what cause this?

Posted by Blisk

|

what cause this? February 19, 2016 07:42AM |

Registered: 8 years ago Posts: 74 |

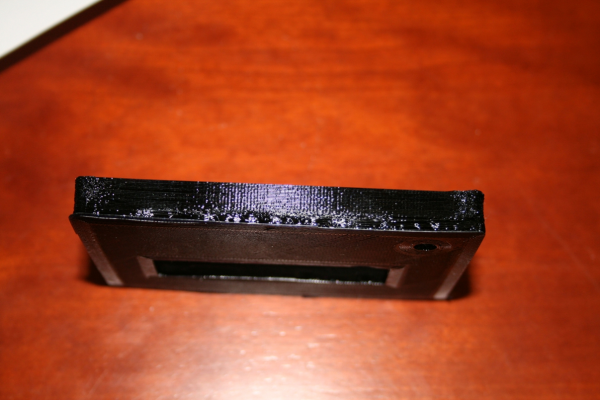

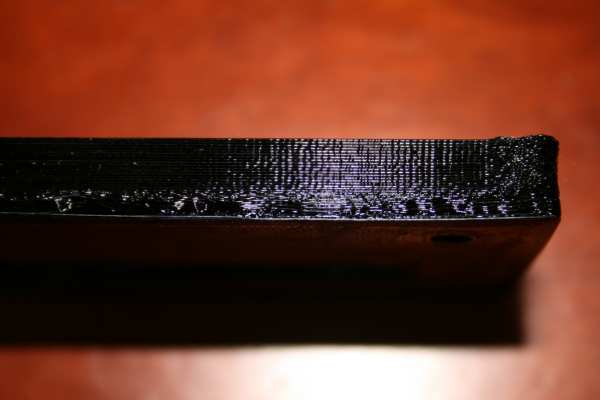

Can someone helps me with settings.

Don't know why printer prints like this?

Material is PLA printed on 210 oC and heatbed on 70 oC

And it is 0,5 mm smaller than it should be.

Edited 2 time(s). Last edit at 02/19/2016 07:43AM by Blisk.

Don't know why printer prints like this?

Material is PLA printed on 210 oC and heatbed on 70 oC

And it is 0,5 mm smaller than it should be.

Edited 2 time(s). Last edit at 02/19/2016 07:43AM by Blisk.

|

Re: what cause this? February 19, 2016 12:26PM |

Admin Registered: 16 years ago Posts: 13,884 |

... seems the 70 degC are too much - this deformation/shrinkage of the first layers is called "elephant foot" and shows the contraction of the outer shells with contracted inner filling structures -- the upper shells are then printed with appropriate temps/cooling, so don't show artifacts ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: what cause this? February 19, 2016 01:53PM |

Registered: 8 years ago Posts: 74 |

|

Re: what cause this? February 26, 2016 01:14AM |

Registered: 9 years ago Posts: 705 |

|

Re: what cause this? February 26, 2016 08:23AM |

Registered: 8 years ago Posts: 74 |

|

Re: what cause this? February 26, 2016 08:57AM |

Registered: 11 years ago Posts: 5,780 |

In general, if the layers of your prints aren't shifting the acceleration is OK. Before you mess with acceleration settings, I recommend that you calibrate the machine.

Check the temperature of the bed with a thermocouple. Controllers often report incorrect temperatures. When you set it to 70C is that what you get?

It looks like you haven't calibrated the printer/extruder. Start by doing that. I like to use the procedures here: [reprap.org]

Pay particular attention to the extruder calibration.

When you calibrate the extruder, you can use either the flow/extrusion multiplier or measured filament diameter to get accurate line widths. Filament is only rarely the nominal diameter. If you slice at 1.75mm and the filament diameter is 1.79mm you will over extrude. If the diameter is 1.72 you will under extrude.

Flow/extrusion multiplier method: When you slice, use the nominal filament diameter (1.75 or 3 mm). Print a single walled test part (use a 20 mm cube printed in spiral vase mode) and measure the wall thickness. You set the flow/extrusion multiplier to target width/ actual width. Mark that value on the filament spool- you will need it every time you print from that spool. You will have to print a test part with every new spool and mark the flow/extrusion multiplier value on the spool. This has to be done because filament diameters vary from one spool to the next. 1/100ths of a mm matter! You can set the flow/extrusion multiplier in the slicer or at print time. If you do it at print time you shouldn't have to reslice when you change spools- just enter the new flow value when you print.

Filament diameter method: Slice using the average of 20-30 measured diameters of the filament. Mark that average value on the spool and do this for every new spool of filament before you print with it. Variation: use volumetric extrusion. You always slice with the filament diameter set to 1.128379 mm. When you print you enter the actual filament diameter (measured average) using the M200 command if you're using a host computer to control the printer, or enter the diameter value using the LCD panel if your firmware has that set up (Smoothieware does, I don't know about others). With this method you don't have to reslice every time you change filament spools/colors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Check the temperature of the bed with a thermocouple. Controllers often report incorrect temperatures. When you set it to 70C is that what you get?

It looks like you haven't calibrated the printer/extruder. Start by doing that. I like to use the procedures here: [reprap.org]

Pay particular attention to the extruder calibration.

When you calibrate the extruder, you can use either the flow/extrusion multiplier or measured filament diameter to get accurate line widths. Filament is only rarely the nominal diameter. If you slice at 1.75mm and the filament diameter is 1.79mm you will over extrude. If the diameter is 1.72 you will under extrude.

Flow/extrusion multiplier method: When you slice, use the nominal filament diameter (1.75 or 3 mm). Print a single walled test part (use a 20 mm cube printed in spiral vase mode) and measure the wall thickness. You set the flow/extrusion multiplier to target width/ actual width. Mark that value on the filament spool- you will need it every time you print from that spool. You will have to print a test part with every new spool and mark the flow/extrusion multiplier value on the spool. This has to be done because filament diameters vary from one spool to the next. 1/100ths of a mm matter! You can set the flow/extrusion multiplier in the slicer or at print time. If you do it at print time you shouldn't have to reslice when you change spools- just enter the new flow value when you print.

Filament diameter method: Slice using the average of 20-30 measured diameters of the filament. Mark that average value on the spool and do this for every new spool of filament before you print with it. Variation: use volumetric extrusion. You always slice with the filament diameter set to 1.128379 mm. When you print you enter the actual filament diameter (measured average) using the M200 command if you're using a host computer to control the printer, or enter the diameter value using the LCD panel if your firmware has that set up (Smoothieware does, I don't know about others). With this method you don't have to reslice every time you change filament spools/colors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: what cause this? March 01, 2016 08:39AM |

Registered: 8 years ago Posts: 183 |

|

Re: what cause this? March 03, 2016 04:58AM |

Registered: 8 years ago Posts: 74 |

Thank you for alot of advices. And really good explanation of calibration by the_digital_dentist.

Temperature of bed is higher after I changed heatbed and it is alu now withouth glass on it so I use lower temperatures of heatbed.

Yes I did calibrate it and major problem I see here is that extruder stops alot when printing circle, this never happend before and I think it is after I have upgraded repetier.

Printing circles should be smooth withouth stopping. Here is video of it.

[cloud.povej.net]

Any suggestions why this happend?

Temperature of bed is higher after I changed heatbed and it is alu now withouth glass on it so I use lower temperatures of heatbed.

Yes I did calibrate it and major problem I see here is that extruder stops alot when printing circle, this never happend before and I think it is after I have upgraded repetier.

Printing circles should be smooth withouth stopping. Here is video of it.

[cloud.povej.net]

Any suggestions why this happend?

|

Re: what cause this? March 07, 2016 10:51AM |

Registered: 8 years ago Posts: 183 |

Sorry, only registered users may post in this forum.