Edges of recengular shapes are OK, but circles are disaster

Posted by usen

|

Re: Edges of recengular shapes are OK, but circles are disaster November 29, 2015 04:02PM |

Registered: 9 years ago Posts: 245 |

Are you sure the Z-axis runs as it should? By the even displacements it looks as if the axis/bed is being forced askew and then snaps back. Probably every full revolution of your ball screw. Like every 8th or 10th mm or something like it?Quote

usen

Quote

Downunder35m

You have to measure what comes out of the extruder and adjust the stepping accordingly.

Works best with the cold extrusion prevent disabled in the firmware as you can play back and forth without the hotend and wasting filament.

Mark the filament and extrude 10mm - measure it.

It is not 10mm +-0.3mm already adjust the stepping a bit.

Extrude 30mm and check again.

If required adjust stepping.

Extrude 50mm and check.

Adjust stepping, check again, adjust stepping until you are spot on.

I arranged extruder by changing M97. Extruder extrudes exactly what I want. I printed a new calibration cube and results are below. There are leaps when it fills inner and wall, as you see. And corners are not good, not parallel or smooth.

The filament gaps: make sure the extruded bit is not making excessive marks. Try raising temperature. Looks like missed steps to me.

Edit: spelling

Edited 1 time(s). Last edit at 11/29/2015 04:04PM by dintid.

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

|

Re: Edges of recengular shapes are OK, but circles are disaster November 30, 2015 06:15AM |

Registered: 8 years ago Posts: 38 |

Quote

Paul Wanamaker

I think your primary issue is with extrusion, there are multiple indicators:

- Gaps in printing

- That diagonal pattern that you see, with blobbing. I believe this is caused by a slight temporary underextrusion on the previous layer, and when the next layer goes over that spot it doesn't quite have enough foundation to stick to, and so a blob forms that eventually sticks a short distance later. Then on the next layer the blob sticks to the beginning of the lower blob, and so it builds up at an angle.

- Don't trust that your hot-end thermistor is exactly right. Try slightly higher and lower temps to see what that particular filament needs to flow correctly.

- As stated this could also be caused by some blockage - pull the filament out while the hot end is cooling and it could remove it.

- Watch the extruder temp while it's printing - is it consistently at the right temp? If not you may need to do a PID calibration.

- Watch the heatbed temp as well.

- Make sure the filament drive gear is not getting clogged.

- You can also experiment with a slightly wider or narrower extrusion width to see what your extruder likes, or a slightly taller layer height.

[Edit - more]

- Make sure the extruder is clamping the filament securely enough

- Put marks on the extruder stepper shaft and whatever it's connected to -to make sure it's not slipping (flat ground on shaft)?

- As stated previously - watch it the extruder gear carefully to see if it is slipping back. I think it's a temp issue tho.

There is a very evident repeating wave pattern in the perimeter.

- You can measure the distance. Is this distance related to the ball screw's pitch?

Dear Paul,

Firstly, thank you for your answer. I try to answer in terms of your list:

- Don't trust that your hot-end thermistor is exactly right. Try slightly higher and lower temps to see what that particular filament needs to flow correctly.

->> I realized that my hot-end thermistor measured wrong temperature. I changed the thermistor and covered with capton tape. I see 208 centigrade degree in the webinterface (GUI), but I measure about 230 centigrade degree with multimeter. Previous printing parts in this page are printed 245 centigrade degree in GUI, but I printed 277 centigrade degree. I realized 2 days ago.

- As stated this could also be caused by some blockage - pull the filament out while the hot end is cooling and it could remove it.

->> Yes, you are right. Most probably, wrong hot-end temperature causes gaps or wrong printing.

- Watch the extruder temp while it's printing - is it consistently at the right temp? If not you may need to do a PID calibration.

->> Most of the time, I see constant temperature in the GUI. However, I will check with multimeter or other equipment.

- Watch the heatbed temp as well.

->> My heatbed warms up slowly. In 15 min. temperature reaches 60 centigrade degree and constantly goes on.

- Make sure the filament drive gear is not getting clogged.

- You can also experiment with a slightly wider or narrower extrusion width to see what your extruder likes, or a slightly taller layer height.

[Edit - more]

- Make sure the extruder is clamping the filament securely enough

- Put marks on the extruder stepper shaft and whatever it's connected to -to make sure it's not slipping (flat ground on shaft)?

->> The second thing I realized that filament drive gear (Makerbot Drive Gear) couldn't push the filament exactly. Lately, step motor starts to slip steps. I will change extruder mould or holder system. What do you thing about this design: Bernis Simple Extruder?

- As stated previously - watch it the extruder gear carefully to see if it is slipping back. I think it's a temp issue tho.

->> I will check this after changing extruder holder system.

Edited 1 time(s). Last edit at 11/30/2015 06:24AM by usen.

|

Re: Edges of recengular shapes are OK, but circles are disaster November 30, 2015 08:08AM |

Registered: 10 years ago Posts: 14,672 |

Quote

usen

->> I realized that my hot-end thermistor measured wrong temperature. I changed the thermistor and covered with capton tape. I see 208 centigrade degree in the webinterface (GUI), but I measure about 230 centigrade degree with multimeter. Previous printing parts in this page are printed 245 centigrade degree in GUI, but I printed 277 centigrade degree. I realized 2 days ago.

Sounds like you have the wrong B value in your M305 P1 command in config.g. What thermistor are you using, and what B value?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Edges of recengular shapes are OK, but circles are disaster November 30, 2015 10:52AM |

Registered: 8 years ago Posts: 38 |

Quote

dc42

Quote

usen

->> I realized that my hot-end thermistor measured wrong temperature. I changed the thermistor and covered with capton tape. I see 208 centigrade degree in the webinterface (GUI), but I measure about 230 centigrade degree with multimeter. Previous printing parts in this page are printed 245 centigrade degree in GUI, but I printed 277 centigrade degree. I realized 2 days ago.

Sounds like you have the wrong B value in your M305 P1 command in config.g. What thermistor are you using, and what B value?

M305 P1 T100000 R4700 B3950

|

Re: Edges of recengular shapes are OK, but circles are disaster November 30, 2015 11:03AM |

Registered: 10 years ago Posts: 580 |

Quote

What do you thing about this design: Bernis Simple Extruder?

I'm not thrilled with it, because the spring tension needs to be adjustable.

The following are my criteria for a reliable extruder:

- Adjustable spring tension that can be set high.

- A contoured drive gear with teeth that are not too sharp. A sharp drive gear will chew up the filament and clog with swarf from regular use and retractions - not acceptable.

- A tension bearing that is grooved so it can apply greater force without crushing a flat spot like this one

- A motor that is powerful enough.

I had a lot of extruder problems at the start.

For my custom direct drive extruder I used powerful a 0.9 degree NEMA23 from Phidgets that I run at 2A (with a quiet fan), with a Mark7 gear that did not have sharp teeth (I ordered from 2 places to be sure) and bored it out on a lathe for the Nema23 shaft diameter. It never clogs or even creates swarf, and never slips.

Hope that helps.

|

Re: Edges of recengular shapes are OK, but circles are disaster November 30, 2015 11:21AM |

Registered: 10 years ago Posts: 14,672 |

Quote

usen

Quote

dc42

Quote

usen

->> I realized that my hot-end thermistor measured wrong temperature. I changed the thermistor and covered with capton tape. I see 208 centigrade degree in the webinterface (GUI), but I measure about 230 centigrade degree with multimeter. Previous printing parts in this page are printed 245 centigrade degree in GUI, but I printed 277 centigrade degree. I realized 2 days ago.

Sounds like you have the wrong B value in your M305 P1 command in config.g. What thermistor are you using, and what B value?

M305 P1 T100000 R4700 B3950

And what thermistor are you using? Are you sure it has a B value of 3950? For example, the thermistor used by E3D in their hot ends has a quoted B value of 4267, although 4388 is more accurate at typical hot end temperatures. Using too low a B value will make the firmware report values that are lower than actual.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Edges of recengular shapes are OK, but circles are disaster November 30, 2015 11:45AM |

Registered: 8 years ago Posts: 38 |

Quote

dc42

Quote

usen

Quote

dc42

Quote

usen

->> I realized that my hot-end thermistor measured wrong temperature. I changed the thermistor and covered with capton tape. I see 208 centigrade degree in the webinterface (GUI), but I measure about 230 centigrade degree with multimeter. Previous printing parts in this page are printed 245 centigrade degree in GUI, but I printed 277 centigrade degree. I realized 2 days ago.

Sounds like you have the wrong B value in your M305 P1 command in config.g. What thermistor are you using, and what B value?

M305 P1 T100000 R4700 B3950

And what thermistor are you using? Are you sure it has a B value of 3950? For example, the thermistor used by E3D in their hot ends has a quoted B value of 4267, although 4388 is more accurate at typical hot end temperatures. Using too low a B value will make the firmware report values that are lower than actual.

I use MF58 100k NTC model thermistor.

|

Re: Edges of recengular shapes are OK, but circles are disaster November 30, 2015 12:18PM |

Registered: 10 years ago Posts: 14,672 |

Max operating temperature of the MF58 is quoted as 200C, so it isn't really suitable. Also the temperature data table stops at 110C. If you want one in a similar package, I suggest this [www.digikey.co.uk].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Edges of recengular shapes are OK, but circles are disaster December 01, 2015 09:24AM |

Registered: 8 years ago Posts: 38 |

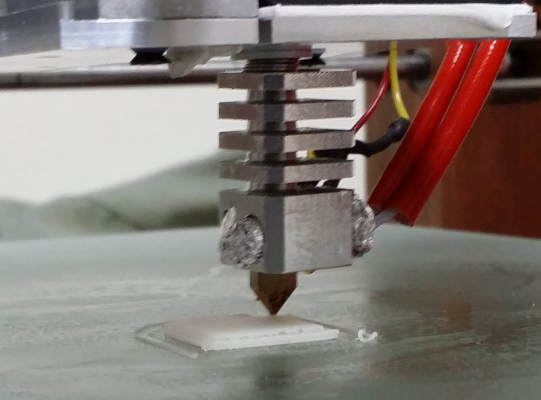

My layer and infill problem still continues.

I changed extruder holder system and hot-end temperature (I measure nozzle 220 centigrade degree and fin 245 centigrade degree from multimeter):

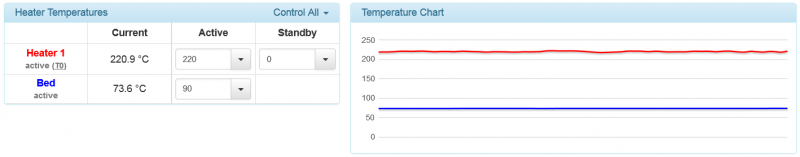

The picture from Duet Webinterface. Heater 1 (Hot-end temp.) is not continuous as you can see.

----------------------------------------------------------------------------------------------------------------------------------------

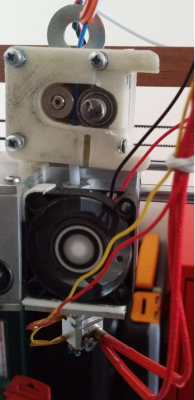

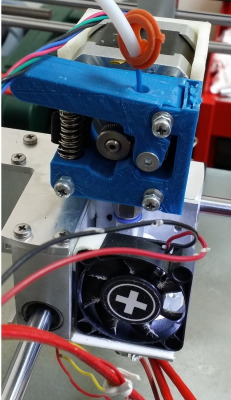

My extruder system was below:

----------------------------------------------------------------------------------------------------------------------------------------

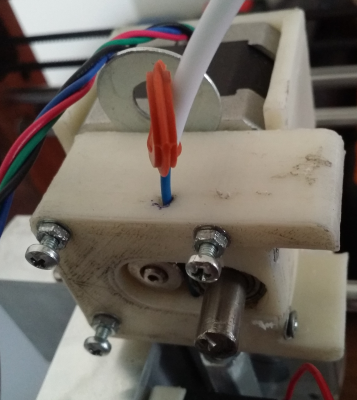

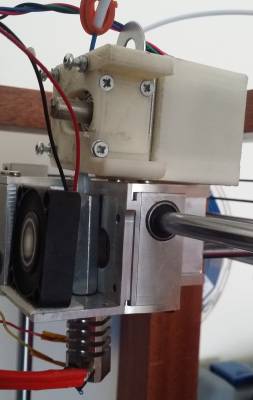

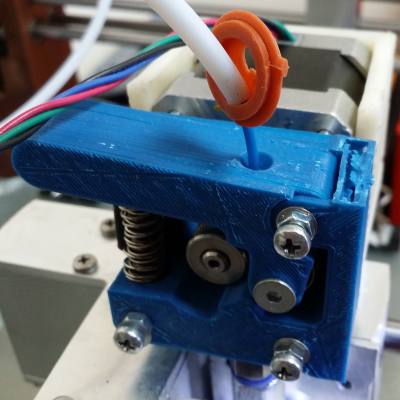

Then I changed extruder filament drive gear system:

----------------------------------------------------------------------------------------------------------------------------------------

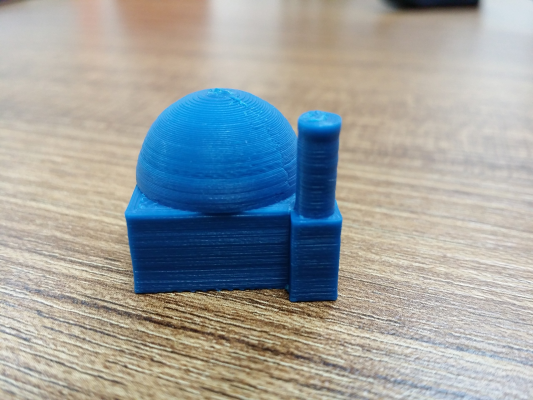

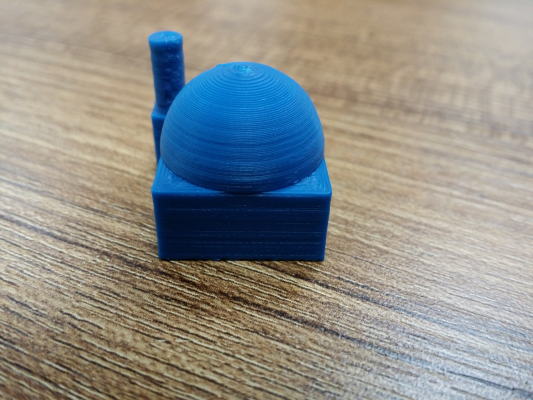

I printed a calibration part that has g-code created from Slic3r to see shape that has different size and shape:

----------------------------------------------------------------------------------------------------------------------------------------

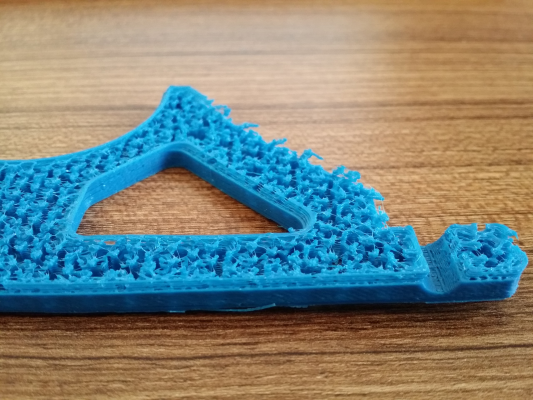

I printed a part that has g-code created from Cura (Left) (Rectangular Infill) and Slic3r -I stopped printing when I saw layers infill- (Right) (Honeycump Infill):

Part size is 194.6 x 66.0 x 10.0 mm.

Edited 2 time(s). Last edit at 12/01/2015 09:50AM by usen.

I changed extruder holder system and hot-end temperature (I measure nozzle 220 centigrade degree and fin 245 centigrade degree from multimeter):

The picture from Duet Webinterface. Heater 1 (Hot-end temp.) is not continuous as you can see.

----------------------------------------------------------------------------------------------------------------------------------------

My extruder system was below:

----------------------------------------------------------------------------------------------------------------------------------------

Then I changed extruder filament drive gear system:

----------------------------------------------------------------------------------------------------------------------------------------

I printed a calibration part that has g-code created from Slic3r to see shape that has different size and shape:

----------------------------------------------------------------------------------------------------------------------------------------

I printed a part that has g-code created from Cura (Left) (Rectangular Infill) and Slic3r -I stopped printing when I saw layers infill- (Right) (Honeycump Infill):

Part size is 194.6 x 66.0 x 10.0 mm.

Edited 2 time(s). Last edit at 12/01/2015 09:50AM by usen.

|

Re: Edges of recengular shapes are OK, but circles are disaster December 01, 2015 09:37AM |

Registered: 8 years ago Posts: 778 |

|

Re: Edges of recengular shapes are OK, but circles are disaster December 01, 2015 11:06AM |

Registered: 10 years ago Posts: 14,672 |

What hot end is that? I don't recognise it. Shouldn't there be cool air blowing over the fins?

The varying temperature could mean that extrusion is jerky, which would also explain your print quality issues.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The varying temperature could mean that extrusion is jerky, which would also explain your print quality issues.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Edges of recengular shapes are OK, but circles are disaster December 01, 2015 11:34AM |

Registered: 8 years ago Posts: 38 |

Quote

dc42

What hot end is that? I don't recognise it. Shouldn't there be cool air blowing over the fins?

The varying temperature could mean that extrusion is jerky, which would also explain your print quality issues.

I don't understand what you can say. Design of the fins are incorrect or position of them are incorrect? If you were in my place, what did you do? I want to solve printing problem, because I try to fix this for weeks

|

Re: Edges of recengular shapes are OK, but circles are disaster December 01, 2015 11:56AM |

Registered: 8 years ago Posts: 38 |

Quote

Downunder35m

Ususally you get infills like that if a rectangular infill pattern is selected and he infill speed is far too high.

This causes the filament to only bind to the cross sections without forming a bridge between them.

Either reduce the infill speed and / or try a lower layer height.

What is your infill speed?

Which program do you use? Could you please give settings of the program to me? I want to test and calibrate settings for my printer.

|

Re: Edges of recengular shapes are OK, but circles are disaster December 01, 2015 07:23PM |

Registered: 8 years ago Posts: 778 |

Depending on the material and part I print the solid infill speed is between 20 and 60mm/s, normal infill again depending on the material between 30 and 100mm/s.

Giving you my settings would not help as your machine is different

Only a proper calibration with some test to check the max possible speeds will help you.

Giving you my settings would not help as your machine is different

Only a proper calibration with some test to check the max possible speeds will help you.

|

Re: Edges of recengular shapes are OK, but circles are disaster December 02, 2015 04:19AM |

Registered: 8 years ago Posts: 38 |

Quote

Downunder35m

Depending on the material and part I print the solid infill speed is between 20 and 60mm/s, normal infill again depending on the material between 30 and 100mm/s.

Giving you my settings would not help as your machine is different

Only a proper calibration with some test to check the max possible speeds will help you.

What is the difference between solid and normal infill?

|

Re: Edges of recengular shapes are OK, but circles are disaster December 02, 2015 04:34AM |

Registered: 8 years ago Posts: 778 |

|

Re: Edges of recengular shapes are OK, but circles are disaster December 16, 2015 05:26AM |

Registered: 8 years ago Posts: 38 |

Hi everyone,

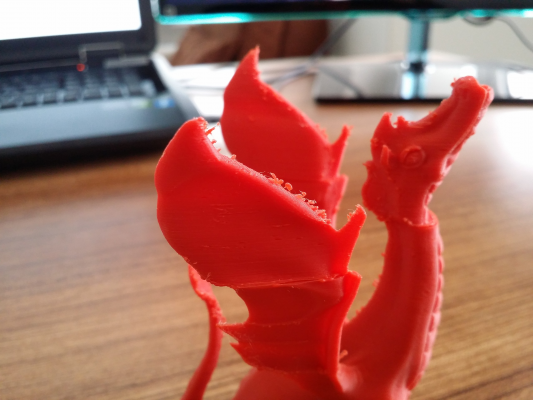

I fixed extruder and results are below:

- Part: [www.thingiverse.com]

- Programme: Cura 15.04.3

- Scale: 0.75

- Room Temperature: 15 °C (but, I covered the machine with cloth)

- Heated Bed: 85 °C.

- No support.

- Cura says 9.5 hours, but I printed 17 hours!!! This is my serious another problem

The other features in picture:

Test results:

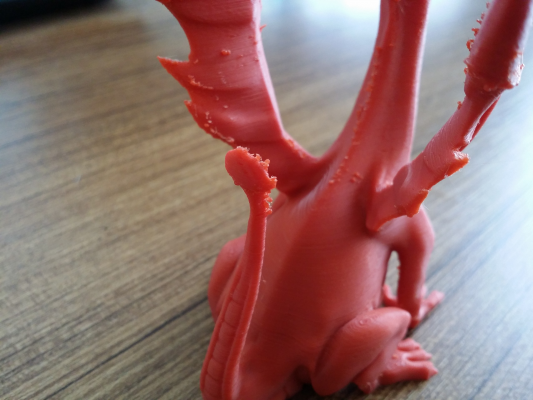

Surface quality is better in terms of last tests, but there is shifted layers in neck of the dragon. I printed Darth Vader (http://www.thingiverse.com/thing:1169476/) 2 days ago and Darth is longer than dragon I printed. There was no shifted layers in same height. The other problems are residual parts in perimeters you can see and navel of the dragon was printed bad, I don't understand. Does this happen arise from angle?

I fixed extruder and results are below:

- Part: [www.thingiverse.com]

- Programme: Cura 15.04.3

- Scale: 0.75

- Room Temperature: 15 °C (but, I covered the machine with cloth)

- Heated Bed: 85 °C.

- No support.

- Cura says 9.5 hours, but I printed 17 hours!!! This is my serious another problem

The other features in picture:

Test results:

Surface quality is better in terms of last tests, but there is shifted layers in neck of the dragon. I printed Darth Vader (http://www.thingiverse.com/thing:1169476/) 2 days ago and Darth is longer than dragon I printed. There was no shifted layers in same height. The other problems are residual parts in perimeters you can see and navel of the dragon was printed bad, I don't understand. Does this happen arise from angle?

|

Re: Edges of recengular shapes are OK, but circles are disaster December 26, 2015 01:50PM |

Registered: 10 years ago Posts: 580 |

usen,

I've just written a troubleshooting guide for Shifted Layers / Offset Layers / Missed Steps. I'm trying to contact an admin to get that page in the Troubleshooting index.

I'm not sure about the other problem, showing on the dragon's stomach. Are you printing at a very low layer height? You may want to start a new topic under Printing.

Hope that helps.

I've just written a troubleshooting guide for Shifted Layers / Offset Layers / Missed Steps. I'm trying to contact an admin to get that page in the Troubleshooting index.

I'm not sure about the other problem, showing on the dragon's stomach. Are you printing at a very low layer height? You may want to start a new topic under Printing.

Hope that helps.

Sorry, only registered users may post in this forum.