DIY 3D printer enclosure guide  February 17, 2016 05:10PM |

Registered: 8 years ago Posts: 16 |

Here's a walkthrough a guest writer wrote about building a DIY enclosure for his delta. Of course, his delta is pretty big, but there are tips and considerations that will essentially be the same no matter how big your enclosure will have to be that's quite useful. A good read to get you thinking about an enclosure if you don't already have one!

Do you have more tips on enclosures? Any experiences you can share about building your own?

[blog.pinshape.com]

Do you have more tips on enclosures? Any experiences you can share about building your own?

[blog.pinshape.com]

Re: DIY 3D printer enclosure guide  February 17, 2016 11:52PM |

Registered: 8 years ago Posts: 778 |

Currently thinking of making one from polysterene foam.

Easy to cut with a hot wire and as easy to create finger and notches to fit the parts together with self support.

Will create some instructions if I finally managet to get enough free time again to do some serious work on the machine.

Easy to cut with a hot wire and as easy to create finger and notches to fit the parts together with self support.

Will create some instructions if I finally managet to get enough free time again to do some serious work on the machine.

Re: DIY 3D printer enclosure guide  February 18, 2016 03:46AM |

Registered: 9 years ago Posts: 125 |

I don't have the enclosure, but the correct material for it is Polycarbonate ( -100... +120°C ) . No acrylic: [www.youtube.com]

Polysterene foam, well it's quite fragile material, but as a cheap emergency...perhaps.

Polycarbonate price here about 50€ / $ 950 * 1250mm / 2mm.

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

Polysterene foam, well it's quite fragile material, but as a cheap emergency...perhaps.

Polycarbonate price here about 50€ / $ 950 * 1250mm / 2mm.

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

Re: DIY 3D printer enclosure guide  February 18, 2016 08:50AM |

Registered: 11 years ago Posts: 5,780 |

I built an enclosure the first generation of my printer using 1" thick PIR foam. PIR is a little safer than polystyrene foam because it doesn't melt or burn. It cuts easily with a razor knife. I printed a bunch of clips so I could take the enclosure apart, transport it with the printer, then set it all up again, but holding it together with duct tape works fine if you don't need to transport it.

That enclosure was insulated well enough that the bed heater elevated the temperature inside the box to about 45C which allowed printing ABS without delamination or warping.

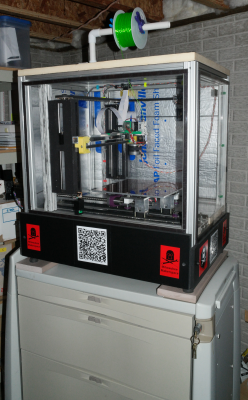

That box was huge because I did not design the printer to be enclosed. Had I known it was necessary to enclose the printer and have a warm chamber to print ABS, I would have designed the printer to be easier to enclose from the start. When I redesigned and rebuilt the machine, I designed it for easy and compact enclosure and moved the electronics outside the warm print chamber. I used a rectangular frame for the printer which allows easy attachment of flat panels to the top, bottom and sides of the printer. I hold them on with magnetic tape strips which seals the printer almost airtight yet allows easy access to the machine for adjustments, etc. This is what it looks like now- insulation panels on four sides, clear polycarbonate on two:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

That enclosure was insulated well enough that the bed heater elevated the temperature inside the box to about 45C which allowed printing ABS without delamination or warping.

That box was huge because I did not design the printer to be enclosed. Had I known it was necessary to enclose the printer and have a warm chamber to print ABS, I would have designed the printer to be easier to enclose from the start. When I redesigned and rebuilt the machine, I designed it for easy and compact enclosure and moved the electronics outside the warm print chamber. I used a rectangular frame for the printer which allows easy attachment of flat panels to the top, bottom and sides of the printer. I hold them on with magnetic tape strips which seals the printer almost airtight yet allows easy access to the machine for adjustments, etc. This is what it looks like now- insulation panels on four sides, clear polycarbonate on two:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: DIY 3D printer enclosure guide  February 19, 2016 02:00AM |

Registered: 8 years ago Posts: 778 |

Polysterene is not only what you know as the white, soft stuff used to protect your new TV

There are different grades, the standard stuff has a desnity of only about 15kg per m³.

High density foam has up to 200kg per m³.

In home depots you can often get so called hard foam sheets - they are higher density polystyrene.

If labeled for insulation as well it means they are treated to be fire and flame retardant.

On those sheets you can walk without leaving footprints, so they should do well enough for an enclosure

You can also get "oven sheets" - sorry no clue about the real name as I have only seen them with that one.

They are thin aluminium sheets with a compressed layer of rock wool between them.

Only about 8mm tick but good insulator and extreme structural qualities compared to any foam.

Downside is the added labour in makin an enclosure as you either need a slot system to slide the sheets in or cut them so you can fold the corners for riveting.

IMHO opinion and if money is no issue I would always opt for aluminum profiles and clear acrylic sheets.

You can add proper hinges, door seals, even safety switches if you want to go nuts.

But it is alo the best looking option with the best comparison to industrial quality.

There are different grades, the standard stuff has a desnity of only about 15kg per m³.

High density foam has up to 200kg per m³.

In home depots you can often get so called hard foam sheets - they are higher density polystyrene.

If labeled for insulation as well it means they are treated to be fire and flame retardant.

On those sheets you can walk without leaving footprints, so they should do well enough for an enclosure

You can also get "oven sheets" - sorry no clue about the real name as I have only seen them with that one.

They are thin aluminium sheets with a compressed layer of rock wool between them.

Only about 8mm tick but good insulator and extreme structural qualities compared to any foam.

Downside is the added labour in makin an enclosure as you either need a slot system to slide the sheets in or cut them so you can fold the corners for riveting.

IMHO opinion and if money is no issue I would always opt for aluminum profiles and clear acrylic sheets.

You can add proper hinges, door seals, even safety switches if you want to go nuts.

But it is alo the best looking option with the best comparison to industrial quality.

Re: DIY 3D printer enclosure guide  February 19, 2016 06:37AM |

Registered: 10 years ago Posts: 35 |

I made my enclosure from a wooden frame lined with drywall on the inside, and oak plywood on the outside. Drywall (or gypboard) is used for house interiors and is very very difficult to burn. I've had this chamber to 100C on several occasions for polycarbonate prints, and shows no sign of discoloration. The drywall is inexpensive, insulating, and also pretty cheap. It cuts with a razor knife. Once you tape the edges and mud them in, you get a fairly airtight chamber (no need for fancy ventilation). Downside is that it is a little messy to fabricate from, and its heavier than other coverings.

Re: DIY 3D printer enclosure guide  December 15, 2016 04:18PM |

Registered: 7 years ago Posts: 1 |

Hi dtwrv6,

I had the exact same idea, to use drywall on the inside and wood on the outside. After all, wood and heat dont go together well.

Could you please post some photos of what you did? I would really appreciate it.

Because I live in a small apartment I dont want it full of fumes either, so I plan to build in a scrubber and extractor fan.

Thanks

I had the exact same idea, to use drywall on the inside and wood on the outside. After all, wood and heat dont go together well.

Could you please post some photos of what you did? I would really appreciate it.

Because I live in a small apartment I dont want it full of fumes either, so I plan to build in a scrubber and extractor fan.

Thanks

Sorry, only registered users may post in this forum.