|

Holes + Bad Details! Prusa I3 March 05, 2016 11:58PM |

Registered: 8 years ago Posts: 49 |

Hi,

Thank you all for your useful contributions. I have learned a lot by reading other posts and comments.

There is another "holes" thread just a few posts below me, but that problem did not have a photo and I was unable to compare that with mine so I am posting my own question.

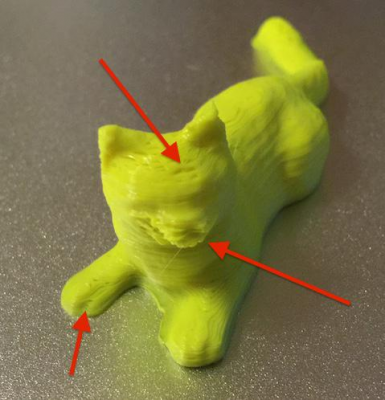

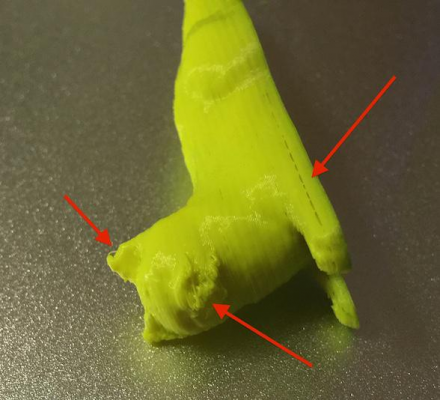

While my printer is fine with stuff like parts that are made up of rectangles and cubes, I do not have much success when it comes to items that are of different shapes and require detail. I encounter holes and gaps when printing such items. For example, I just printed the following: [www.thingiverse.com]. I have attached photos for reference. As you can see the face of the cat is almost unidentifiable. The printer extruded plastic but the plastic instead just curled up and caused a hole! At other locations such as the legs, you can see a horizontal gap line. And one of the ears is just... weird..

I print with PLA on a heated bed @ 70degrees. The extrusion temp for the cat print was 190. I have previously printed with 185, 200, and 205. So far, however, 190 has been better than the other temps.

What could be causing this? Any thoughts on how to fix this issue? I am starting to think perhaps the plastic quality is not good...

Thanks!!

Thank you all for your useful contributions. I have learned a lot by reading other posts and comments.

There is another "holes" thread just a few posts below me, but that problem did not have a photo and I was unable to compare that with mine so I am posting my own question.

While my printer is fine with stuff like parts that are made up of rectangles and cubes, I do not have much success when it comes to items that are of different shapes and require detail. I encounter holes and gaps when printing such items. For example, I just printed the following: [www.thingiverse.com]. I have attached photos for reference. As you can see the face of the cat is almost unidentifiable. The printer extruded plastic but the plastic instead just curled up and caused a hole! At other locations such as the legs, you can see a horizontal gap line. And one of the ears is just... weird..

I print with PLA on a heated bed @ 70degrees. The extrusion temp for the cat print was 190. I have previously printed with 185, 200, and 205. So far, however, 190 has been better than the other temps.

What could be causing this? Any thoughts on how to fix this issue? I am starting to think perhaps the plastic quality is not good...

Thanks!!

|

Re: Holes + Bad Details! Prusa I3 March 06, 2016 08:15AM |

Registered: 9 years ago Posts: 1,873 |

Do you have a fan to cool the printed part? PLA suffers from heat build up in the print which is a lot easier to control if you have a well directed fan (or two) that can cool the print.

What speed are you printing at? Many ills can be cured by dropping the speed. For a test you could try printing the whole model at 15 mm/s and see if it improves.

That model doesn't seem to contain a whole lot of detail, so don't expect more than is there to print. I'm not sure if the second picture on the thingiverse page is a print or the original thing that he scanned perhaps. Either way it has more detail in it than the model, so if it's a print it's been post processed. Compare your prints with other peoples in the 'made' tab.

Small detail is also hard if you are using a larger nozzle diameter. You can move things in your favour by scaling up the model, as long as you don't mind a bigger print

The gaps are interesting. I'm not sure what might be causing this. Does the hotend pop, sizzle or hiss at all during the print? That would be a sign of too much moisture in the filament.

What speed are you printing at? Many ills can be cured by dropping the speed. For a test you could try printing the whole model at 15 mm/s and see if it improves.

That model doesn't seem to contain a whole lot of detail, so don't expect more than is there to print. I'm not sure if the second picture on the thingiverse page is a print or the original thing that he scanned perhaps. Either way it has more detail in it than the model, so if it's a print it's been post processed. Compare your prints with other peoples in the 'made' tab.

Small detail is also hard if you are using a larger nozzle diameter. You can move things in your favour by scaling up the model, as long as you don't mind a bigger print

The gaps are interesting. I'm not sure what might be causing this. Does the hotend pop, sizzle or hiss at all during the print? That would be a sign of too much moisture in the filament.

|

Re: Holes + Bad Details! Prusa I3 March 06, 2016 07:34PM |

Registered: 8 years ago Posts: 49 |

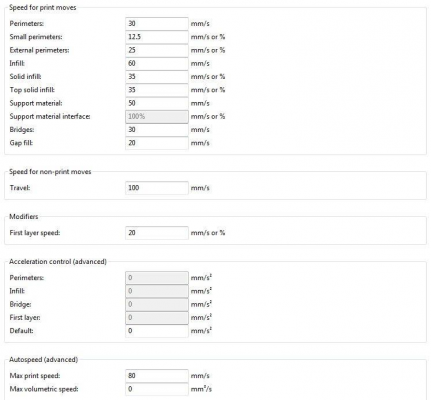

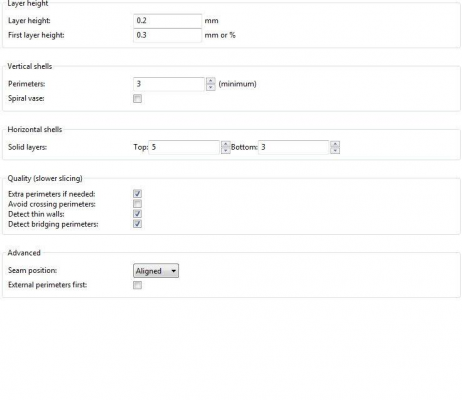

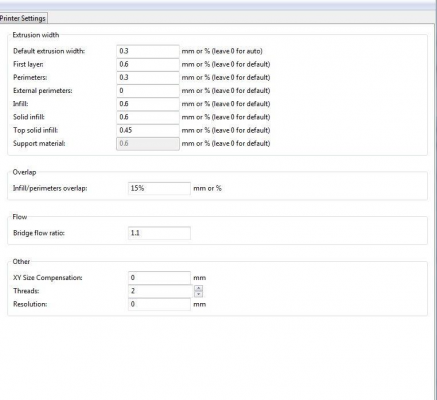

Ah! I see. I am not sure how the speed really works in slic3r and hence I have not changed the speed settings from default. I have it attached for you to review.

In terms of the fan, yes I do have a fan. But for that, as well, I have not touched the settings as I have no idea which setting works and how it works... It is the default @ Automatic cooling min 35%- max 100%. Bridges fan speed is 100% and not active for the first 3 layers.

Cooling threshold is: enable fan is layer print time is below: 60seconds. And Slow down if layer print time is below 5seconds. Min print speed is 10mm/s.

My nozzle size is 0.30mm. I think that should be good enough to at least print the face of my car properly But you are right, the second photo of the cat is indeed the object he scanned.

But you are right, the second photo of the cat is indeed the object he scanned.

I do not hear any pop, sizzle or hiss during prints. It should be noted that I experience the same horizontal gaps when printing with ABS as well so it should be a setting problem of some sort.

Let me know what you think.

In terms of the fan, yes I do have a fan. But for that, as well, I have not touched the settings as I have no idea which setting works and how it works... It is the default @ Automatic cooling min 35%- max 100%. Bridges fan speed is 100% and not active for the first 3 layers.

Cooling threshold is: enable fan is layer print time is below: 60seconds. And Slow down if layer print time is below 5seconds. Min print speed is 10mm/s.

My nozzle size is 0.30mm. I think that should be good enough to at least print the face of my car properly

But you are right, the second photo of the cat is indeed the object he scanned.

But you are right, the second photo of the cat is indeed the object he scanned.I do not hear any pop, sizzle or hiss during prints. It should be noted that I experience the same horizontal gaps when printing with ABS as well so it should be a setting problem of some sort.

Let me know what you think.

|

Re: Holes + Bad Details! Prusa I3 March 06, 2016 07:55PM |

Registered: 9 years ago Posts: 1,873 |

Ok, those speeds all look very reasonable, so I don't think the problem is there. I can't think of anything in the software that would cause random gaps like you are seeing, so I think it's more likely to be a mechanical problem. It might be worth making a mark with a sharpie across the end of the extruder motor shaft onto the drive gear so that you can check if the gear is slipping - that might be the sort of problem we're looking for.

Can you post a photo of the print head so we can see how the cooling fan is set up? From what you described, I would have expected the cooling to be more effective than it appears from the prints.

Can you post a photo of the print head so we can see how the cooling fan is set up? From what you described, I would have expected the cooling to be more effective than it appears from the prints.

|

Re: Holes + Bad Details! Prusa I3 March 06, 2016 10:48PM |

Registered: 8 years ago Posts: 49 |

Can you please elaborate on the sharpie method a bit? I am not sure where to put the marks. I have done it for measuring the amount of extrusion as per calibration guides but I am not sure how I could utilize the method to check the gear for slipping. I know my motor used to make clicking noises and not extrude enough, which then I fixed by increasing the voltage and increasing the Z-offset.

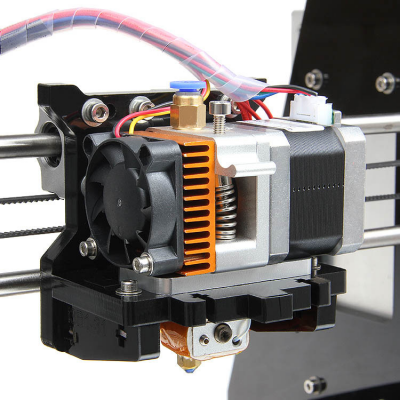

As for my extruder set-up, I have attached a stock photo of my printer from the manufacturer. I have not touched anything, but I will soon have to print an addition part to mount the auto-level sensor to and set that up. Do I need further fans? I could purchase one or two if required.

Thanks for your help again! Really appreciate it!

As for my extruder set-up, I have attached a stock photo of my printer from the manufacturer. I have not touched anything, but I will soon have to print an addition part to mount the auto-level sensor to and set that up. Do I need further fans? I could purchase one or two if required.

Thanks for your help again! Really appreciate it!

|

Re: Holes + Bad Details! Prusa I3 March 07, 2016 04:33AM |

Registered: 10 years ago Posts: 550 |

If you did not change any settings, what setting are you using for layer height and width?Quote

devilmostwanted

Ah! I see. I am not sure how the speed really works in slic3r and hence I have not changed the speed settings from default. I have it attached for you to review.

In terms of the fan, yes I do have a fan. But for that, as well, I have not touched the settings as I have no idea which setting works and how it works...

|

Re: Holes + Bad Details! Prusa I3 March 07, 2016 06:59AM |

Registered: 9 years ago Posts: 1,873 |

Ah, OK. For the MK8 extruder style that you have, seeing the end of the motor shaft is a pain. You have to take the fan and heatsink off, then you will be able to see both the end of the shaft and the gear and you can put a witness mark with either a sharpie or a sharp point that shows the alignment. You'd have to put it all back together again, run some prints and then take it apart to check if the lines were still aligned. A pain I know. The other thing you can look for when you take it apart is that one of the two set screws should be against the flat part of the shaft. If it isn't, the gear is probably slipping, you could remove it and look for marks left by the screws as they drag on the shaft, or you could just re-align it so that one of the screws is on the flat and then tighten the setscrews again. It's difficult to give guidance on how tight the set screws need to be, but most people tend to under-tighten, so slipping gears are common. On the other hand, you don't want to strip the thread on the gears. You need the screws as tight as possible without stripping the thread, which takes some experience or ideally a mini torque-wrench (I don't have one, I don't think many people do!).

The fan you have in the picture is just for cooling the extruder. It needs to be connected directly to the 12v power and should run all the time. You'll need another fan for blowing on the print, and that's the one that should be under software control.

Edited 1 time(s). Last edit at 03/07/2016 06:59AM by JamesK.

The fan you have in the picture is just for cooling the extruder. It needs to be connected directly to the 12v power and should run all the time. You'll need another fan for blowing on the print, and that's the one that should be under software control.

Edited 1 time(s). Last edit at 03/07/2016 06:59AM by JamesK.

|

Re: Holes + Bad Details! Prusa I3 March 07, 2016 12:34PM |

Registered: 8 years ago Posts: 49 |

Frans@France, thanks for your reply. I have attached layer height and width settings for you.

And James, thanks again. I did the sharpie test and I did not see any slippage, so the problem should not be from there.

In terms of the fan, I did not know it was just for the extruder!!! I mean there is so much flow coming from that to under my hot-end that I just thought maybe that works as the cooling fan as well! I found an old 60mm CPU fan from years ago and I am going to wire it to my board. Is 60mm a good size? Or should I go buy a 40mm? And do I point it directly at my print? I'd have to sit down and design a fan holder now! Let me know what you think!

And James, thanks again. I did the sharpie test and I did not see any slippage, so the problem should not be from there.

In terms of the fan, I did not know it was just for the extruder!!! I mean there is so much flow coming from that to under my hot-end that I just thought maybe that works as the cooling fan as well! I found an old 60mm CPU fan from years ago and I am going to wire it to my board. Is 60mm a good size? Or should I go buy a 40mm? And do I point it directly at my print? I'd have to sit down and design a fan holder now! Let me know what you think!

|

Re: Holes + Bad Details! Prusa I3 March 07, 2016 01:44PM |

Registered: 9 years ago Posts: 1,873 |

Ok, well good to have ruled out a slipping gear. Leaves us with a mystery for the gaps in the extrusion but hopefully something will turn up.

60mm may be a bit cumbersome for the part fan, but I'm sure you could make it work. I think 40mm is probably the most common size that people use - take a look on thingiverse to get some ideas. I use a pair of 50mm blower fans and this duct, although it's a bit short for my current setup. Trying out some different fans and duct designs is on the todo list, but almost anything is better than nothing!

Your extruder cooling fan shouldn't spill any air onto the print - you want to try and prevent that if you can. It's interesting, on my mk8's the heatsink was vertical, and the exhaust air went straight up. I also had a slightly larger base plate for the carriage, which probably helped prevent any back draft from the fan going down.

60mm may be a bit cumbersome for the part fan, but I'm sure you could make it work. I think 40mm is probably the most common size that people use - take a look on thingiverse to get some ideas. I use a pair of 50mm blower fans and this duct, although it's a bit short for my current setup. Trying out some different fans and duct designs is on the todo list, but almost anything is better than nothing!

Your extruder cooling fan shouldn't spill any air onto the print - you want to try and prevent that if you can. It's interesting, on my mk8's the heatsink was vertical, and the exhaust air went straight up. I also had a slightly larger base plate for the carriage, which probably helped prevent any back draft from the fan going down.

|

Re: Holes + Bad Details! Prusa I3 March 08, 2016 12:05AM |

Registered: 8 years ago Posts: 49 |

Your set up sounds pretty cool! Those blower fans look pretty serious!!!

I currently have this: [www.thingiverse.com] (the very last photo) printed to mount my sensor which should be arriving any day now (but more help on that most likely when it arrives!). There is already a little hook on top of the part. So now I am trying to design something that I can mount to the little hook on top of the sensor holder. Although the designer has provided a model for the fan, it is meant for 40mm. I may have to either design one myself or replicate the existing model and increase the size to 60mm. I think it should work..

I found a 50mm fan as well but it only has a 2-pin connector, meaning it does not have the signal wire. The signal is important for speed control, no?

Thanks!!

I currently have this: [www.thingiverse.com] (the very last photo) printed to mount my sensor which should be arriving any day now (but more help on that most likely when it arrives!). There is already a little hook on top of the part. So now I am trying to design something that I can mount to the little hook on top of the sensor holder. Although the designer has provided a model for the fan, it is meant for 40mm. I may have to either design one myself or replicate the existing model and increase the size to 60mm. I think it should work..

I found a 50mm fan as well but it only has a 2-pin connector, meaning it does not have the signal wire. The signal is important for speed control, no?

Thanks!!

|

Re: Holes + Bad Details! Prusa I3 March 08, 2016 06:52AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Holes + Bad Details! Prusa I3 March 09, 2016 12:32AM |

Registered: 8 years ago Posts: 49 |

EDIT: Problem was with the board connection. Solved now!

I see,

I temporarily set up something with the 60mm fan to test out how I could control it, yet I had no success.

Specifically, I first connected the + and - (2pin) then went to repetier-host and played around with the "fan" control in the manual control section. It did absolutely nothing. Then I connected the 3rd pin and tried. Again, no success.

How would I control the fan? Turn it on or off even... The 60mm is SO strong that it prevents my heated-bed from reaching the usual 70c temperature that it would normally reach in 5 mins!

Edited 1 time(s). Last edit at 03/09/2016 02:25AM by devilmostwanted.

I see,

I temporarily set up something with the 60mm fan to test out how I could control it, yet I had no success.

Specifically, I first connected the + and - (2pin) then went to repetier-host and played around with the "fan" control in the manual control section. It did absolutely nothing. Then I connected the 3rd pin and tried. Again, no success.

How would I control the fan? Turn it on or off even... The 60mm is SO strong that it prevents my heated-bed from reaching the usual 70c temperature that it would normally reach in 5 mins!

Edited 1 time(s). Last edit at 03/09/2016 02:25AM by devilmostwanted.

|

Re: Holes + Bad Details! Prusa I3 March 09, 2016 06:17AM |

Registered: 8 years ago Posts: 18 |

|

Re: Holes + Bad Details! Prusa I3 March 11, 2016 06:22PM |

Registered: 8 years ago Posts: 49 |

Hi Danikin,

The problem is solved.

The fan now works. But NOW i have another (i think) problem. I noticed during prints my extruder fan goes off and on randomly and I can actually hear its speed changing. Is this a normal behaviour? I had never noticed it before. I checked my Gcode and the only "Fan" there is the PWM fan that I just installed...Could it be a bad board? Power supply? Maybe my new fan is sucking too much power from the board? Help!

The problem is solved.

The fan now works. But NOW i have another (i think) problem. I noticed during prints my extruder fan goes off and on randomly and I can actually hear its speed changing. Is this a normal behaviour? I had never noticed it before. I checked my Gcode and the only "Fan" there is the PWM fan that I just installed...Could it be a bad board? Power supply? Maybe my new fan is sucking too much power from the board? Help!

|

Re: Holes + Bad Details! Prusa I3 March 11, 2016 07:36PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Holes + Bad Details! Prusa I3 March 11, 2016 09:47PM |

Registered: 8 years ago Posts: 49 |

Quote

JamesK

No, not normal. Where is the extruder fan connected? If you have it connected to the psu 12v then possibly you have a broken/intermittent wire.

Everything gets power from the board itself. And the board gets power from PSU.

Okay further investigation shows frequent voltage drops on my board. I checked and my fans usually get about 10.50v, but every minute or so this voltage drops to 9.70-9.80 and then back up to 10.50 in 2 seconds. Fans aren't the only part where this voltage change happens. My heated bed keeps going off every few minutes as well and comes back on within seconds (This happens at the same time as when fans get 9.80v).

I should mention that my board was not getting enough power from PSU before. PSU was sending only about 10.8v to my board and hence my heated bed was never able to reach 110c for ABS(it would get stuck on 106c). There is a little switch on my PSU where i can increase the power that PSU sends to the board. I increased it so it is now sending exactly 11.99v. My heated bed problem went away and now I can reach 110 easily within 10 minutes. However, since then I started "noticing" my fan noises get louder and then quieter every few minutes. These may have been there before but I couldn't tell since the printer was weak enough to begin with and the fans were never this loud.

|

Re: Holes + Bad Details! Prusa I3 March 12, 2016 07:16AM |

Registered: 9 years ago Posts: 1,873 |

OK, I'm a little confused. The extruder fan should connect directly to the psu supply, so if you see a different voltage at the fan than at the power supply then something is wrong. If the voltage measured at the power supply changes when nothing is drawing power then something weird is going on and you should replace the power supply. If the voltage at the power supply drops a lot (say more than 0.5V) when the bed turns on then the supply is under powered and you need a bigger one. If the voltage at the power supply remains constant but the power at the bed and fans drops when the bed turns on then you need bigger wires.

It will be difficult to get good prints unless the printer delivers reasonably constant power to the heaters and motors, so this is a good thing to check out.

It will be difficult to get good prints unless the printer delivers reasonably constant power to the heaters and motors, so this is a good thing to check out.

|

Re: Holes + Bad Details! Prusa I3 March 12, 2016 11:28AM |

Registered: 8 years ago Posts: 49 |

The unit I have has a custom board where it receives two 12v inputs from the PSU. Hence it eliminates the need to connect fans directly to the PSU. In fact there is no extra space on the PSU for me to connect anything else.

I did further further investigations! I measured the output of my PSU to the board during and after the heating of extruder and the bed while PWM fan is at full speed. Here are the results:

1. During the heating process PSU provides two consistent streams of 12v (remember board gets two 12v input).

2. Once heating has been completed, the PSU starts to act a bit crazy: it makes clicking and hissing noises every, say 30 seconds, and the voltage (on both outputs) swings from 12 to about 10.90 and then back up. During this time, the LED on the PSU blinks as well.

2.1. When this happens the LED of the bed goes out and I can hear the fans slowing down.

3.I tried to lower the voltage being sent to the board from 12v to 11. Same thing happened but less frequently. Then I lowered it to its original value at 10.80 and the problem went away! Then back up to 12v and problem back!

4. When turning off the printer a hissing sound that lasts about 2 seconds comes from the PSU.

Is it safe to assume that the PSU is dying?

I did further further investigations! I measured the output of my PSU to the board during and after the heating of extruder and the bed while PWM fan is at full speed. Here are the results:

1. During the heating process PSU provides two consistent streams of 12v (remember board gets two 12v input).

2. Once heating has been completed, the PSU starts to act a bit crazy: it makes clicking and hissing noises every, say 30 seconds, and the voltage (on both outputs) swings from 12 to about 10.90 and then back up. During this time, the LED on the PSU blinks as well.

2.1. When this happens the LED of the bed goes out and I can hear the fans slowing down.

3.I tried to lower the voltage being sent to the board from 12v to 11. Same thing happened but less frequently. Then I lowered it to its original value at 10.80 and the problem went away! Then back up to 12v and problem back!

4. When turning off the printer a hissing sound that lasts about 2 seconds comes from the PSU.

Is it safe to assume that the PSU is dying?

|

Re: Holes + Bad Details! Prusa I3 March 12, 2016 11:39AM |

Registered: 9 years ago Posts: 1,873 |

Quote

devilmostwanted

The unit I have has a custom board where it receives two 12v inputs from the PSU. Hence it eliminates the need to connect fans directly to the PSU. In fact there is no extra space on the PSU for me to connect anything else.

Multiple 12v inputs on the control board is normal, but doesn't mean you have to connect everything there. What sort of board is it, and where on the board do you have the extruder fan connected at the moment?

Quote

I did further further investigations! I measured the output of my PSU to the board during and after the heating of extruder and the bed while PWM fan is at full speed. Here are the results:

1. During the heating process PSU provides two consistent streams of 12v (remember board gets two 12v input).

2. Once heating has been completed, the PSU starts to act a bit crazy: it makes clicking and hissing noises every, say 30 seconds, and the voltage (on both outputs) swings from 12 to about 10.90 and then back up. During this time, the LED on the PSU blinks as well.

2.1. When this happens the LED of the bed goes out and I can hear the fans slowing down.

3.I tried to lower the voltage being sent to the board from 12v to 11. Same thing happened but less frequently. Then I lowered it to its original value at 10.80 and the problem went away! Then back up to 12v and problem back!

4. When turning off the printer a hissing sound that lasts about 2 seconds comes from the PSU.

Is it safe to assume that the PSU is dying?

Sure sounds like it is dying to me. I'd order a new one straight away, and don't leave the existing one running un-attended.

Sorry, only registered users may post in this forum.