Warp Free ABS Printing (Also PETG?)

Posted by xelad

|

Warp Free ABS Printing (Also PETG?) October 05, 2015 06:20AM |

Registered: 8 years ago Posts: 58 |

Hi guys i'm looking for some help/advice/experience.

After finally getting my print set up right with the heated bed etc. I've started trying to print ABS, but no matter what i do i just can't seem to get it warp free. Im using E3D Everyday ABS Filament.

I've tried all kinds of bed temps from 80c - 130c with all kinds of nozzle temperatures from 230c-250c, using UHU Stick, Hairspray, 3M Painters Tape. After trying all kinds of combinations interchanging between all methods i still cant get the prints to not warp, once they get to 40-50mm tall they start lifting. Does ABS simply need a chamber to print well? Could my filament be poo?

I've ordered a spool of PETG to try and see how it compares strength wise, though im not really impressed with the ABS it stills quite brittle.

Thanks

Alex

After finally getting my print set up right with the heated bed etc. I've started trying to print ABS, but no matter what i do i just can't seem to get it warp free. Im using E3D Everyday ABS Filament.

I've tried all kinds of bed temps from 80c - 130c with all kinds of nozzle temperatures from 230c-250c, using UHU Stick, Hairspray, 3M Painters Tape. After trying all kinds of combinations interchanging between all methods i still cant get the prints to not warp, once they get to 40-50mm tall they start lifting. Does ABS simply need a chamber to print well? Could my filament be poo?

I've ordered a spool of PETG to try and see how it compares strength wise, though im not really impressed with the ABS it stills quite brittle.

Thanks

Alex

|

Re: Warp Free ABS Printing (Also PETG?) October 05, 2015 06:48AM |

Registered: 10 years ago Posts: 14,672 |

Yes, to get warp-free ABS prints you need a warm chamber. I found that putting 2 plastic bags over my delta printer was enough to get warp-free 60mm high prints, but obviously a proper temperature-controller chamber is better. The electronics and preferably also the motors should be outside the chamber.

If your ABS is brittle then perhaps the inter-layer adhesion is poor. Check that your hot end cooling fan cools only the hot end heatsink and doesn't blow air anywhere near the nozzle or the print. Also check for backwash from the fan inlet.

I haven't tried PETG yet.

Edited 1 time(s). Last edit at 10/05/2015 06:49AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If your ABS is brittle then perhaps the inter-layer adhesion is poor. Check that your hot end cooling fan cools only the hot end heatsink and doesn't blow air anywhere near the nozzle or the print. Also check for backwash from the fan inlet.

I haven't tried PETG yet.

Edited 1 time(s). Last edit at 10/05/2015 06:49AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Warp Free ABS Printing (Also PETG?) October 05, 2015 09:39AM |

Registered: 8 years ago Posts: 5,232 |

PETG is much less problematic in terms of heated bed, warping, fumes etc. I´m printing Kossel 800 delta corners with PETG on a cold bed ( with brim ) and they are almost unbreakable.

The only drawback with PETG is the stringy and blobby result and the recommended slow print speed. A lot of cleaning and "fuzz shaving " is required. Also I´ve no idea how to treat the surface afterwards like ABS has with Acetone.

-Olaf

Edited 1 time(s). Last edit at 10/05/2015 09:40AM by o_lampe.

The only drawback with PETG is the stringy and blobby result and the recommended slow print speed. A lot of cleaning and "fuzz shaving " is required. Also I´ve no idea how to treat the surface afterwards like ABS has with Acetone.

-Olaf

Edited 1 time(s). Last edit at 10/05/2015 09:40AM by o_lampe.

|

Re: Warp Free ABS Printing (Also PETG?) October 05, 2015 10:44AM |

Registered: 8 years ago Posts: 778 |

If only the lifting is a problem and you don't mind the look try cardboard.

I use it for Nylon but found it also works really well for ABS if primed with a bit of juice.

The presswood that you find on the back of furniture works as well and lasts a bit longer.

I have a dedicated glass plate for the cardboard, a layer of painters tape and than with some good glue the cardboard is put on.

Cerial boxes are great, and if you give the surface a sanding with 80grid even the first print sticks properly - it improves with the prints as surface becomes really rough.

I use it for Nylon but found it also works really well for ABS if primed with a bit of juice.

The presswood that you find on the back of furniture works as well and lasts a bit longer.

I have a dedicated glass plate for the cardboard, a layer of painters tape and than with some good glue the cardboard is put on.

Cerial boxes are great, and if you give the surface a sanding with 80grid even the first print sticks properly - it improves with the prints as surface becomes really rough.

|

Re: Warp Free ABS Printing (Also PETG?) October 05, 2015 02:30PM |

Registered: 8 years ago Posts: 80 |

|

Re: Warp Free ABS Printing (Also PETG?) October 05, 2015 10:38PM |

Registered: 8 years ago Posts: 430 |

|

Re: Warp Free ABS Printing (Also PETG?) October 06, 2015 04:00AM |

Registered: 8 years ago Posts: 58 |

|

Re: Warp Free ABS Printing (Also PETG?) October 06, 2015 06:06AM |

Registered: 10 years ago Posts: 14 |

|

Re: Warp Free ABS Printing (Also PETG?) October 06, 2015 06:58AM |

Registered: 8 years ago Posts: 58 |

|

Re: Warp Free ABS Printing (Also PETG?) October 29, 2015 02:41PM |

Registered: 8 years ago Posts: 310 |

I use this stuff, its cheap and worked really well as advertised, I tried all 3 material they listed and all worked out perfect, 8 euro a pack goes a long way, I used just little under half the pack and I got 40+ prints out of it so far, with the biggest part being 185mm x 185mm x 185mm in size, not exactly a square box but it was that big, start to finish not a single lift

can't find link I bought it from, but same shop relisted it

printing paste

Edited 1 time(s). Last edit at 10/29/2015 02:42PM by deaconfrost.

can't find link I bought it from, but same shop relisted it

printing paste

Edited 1 time(s). Last edit at 10/29/2015 02:42PM by deaconfrost.

|

Re: Warp Free ABS Printing (Also PETG?) October 30, 2015 05:55AM |

Registered: 8 years ago Posts: 778 |

|

Re: Warp Free ABS Printing (Also PETG?) October 30, 2015 08:17AM |

Registered: 11 years ago Posts: 5,780 |

There are two main problems with ABS printing. The first, prints lifting off the print bed, can affect any size part, and is particularly problematic at sharp corners of prints. The second, which usually only affects parts that are a few cm or more in height, is delamination of the layers.

The first problem is solved by 1) having a flat bed, 2) heated to the right temperature- around 100-105C, and 3) the right surface material on the bed. If you're having trouble getting ABS prints to stick to your printer's bed, it is either 1) not flat enough (a very common problem) or 2) it isn't hot enough (another common problem), or 3) you don't have the right surface treatment, or some combination of the three. If you find you're having to put glue, hairspray, abs juice, or other messy stuff on the bed, you probably have deficiencies in one or more of those three areas. Of course, you have to print with the right extruder temperature (230-250C), and it's usually a good idea to print the first layer slowly.

I have found that clean kapton tape applied directly to a 1/4" cast aluminum bed plate supported by a 3 point leveling system and supplied with plenty of heat using PID control of temperature works VERY reliably. I have heard people complain that Kapton tape is too fragile and they have to keep replacing it because it tears easily. I use 5 mil thick tape and it lasts for months of daily printing. I use 2" wide tape so that when it eventually does need replacement, I can replace only the damaged strips. I bought a roll of tape (http://www.amazon.com/Mil-Kapton-Tape-Polyimide-yds/dp/B0076DYH9Y/ref=sr_1_6?ie=UTF8&qid=1446206644&sr=8-6&keywords=5+mil+kapton+lucent+path) more than 2 years ago and I still have plenty left even though my print bed is 12.5" x 12". I have also heard people say that ABS won't stick to clean kapton for them. That is an indication that they have other problems such as inadequate bed heating or flatness, or are trying to print the first layer too fast or at too low a temperature. When I say "clean" I mean kapton tape that has been wiped down with pure acetone, NOT fingernail polish remover which contains things like lanolin or glycerin - i.e. grease- read the label!

The second problem is addressed by enclosing the printer and ensuring that the temperature inside the enclosure gets up to around 45-50C when printing. Just preventing air drafts isn't enough. It has to get warm inside the build chamber. An enclosure can be as simple as a trash bag or cardboard box placed over the printer, but you have to check the temperature to make sure it is working. You can do that by heating up the bed and leaving the extruder off. Use the temperature reading from the extruder to see if the enclosure is getting warm enough. If it isn't warm enough, add insulation or heat.

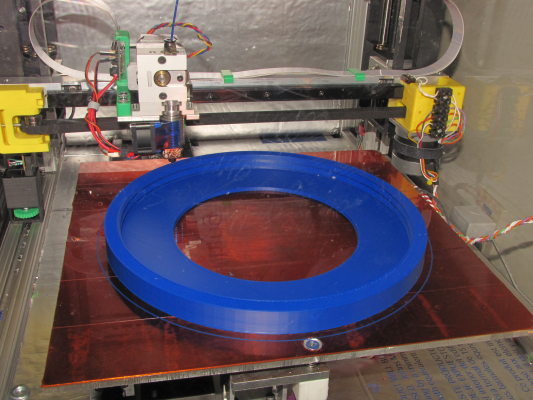

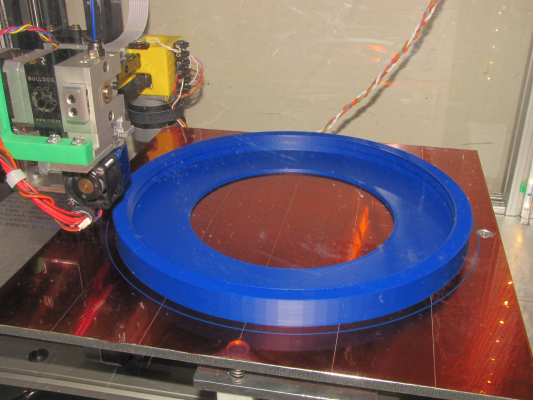

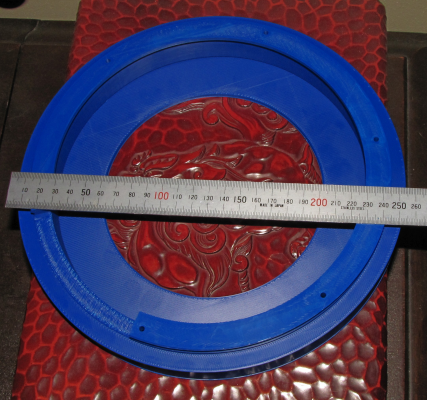

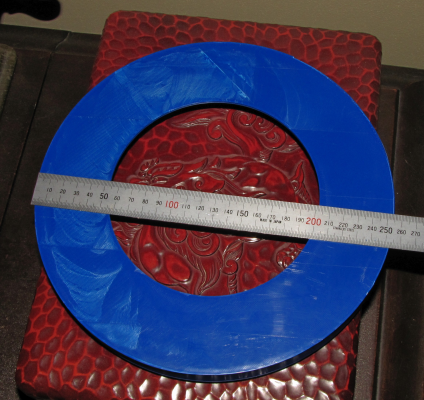

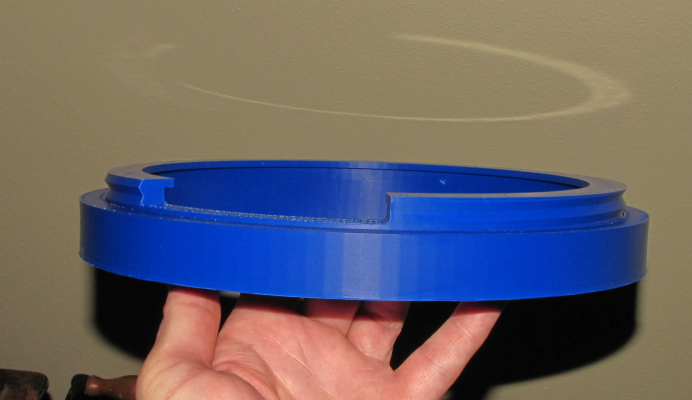

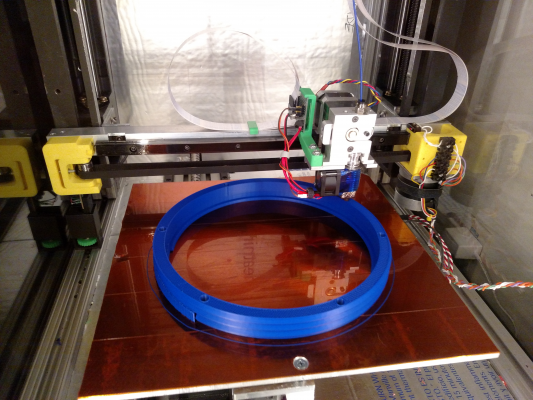

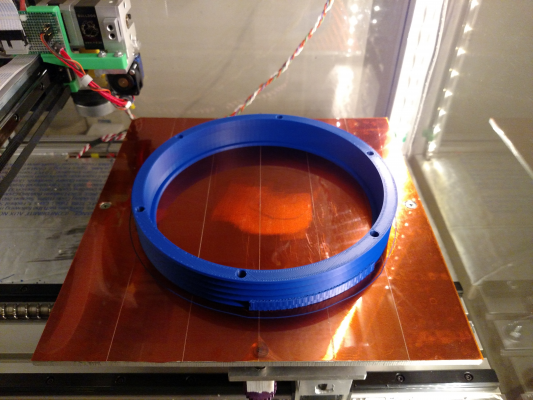

Here are a couple recent prints I made- two threaded parts of an iris assembly that screw together. I made the tolerance between the two a little tight and it takes a little more effort than I would like to screw them together, so I'll probably reprint the outer cover with the X and Y axes scaled up about 0.5mm. The cover piece took some effort to get free of the print bed, so I may use a raft for that part as well.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The first problem is solved by 1) having a flat bed, 2) heated to the right temperature- around 100-105C, and 3) the right surface material on the bed. If you're having trouble getting ABS prints to stick to your printer's bed, it is either 1) not flat enough (a very common problem) or 2) it isn't hot enough (another common problem), or 3) you don't have the right surface treatment, or some combination of the three. If you find you're having to put glue, hairspray, abs juice, or other messy stuff on the bed, you probably have deficiencies in one or more of those three areas. Of course, you have to print with the right extruder temperature (230-250C), and it's usually a good idea to print the first layer slowly.

I have found that clean kapton tape applied directly to a 1/4" cast aluminum bed plate supported by a 3 point leveling system and supplied with plenty of heat using PID control of temperature works VERY reliably. I have heard people complain that Kapton tape is too fragile and they have to keep replacing it because it tears easily. I use 5 mil thick tape and it lasts for months of daily printing. I use 2" wide tape so that when it eventually does need replacement, I can replace only the damaged strips. I bought a roll of tape (http://www.amazon.com/Mil-Kapton-Tape-Polyimide-yds/dp/B0076DYH9Y/ref=sr_1_6?ie=UTF8&qid=1446206644&sr=8-6&keywords=5+mil+kapton+lucent+path) more than 2 years ago and I still have plenty left even though my print bed is 12.5" x 12". I have also heard people say that ABS won't stick to clean kapton for them. That is an indication that they have other problems such as inadequate bed heating or flatness, or are trying to print the first layer too fast or at too low a temperature. When I say "clean" I mean kapton tape that has been wiped down with pure acetone, NOT fingernail polish remover which contains things like lanolin or glycerin - i.e. grease- read the label!

The second problem is addressed by enclosing the printer and ensuring that the temperature inside the enclosure gets up to around 45-50C when printing. Just preventing air drafts isn't enough. It has to get warm inside the build chamber. An enclosure can be as simple as a trash bag or cardboard box placed over the printer, but you have to check the temperature to make sure it is working. You can do that by heating up the bed and leaving the extruder off. Use the temperature reading from the extruder to see if the enclosure is getting warm enough. If it isn't warm enough, add insulation or heat.

Here are a couple recent prints I made- two threaded parts of an iris assembly that screw together. I made the tolerance between the two a little tight and it takes a little more effort than I would like to screw them together, so I'll probably reprint the outer cover with the X and Y axes scaled up about 0.5mm. The cover piece took some effort to get free of the print bed, so I may use a raft for that part as well.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Warp Free ABS Printing (Also PETG?) October 30, 2015 04:58PM |

Registered: 8 years ago Posts: 310 |

I don't really know what type of glue they maybe, but worked well for me than the glue I have tried, especially with abs, first time i printed big object with abs without lift is when I tried that stuff, its cheap and I though I give it a go since I was getting something from that seller anyway.

Sorry, only registered users may post in this forum.