At my wits end with PETG

Posted by Lymphomaniac1

|

At my wits end with PETG February 28, 2016 09:13PM |

Registered: 8 years ago Posts: 80 |

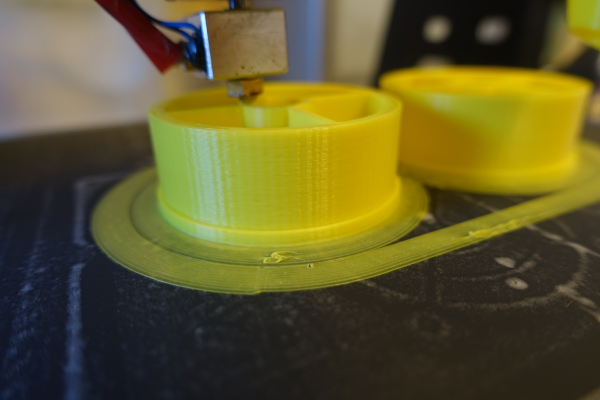

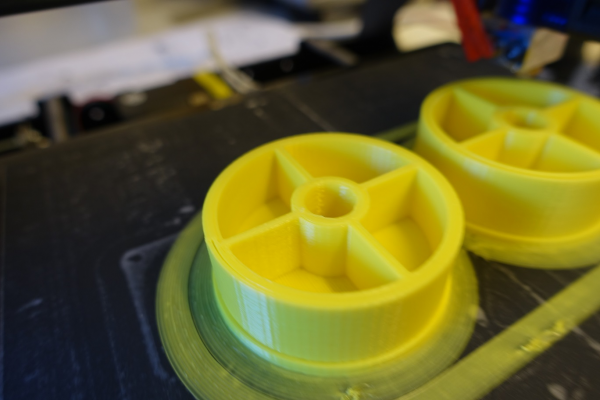

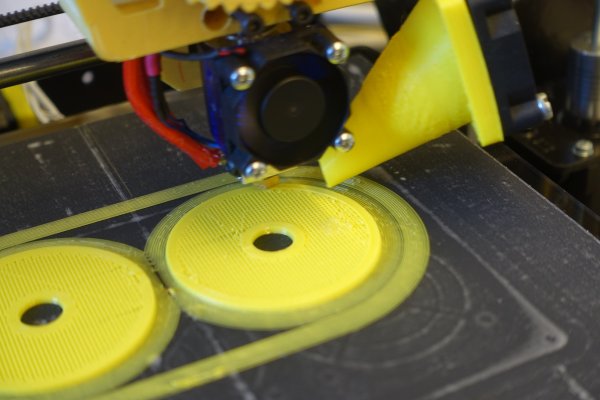

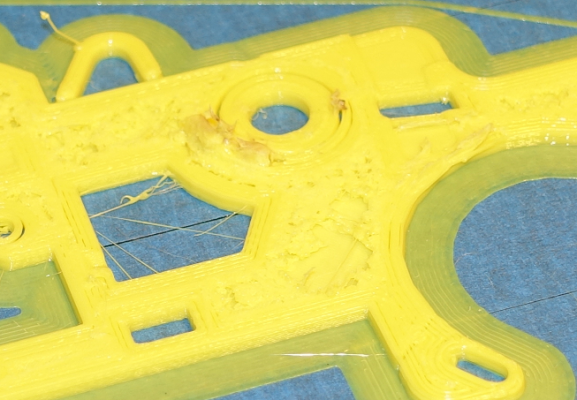

Everyone says that PETG is sooooo easy to use. Well I at my wits end. I got 3 rolls of PETG from 3 different manufacturers and they all do the same thing. With each new roll I used a new hot end with a new nozzle and the same thing happens with each. The extruded PETG whips around after coming out of the nozzle and the loose end sticks to the nozzle either making a loop or a blob. I would think that the nozzle is clogged, but the whole hot end is new including the nozzle. I am using a 0.3 mm nozzle though the same thing has happened with a .4 mm nozzle. I tried using the PETG at 230°C, 235°C 240°C 245°C and 250°C. When I tried to print the Airtrippers Pocket Filament Reel Rollers from Thingiverse the perimeters seem to print fine but the infill just blobs up and I can not even get the first layer down. Does anybody know what is going on? Does anybody have any suggestions?

Thanx in advanced.

Stuart

Thanx in advanced.

Stuart

|

Re: At my wits end with PETG February 28, 2016 11:51PM |

Registered: 8 years ago Posts: 778 |

Did you calibrate for the new material or just experimented with the temps?

PETG needs 230-250° depending on the hotend and speed used.

I would suggest to start at 240° at a low speed of just 15mm/s and work from there until you find the limits that work best for you.

A proper first layer height calibration is certainly required as this stuff does not like to stick, almost like nylon.

Have not tried it as I ran out of sample material but printing on cardboard might work as it does for nylon.

Looks ugly but helps to get you going on the tuning for the settings.

PETG needs 230-250° depending on the hotend and speed used.

I would suggest to start at 240° at a low speed of just 15mm/s and work from there until you find the limits that work best for you.

A proper first layer height calibration is certainly required as this stuff does not like to stick, almost like nylon.

Have not tried it as I ran out of sample material but printing on cardboard might work as it does for nylon.

Looks ugly but helps to get you going on the tuning for the settings.

|

Re: At my wits end with PETG February 29, 2016 03:23AM |

Registered: 8 years ago Posts: 5,232 |

I'm using "winbo-tech.com" PETG at 210-215°C on a cold bed with blue masking tape. Works fine, once you find the right nozzle/bed distance.

Cold bed only works with fixed beds like on my delta. With my Prusa i3 I have to heat the bed to 40-45°C. At 45C it sticks like hell.

Why not try to reduce temp and feed manually to get a feel for the required force?

Cold bed only works with fixed beds like on my delta. With my Prusa i3 I have to heat the bed to 40-45°C. At 45C it sticks like hell.

Why not try to reduce temp and feed manually to get a feel for the required force?

|

Re: At my wits end with PETG February 29, 2016 09:02AM |

Registered: 9 years ago Posts: 1,873 |

Hi Stuart, you're not alone - I find the stuff difficult as all hell to print too. It seems to have a much more gritty/crystalline property than most plastics, with a narrower range of nozzle temperatures before things start going wrong. If you stick with it you can get decent results, and the resulting prints are impressively strong, so it's worth some effort.

I'm using filaments.ca own brand petg, natural and printing it at 250C with 85C bed using glue stick on glass. I use fairly aggressive part cooling fan settings, with the fans always running at at least 10%. Print speeds are 15 mm/s for the first layer and 30 for the rest. I had problems with infill breaking up unto blobs which then move around the print until they find something to stick to, usually catastrophically. Using honeycomb fill seemed to have the best success.

Some people seem to have a much easier time with petg, so I'm guessing there's a lot of variation between different brands.

Edited 1 time(s). Last edit at 02/29/2016 09:03AM by JamesK.

I'm using filaments.ca own brand petg, natural and printing it at 250C with 85C bed using glue stick on glass. I use fairly aggressive part cooling fan settings, with the fans always running at at least 10%. Print speeds are 15 mm/s for the first layer and 30 for the rest. I had problems with infill breaking up unto blobs which then move around the print until they find something to stick to, usually catastrophically. Using honeycomb fill seemed to have the best success.

Some people seem to have a much easier time with petg, so I'm guessing there's a lot of variation between different brands.

Edited 1 time(s). Last edit at 02/29/2016 09:03AM by JamesK.

|

Re: At my wits end with PETG February 29, 2016 09:38PM |

Registered: 8 years ago Posts: 195 |

|

Re: At my wits end with PETG March 01, 2016 07:59AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: At my wits end with PETG March 03, 2016 10:55AM |

Registered: 8 years ago Posts: 80 |

|

Re: At my wits end with PETG March 03, 2016 10:59AM |

Registered: 8 years ago Posts: 80 |

|

Re: At my wits end with PETG March 04, 2016 02:44AM |

Registered: 8 years ago Posts: 5,232 |

Quote

JamesK

You're getting good layer adhesion at 210? I could pop layers apart with a fingernail at those sort of temps.

I've printed a few single wall tealight-holders and they are tougher than the PLA versions. The semi seethrough effect is another bonus.

My temp sensor isn't calibrated, so 210°C on my display might differ from other printers.

Printing slow was the key to success, I guess.

Edited 1 time(s). Last edit at 03/04/2016 02:45AM by o_lampe.

|

Re: At my wits end with PETG March 04, 2016 06:21AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: At my wits end with PETG March 05, 2016 12:57AM |

Registered: 8 years ago Posts: 778 |

I just got a 20$ multimeter with temp sensor.

Glued sensor into a small brass block that has a nice dint in the top for the nozzle tip.

Rest head on it for 15 or 20 min and compare the results.

Some multimeters even allow to set for different sensor types.

In any case it pays off to pay attention and with a bit of luck you even get one that uses sensors of the same kind as Marlin support.

That way you can make sure your readings are what they should be and if not even tweak the resistor tables to make it a perfect match.

After all you only need to disconnect the sensor and plug it into the multimeter to confirm it is still working

Glued sensor into a small brass block that has a nice dint in the top for the nozzle tip.

Rest head on it for 15 or 20 min and compare the results.

Some multimeters even allow to set for different sensor types.

In any case it pays off to pay attention and with a bit of luck you even get one that uses sensors of the same kind as Marlin support.

That way you can make sure your readings are what they should be and if not even tweak the resistor tables to make it a perfect match.

After all you only need to disconnect the sensor and plug it into the multimeter to confirm it is still working

|

Re: At my wits end with PETG March 13, 2016 09:48AM |

Registered: 8 years ago Posts: 260 |

I start with PETG to day, what I notest is that I can't use the high speed that I am using for PLA, I am now at 80mm/s extruding speed for infill, PLA was already at 120mm/s

If i go high the extruder can't push the filament in any more. Increasing temperature helps, but then the nozzle always drips.

Temperature now is 225c tried also 250c. Still having troubles with nozzle getting dirty and then at some point it drops of.

If i go high the extruder can't push the filament in any more. Increasing temperature helps, but then the nozzle always drips.

Temperature now is 225c tried also 250c. Still having troubles with nozzle getting dirty and then at some point it drops of.

|

Re: At my wits end with PETG March 13, 2016 10:23AM |

Registered: 9 years ago Posts: 1,873 |

Yes, stringing/oozing and blobs of plastic breaking off and getting pushed around by the head are the problems I was fighting. I should get the roll out and try some more, I haven't used it in quite a while. I'd like to get a roll in a matte colour - I bought all my first rolls in 'natural' thinking it would have the best chance of printing well without any additives, but I find the transparent filaments very difficult to see the details of individual layers for judging extrusion.

|

Re: At my wits end with PETG March 13, 2016 11:04AM |

Registered: 8 years ago Posts: 260 |

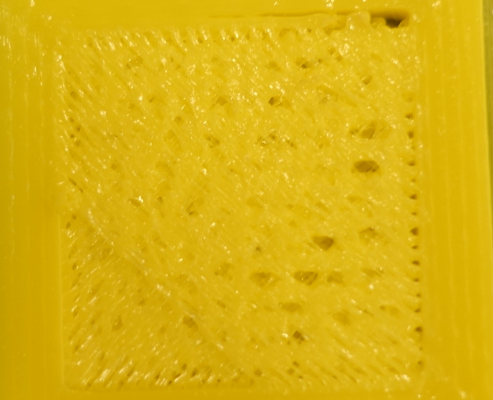

Not bad

But :-)

The wall is not solid, every where ?

and infill sometimes bad

I will increase retract, I even read that people use 6mm retract with 3mm filament

I now have 90% filament multiplier to keep the nozzle clean. ( not succeeding ) ( feeding is calibrated with PLA ) And PLA multiplier is 1, needs to be a little bit lower ~2% )

I think the extrude extrudes more PETG than PLA with the same number of steps.

I also decreased infill/perimeters overlap to 0, that shows.

Maybe I shout polish the outside of the nozzle to mirror shine.

The big problem is directional changes, the filament keeps flowing, and then you have to much. Maybe smaller nozzle, now use 0.4

But :-)

The wall is not solid, every where ?

and infill sometimes bad

I will increase retract, I even read that people use 6mm retract with 3mm filament

I now have 90% filament multiplier to keep the nozzle clean. ( not succeeding ) ( feeding is calibrated with PLA ) And PLA multiplier is 1, needs to be a little bit lower ~2% )

I think the extrude extrudes more PETG than PLA with the same number of steps.

I also decreased infill/perimeters overlap to 0, that shows.

Maybe I shout polish the outside of the nozzle to mirror shine.

The big problem is directional changes, the filament keeps flowing, and then you have to much. Maybe smaller nozzle, now use 0.4

|

Re: At my wits end with PETG March 13, 2016 11:25AM |

Registered: 8 years ago Posts: 260 |

I really think that I am under extruding now

But it is still very strong

and getting them of the bed was very difficult during printing 70 degrees, cooled down 25

Edited 1 time(s). Last edit at 03/13/2016 11:30AM by amigob.

But it is still very strong

and getting them of the bed was very difficult during printing 70 degrees, cooled down 25

Edited 1 time(s). Last edit at 03/13/2016 11:30AM by amigob.

|

Re: At my wits end with PETG March 13, 2016 03:12PM |

Registered: 8 years ago Posts: 260 |

Got big problems to let it stick to the bed, so I just got the blue tape out and reduced bed temperature to 60c

Going resanble wel, need to remove some ex aces filament from the nozzle now and then, baby sitting :-)

Going resanble wel, need to remove some ex aces filament from the nozzle now and then, baby sitting :-)

|

Re: At my wits end with PETG March 13, 2016 03:44PM |

Registered: 8 years ago Posts: 260 |

And then the infill at 80mm/s it just didn't stick

I need to slow down, for PETG :-)

Edited 1 time(s). Last edit at 03/13/2016 03:48PM by amigob.

I need to slow down, for PETG :-)

Edited 1 time(s). Last edit at 03/13/2016 03:48PM by amigob.

|

Re: At my wits end with PETG March 13, 2016 05:47PM |

Registered: 8 years ago Posts: 260 |

It is going in the right direction, but a lot is about reducing speed en decreasing acceleration

overlap = 15% again

Acceleration to 1000mm/s^2

infill 60%

shell = 50mm/s

infill = 60mm/s

Start of the shell is not going ok, but a lot less then with high acceleration ( give the PETG time to stick

first layer

Infill messy

outer shell

I think I have to reduce temperature of not 1 layer layers is now 235 I will reduce to 225,

first layer is 245, fan is on when doing infill ( set to auto slil3r )

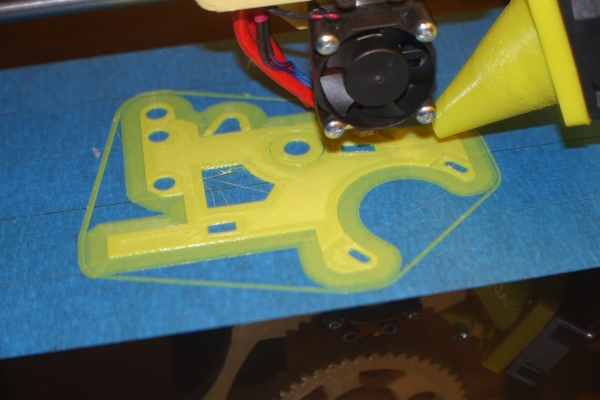

Tomorrow a new try of my low wight dual wades :-)

Edited 1 time(s). Last edit at 03/13/2016 05:51PM by amigob.

overlap = 15% again

Acceleration to 1000mm/s^2

infill 60%

shell = 50mm/s

infill = 60mm/s

Start of the shell is not going ok, but a lot less then with high acceleration ( give the PETG time to stick

first layer

Infill messy

outer shell

I think I have to reduce temperature of not 1 layer layers is now 235 I will reduce to 225,

first layer is 245, fan is on when doing infill ( set to auto slil3r )

Tomorrow a new try of my low wight dual wades :-)

Edited 1 time(s). Last edit at 03/13/2016 05:51PM by amigob.

|

Re: At my wits end with PETG March 13, 2016 05:55PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: At my wits end with PETG March 14, 2016 03:16AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: At my wits end with PETG March 14, 2016 03:38AM |

Registered: 8 years ago Posts: 260 |

|

Re: At my wits end with PETG March 15, 2016 11:06AM |

Registered: 8 years ago Posts: 260 |

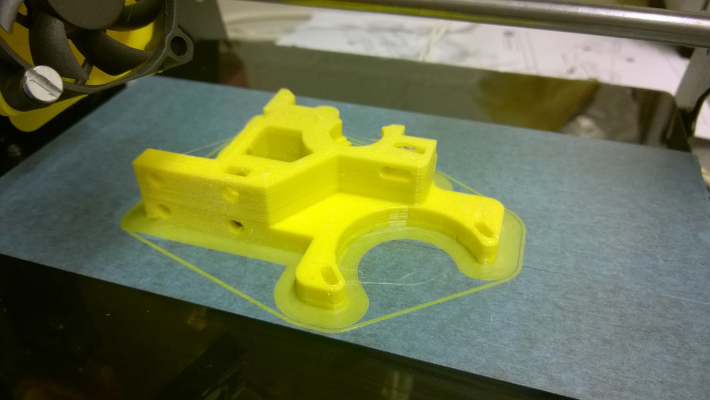

it is going the right way,

I stopped the print because my stl was not complete support for the baring gap was not in the STL

But when stopping it I saw that I was printing at 275 degrees, oeps. I made a type in the slicer 345 iso 245.

It didn't do bad :-) no pollution on the nozzle.

So I will increase first layer temperature to 255, because I had still problems with the first layer I even reduced the acceleration to 500mm//s^2 and overlap to 25%. PETG needs some thing to stick to when doing small infills.

But with a bed temperature of 90 degrees the object says flexible.

I did some design changes and I will go to 7 perimeters so that I don't have the 1.5mm zigzag move.

I also think that I am going to do 100% infill, it seems to go way better then 60 or 70% in fill.

Edited 1 time(s). Last edit at 03/15/2016 11:07AM by amigob.

I stopped the print because my stl was not complete support for the baring gap was not in the STL

But when stopping it I saw that I was printing at 275 degrees, oeps. I made a type in the slicer 345 iso 245.

It didn't do bad :-) no pollution on the nozzle.

So I will increase first layer temperature to 255, because I had still problems with the first layer I even reduced the acceleration to 500mm//s^2 and overlap to 25%. PETG needs some thing to stick to when doing small infills.

But with a bed temperature of 90 degrees the object says flexible.

I did some design changes and I will go to 7 perimeters so that I don't have the 1.5mm zigzag move.

I also think that I am going to do 100% infill, it seems to go way better then 60 or 70% in fill.

Edited 1 time(s). Last edit at 03/15/2016 11:07AM by amigob.

|

Re: At my wits end with PETG March 15, 2016 03:54PM |

Registered: 8 years ago Posts: 319 |

Well I like PETG more than PLA. I have major issues with PLA sticking to a glass bed. So I have to use Kapton tape. Well then I switched to an IR sensor so I had to remove the tape and clean the glass everytime. If I use gluesticks, I had to clean the glass bed everytime as wellI gave up with PLA. Moved to PETG. It sticks to the glass plate way too well. It actually pulled off glass from it one time when I heated it to 110deg. So the trick with PETG is what everyone is saying, Slow down.

My hotened temp is 235 to 238. Fan is the enemy of PETG. At least for me. The only time I use a fan is for bridging. Otherwise I lower the temp of the nozzle and use NO fan. If I do use the fan you have to increase the nozzle temp a bit. My bed temp is now 73deg C.

I said this in another post. The most important thing for any print is the nozzle height esp for PETG. What I did to compensate for the z height is add a full thickness 1st layer. ie 0.4mm thickness for my .4mm nozzle. After that the PETG will stick to itself really well. But you cant have the fan blowing on it or the adhesion is terrible because it will cool to fast. If you want impossible adhesion make the nozzle -.05 to -.1. This will adhere to the bed so well that it will tear glass off of it. I only do this when I make a large part so that there is no chance of warping. This is especially true of a 6hr long print. I dont want any warping to happen 4hrs into the print and ruin the project.

Just my notes. I am no expert but I love PETG.

Edited 1 time(s). Last edit at 03/15/2016 03:55PM by DRTak.

My hotened temp is 235 to 238. Fan is the enemy of PETG. At least for me. The only time I use a fan is for bridging. Otherwise I lower the temp of the nozzle and use NO fan. If I do use the fan you have to increase the nozzle temp a bit. My bed temp is now 73deg C.

I said this in another post. The most important thing for any print is the nozzle height esp for PETG. What I did to compensate for the z height is add a full thickness 1st layer. ie 0.4mm thickness for my .4mm nozzle. After that the PETG will stick to itself really well. But you cant have the fan blowing on it or the adhesion is terrible because it will cool to fast. If you want impossible adhesion make the nozzle -.05 to -.1. This will adhere to the bed so well that it will tear glass off of it. I only do this when I make a large part so that there is no chance of warping. This is especially true of a 6hr long print. I dont want any warping to happen 4hrs into the print and ruin the project.

Just my notes. I am no expert but I love PETG.

Edited 1 time(s). Last edit at 03/15/2016 03:55PM by DRTak.

|

Re: At my wits end with PETG March 15, 2016 04:37PM |

Registered: 8 years ago Posts: 260 |

|

Re: At my wits end with PETG March 16, 2016 06:32AM |

Registered: 8 years ago Posts: 155 |

Hi All. I would like some help with petg, please correct me if Im wrong:

1.- Pla starts to soften at low temperatures, ABS is more resistant to this, but can it be posible that, despite petg fusion temperature is around 230-250 (way higher than PLA), it starts to soften also at low temperatures? even lower than ABS ????? Would this explain why is ssomehow difficult to use petg with all metal hotends?

2- I have read thatn low speeds should be used. What do you mean with low speed? I have read people printing at 100mm/s ??!!!!! but someone speaks of 15 mm/s

thanks in advance,

Martin

1.- Pla starts to soften at low temperatures, ABS is more resistant to this, but can it be posible that, despite petg fusion temperature is around 230-250 (way higher than PLA), it starts to soften also at low temperatures? even lower than ABS ????? Would this explain why is ssomehow difficult to use petg with all metal hotends?

2- I have read thatn low speeds should be used. What do you mean with low speed? I have read people printing at 100mm/s ??!!!!! but someone speaks of 15 mm/s

thanks in advance,

Martin

|

Re: At my wits end with PETG March 16, 2016 06:57AM |

Registered: 8 years ago Posts: 260 |

1. I have no experiments with really using PETG in an application yet. But When I stop a PETG print the complete object could be bend ( so still soft )

I expect that the object was around 80 to 90 degrees. So to my opinion it can't handle heat that well. But I will try to use the new narrow ( wades type ) extruder with the e3D v6 so we will know. I don't know how warm the E3D becomes at the mounting point ( still need to buy a temperature meter gun )

2 my first layer is now printed at 20mm/s ( I call that slow) . Inner perimeters and infill at 50mm/s and outer 30 mm/s. My acceleration is now 500mm/s^2

I think at this moment the low acceleration is making printing PETG possible for me. I also use 20% overlap, The first layer still has problems attaching to the heatbed ( blue tape ). Removing it was not that big problem the extruder came of with the tape. When it was cooled down I already saw that the tape was pulled of the glass plate because I saw air bubbles underneath the tape.

it looks reasonably good , it feels very strong. I didn't fit the bearings yet, but I think the fit very tight. I had to drill the filament hole a little bit.

When I print the rest of the parts I will use no tape and the first layer method that DRTak mentioned

Edited 1 time(s). Last edit at 03/16/2016 06:58AM by amigob.

I expect that the object was around 80 to 90 degrees. So to my opinion it can't handle heat that well. But I will try to use the new narrow ( wades type ) extruder with the e3D v6 so we will know. I don't know how warm the E3D becomes at the mounting point ( still need to buy a temperature meter gun )

2 my first layer is now printed at 20mm/s ( I call that slow) . Inner perimeters and infill at 50mm/s and outer 30 mm/s. My acceleration is now 500mm/s^2

I think at this moment the low acceleration is making printing PETG possible for me. I also use 20% overlap, The first layer still has problems attaching to the heatbed ( blue tape ). Removing it was not that big problem the extruder came of with the tape. When it was cooled down I already saw that the tape was pulled of the glass plate because I saw air bubbles underneath the tape.

it looks reasonably good , it feels very strong. I didn't fit the bearings yet, but I think the fit very tight. I had to drill the filament hole a little bit.

When I print the rest of the parts I will use no tape and the first layer method that DRTak mentioned

Edited 1 time(s). Last edit at 03/16/2016 06:58AM by amigob.

|

Re: At my wits end with PETG March 16, 2016 08:01AM |

Registered: 8 years ago Posts: 319 |

Quote

Tinchus

Hi All. I would like some help with petg, please correct me if Im wrong:

1.- Pla starts to soften at low temperatures, ABS is more resistant to this, but can it be posible that, despite petg fusion temperature is around 230-250 (way higher than PLA), it starts to soften also at low temperatures? even lower than ABS ????? Would this explain why is ssomehow difficult to use petg with all metal hotends?

2- I have read thatn low speeds should be used. What do you mean with low speed? I have read people printing at 100mm/s ??!!!!! but someone speaks of 15 mm/s

thanks in advance,

Martin

1. I think you have to use a metal hotend for PETG. It requires temps above 230deg unlike PLA. I print PLA at 190.

2. Low speed is 15 to 50mm/s. 100 is PLA speed way too fast. You can adjust up from there. I adjusted to 43mm/s after testing a bunch of prints. I was trying to speed up print times.

|

Re: At my wits end with PETG March 16, 2016 08:28AM |

Registered: 9 years ago Posts: 1,873 |

Petg has a fair bit of flex even when cold, so if you need a very rigid structure you need to design it with more bulk than for a stiffer plastic like pla. Same for nylon. The flexibility makes it next to impossible to snap into pieces though, so you get a lot of strength in trade for the reduced stiffness. The main reason I'm setting up a dual extruder is so that I can try composites of plastics to get the best of both worlds.

|

Re: At my wits end with PETG March 16, 2016 08:44AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: At my wits end with PETG March 16, 2016 12:21PM |

Registered: 8 years ago Posts: 319 |

Quote

JamesK

Quote

I think you have to use a metal hotend for PETG.

I was printing it at 250C with a ptfe liner. I haven't tried it in an all metal hotend yet.

Well, the ptfe liner in my nozzle melts above 260 deg. So I just have a little bit left in the inner bore. But I have removed it from touching the nozzle. I only left it in there for PLA.

JamesK. I just saw a video of PETG and taulman Nylon alloy 910. It looks like they have the same properties and PETG is cheaper. I really wanted Nylon Bridge but its way too flexible according to the reviews. Only difference is Alloy 910 is hard to break.

Right now, my PETG is crackling. I think it has absorbed too much moisture. But not much you can do when its attached to your printer for prints.

Sorry, only registered users may post in this forum.