Can´t find a solution for my Z-ribbing, help?

Posted by daishi

Can´t find a solution for my Z-ribbing, help?  February 27, 2016 09:13AM |

Registered: 10 years ago Posts: 23 |

Hi,

I built a new printer, a modified spark cube and need your help.

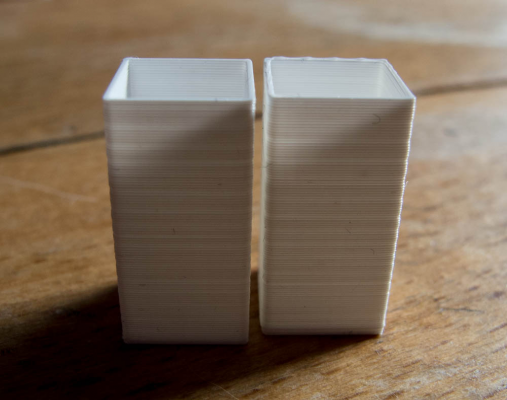

Unfortunately I see some minor Z-ribbing in all of my prints. Here is an example with a calibration object:

And a closeup with increased contrast to see the layers better:

It is not wobble, but ribbing, the complete layer is either pushed to the outside or to the inside of the object.

Also the distortions seam to vary from object to object. There are some lines that look the same, but most of them seem to be random.

The prints are in 0.2mm layers.

The lead screw is a TR8x2, so I am using 20 full steps per layer.

I already tried various things:

1) guiding the filament by hand, so it has always the same tension.

2) removing the lower guide of leadscrew.

3) using a self printed rigid z-coupler instead of the aluminum one.

4) checking of the guide rods: all is perfectly vertical.

5) changing the micro steps of the stepper from 32 to 16

6) upping the printing temperature.

7) using a perfectly fitting self printed nut with no gap for the Z-axis

Nothing had an effect on the ribbing.

The ribbing also does not seem to be connected to the pitch of the leadscrew, they seem to be between 0.8mm and 1.3mm apart from each other, not 2mm.

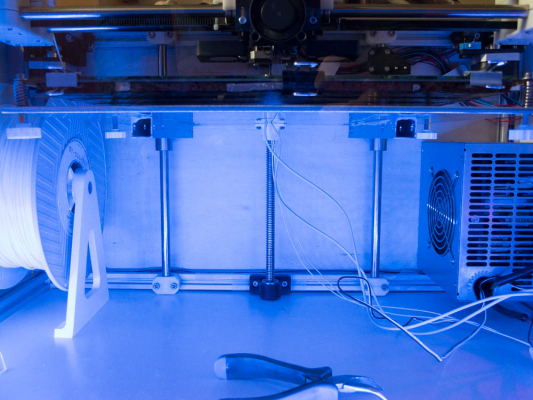

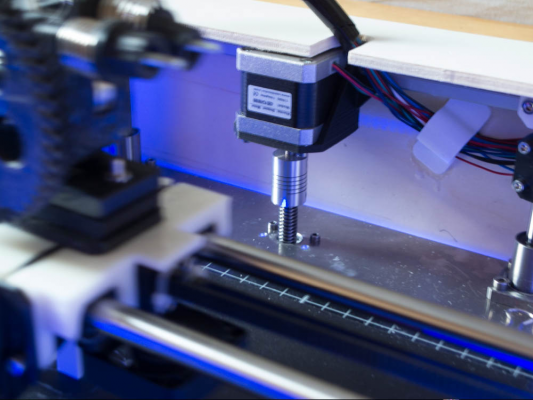

Here are two pictures of my printer:

The printer is a coreXY and I am running the latest version of Marlin

Do you know what the cause of this ribbing could be?

Edited 1 time(s). Last edit at 02/27/2016 09:15AM by daishi.

I built a new printer, a modified spark cube and need your help.

Unfortunately I see some minor Z-ribbing in all of my prints. Here is an example with a calibration object:

And a closeup with increased contrast to see the layers better:

It is not wobble, but ribbing, the complete layer is either pushed to the outside or to the inside of the object.

Also the distortions seam to vary from object to object. There are some lines that look the same, but most of them seem to be random.

The prints are in 0.2mm layers.

The lead screw is a TR8x2, so I am using 20 full steps per layer.

I already tried various things:

1) guiding the filament by hand, so it has always the same tension.

2) removing the lower guide of leadscrew.

3) using a self printed rigid z-coupler instead of the aluminum one.

4) checking of the guide rods: all is perfectly vertical.

5) changing the micro steps of the stepper from 32 to 16

6) upping the printing temperature.

7) using a perfectly fitting self printed nut with no gap for the Z-axis

Nothing had an effect on the ribbing.

The ribbing also does not seem to be connected to the pitch of the leadscrew, they seem to be between 0.8mm and 1.3mm apart from each other, not 2mm.

Here are two pictures of my printer:

The printer is a coreXY and I am running the latest version of Marlin

Do you know what the cause of this ribbing could be?

Edited 1 time(s). Last edit at 02/27/2016 09:15AM by daishi.

Re: Can´t find a solution for my Z-ribbing, help?  February 27, 2016 09:49AM |

Registered: 11 years ago Posts: 560 |

If you can get adhesion to your bed, try a print without the bed heat on. Try glue stick or blue tape. You may have bed flex caused by the heating and cooling.

If this is a smoother print, change your bed springs to the stiffest springs you can use, or tighten your bed screws as tight as you can with still being able to level the bed.

Edited 1 time(s). Last edit at 02/27/2016 09:50AM by Dirty Steve.

If this is a smoother print, change your bed springs to the stiffest springs you can use, or tighten your bed screws as tight as you can with still being able to level the bed.

Edited 1 time(s). Last edit at 02/27/2016 09:50AM by Dirty Steve.

Re: Can´t find a solution for my Z-ribbing, help?  February 27, 2016 10:09AM |

Registered: 11 years ago Posts: 5,780 |

It looks like overextrusion is contributing to the problem. Have you calibrated the extruder? How do you set filament diameter when printing?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: Can´t find a solution for my Z-ribbing, help?  February 27, 2016 10:40AM |

Registered: 10 years ago Posts: 23 |

Wow!

Thanks for the fast responses!

I tried printing with the heated bed turned off and it looks way better:

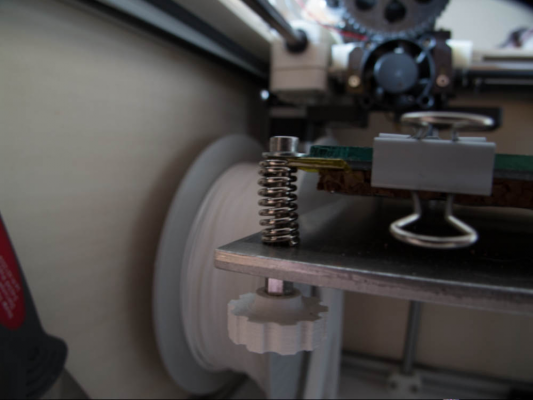

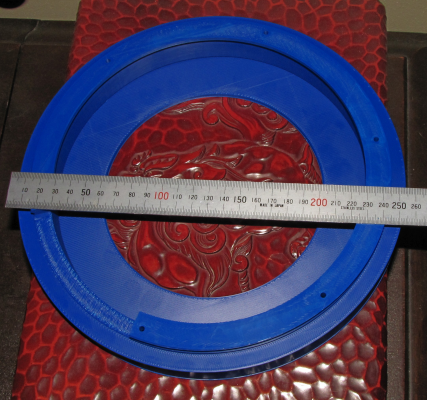

Here is a picture of my bed-screws. They already are pretty stiff ones.

Maybe there is something wrong with my bed leveling in general?

Is it bad to have 6 clamps for the glass surface?

The remaining distortion really could be over extrusion.

I calibrated the extruder steps by extruding 100mm and measuring the real extrusion.

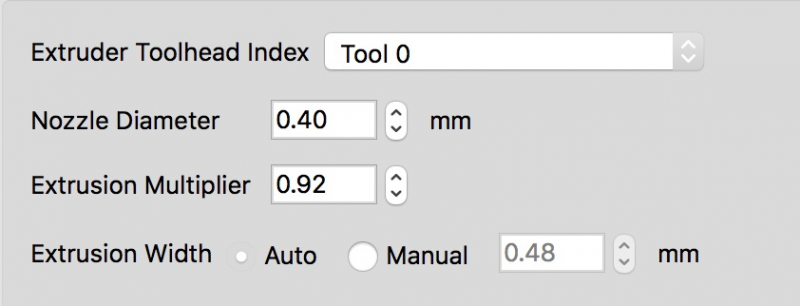

After that I printed a single wall object and adjusted the extrusion multiplier in Simplify3D to get a wall of 0.48mm.

Here are my current settings:

Thanks for the fast responses!

I tried printing with the heated bed turned off and it looks way better:

Here is a picture of my bed-screws. They already are pretty stiff ones.

Maybe there is something wrong with my bed leveling in general?

Is it bad to have 6 clamps for the glass surface?

The remaining distortion really could be over extrusion.

I calibrated the extruder steps by extruding 100mm and measuring the real extrusion.

After that I printed a single wall object and adjusted the extrusion multiplier in Simplify3D to get a wall of 0.48mm.

Here are my current settings:

Re: Can´t find a solution for my Z-ribbing, help?  February 27, 2016 11:17AM |

Registered: 11 years ago Posts: 5,780 |

I see you have the diameter set to 1.77 mm and the extrusion multiplier set to 0.92. I assume that 1.77 mm is the average measured diameter of the nominal 1.75 mm filament the printer uses. Usually, you use the nominal diameter (1.75 mm) then adjust the extrusion multiplier/flow to compensate for filament that is larger/smaller than the nominal diameter.

Alternatively, you can set the extrusion multiplier/flow control to 1 and use the average measured diameter of the filament.

If the extruder is well calibrated, either one alone will give accurate results. It's a little strange to use both at the same time. If you enter the average measured filament diameter and it produces incorrect line width, the extruder needs recalibration.

Whichever you decide to use- flow compensation or average measured filament diameter, be sure to mark the value on the spool so you can use it next time you use that filament.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Alternatively, you can set the extrusion multiplier/flow control to 1 and use the average measured diameter of the filament.

If the extruder is well calibrated, either one alone will give accurate results. It's a little strange to use both at the same time. If you enter the average measured filament diameter and it produces incorrect line width, the extruder needs recalibration.

Whichever you decide to use- flow compensation or average measured filament diameter, be sure to mark the value on the spool so you can use it next time you use that filament.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: Can´t find a solution for my Z-ribbing, help?  February 27, 2016 11:21AM |

Registered: 11 years ago Posts: 560 |

I would say tighten the screws. I have the same configuration, heated PCB mounted with screws with glass and clips. There is flex in the PCB from the mount points to the glass and clips. I have the same issue at times, not sure of and haven't run across a method to make this a more stable setup.

Also you can try to tighter PID tune your bed, to reduce temperature swing.

Edited 1 time(s). Last edit at 02/27/2016 11:24AM by Dirty Steve.

Also you can try to tighter PID tune your bed, to reduce temperature swing.

Edited 1 time(s). Last edit at 02/27/2016 11:24AM by Dirty Steve.

Re: Can´t find a solution for my Z-ribbing, help?  February 27, 2016 11:40AM |

Registered: 10 years ago Posts: 23 |

Hm,

tightening the screws did´t help. Maybe I need to mount the bed differently somehow.

Right now I am printing PLA with a bed temperature of 40°C, maybe I should rise the temperature to 60° so that the whole glass gets heated better?

I could just leave the bed off for PLA, but I also want to print ABS and there I will be needing the heated bed.

@the_digital_dentist:

You are right, I really should only use one of the settings.

I will recalibrate the extruder and use the extrusion multiplier to compensate for the different real diameter.

Thanks for the tips !

!

tightening the screws did´t help. Maybe I need to mount the bed differently somehow.

Right now I am printing PLA with a bed temperature of 40°C, maybe I should rise the temperature to 60° so that the whole glass gets heated better?

I could just leave the bed off for PLA, but I also want to print ABS and there I will be needing the heated bed.

@the_digital_dentist:

You are right, I really should only use one of the settings.

I will recalibrate the extruder and use the extrusion multiplier to compensate for the different real diameter.

Thanks for the tips

!

!

Re: Can´t find a solution for my Z-ribbing, help?  February 27, 2016 12:06PM |

Registered: 10 years ago Posts: 23 |

Re: Can´t find a solution for my Z-ribbing, help?  February 27, 2016 12:54PM |

Registered: 11 years ago Posts: 560 |

I haven't run across or figured out a better bed mount setup myself. I print on 1/4" mirror.

You will still see bed flex at higher temps, it's the high/low swing around the set temp that causes the variation in the print. I think the flex is in the PCB heater and not the glass itself. I don't think the glass is changing much in a 3-5 degree temperature swing, and you can flex a PCB heater by hand.

Edited 1 time(s). Last edit at 02/27/2016 12:57PM by Dirty Steve.

You will still see bed flex at higher temps, it's the high/low swing around the set temp that causes the variation in the print. I think the flex is in the PCB heater and not the glass itself. I don't think the glass is changing much in a 3-5 degree temperature swing, and you can flex a PCB heater by hand.

Edited 1 time(s). Last edit at 02/27/2016 12:57PM by Dirty Steve.

Re: Can´t find a solution for my Z-ribbing, help?  February 28, 2016 07:51AM |

Registered: 8 years ago Posts: 183 |

I had this problem to the point where some layers were about 1mm higher or lower during extrusion than they should be. The result was simply maddening. I wasn't running PID on my heatbed, so I used that and then figured out that I really need something besides glass. The problem with glass is that it gets clipped to the heater (usually). This means that it has to follow the motions of the warping bed.

I got a aluminum plate from Online Metals, drilled four holes and a place to mount the thermistor and also used silicon tubing instead of springs. The main benefit of using aluminum is that sits on top of the heater, just under the heads of the bolts. This means that its Z position will never, ever change. Of course, the heater flexing underneath could be enough to bend the aluminum, but since its aluminum and not glass it stands up well.

Master Tinkerer

I got a aluminum plate from Online Metals, drilled four holes and a place to mount the thermistor and also used silicon tubing instead of springs. The main benefit of using aluminum is that sits on top of the heater, just under the heads of the bolts. This means that its Z position will never, ever change. Of course, the heater flexing underneath could be enough to bend the aluminum, but since its aluminum and not glass it stands up well.

Master Tinkerer

Re: Can´t find a solution for my Z-ribbing, help?  February 28, 2016 12:34PM |

Registered: 10 years ago Posts: 23 |

Hi,

thanks for the tips!

I made some tests today:

changing the bed from Bigbang to PID already helps a lot.

As you mentioned, the glas seems still to be flexing a little and that still causes some minor ribbing.

Upgrading to an aluminum bed sounds good. Did you use a machined sheet or just a normal one?

Another option would be to use a thicker glas (mine is 3mm), that is stiffer, or to decouple the bed from the heater pcb somehow.

I will keep you posted on my progress !

!

thanks for the tips!

I made some tests today:

changing the bed from Bigbang to PID already helps a lot.

As you mentioned, the glas seems still to be flexing a little and that still causes some minor ribbing.

Upgrading to an aluminum bed sounds good. Did you use a machined sheet or just a normal one?

Another option would be to use a thicker glas (mine is 3mm), that is stiffer, or to decouple the bed from the heater pcb somehow.

I will keep you posted on my progress

!

!

Re: Can´t find a solution for my Z-ribbing, help?  February 28, 2016 01:17PM |

Registered: 8 years ago Posts: 183 |

Re: Can´t find a solution for my Z-ribbing, help?  February 28, 2016 01:22PM |

Registered: 8 years ago Posts: 183 |

Using thicker glass will only help a little. The main problem (I think) is that the plate is rising with the PCB, so bend-resistance can't fully remove the banding. I have no idea if the alu I got was a milled plate or rolled sheet, but it was a bit rougher than I would have liked. Also, the mail carrier dropped it through the door. This left a small deformation that needed some filing. If you are going to get aluminum you should try and get about 3-5mm extra past the center of your mounting holes per side. Also, you can mount the thermistor like THIS. If you are going to mount the thermistor on the side of the plate, which is totally fine (I did that), be sure to get something at least slightly thicker than 4mm. If you want to go thin and mount it on the bottom (top mounting is just dumb), factor in the extra material you will need (just on the one side) to fit the (tapped / not tapped) holes and a washer. Or, you could just leave the thermistor tapped to the PCB or wherever it is now, but this can give incorrect temperature readings.

Master Tinkerer

Master Tinkerer

Re: Can´t find a solution for my Z-ribbing, help?  February 28, 2016 02:36PM |

Registered: 11 years ago Posts: 5,780 |

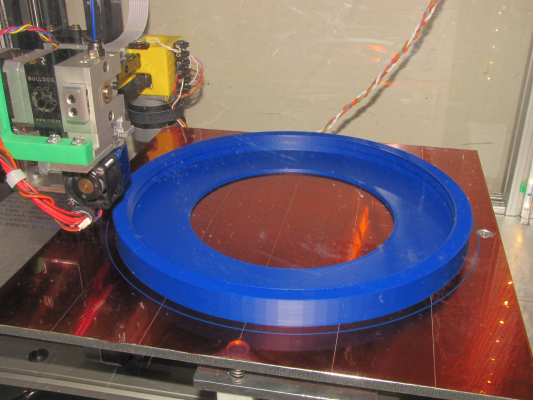

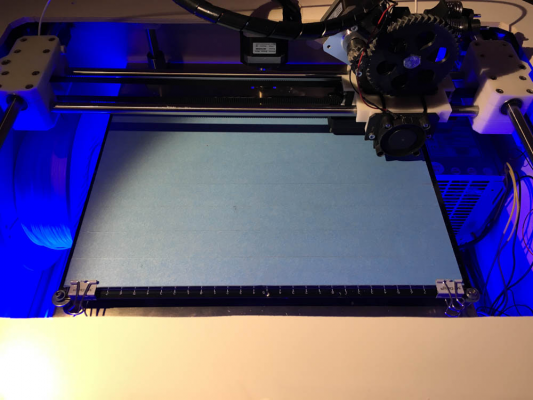

You don't need glass, just a flat aluminum plate. I print on a 317 x 305 x 6.35 mm cast aluminum tooling plate bed with a layer of 5 mil kapton tape. The plate is supported by a three screw leveling system that allows it to be leveled without bending it or the undercarriage as 4 screws will tend to do. Tooling plate comes milled flat and is flat enough to print edge to edge (see: [vimeo.com] and [vimeo.com]).

A lot of people start with a thin aluminum "heat spreader" that isn't flat, then add a piece of glass on top of it hoping to make things flat enough to print on. Why stack an unknown flatness glass plate on top of a thin, nonflat aluminum plate, and then hope for the best, when you could just use a flat aluminum plate that will ultimately end up being about the same total mass/thickness but will deliver even heating (which glass won't)?

In case you still have any doubts about the flatness of cast tooling plate, here's a 250 mm wide, warp-free, delamination-free, ABS print:

Notice that the bed support screws are countersunk- there are no clips or anything else standing above the surface of the bed to crash into the extruder.

Also note- there's nothing on the aluminum plate but a clean layer of kapton tape. No glue, hairspray, ABS juice or other slop.

Edited 5 time(s). Last edit at 02/28/2016 02:47PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

A lot of people start with a thin aluminum "heat spreader" that isn't flat, then add a piece of glass on top of it hoping to make things flat enough to print on. Why stack an unknown flatness glass plate on top of a thin, nonflat aluminum plate, and then hope for the best, when you could just use a flat aluminum plate that will ultimately end up being about the same total mass/thickness but will deliver even heating (which glass won't)?

In case you still have any doubts about the flatness of cast tooling plate, here's a 250 mm wide, warp-free, delamination-free, ABS print:

Notice that the bed support screws are countersunk- there are no clips or anything else standing above the surface of the bed to crash into the extruder.

Also note- there's nothing on the aluminum plate but a clean layer of kapton tape. No glue, hairspray, ABS juice or other slop.

Edited 5 time(s). Last edit at 02/28/2016 02:47PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: Can´t find a solution for my Z-ribbing, help?  February 29, 2016 06:45AM |

Registered: 10 years ago Posts: 23 |

Ok,

you are right. There is no point in starting with a glas plate, just to switch to something stiffer later.

I will order a machined 5mm aluminum plate that fits my 300x200 pcb heater.

The thing is that I don´t want to screw the plate down but fix it using the clips so I can still remove it to get the prints off it.

But I don´t think the pcb will be able to bent a 5mm aluminum plate.

you are right. There is no point in starting with a glas plate, just to switch to something stiffer later.

I will order a machined 5mm aluminum plate that fits my 300x200 pcb heater.

The thing is that I don´t want to screw the plate down but fix it using the clips so I can still remove it to get the prints off it.

But I don´t think the pcb will be able to bent a 5mm aluminum plate.

Re: Can´t find a solution for my Z-ribbing, help?  March 02, 2016 07:04AM |

Registered: 8 years ago Posts: 183 |

5mm is about as thick as you want, but it should do. I was a little worried about weigh vs strength- 4 or 3.5mm would have been nice, maybe thiner if I underestimate alu. I recommend using the PCB as a template to mark and drill the holes. The thing with 5mm is that you could easily sink the bolts flush and make the entire surface printable. If your nozzle or fan nozzles don't hit them then I would just leave them. How are you going to mount the thermistor? Tape to the PCB? E3D style?

Master Tinkerer

Master Tinkerer

Re: Can´t find a solution for my Z-ribbing, help?  March 03, 2016 06:09AM |

Registered: 10 years ago Posts: 23 |

The aluminum plate is 300x200x5, but the holes of the PCB are around 315x215 apart.

My plan is to clip the plate to the PCB like the original glas plate was.

I know it would be more ideal to bolt it all together, but this way I can still remove the printbed to get the parts off it and it should be heavy and stiff enough to prevent any unwanted movement.

I guess the thermistor will stay taped to the middle of the PCB for now.

The plate should arrive today, so I could tell you later if it worked out or if I need to to some more modifications to the printbed.

My plan is to clip the plate to the PCB like the original glas plate was.

I know it would be more ideal to bolt it all together, but this way I can still remove the printbed to get the parts off it and it should be heavy and stiff enough to prevent any unwanted movement.

I guess the thermistor will stay taped to the middle of the PCB for now.

The plate should arrive today, so I could tell you later if it worked out or if I need to to some more modifications to the printbed.

Re: Can´t find a solution for my Z-ribbing, help?  March 03, 2016 06:26AM |

Registered: 11 years ago Posts: 560 |

Re: Can´t find a solution for my Z-ribbing, help?  March 03, 2016 01:25PM |

Registered: 10 years ago Posts: 23 |

Hi Steve,

luckily you were wrong:

I just installed the aluminum print bed and did a test print: near perfect layer alignment!

I guess the plate is stiff enough to prevent the pcb from bending too much.

Here is the printbed, right now with painters tape, but that will soon change:

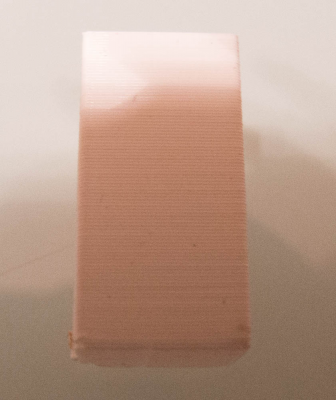

And here a picture of the print:

Looks even better than on glas with the heatbed off.

Thank you so much guys for your help! I would´t have found the source of the problem without you!

Edited 2 time(s). Last edit at 03/03/2016 01:27PM by daishi.

luckily you were wrong:

I just installed the aluminum print bed and did a test print: near perfect layer alignment!

I guess the plate is stiff enough to prevent the pcb from bending too much.

Here is the printbed, right now with painters tape, but that will soon change:

And here a picture of the print:

Looks even better than on glas with the heatbed off.

Thank you so much guys for your help! I would´t have found the source of the problem without you!

Edited 2 time(s). Last edit at 03/03/2016 01:27PM by daishi.

Re: Can´t find a solution for my Z-ribbing, help?  March 03, 2016 03:01PM |

Registered: 8 years ago Posts: 183 |

Re: Can´t find a solution for my Z-ribbing, help?  March 04, 2016 11:38PM |

Registered: 8 years ago Posts: 155 |

Hi all! I dont have this issue but I do have an alu,imiu, bed. I dont use a glass on top of it. Just hair spray. But I have many time adhesion problems. As I can see you are useing the aluminium and kapton tape on top? just capton tape??? ABS stays in the kapton tape without hair spray/glue/etc?

I have examined the alumium bed and is really flat.

I have examined the alumium bed and is really flat.

Re: Can´t find a solution for my Z-ribbing, help?  March 05, 2016 07:28AM |

Registered: 11 years ago Posts: 5,780 |

I use only clean kapton tape (5 mils thick = 127 um thick) on my printer's bed. I clean it with acetone at room temperature before printing, heat it to 105C, and ABS parts stick quite well.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.