*grrrrr* warping halfway the print

Posted by wouterheer

|

*grrrrr* warping halfway the print February 17, 2016 10:52AM |

Registered: 8 years ago Posts: 21 |

Hi All,

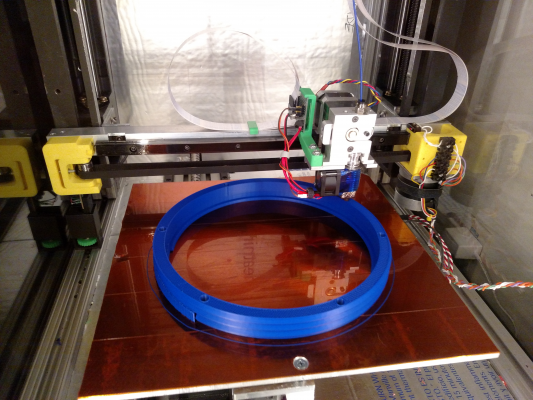

Finally I got my ABS print to stick to the print serface with ABS slurry on top of kapton tape...

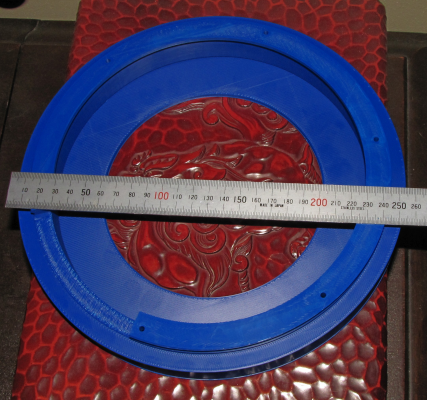

After the print completed i saw the kapton tape had came loose from the glass in the middle of the print, warping due to this was minimal. but.... the warping did not start at the bottom of the printed object, but halfway :-( (see attached picture). I don't have a clue hot to fix this one :-(

ABS 1,75 mm

Fill 20%

Bed tem 85 C first layer, 80 C next layers

Heated Bed MK3 with Brosolate glass, Kapton Tape and ABS slurry

ABS print temp 235 C with E3DV6 lite head.

No object cooling.

Thanks!

Wouter.

Finally I got my ABS print to stick to the print serface with ABS slurry on top of kapton tape...

After the print completed i saw the kapton tape had came loose from the glass in the middle of the print, warping due to this was minimal. but.... the warping did not start at the bottom of the printed object, but halfway :-( (see attached picture). I don't have a clue hot to fix this one :-(

ABS 1,75 mm

Fill 20%

Bed tem 85 C first layer, 80 C next layers

Heated Bed MK3 with Brosolate glass, Kapton Tape and ABS slurry

ABS print temp 235 C with E3DV6 lite head.

No object cooling.

Thanks!

Wouter.

|

Re: *grrrrr* warping halfway the print February 17, 2016 11:00AM |

Registered: 9 years ago Posts: 125 |

I have never used ABS juice over Kapton tape. Just directly over the glass bad. It sticks very well. My bed temp between 105-108 Celsius.

Perhaps you have too low hot end temp for the ABS? Once I got grease dropping from the extruder gears or X-bar over the print. If it just cracked and did not warp very badly, glue it with the ABS slurry, strong as printed.

Edited 4 time(s). Last edit at 02/17/2016 11:09AM by Plasteroid.

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

Perhaps you have too low hot end temp for the ABS? Once I got grease dropping from the extruder gears or X-bar over the print. If it just cracked and did not warp very badly, glue it with the ABS slurry, strong as printed.

Edited 4 time(s). Last edit at 02/17/2016 11:09AM by Plasteroid.

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

|

Re: *grrrrr* warping halfway the print February 20, 2016 12:42AM |

Registered: 8 years ago Posts: 916 |

|

Re: *grrrrr* warping halfway the print February 20, 2016 01:23AM |

Registered: 9 years ago Posts: 294 |

my opinion is that you are running bed temp low enough for abs. You should try 95-105 that is what work for me. Also the point that the tape come lose says that the glass was not clear enough when you attached the kapton . use some aceton to clean it well and then try to print .

it is very important the quality of the kapton . I saw that there are difference in quality there . So if you have a kapton from another supplier you might wanna try this .

it is very important the quality of the kapton . I saw that there are difference in quality there . So if you have a kapton from another supplier you might wanna try this .

|

Re: *grrrrr* warping halfway the print February 20, 2016 07:51AM |

Registered: 11 years ago Posts: 5,780 |

There are two issues with printing ABS. Getting it to stick to the bed is one, delamination (splitting/warping) is another. 85C is a bit low for the bed temperature. You want to be closer to the glass transition temperature of 105C. Check the temperature with a thermocouple. Your printer's controller may be reporting an incorrect temperature. My printer's controller says the bed is at 90C when it is actually 105C. I routinely print large ABS parts with nothing but clean (wiped with pure acetone, not fingernail polish remover, at room temperature) kapton tape on the bed.

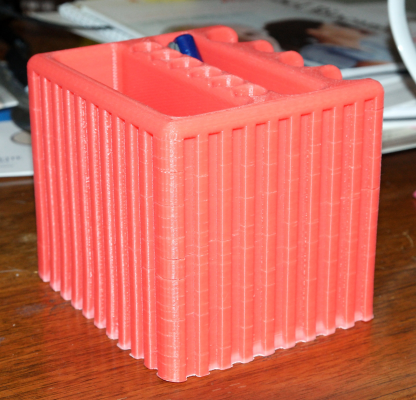

Warping/delamination can be reduced a bit by using non-smooth surfaces in your part designs when possible, but are best controlled by printing in a warm, enclosed chamber. 45-50C seems to be adequate to prevent warping/delamination in most cases. This 100mm tall object was originally printed in open air with smooth sides and tore itself apart before it was half complete (unfortunately I did not keep it or make any photos). I redesigned it with corrugated sides and printed again in open air and you can see there is still some minor delamination, but the part would still be functional (a coin/phone/pen holder for my car). The elephant footing at the bottom of the part indicates that I had the bed temperature set too high when I printed this- that was probably before I actually measured the bed temperature and compared it to the temperature I had set.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Warping/delamination can be reduced a bit by using non-smooth surfaces in your part designs when possible, but are best controlled by printing in a warm, enclosed chamber. 45-50C seems to be adequate to prevent warping/delamination in most cases. This 100mm tall object was originally printed in open air with smooth sides and tore itself apart before it was half complete (unfortunately I did not keep it or make any photos). I redesigned it with corrugated sides and printed again in open air and you can see there is still some minor delamination, but the part would still be functional (a coin/phone/pen holder for my car). The elephant footing at the bottom of the part indicates that I had the bed temperature set too high when I printed this- that was probably before I actually measured the bed temperature and compared it to the temperature I had set.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: *grrrrr* warping halfway the print February 20, 2016 08:16AM |

Registered: 9 years ago Posts: 294 |

|

Re: *grrrrr* warping halfway the print February 20, 2016 10:24AM |

Registered: 11 years ago Posts: 5,780 |

The plate is 6.35 mm cast aluminum tooling plate with a Kapton heater stuck to the bottom and 5 mil Kapton tape on the top surface. Click the link in my sig, below to see details of my printer.

I don't remove the plate to detach prints. I use something similar to this to pry parts loose: [www.ebay.com] I tried using a wood chisel and a large, sharp floor scraper, but the sharp corners of the blades kept tearing the Kapton so I went back to the small scraper. The handle on the small scraper isn't very comfortable when applying pressure to it, so I should probably design and print a new handle for it.

I let the bed cool to room temperature before removing parts. Smaller parts often just let go without any effort, larger ones usually have to be pried loose. The Kapton tape on the bed surface usually lasts for a few months before I damage it with the scraper, then I usually just replace the the center two strips (2" wide) and its as good as new again. I've used thinner Kapton on printers at the makerspace and found it is too easy to tear it.

Edited 1 time(s). Last edit at 02/20/2016 10:25AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't remove the plate to detach prints. I use something similar to this to pry parts loose: [www.ebay.com] I tried using a wood chisel and a large, sharp floor scraper, but the sharp corners of the blades kept tearing the Kapton so I went back to the small scraper. The handle on the small scraper isn't very comfortable when applying pressure to it, so I should probably design and print a new handle for it.

I let the bed cool to room temperature before removing parts. Smaller parts often just let go without any effort, larger ones usually have to be pried loose. The Kapton tape on the bed surface usually lasts for a few months before I damage it with the scraper, then I usually just replace the the center two strips (2" wide) and its as good as new again. I've used thinner Kapton on printers at the makerspace and found it is too easy to tear it.

Edited 1 time(s). Last edit at 02/20/2016 10:25AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: *grrrrr* warping halfway the print February 20, 2016 12:34PM |

Registered: 8 years ago Posts: 21 |

All, thanks A LOT for all the extensieve answers, I have a lot to try/test the next few days :-) I will let you guys know what works for me... One thing giving me some grief at the moment is the fact that I can't manage to het the bed above 85 degrees. Will it help to isolatie the bottom of the heated bed woth Cork?

|

Re: *grrrrr* warping halfway the print February 21, 2016 01:57AM |

Registered: 9 years ago Posts: 294 |

Quote

wouterheer

. . Will it help to isolatie the bottom of the heated bed woth Cork?

sure it will . i bet it ll give more 5c-10c . In my new mendel i have a 5.8mm ( copying the dentist and others here ...) aluminum sheet i have the heater below that under the heater there is some wood board (mdf 3mm) and i have the intention of installing some cork around 3mm thick and a fiberglass sheet . All that for making my bed reach out the 110 easily with a cheap heater.

Even if you could reach that temp then again the isolation would be a must thing to do to save some energy and also let the heater rest for and every few seconds during prints .

@ tdd . thanks a lot for ur infos . you see when i ve thought to do what you have did for the bed i didn't thought that sometimes i am taking off the glass of my reprappro mendel to apply force for a print to pop out.! 2" kapton. this is also nice. Thanks dentist.

|

Re: *grrrrr* warping halfway the print February 21, 2016 07:16AM |

Registered: 11 years ago Posts: 5,780 |

You are having a common problem with the heaters supplied with printer kits and sold in the aftermarket- too low power for ABS printing (I know they probably said the machine could print ABS, but here's a valuable tip that will help you for the rest of your life: marketing people often lie to sell products). Insulating the bottom side of the bed will help a little, but there's no substitute for power. If your power supply is adjustable, cranking it up a couple Volts might help (assuming it doesn't cause other problems).

As a point of reference, I have a 450W heater on my printer's 317 x 305 x 6.35 mm aluminum bed (about 0.5 W/cm^2) and it gets to 105C in about 5 minutes. If you shop for another heater, look for similar power density. If they don't specify the power, don't buy the heater.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

As a point of reference, I have a 450W heater on my printer's 317 x 305 x 6.35 mm aluminum bed (about 0.5 W/cm^2) and it gets to 105C in about 5 minutes. If you shop for another heater, look for similar power density. If they don't specify the power, don't buy the heater.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: *grrrrr* warping halfway the print February 21, 2016 07:56AM |

Registered: 9 years ago Posts: 1,873 |

I think the problem with the cheap pcb heaters is mostly lack of quality control. If you are lucky you get a good one - mine will go from 20 to 95C in 7 minutes and will hold 110C against 20 ambient without problem using a normal PC supply giving 12.0V under load. Quicker heat up times would be nice, but at under 10 minutes it doesn't cause me a huge problem, I usually just put the heater on while I'm getting everything ready. 95C is enough to get good first layer adhesion with ABS so that's the longest I have to wait for at the moment. Once I get the enclosure done I would expect the increased ambient to add directly to the maximum bed temperature, so if I need a 135C bed for pom that should be achievable with a 45 to 50C chamber.

|

Re: *grrrrr* warping halfway the print February 21, 2016 10:19AM |

Registered: 9 years ago Posts: 294 |

i dont think it has to do with the pcb's but with the supplies. my mk2b heater got to 70c in about 20 minutes with 10v from my psu. On the other hand the heater that rpp ship to me needs about 20 minutes to get to 100 . the only difference between them is the psu .

of course a higher rating watt heater would easily do the difference. I intend to get one sometime.

of course a higher rating watt heater would easily do the difference. I intend to get one sometime.

|

Re: *grrrrr* warping halfway the print February 24, 2016 07:16PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: *grrrrr* warping halfway the print February 25, 2016 05:01AM |

Registered: 10 years ago Posts: 550 |

try higher infill (more surface for interlayer bonding) and/or higher print temp (beter interlayer bonding) and/or more perimeters (more interlayer bonding surface) or redesign the corner where it started warping.Quote

wouterheer

the warping did not start at the bottom of the printed object, but halfway :-( (see attached picture). I don't have a clue hot to fix this one :-(

Fill 20%

ABS print temp 235 C with E3DV6 lite head.

Sorry, only registered users may post in this forum.