Problems with Dual Z Axis Drivers

Posted by CTCHunter1

|

Anonymous User

Re: Problems with Dual Z Axis Drivers April 11, 2016 04:18AM |

To modify a Prusa for one Z is easy and it works. I fail to understand why people keep trying desperately to avoid simple solutions for simple problems.

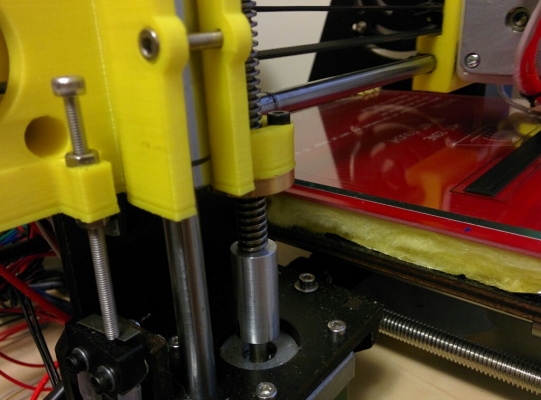

Here what I did on my Geetech plus other things.

Geetech Prusa

So far I have not changed the stepper driver currents except for the extruder which I designed from scratch and has more than 5 times the grip of the supplied MK8 which was slipping.

My X, Y, Z motor steppers are 1A StepStick set to deliver 500mA. Plenty of margin left.

For the extruder, I use a 1.5A Stepstick set to deliver 1A. With a sheet of paper squeezed between nozzle (0.35) and bed at Z 0, PLA 200 °C, it extrudes without problem, pushing the bed and oozing on the side without loosing step.

It took me less time then to implement this funny autobed level with the servo monopod which I confirm is unnecessary for a properly built cheap Prusa and is likely to introduce other problems.

which I confirm is unnecessary for a properly built cheap Prusa and is likely to introduce other problems.

PS: Not everyone seem convinced but facts stay facts.

Edited 1 time(s). Last edit at 04/11/2016 04:32AM by MKSA.

Here what I did on my Geetech plus other things.

Geetech Prusa

So far I have not changed the stepper driver currents except for the extruder which I designed from scratch and has more than 5 times the grip of the supplied MK8 which was slipping.

My X, Y, Z motor steppers are 1A StepStick set to deliver 500mA. Plenty of margin left.

For the extruder, I use a 1.5A Stepstick set to deliver 1A. With a sheet of paper squeezed between nozzle (0.35) and bed at Z 0, PLA 200 °C, it extrudes without problem, pushing the bed and oozing on the side without loosing step.

It took me less time then to implement this funny autobed level with the servo monopod

which I confirm is unnecessary for a properly built cheap Prusa and is likely to introduce other problems.

which I confirm is unnecessary for a properly built cheap Prusa and is likely to introduce other problems.PS: Not everyone seem convinced but facts stay facts.

Edited 1 time(s). Last edit at 04/11/2016 04:32AM by MKSA.

|

Re: Problems with Dual Z Axis Drivers April 11, 2016 06:20AM |

Registered: 9 years ago Posts: 1,873 |

Quote

the_digital_dentist

I read at one manufacturer's site that for gear-belt pulleys, you want a minimum of 6 teeth or a minimum of 90 degrees wrapped, whichever is greater. Make sure the tension is good, too.

Yes, I think I remember seeing that when I did the layout. With around 90 degrees (just slightly over) on a 20 tooth pulley I'm obviously just on the wrong side of the limit, even with relatively light loads and plenty of tension. I never see/hear the belt skip, but then it would have to be a very rare event or the problem would be much worse than it is.

CTC - I haven't seen any signs of the motor missing steps, my problem is just the X axis moving out of alignment with the XY plane. I think my problem is that the construction of my printer is fairly stiff (it's an aluminum & steel rep-strap), and for some reason the natural alignment of the X axis is slightly off, i.e. the position it wants to return to if I disconnect the belt is a little higher on the left than the right. I can bring it into alignment with the screws but it always eventually returns to it's preferred (miss)alignment. I probably need to make a jig to help re-align the entire frame, as well as add the idler. My todo list gets ever longer!

|

Re: Problems with Dual Z Axis Drivers April 11, 2016 11:36PM |

Registered: 8 years ago Posts: 35 |

Quote

JamesK

natural alignment of the X axis is slightly off

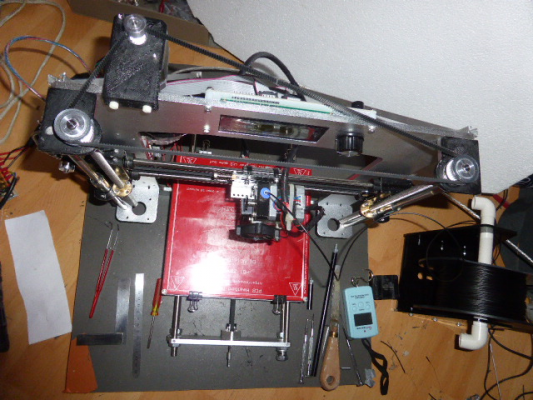

I have the same issues on my P3steel build. Without screws, the right wants to be ~3mm higher than the left z-axis. I think it's from lack of squareness in my x-motor and x-idler z-axis mounts I repraped(3D printed) them with my previous i3 build.

Your on a belt system with one z-axis motor. You can only see the motor missing steps though parts coming out out of spec. in z. It still probably wouldn't be very pronounced. Missing steps in a belt system won't cause misalignment which is the purpose of the belt. It sounds like your printer is large.

I've asking if you've marked your two z-axis couplers or whatever your can mark on the screws of your system. Maybe just mark the screws/threaded rod. It seems impossible for the axis to drift out alignment unless those screws also drift. When I was having z-axis problems on my build they were drifting.

I'm pretty happy with the results I've been getting with 2 a-axis drivers, full DRV8825 32 microsteping, & repetier firmeware. My part is finally in spec. in Z. It took 15th print attempts to get this which lead to diagnosing and fixing of this issue. My marks on my z-axis couplers are aligned after the print. I've turned the the current on the DRV8825s to .85 Vref or 1.7 A and everything is good. I can probably still go lower.

Edited 7 time(s). Last edit at 04/11/2016 11:59PM by CTCHunter1.

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 04:12AM |

Registered: 8 years ago Posts: 260 |

I will solve this miss alignment later on in Repetier, maybe I really need to start my own fork.

I will just use the mini infrared height sensor, at the start of a print to align the bed with the X axes.

With some smart mathematics and doing 2 prob's one left and one right should do the job.

To do the smart mathematics you need to know the distances of the two screw leads , and the distances of the sensor to the left screw lead at home position.

With some trigonometry I can make the X axes move parallel to the bed. So the calculation will not be the same for every prusa.

Mhh, think of it with 3 prob's, left, right, left ( left one is the same position but after a correction on the right screw is done ), I probably can do it without the dimensions

of the printer. Because then I can measure/calculate the effect on the left measure position, when right screw lead was adjusted.

Edited 1 time(s). Last edit at 04/12/2016 04:14AM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

I will just use the mini infrared height sensor, at the start of a print to align the bed with the X axes.

With some smart mathematics and doing 2 prob's one left and one right should do the job.

To do the smart mathematics you need to know the distances of the two screw leads , and the distances of the sensor to the left screw lead at home position.

With some trigonometry I can make the X axes move parallel to the bed. So the calculation will not be the same for every prusa.

Mhh, think of it with 3 prob's, left, right, left ( left one is the same position but after a correction on the right screw is done ), I probably can do it without the dimensions

of the printer. Because then I can measure/calculate the effect on the left measure position, when right screw lead was adjusted.

Edited 1 time(s). Last edit at 04/12/2016 04:14AM by amigob.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 07:33AM |

Registered: 11 years ago Posts: 5,780 |

What you have described is EXACTLY the problem with dual motor Z axes. Adjusting the X axis to the bed is perfectly wrong! The X axis has to be orthogonal to the Z axis. If you tweak the X axis to match the bed (like certain people at the makerspace keep doing in spite of having it explained to them about 100 times) it may not be orthogonal to the Z axis. The bed should be leveled relative to the X and Y axes. If the axes (all of them) are not orthogonal you cannot print accurately shaped and sized items. If your prints aren't accurately shaped and sized you'll be limited to printing Yoda heads and tugboats. Even the most hardcore Starwars fan gets tired of that eventually and wants to print something else.

Autoleveling won't help either. Autoleveling assumes the axes are orthogonal. If the X axis tilts, you may get the first layer to stick with autoleveling but the print will not be accurately shaped or sized.

Properly aligning the X axis to the Z axis requires printing a rectangular part and measuring the diagonals. When the diagonals in the XZ plane measure the same, the axes are orthogonal. With a dual motor setup, you can never be sure that that relationship will last. Some uninformed or willfully ignorant person may come along and twist one of the screws manually to "level" the bed, or some electrical or mechanical problem may cause the screws to lose sync and tilt the axis.

TLDR: Dual motor Z axes suck!

Edited 1 time(s). Last edit at 04/12/2016 07:33AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Autoleveling won't help either. Autoleveling assumes the axes are orthogonal. If the X axis tilts, you may get the first layer to stick with autoleveling but the print will not be accurately shaped or sized.

Properly aligning the X axis to the Z axis requires printing a rectangular part and measuring the diagonals. When the diagonals in the XZ plane measure the same, the axes are orthogonal. With a dual motor setup, you can never be sure that that relationship will last. Some uninformed or willfully ignorant person may come along and twist one of the screws manually to "level" the bed, or some electrical or mechanical problem may cause the screws to lose sync and tilt the axis.

TLDR: Dual motor Z axes suck!

Edited 1 time(s). Last edit at 04/12/2016 07:33AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 07:58AM |

Registered: 8 years ago Posts: 260 |

I think you don't understand what I want to correct.

It is no replacement for badly setup Prusa's or ABL

You still have to setup your system Bed to Z orthogonal.

Because we use 2 steppers for Z sometimes the sync is lost . I have to redo the Z axes ones in two weeks, for instance if I press the reset button on a Z move.

Because I use 2 drivers I can restore this using the height sensor. Normally it only takes me a few minutes using feeler gauges, so no problem.

But detecting that there is a problem is mostly done when the print is started ( first layer bad )

What I will make is just restore the correct relation between left and right lead screw. It will just bring the X axes and bed parallel again.

I already have the height sensor so why not us it. using the the IR height sensor will be 15 sec or so and can be done when I heat up the bed.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

It is no replacement for badly setup Prusa's or ABL

You still have to setup your system Bed to Z orthogonal.

Because we use 2 steppers for Z sometimes the sync is lost . I have to redo the Z axes ones in two weeks, for instance if I press the reset button on a Z move.

Because I use 2 drivers I can restore this using the height sensor. Normally it only takes me a few minutes using feeler gauges, so no problem.

But detecting that there is a problem is mostly done when the print is started ( first layer bad )

What I will make is just restore the correct relation between left and right lead screw. It will just bring the X axes and bed parallel again.

I already have the height sensor so why not us it. using the the IR height sensor will be 15 sec or so and can be done when I heat up the bed.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 08:36AM |

Registered: 9 years ago Posts: 1,873 |

Quote

Your on a belt system with one z-axis motor. You can only see the motor missing steps though parts coming out out of spec. in z. It still probably wouldn't be very pronounced. Missing steps in a belt system won't cause misalignment which is the purpose of the belt. It sounds like your printer is large.

I've asking if you've marked your two z-axis couplers or whatever your can mark on the screws of your system. Maybe just mark the screws/threaded rod. It seems impossible for the axis to drift out alignment unless those screws also drift. When I was having z-axis problems on my build they were drifting.

Good points. I have witness marks on all the parts of the Z power train, but I was using them to look for slipping joints somewhere in the pulley->bearing block shaft->coupler->lead screw connections. I've never really looked for an absolute position of the marks with respect to a fixed Z height which would show up missing steps. The screws are 8 mm lead, so I rather assumed that missing steps would show up as an obvious irregularity in the Z surface finish, along with inaccurate Z dimensions, but I may have been wrong. I typically print with 0.24mm layers, and a full step is 0.04mm or 17%. My surface finish is far from perfect, so I could believe that an occasional missed Z step could be hiding in there. And other than the first couple of test prints I haven't been actively looking for errors in Z dimensionality. It can't be missing a lot of steps or I would have noticed non-circular holes in the mounting plates that I print with the long axis in Z, but it's possible that it loses a step now and again without me being aware of it. Parts with a lot of retraction using Z hop would probably be most likely to lose steps, and I've had a couple like that recently without signs of trouble. Still, thanks for making me think more on the problem, I'll have to see if I can come up with a more rigorous test for the Z axis!

You mentioned printer size, mine is (currently) just a fairly typical 200mm3 build volume. I just have a tendency to over-build

Edited 1 time(s). Last edit at 04/12/2016 08:37AM by JamesK.

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 08:39AM |

Registered: 11 years ago Posts: 5,780 |

The problem is that on most printers the bed has to be releveled frequently, so using the bed as a reference for the axis alignment is a bad idea. After setting the X axis orthogonal to Z, put collars on the Z axis screws or the rails so that the ends of the X axis are physically stopped when the X axis hits them. Then you could just send the X axis downward and crash it into the stops and and the tilt will correct itself. When the first end of the X axis hits the stop that motor will start slipping. When the second end has hit the stop you know that the X axis is orthogonal to Z again. It will probably be pretty noisy, but it will work and it will only take a second or two to do it after the initial set-up. You could always twist the screws manually if you don't want to "crash" it electrically.

There's still a problem. This procedure guarantees that the X axis will be orthogonal to the Z axis for the first layer, but the tilting that keeps occurring and requiring repositioning the X axis every couple weeks happens when you are printing. That means you may be OK at the start of the print but not at the end. Sometime during a print the screws lose sync and that may or may not wreck your print, depending on how far out of sync they get. You certainly can't trust it. Autoleveling won't help here either because it assumes that the axes are orthogonal and that they stay that way throughout the print.

TLDR: dual Z axis motors suck.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

There's still a problem. This procedure guarantees that the X axis will be orthogonal to the Z axis for the first layer, but the tilting that keeps occurring and requiring repositioning the X axis every couple weeks happens when you are printing. That means you may be OK at the start of the print but not at the end. Sometime during a print the screws lose sync and that may or may not wreck your print, depending on how far out of sync they get. You certainly can't trust it. Autoleveling won't help here either because it assumes that the axes are orthogonal and that they stay that way throughout the print.

TLDR: dual Z axis motors suck.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 08:42AM |

Registered: 8 years ago Posts: 116 |

Quote

the_digital_dentist

What you have described is EXACTLY the problem with dual motor Z axes. Adjusting the X axis to the bed is perfectly wrong! The X axis has to be orthogonal to the Z axis. If you tweak the X axis to match the bed (like certain people at the makerspace keep doing in spite of having it explained to them about 100 times) it may not be orthogonal to the Z axis. The bed should be leveled relative to the X and Y axes. If the axes (all of them) are not orthogonal you cannot print accurately shaped and sized items. If your prints aren't accurately shaped and sized you'll be limited to printing Yoda heads and tugboats. Even the most hardcore Starwars fan gets tired of that eventually and wants to print something else.

Autoleveling won't help either. Autoleveling assumes the axes are orthogonal. If the X axis tilts, you may get the first layer to stick with autoleveling but the print will not be accurately shaped or sized.

Properly aligning the X axis to the Z axis requires printing a rectangular part and measuring the diagonals. When the diagonals in the XZ plane measure the same, the axes are orthogonal. With a dual motor setup, you can never be sure that that relationship will last. Some uninformed or willfully ignorant person may come along and twist one of the screws manually to "level" the bed, or some electrical or mechanical problem may cause the screws to lose sync and tilt the axis.

TLDR: Dual motor Z axes suck!

I have to respectfully disagree. If your premise is that the motors may not do what the gcode tells them to do, then the whole machine is flawed, not just the dual-stepper Z. In theory, a single motor driving two leadscrews via a belt and pulley arrangement is flawed in that the second leadscrew is necessarily going to lag the first due to stretching, backlash, etc. In practice, I doubt this is much of a problem, but then again, in practice (at least in my experience) the dual-stepper Z is not a problem.

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 08:56AM |

Registered: 9 years ago Posts: 1,873 |

Quote

If your premise is that the motors may not do what the gcode tells them to do, then the whole machine is flawed, not just the dual-stepper Z. In theory, a single motor driving two leadscrews via a belt and pulley arrangement is flawed in that the second leadscrew is necessarily going to lag the first due to stretching, backlash, etc. In practice, I doubt this is much of a problem, but then again, in practice (at least in my experience) the dual-stepper Z is not a problem.

All designs are compromises, so the trick is choosing the appropriate compromises for each situation. The Z axis is unusually critical in terms of alignment, so it's a good place to expend extra effort. Even though I'm having some problems with the belt approach I'm still inclined to think it's a good idea - I just didn't execute it very well.

I think the major problem with the two-motor Z axis isn't that the motors don't do what's asked of them, it's that when the motors are off the only thing maintaining the critical alignment is the detent force. With a single motor arrangement alignment is passively maintained even when powered down.

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 08:57AM |

Registered: 8 years ago Posts: 260 |

> dual Z axis motors suck.

I feel some frustration here, and sorry I disagree.

My bed is fixed.

So my bed is the reference, and I don't need to readjust it on my P3steel , I measured it after I vigorously had to remove an printed object. no difference.

> X axis every couple weeks happens when you are printing

So it mist a step that is 0.5mm divided by 200 is a whopping 2.5um, that will keep me awake, come on, really.

and the next print it will be corrected by this simple inline calibration.

Simple thinks can fix a lot of problems.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

I feel some frustration here, and sorry I disagree.

My bed is fixed.

So my bed is the reference, and I don't need to readjust it on my P3steel , I measured it after I vigorously had to remove an printed object. no difference.

> X axis every couple weeks happens when you are printing

So it mist a step that is 0.5mm divided by 200 is a whopping 2.5um, that will keep me awake, come on, really.

and the next print it will be corrected by this simple inline calibration.

Simple thinks can fix a lot of problems.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 09:01AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 11:18AM |

Registered: 8 years ago Posts: 260 |

I mounted a 3mm bold in the blocks that are glued to the glass plate.

Two self-locking nuts ( I whore then down with a tap ) one above the carrier and one below. It is easy to adjust because you can also use tension on the nut for the last 10Um

To level the bed ( orthogonal to Z ) in X I just used a big square ( don't know how it is really called in English )

then get the X axes parallel to the bed and then the single bed mount adjust on the other side with the use of the nozzle spacing with the feeler gauges.

Then adjust the Z end stop, to get the correct Z nozzle height. and done.

Don't forget to check that both Z axes are not having backlash. ( because that is worse than having a small angle between the bed and the Z )

There is a fundamental problem with belt drive for Z also , your lead screw will become part of the rigid system and if it is bend you will see this as a Z wobble. So M5 and M8 are out of the question, the lead screw need to be strait.

The nice thing about the glass plate is still, that all my objects will come loose by it self when it is cooled down, the only way to speed it up is to put a fan on it :-)

.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

Two self-locking nuts ( I whore then down with a tap ) one above the carrier and one below. It is easy to adjust because you can also use tension on the nut for the last 10Um

To level the bed ( orthogonal to Z ) in X I just used a big square ( don't know how it is really called in English )

then get the X axes parallel to the bed and then the single bed mount adjust on the other side with the use of the nozzle spacing with the feeler gauges.

Then adjust the Z end stop, to get the correct Z nozzle height. and done.

Don't forget to check that both Z axes are not having backlash. ( because that is worse than having a small angle between the bed and the Z )

There is a fundamental problem with belt drive for Z also , your lead screw will become part of the rigid system and if it is bend you will see this as a Z wobble. So M5 and M8 are out of the question, the lead screw need to be strait.

The nice thing about the glass plate is still, that all my objects will come loose by it self when it is cooled down, the only way to speed it up is to put a fan on it :-)

.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

|

Anonymous User

Re: Problems with Dual Z Axis Drivers April 12, 2016 05:43PM |

Quote

hoxsiew

Quote

the_digital_dentist

.....

TLDR: !

I have to respectfully disagree. If your premise is that the motors may not do what the gcode tells them to do, then the whole machine is flawed, not just the dual-stepper Z. In theory, a single motor driving two leadscrews via a belt and pulley arrangement is flawed in that the second leadscrew is necessarily going to lag the first due to stretching, backlash, etc. In practice, I doubt this is much of a problem, but then again, in practice (at least in my experience) the dual-stepper Z is not a problem.

Stretching, backlash, on the Z axis ???? with a GT2 belt ???? Can you explain.

I second, digital_dentist "Dual motor Z axes suck"

|

Anonymous User

Re: Problems with Dual Z Axis Drivers April 12, 2016 06:03PM |

Quote

amigob

I mounted a 3mm bold in the blocks that are glued to the glass plate.

Two self-locking nuts ( I whore then down with a tap ) one above the carrier and one below. It is easy to adjust because you can also use tension on the nut for the last 10Um

To level the bed ( orthogonal to Z ) in X I just used a big square ( don't know how it is really called in English )

then get the X axes parallel to the bed and then the single bed mount adjust on the other side with the use of the nozzle spacing with the feeler gauges.

Then adjust the Z end stop, to get the correct Z nozzle height. and done.

Don't forget to check that both Z axes are not having backlash. ( because that is worse than having a small angle between the bed and the Z )

There is a fundamental problem with belt drive for Z also , your lead screw will become part of the rigid system and if it is bend you will see this as a Z wobble. So M5 and M8 are out of the question, the lead screw need to be strait.

The nice thing about the glass plate is still, that all my objects will come loose by it self when it is cooled down, the only way to speed it up is to put a fan on it :-)

.

Leadscrew part of a rigid system ??? Not at all, unless poorly done.

M5 M8 are ALWAYS out of the question for a proper design. IT IS TO BOLT THINGS TOGETHER NOT MOVE THEM !

A leadscrew straightness is part of its specification !

The nuts and leadscrew (T8 8mm lead) I installed have a huge backlash and it doesn't affect my print. Again, just a matter of proper design.

BTW, most of the wobble you get is not just the bent M rods but the screw/coupler gross misalignment. Excessive play because of poor smooth rod too. Most are regular rod, not the real stuff, g6 class and hardened.

Edited 1 time(s). Last edit at 04/12/2016 06:14PM by MKSA.

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 06:06PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 08:53PM |

Registered: 8 years ago Posts: 116 |

I completely re-did mine; trapezoidal leadscrews (T8x2 single start, not 4-start) and rigid couplers and bronze nuts made on a lathe. I machined the ends of the leadscrews down to 5 mm so they butt up to the stepper shaft in the coupler.

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 09:01PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Problems with Dual Z Axis Drivers April 12, 2016 11:39PM |

Registered: 8 years ago Posts: 35 |

Re: the_digital_dentist: aligning axis to bed and my plumb line

Agree, axis should be square. If you were I was out when this thread was started then aligning the axis to the bed after prints can make sense. It's the axis that's drifting out of alignment during the print because one motor is losing sync causing misalignment. Nothing has changed in the bed so just trim the axis back down before starting again.

This was a problem I had on my i3 build too. I was losing steps on one z-axis. It was just impossible to align the flimsy acrylic frame square with the y-carriage. It would bow as well. I went to a P3Steel so that the frame gets me very close to a square and accurate alignment between the x,y, and z axis, particularly the y and z since those rods are laser cut into the steel. The x axis rods are inserted into printed pieces which can be comprised by poor quality.

I had been going crazy trying to get the bed level to the print head. There seems to be slight bow in the middle of my bed but I think it's caused by twist in the x-axis smooth rods. I started using a plumb line, consisting of dental floss and a fender washer, to set the x-axis screws to be square with the y-axis so there is no tilt between it and the y-axis bars. I adjusted the alignment until it barely scraped both y rods moving in x.

After this I would align the flatness on the bed. Later I noticed that I had slight bowing in the steel plate that the bed is screwed to so I plumb lined it to that piece instead.

Everything is staying in sync now. I'm in the process of reprinting the x-idler and x-motor mount on the p3steel now calibrated and in alignment. Maybe this will fix my "bed bowing". I replaced one of my m5 threaded rods today too this time cutting it on a band saw at work instead of with a hack saw at home that bent the heck out of it.

Edited 2 time(s). Last edit at 04/12/2016 11:47PM by CTCHunter1.

Agree, axis should be square. If you were I was out when this thread was started then aligning the axis to the bed after prints can make sense. It's the axis that's drifting out of alignment during the print because one motor is losing sync causing misalignment. Nothing has changed in the bed so just trim the axis back down before starting again.

This was a problem I had on my i3 build too. I was losing steps on one z-axis. It was just impossible to align the flimsy acrylic frame square with the y-carriage. It would bow as well. I went to a P3Steel so that the frame gets me very close to a square and accurate alignment between the x,y, and z axis, particularly the y and z since those rods are laser cut into the steel. The x axis rods are inserted into printed pieces which can be comprised by poor quality.

I had been going crazy trying to get the bed level to the print head. There seems to be slight bow in the middle of my bed but I think it's caused by twist in the x-axis smooth rods. I started using a plumb line, consisting of dental floss and a fender washer, to set the x-axis screws to be square with the y-axis so there is no tilt between it and the y-axis bars. I adjusted the alignment until it barely scraped both y rods moving in x.

After this I would align the flatness on the bed. Later I noticed that I had slight bowing in the steel plate that the bed is screwed to so I plumb lined it to that piece instead.

Everything is staying in sync now. I'm in the process of reprinting the x-idler and x-motor mount on the p3steel now calibrated and in alignment. Maybe this will fix my "bed bowing". I replaced one of my m5 threaded rods today too this time cutting it on a band saw at work instead of with a hack saw at home that bent the heck out of it.

Edited 2 time(s). Last edit at 04/12/2016 11:47PM by CTCHunter1.

|

Re: Problems with Dual Z Axis Drivers April 13, 2016 12:07AM |

Registered: 8 years ago Posts: 116 |

Am I just lucky? I've never had a Z-skip--even when I ran M8x1.25 all-thread. I can print multi-hour long prints for days and every time I "home all" the axes go right where I set them when I last adjusted my z-endstop--and I only ever do that if I take something apart.

Is it different with different boards? I have a GT-2560 knockoff. It has a single pololu board for both z-steppers. They are wired in parallel with two sockets on the main board. I'm running less current on this board than any of the other axes (I haven't calculated the current, but I'm getting about 0.75V on the pot for the z-driver and about 0.9V on the X and Y)

Is it different with different boards? I have a GT-2560 knockoff. It has a single pololu board for both z-steppers. They are wired in parallel with two sockets on the main board. I'm running less current on this board than any of the other axes (I haven't calculated the current, but I'm getting about 0.75V on the pot for the z-driver and about 0.9V on the X and Y)

|

Re: Problems with Dual Z Axis Drivers April 13, 2016 12:26AM |

Registered: 8 years ago Posts: 35 |

An ounce of luck is worth a pound of skill. That's great news. I hope most people never have z-axis problems.

What kind of firmware (Marlin/Repetier) are you/r running the GT-2560?

What is the max current on your z-axis steppers? It's normally marked on side of the motors. Mine is 2.25 A. My understanding is you can have sub optimal performance if you under drive the motors. I'm not sure it's really true.

Have you marked your z-xis couplers? It seems unlikely that you'd be able to rehome to alignment if one axis was drifting though.

Edited 1 time(s). Last edit at 04/13/2016 12:27AM by CTCHunter1.

What kind of firmware (Marlin/Repetier) are you/r running the GT-2560?

What is the max current on your z-axis steppers? It's normally marked on side of the motors. Mine is 2.25 A. My understanding is you can have sub optimal performance if you under drive the motors. I'm not sure it's really true.

Have you marked your z-xis couplers? It seems unlikely that you'd be able to rehome to alignment if one axis was drifting though.

Edited 1 time(s). Last edit at 04/13/2016 12:27AM by CTCHunter1.

|

Anonymous User

Re: Problems with Dual Z Axis Drivers April 13, 2016 03:23AM |

Quote

hoxsiew

I completely re-did mine; trapezoidal leadscrews (T8x2 single start, not 4-start) and rigid couplers and bronze nuts made on a lathe. I machined the ends of the leadscrews down to 5 mm so they butt up to the stepper shaft in the coupler.

It is fine, in line with good practice, but beyond the capabilities in term of equipment and skills required, of most people here.

You solved the mechanical issues but you still have two Z motors which may still become out of synch.

What I did, get rid of the problems without requiring any special tools and using off the shelf components and printed parts.

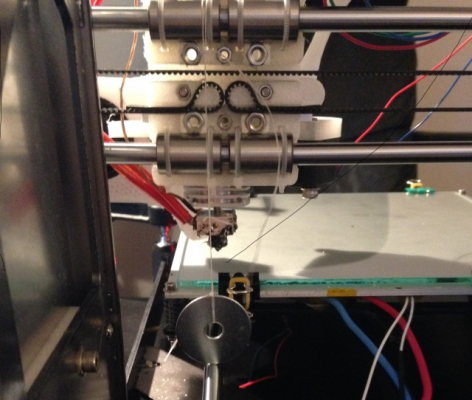

Note that I am now using a 36 t pulley for the motor as for the leadscews. Despite the 8mm lead, my unique Z motor works flawlessly event with I set to 500ma ! I measured the "static" torque to move up, 6 Ncm . Plenty of margin left.

Edited 1 time(s). Last edit at 04/13/2016 03:24AM by MKSA.

|

Re: Problems with Dual Z Axis Drivers April 13, 2016 06:19AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Problems with Dual Z Axis Drivers April 13, 2016 06:55AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Problems with Dual Z Axis Drivers April 13, 2016 07:14AM |

Registered: 11 years ago Posts: 5,780 |

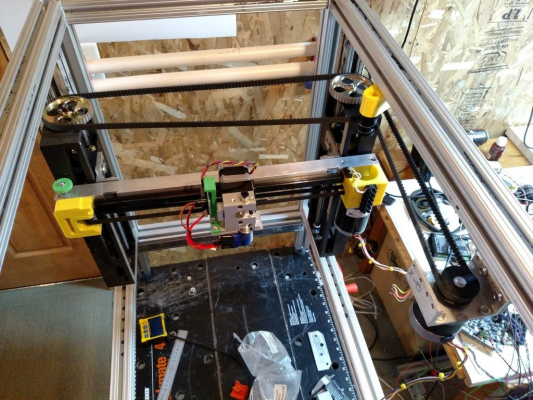

Yes, it's a good, but expensive way to go. I got lucky and got those two units for free. The guide rails in those are 5/8" diameter IRIC, and are fully supported. The screws are 1/2" lead 4 start, teflon coated, acme thread profile, and I've never seen any of the problems purported to result from imperial threads in the Z axis. I probably won't be so lucky for my next printer...

This is what they looked like before modifications for my printer:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

This is what they looked like before modifications for my printer:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Anonymous User

Re: Problems with Dual Z Axis Drivers April 13, 2016 10:48AM |

|

Re: Problems with Dual Z Axis Drivers April 13, 2016 11:38AM |

Registered: 11 years ago Posts: 5,780 |

cast aluminum, and I have no idea what they came out of.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.