Printer stops extruding at the end of one model

Posted by dantman

|

Printer stops extruding at the end of one model September 13, 2015 10:28AM |

Registered: 9 years ago Posts: 11 |

I've been having some issues with my extruder while trying to print a model.

Part way through the print my extruder completely stops extruding plastic.

If I stop the print, raise up the axis, and tell the printer to extrude plastic. It often works without any extruder clicking.

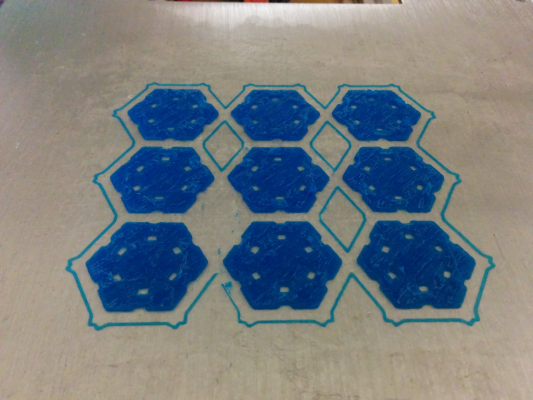

This usually does not happen right away. Typically it happens at the same point, when the printer is trying to finish off the top of the hex pieces for this tie.

I was previously was able to print this part fine. You can see that the top parts of the cylinders are where the extruder stops working.

Even while is has issues finishing off that part, it manages to print other parts 100% fine with no defects (in fact, since I increased the temperature I print at, this print turned out better than most of my other prints)

- Altered the digital pot for my extruder stepper motor in both directions. Downwards from 222 to cool down the stepper (in case it was a thermal issue) and back up after changing extrusion temperature to make sure I wasn’t lacking power

- Increased my temperature from around 195˚C to 215˚C (since MG Chemical’s sheet says to use 210-220˚C) in case the lower temperature was causing a jam when the extruder tried to extrude too fast

- Dismantled my hot end several times

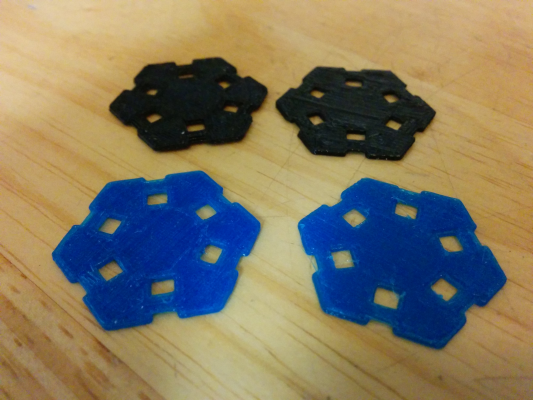

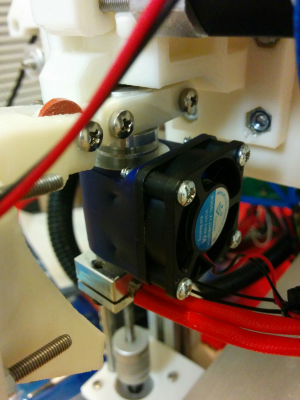

- Cold pulled the nozzle (see the result)

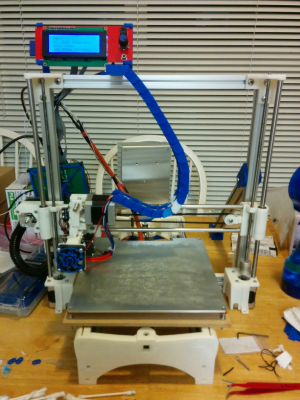

I'm using a modified Wilson TS. With an aluminum heated bed, RAMBo, E3D v6 (directly from e3d online), and a 24V power supply. My fillament is 1.75mm PLA from MG Chemicals.

Part way through the print my extruder completely stops extruding plastic.

- I hear the expected clicking noise from the extruder stepper motor. The stepper jumps backwards instead of grinding the filament.

- And sometimes I hear a sort of creaking noise (from the filament?)

If I stop the print, raise up the axis, and tell the printer to extrude plastic. It often works without any extruder clicking.

This usually does not happen right away. Typically it happens at the same point, when the printer is trying to finish off the top of the hex pieces for this tie.

I was previously was able to print this part fine. You can see that the top parts of the cylinders are where the extruder stops working.

Even while is has issues finishing off that part, it manages to print other parts 100% fine with no defects (in fact, since I increased the temperature I print at, this print turned out better than most of my other prints)

- Altered the digital pot for my extruder stepper motor in both directions. Downwards from 222 to cool down the stepper (in case it was a thermal issue) and back up after changing extrusion temperature to make sure I wasn’t lacking power

- Increased my temperature from around 195˚C to 215˚C (since MG Chemical’s sheet says to use 210-220˚C) in case the lower temperature was causing a jam when the extruder tried to extrude too fast

- Dismantled my hot end several times

- Cold pulled the nozzle (see the result)

I'm using a modified Wilson TS. With an aluminum heated bed, RAMBo, E3D v6 (directly from e3d online), and a 24V power supply. My fillament is 1.75mm PLA from MG Chemicals.

|

Re: Printer stops extruding at the end of one model September 21, 2015 03:43PM |

Registered: 8 years ago Posts: 13 |

Did you heat up your hotend to 210-215 and then tighten the nozzle/heatbreak as per the instructions on the E3D website? All metal hotends all have to be tightened once they heat up to their normal extrusion temperature or else PLA leaks into the threads/out of the threads and it's not always apparent that it's doing this. This in turn causes extra friction and thus more force to be required to extrude. I've experienced this first hand several times. Other symptoms are under extrusion, partially missed layers etc.

On more brittle filaments, I've found that 210-215 is the sweet spot. My speed is 65mm/s for infill and 60mm/s for perimeters. this is for direct drive on a geared extruder I can easily hit 80mm/s on infill. Direct Drive extruders barely have enough power. I'm using a 40mm NEMA17 with A4988 and I have to have the motor current cranked almost all the way to 1A. I have a huge heatsink on the stepper to prevent it from melting the PLA extruder.

On more brittle filaments, I've found that 210-215 is the sweet spot. My speed is 65mm/s for infill and 60mm/s for perimeters. this is for direct drive on a geared extruder I can easily hit 80mm/s on infill. Direct Drive extruders barely have enough power. I'm using a 40mm NEMA17 with A4988 and I have to have the motor current cranked almost all the way to 1A. I have a huge heatsink on the stepper to prevent it from melting the PLA extruder.

|

Re: Printer stops extruding at the end of one model September 22, 2015 04:17AM |

Registered: 9 years ago Posts: 11 |

Yes, I tightened it while hot each time. Except the time I was purging an actual clog and carelessly tried to push some fillament through and had to clean it up.

I tried reducing my printing speed from 40mm/s to 10mm/s and I managed to print one in blue PLA. But I tried black PLA on the same settings today and it failed.

I tried reducing my printing speed from 40mm/s to 10mm/s and I managed to print one in blue PLA. But I tried black PLA on the same settings today and it failed.

|

Re: Printer stops extruding at the end of one model September 22, 2015 08:47AM |

Registered: 8 years ago Posts: 778 |

I modified several chinese E3D clones now and no matter from where they come, they all face similar issues.

Maybe one of them fits your problem:

The stainless steel heat break is just drilled but not polished, also in some cases it is quite tight - I used a cordless drill and fine sandpaper glued on a metal pin to smooth the inside.

The heat break does not form a perfect fit with the top of the cold end, there is a little gap - It can be fixed on a lathe by removing a bit of the thread on the top of the heat sink, I did not bother bout used the method above to make sure the diameters are even and smooth.

The top of cold end has a hole supposed to be slightly larger than the filament diameter - in all my cases this was an extremly tight fit, I drilled the 3.0mm holes to 3.2mm for my 3mm filaments.

The problem of failing to extrude usually comes from the marks of the extruder and the expansion of the filament on the way down.

Especially with retraction there can be a lot of friction.

I noticed that mainly the shavings and dust caused by the extruder tend to accumulate within the hotend wherever there is a gap.

For my this was no real issue until I swapped from Nylon to PLA without a proper cleaning of all.

Wasted about half a meter of filament to flush out the Nylon bits at high temp while poking around in the nozzle.

Also be aware that black PLA can be misused as the dumping ground for all PLA mixes, it is not always easy to find black PLA that is not contaminated.

I had to fight for refunds on 3 different rolls as they constantly clogged up the extruder, one even had, what I think was tissue or wool fibres in it.

Edited 1 time(s). Last edit at 09/22/2015 08:49AM by Downunder35m.

Maybe one of them fits your problem:

The stainless steel heat break is just drilled but not polished, also in some cases it is quite tight - I used a cordless drill and fine sandpaper glued on a metal pin to smooth the inside.

The heat break does not form a perfect fit with the top of the cold end, there is a little gap - It can be fixed on a lathe by removing a bit of the thread on the top of the heat sink, I did not bother bout used the method above to make sure the diameters are even and smooth.

The top of cold end has a hole supposed to be slightly larger than the filament diameter - in all my cases this was an extremly tight fit, I drilled the 3.0mm holes to 3.2mm for my 3mm filaments.

The problem of failing to extrude usually comes from the marks of the extruder and the expansion of the filament on the way down.

Especially with retraction there can be a lot of friction.

I noticed that mainly the shavings and dust caused by the extruder tend to accumulate within the hotend wherever there is a gap.

For my this was no real issue until I swapped from Nylon to PLA without a proper cleaning of all.

Wasted about half a meter of filament to flush out the Nylon bits at high temp while poking around in the nozzle.

Also be aware that black PLA can be misused as the dumping ground for all PLA mixes, it is not always easy to find black PLA that is not contaminated.

I had to fight for refunds on 3 different rolls as they constantly clogged up the extruder, one even had, what I think was tissue or wool fibres in it.

Edited 1 time(s). Last edit at 09/22/2015 08:49AM by Downunder35m.

|

Re: Printer stops extruding at the end of one model September 22, 2015 08:57AM |

Registered: 9 years ago Posts: 11 |

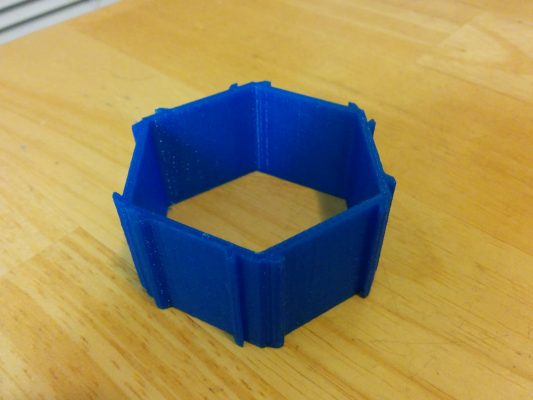

I reduced my retraction distance from the default 4-4.5mm to 1mm and travel speed from 150mm to 50mm. And I managed to get the part to print.

There was a bit of stringing and oozing onto the bed so I bumped it up to 1.5mm and 100mm which reduced that. Though I may need to do some more tweaks.

My hot end is an official E3D-v6 from e3d-online. 1.75mm Universal 24V, and tubing from the bowden kit inside the hot end going from the direct drive extruder exit right down to the heat brake.

So unless E3D is as bad at making their own hot end as the clones are, those probably aren't my issue.

There was a bit of stringing and oozing onto the bed so I bumped it up to 1.5mm and 100mm which reduced that. Though I may need to do some more tweaks.

My hot end is an official E3D-v6 from e3d-online. 1.75mm Universal 24V, and tubing from the bowden kit inside the hot end going from the direct drive extruder exit right down to the heat brake.

So unless E3D is as bad at making their own hot end as the clones are, those probably aren't my issue.

Sorry, only registered users may post in this forum.