Aldi craft glue...

Posted by Downunder35m

|

Aldi craft glue... November 05, 2015 07:14AM |

Registered: 8 years ago Posts: 778 |

Aldi, here in AU has craft glue for under 2$ a bottle on sale.

I thought at that price I really can't do much wrong by trying it for a bed adhesive.

Using a cold bed as usual I tried PLA and ABS with success.

Applied with a scraper as a thin layer the glue offer really good adhesion while it is still quite possible to get the part off the glass.

There are no useful infos on the product itself, other than it comes from China and contains Methanol.

Have to try some Nylon on the weekend but doubt it will stick - but you never know

I thought at that price I really can't do much wrong by trying it for a bed adhesive.

Using a cold bed as usual I tried PLA and ABS with success.

Applied with a scraper as a thin layer the glue offer really good adhesion while it is still quite possible to get the part off the glass.

There are no useful infos on the product itself, other than it comes from China and contains Methanol.

Have to try some Nylon on the weekend but doubt it will stick - but you never know

|

Re: Aldi craft glue... November 17, 2015 05:21AM |

Registered: 8 years ago Posts: 778 |

Well, so far I tried PLA, ABS and Nylon.

The first tow stick really well and PLA often needs a slight knock to come off.

Nylon still tries to curl up and it takes the glue with it.

With a layer of plastic primer before applying the glue this probem was fixed too.

Still Nylon needs a brim to prevent curling up.

For a cold bed these results are really satisfying as I no longer have the need to prepare different glass sheets or do a lot of cleanup.

As the glue is diluted with methanol I simply use normal alcohol to wipe the surface clean, or to evenly spread the glue with a cotton pad.

Now I only need to figure out how to get the same surface finnish on all sides of a print LOL

The first tow stick really well and PLA often needs a slight knock to come off.

Nylon still tries to curl up and it takes the glue with it.

With a layer of plastic primer before applying the glue this probem was fixed too.

Still Nylon needs a brim to prevent curling up.

For a cold bed these results are really satisfying as I no longer have the need to prepare different glass sheets or do a lot of cleanup.

As the glue is diluted with methanol I simply use normal alcohol to wipe the surface clean, or to evenly spread the glue with a cotton pad.

Now I only need to figure out how to get the same surface finnish on all sides of a print LOL

|

Re: Aldi craft glue... November 18, 2015 07:49AM |

Registered: 8 years ago Posts: 778 |

|

Re: Aldi craft glue... November 18, 2015 01:11PM |

Registered: 9 years ago Posts: 752 |

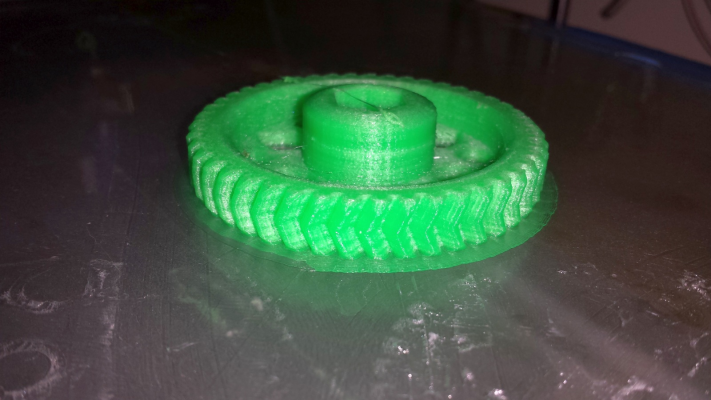

Thanks for sharing! I use Bruynzeel glue and Nylon sticks really well. PLA and ABS not so much, so I continue to use vinyl. I'm also testing acrylic varnish (Crea Patch Pearl, Cre-Ation, from shop 'Action') for ABS, which seems to work well so far. It both sticks well to glass and ABS, but is still relatively easy to remove, without breaking the glass. The Bruynzeel glue (probably PVA glue, diluted) undiluted sticks so well with Nylon I've broken a few glass panes trying to remove the herringbone gear I was printing. There are pieces of glass still on the gear that I can't remove  When the glue is diluted with water it still sticks well and I can remove it without breaking the glass. With larger prints it still warps a bit, so if I really need a solid print I'll sacrifice a glass pane and use undiluted glue on it. Soaking it in hot water doesn't seem to help much.

When the glue is diluted with water it still sticks well and I can remove it without breaking the glass. With larger prints it still warps a bit, so if I really need a solid print I'll sacrifice a glass pane and use undiluted glue on it. Soaking it in hot water doesn't seem to help much.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

When the glue is diluted with water it still sticks well and I can remove it without breaking the glass. With larger prints it still warps a bit, so if I really need a solid print I'll sacrifice a glass pane and use undiluted glue on it. Soaking it in hot water doesn't seem to help much.

When the glue is diluted with water it still sticks well and I can remove it without breaking the glass. With larger prints it still warps a bit, so if I really need a solid print I'll sacrifice a glass pane and use undiluted glue on it. Soaking it in hot water doesn't seem to help much.--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Aldi craft glue... November 18, 2015 06:56PM |

Registered: 8 years ago Posts: 778 |

We are getting more products for nylon prints, nice

I had similar problems with some "solutions", either they did not stick at all or so good that you needed special tools to get the print back.

Never heard of Bruynzeel glue - does it say on the pack it has methanol in it and when dry forms like a thin plastic film?

Could be similar to what Aldi used.

Just for fun I am now trying to get some material with different surface structures to see how it looks on the print.

The glue pulls off the glass quite good and gives a nice shiny finnish, just have to figure out how to make the glue stick not so well on other materials LOL

I got really nice results for all materials with a mix of 1 teaspoon of sugar, 2 tablespoons of lemon juice and 10gr of gum arabic per 100ml of water for all materials.

The sugar binds nicely at higher temps, the lemon juice makes it stick to the glass and the gum arabic gives that little bit of extra for those materials that won't stick anywhere.

But the stuff is too expensive in the long run.

I had similar problems with some "solutions", either they did not stick at all or so good that you needed special tools to get the print back.

Never heard of Bruynzeel glue - does it say on the pack it has methanol in it and when dry forms like a thin plastic film?

Could be similar to what Aldi used.

Just for fun I am now trying to get some material with different surface structures to see how it looks on the print.

The glue pulls off the glass quite good and gives a nice shiny finnish, just have to figure out how to make the glue stick not so well on other materials LOL

I got really nice results for all materials with a mix of 1 teaspoon of sugar, 2 tablespoons of lemon juice and 10gr of gum arabic per 100ml of water for all materials.

The sugar binds nicely at higher temps, the lemon juice makes it stick to the glass and the gum arabic gives that little bit of extra for those materials that won't stick anywhere.

But the stuff is too expensive in the long run.

|

Re: Aldi craft glue... November 22, 2015 02:51AM |

Registered: 8 years ago Posts: 778 |

Currently printing the V2 o this thing in green trimmer line.

Once the print is completed I will upload some pics.

So far about 2/3 of the entire drinking thing is printed and no lifting or curling at all.

How I did get the nylon to stick properly on the cold glass bed:

Applied a thin layer of craft glue, 15 min to let it dry completely.

Wipe with an alcohol soaked make up pad, this only leaves a very thin layer of glue but ensures the glass is really clean and covered at the same time.

After about 5 minutes I apply the secong layer, two lines of glue over the bed (my bed is quite big) and spread with a knife blade.

Now I give it 20 minutes to fully dry and start the print.

But the real magic with nylon here was to reduce the print speed of the first layer down to just 25mm/s and with 0.1mm layer height, 0.2mm for the remaining layers.

The nylon otherwise cooles down on contact too quick and the bonding to the glue and the second layer is very weak.

As this print takes a while to finnish the first layer I manually slowed down the second layer by 30% as well to ensure proper bonding to the first layer.

After that at full speed with currently 60mm/s, solid infill and perimeters 20% slower.

Still need to tweak the retraction a bit to get rid of the small blobs but otherwise I am quite happy.

Once the print is completed I will upload some pics.

So far about 2/3 of the entire drinking thing is printed and no lifting or curling at all.

How I did get the nylon to stick properly on the cold glass bed:

Applied a thin layer of craft glue, 15 min to let it dry completely.

Wipe with an alcohol soaked make up pad, this only leaves a very thin layer of glue but ensures the glass is really clean and covered at the same time.

After about 5 minutes I apply the secong layer, two lines of glue over the bed (my bed is quite big) and spread with a knife blade.

Now I give it 20 minutes to fully dry and start the print.

But the real magic with nylon here was to reduce the print speed of the first layer down to just 25mm/s and with 0.1mm layer height, 0.2mm for the remaining layers.

The nylon otherwise cooles down on contact too quick and the bonding to the glue and the second layer is very weak.

As this print takes a while to finnish the first layer I manually slowed down the second layer by 30% as well to ensure proper bonding to the first layer.

After that at full speed with currently 60mm/s, solid infill and perimeters 20% slower.

Still need to tweak the retraction a bit to get rid of the small blobs but otherwise I am quite happy.

Sorry, only registered users may post in this forum.