problems

Here is how the prints come out now. Notice that you can see straight through the print at 15% infill. I admit the printer underextrudes a little bit but the jamming is still there none the less.

Here is how it printed before I began having problems

Here is how the prints come out now. Notice that you can see straight through the print at 15% infill. I admit the printer underextrudes a little bit but the jamming is still there none the less.

|

Re: Mystery Jam September 13, 2015 03:33PM |

Registered: 8 years ago Posts: 41 |

|

Re: Mystery Jam September 15, 2015 09:59PM |

Registered: 8 years ago Posts: 41 |

|

Re: Mystery Jam September 16, 2015 11:28AM |

Registered: 8 years ago Posts: 183 |

Sorry, only registered users may post in this forum.