Print improvement

Posted by rich1812

|

Print improvement December 15, 2015 10:15AM |

Registered: 9 years ago Posts: 133 |

Hello, I have been 3D print for some time now. By no mean I am an expert. I have just printed this object (in pics) I have never printed something this big and odd in shape, it took a wooly 10 hours!!!! And I wasn't sure it will come out ok, as a result, it didn't come out too badly but messy, tho need a lot of cleaning tho!

I am seeking for advice in how to shorten the print time without reduce the rigidity and how to reduce the messiness and any suggestion on how to make it better in general. Thank you vin advance

Edited 1 time(s). Last edit at 12/15/2015 10:41AM by rich1812.

I am seeking for advice in how to shorten the print time without reduce the rigidity and how to reduce the messiness and any suggestion on how to make it better in general. Thank you vin advance

Edited 1 time(s). Last edit at 12/15/2015 10:41AM by rich1812.

|

Re: Print improvement December 15, 2015 02:53PM |

Registered: 8 years ago Posts: 778 |

Well, if there is one thing working then it would be bridging LOL

The surface looks quite rough, might be too high in temp.

And the strings are a result of the retraction not being set properly.

With the settings correctly the part should come out clean and with little to no need of cleaning up.

The surface looks quite rough, might be too high in temp.

And the strings are a result of the retraction not being set properly.

With the settings correctly the part should come out clean and with little to no need of cleaning up.

|

Re: Print improvement December 16, 2015 07:47AM |

Registered: 9 years ago Posts: 133 |

Quote

Downunder35m

Well, if there is one thing working then it would be bridging LOL

The surface looks quite rough, might be too high in temp.

And the strings are a result of the retraction not being set properly.

With the settings correctly the part should come out clean and with little to no need of cleaning up.

Thank you for the reply.

Considering initially I didn't think it could be done at all, I thought the whole thing would collapse and cave in during printing. LOL.

You are probably right about the temperature. I just printed the second half of the helmet in a lower temp. It has much fewer "spider

web"

|

Re: Print improvement December 16, 2015 09:20AM |

Registered: 8 years ago Posts: 778 |

|

Re: Print improvement December 16, 2015 09:46AM |

Registered: 9 years ago Posts: 133 |

Quote

Downunder35m

Once you got some experience it often comes down to look and feel.

You see the print and you know what should be done to correct it.

Play around with the temp and retraction to get rid of the last spider webs.

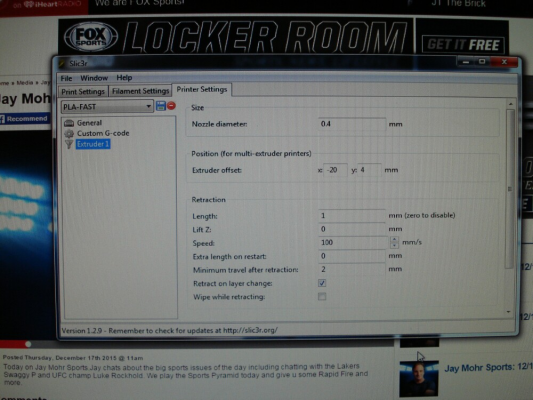

Would you mind telling me more about the retraction? Did you mean the retraction on the extruder motor? And what can I do to fine tune it?

Thanks again.

|

Re: Print improvement December 16, 2015 08:22PM |

Registered: 8 years ago Posts: 778 |

You want to retract the filament when crossing open spaces or changing layers to avoid blobs and strings.

The retraction should be as short as possible but long enough to stop the nozzle from dripping.

The retraction speed should be close to the fasted your exruder can handle to keep the time losses short.

The retraction should be as short as possible but long enough to stop the nozzle from dripping.

The retraction speed should be close to the fasted your exruder can handle to keep the time losses short.

|

Re: Print improvement December 24, 2015 12:08AM |

Registered: 9 years ago Posts: 705 |

|

Re: Print improvement December 24, 2015 09:01AM |

Registered: 8 years ago Posts: 778 |

1mm might not be enough but I am almost certain that 100mm/s is too fast for the retraction, try 30mm/s to start and work your way up.

Also keep in mind that if the retraction is too fast you only stress the filament and extruder.

And, if using longer retractions you can suck in air through the nozzle - that is to be avoided...

Also keep in mind that if the retraction is too fast you only stress the filament and extruder.

And, if using longer retractions you can suck in air through the nozzle - that is to be avoided...

|

Re: Print improvement December 24, 2015 07:29PM |

Registered: 11 years ago Posts: 1,171 |

Sorry, only registered users may post in this forum.