Bulging corners

Posted by Backdraft

|

Bulging corners April 08, 2016 12:14PM |

Registered: 8 years ago Posts: 35 |

I've been trying to resolve this problem for a week now and I can't figure out whats wrong.

I've calibrated the feed rates on X, Y and extruder. The sides of the cube come with in a hundreaths of a mm. Perimeters are with in a tenth.

I've tried different temps ranging from 185-230. The lower temps give better result but doesn't resolve the issue. Any lower and soon I'll be cold extruding.

I have lowered acceleration on Y and X from 2000 to 500. XYjerk lowered from 20 to 5. Belts are tightened, maybe even too much now, but wanted to be sure theres no slack.

Print speeds are 50 and external perimiter at 50%. I've tried lower but issue still persists.

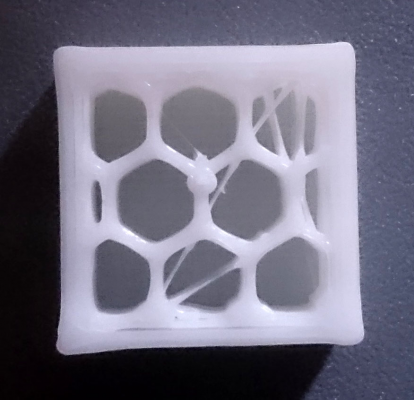

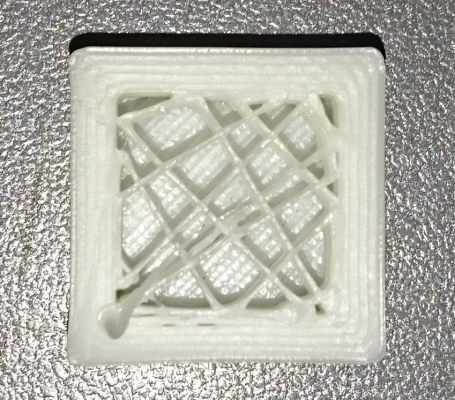

This is printed with PLA 200C at a 45degree angle to the bed (just a test if it makes any difference, it comes out the same when it's at a straight angle).

For some reason the lower left corner is always the worst. In a print thats angled to 45 it's the lowest corner. If it's a backlash issue shouldn't I see the same on the opposide side?

I've calibrated the feed rates on X, Y and extruder. The sides of the cube come with in a hundreaths of a mm. Perimeters are with in a tenth.

I've tried different temps ranging from 185-230. The lower temps give better result but doesn't resolve the issue. Any lower and soon I'll be cold extruding.

I have lowered acceleration on Y and X from 2000 to 500. XYjerk lowered from 20 to 5. Belts are tightened, maybe even too much now, but wanted to be sure theres no slack.

Print speeds are 50 and external perimiter at 50%. I've tried lower but issue still persists.

This is printed with PLA 200C at a 45degree angle to the bed (just a test if it makes any difference, it comes out the same when it's at a straight angle).

For some reason the lower left corner is always the worst. In a print thats angled to 45 it's the lowest corner. If it's a backlash issue shouldn't I see the same on the opposide side?

|

Re: Bulging corners April 08, 2016 01:11PM |

Registered: 10 years ago Posts: 154 |

|

Re: Bulging corners April 08, 2016 02:08PM |

Registered: 9 years ago Posts: 1,873 |

Bulging corners on a test cube are typically caused by over-extrusion as the printhead slows down for the 90 degree angle change. The corner that is the worst is typically the corner where the seam is for changing layers, because that's the corner where the head dwells for the longest. You can usually improve this by decreasing the print-speed and increasing the XY jerk, but obviously going too high will introduce it's own problems - more ringing and increased stresses on your printer. When designing your own parts it's best to use fillets on corners in the XY plane so that the head speed can be maintained.

|

Re: Bulging corners April 08, 2016 03:11PM |

Registered: 8 years ago Posts: 35 |

Quote

JamesK

Bulging corners on a test cube are typically caused by over-extrusion as the printhead slows down for the 90 degree angle change.

Will try decreasing the extrusion a bit more, but as I said, I have calibrated it and the sides of the cube are pretty close to perfect. On a 20mm cube I get around 20.05.

Quote

JamesK

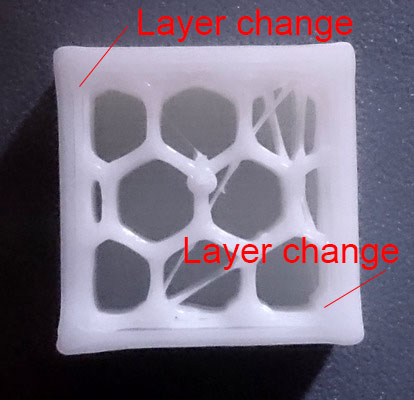

The corner that is the worst is typically the corner where the seam is for changing layers, because that's the corner where the head dwells for the longest.

Yes, thats what I thought also. I've been printing these cubes with zero infill and the corner that bulges the most is where the layer change happens. What confuses me more here is

when I turned the cube 45 degree and added 20% infill, the layer changes happend on two different corner that don't bulge as much.

I have triple checked this since I thought I was looking at the wrong corners. Seriously whats going on here.....

I have triple checked this since I thought I was looking at the wrong corners. Seriously whats going on here.....Quote

JamesK

You can usually improve this by decreasing the print-speed and increasing the XY jerk, but obviously going too high will introduce it's own problems - more ringing and increased stresses on your printer. When designing your own parts it's best to use fillets on corners in the XY plane so that the head speed can be maintained.

Will try increasing XY jerk. I have it quite low now, as I thought it might be making it worse.

Edited 1 time(s). Last edit at 04/08/2016 03:14PM by Backdraft.

|

Re: Bulging corners April 08, 2016 07:07PM |

Registered: 9 years ago Posts: 1,873 |

Quote

What confuses me more here is when I turned the cube 45 degree and added 20% infill, the layer changes happend on two different corner that don't bulge as much. confused smiley I have triple checked this since I thought I was looking at the wrong corners. Seriously whats going on here.....

I'll join you in confusion. The slicers remain a complete mystery to me. Sometimes they seem to change where the seam is for no obvious reason, and don't get me started on some of the weird stuff that Slic3r does for bridging. What's going on with the infill in that print? It seems to be mostly hex with some bits of line - or was that just some ooze that stretched out?

|

Re: Bulging corners April 09, 2016 05:56AM |

Registered: 8 years ago Posts: 35 |

Quote

JamesK

Quote

What confuses me more here is when I turned the cube 45 degree and added 20% infill, the layer changes happend on two different corner that don't bulge as much. confused smiley I have triple checked this since I thought I was looking at the wrong corners. Seriously whats going on here.....

I'll join you in confusion. The slicers remain a complete mystery to me. Sometimes they seem to change where the seam is for no obvious reason, and don't get me started on some of the weird stuff that Slic3r does for bridging. What's going on with the infill in that print? It seems to be mostly hex with some bits of line - or was that just some ooze that stretched out?

Well as far as I've notice the slicer does the same thing every time. Anyway, my point is that the bulge isn't where the layer change happens. So the bad corner isn't because the head is dwelling on that spot a bit longer. Although, to add to the confusion some more, I do get a bulge in the seam when I do a 1 perimiter print.

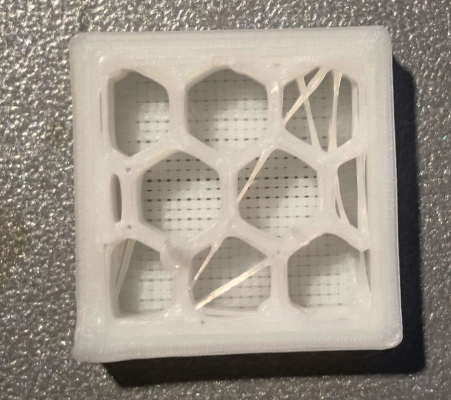

Upping the XY Jerk to 20 made a big difference. Thank you for the tip. All corners are pretty good, except the one on the bottom left, again. Same thing with this, layer change doesn't happen in this corner, it happens in varying places in the infill.

I'm thinking it's a mechanical problem. Some backlash in the bed or something, but why only one corner?

The infill is the default in slic3r. Honeycomb with oozing

Edited 1 time(s). Last edit at 04/09/2016 05:57AM by Backdraft.

|

Re: Bulging corners April 09, 2016 08:27AM |

Registered: 9 years ago Posts: 1,873 |

That looks much better. The oozing is part of the problem then - that makes the tendency to drop more plastic as the head slows down worse. You can probably improve that by lowering the hotend temperature a little. PLA gets pretty runny as the temperatures increase, which is why it can print relatively fast. If you try backing off 5C at a time you might find some improvements. I love honeycomb fill, but it is a bit slow - basic line fill covers the ground a lot faster.

The gaps in the bottom of the print suggest under-extrusion. I'm guessing as part of fighting the corners you backed off the extrusion, so you'll need to bring that back up again. That might have something to do with the first couple of layers seeming to be a bit smaller than the rest. Odd that there's no sign of under-extrusion in the perimeters or fill - that has me confused.

Which just leaves us with the last corner. I think that's the start/end point of each perimeter, so you get the same slow down/ooze problem as at the layer change point. It looks like you have 3 or 4 perimeters in the wall? So each time it changes from one to the next you get a little bit of extra plastic that builds up and causes a bulge. Or at least that's my theory Try lowering the temp a little until the ooze is under control and see if it helps.

Try lowering the temp a little until the ooze is under control and see if it helps.

Edit: What layer height are you using?

Edited 1 time(s). Last edit at 04/09/2016 08:31AM by JamesK.

The gaps in the bottom of the print suggest under-extrusion. I'm guessing as part of fighting the corners you backed off the extrusion, so you'll need to bring that back up again. That might have something to do with the first couple of layers seeming to be a bit smaller than the rest. Odd that there's no sign of under-extrusion in the perimeters or fill - that has me confused.

Which just leaves us with the last corner. I think that's the start/end point of each perimeter, so you get the same slow down/ooze problem as at the layer change point. It looks like you have 3 or 4 perimeters in the wall? So each time it changes from one to the next you get a little bit of extra plastic that builds up and causes a bulge. Or at least that's my theory

Try lowering the temp a little until the ooze is under control and see if it helps.

Try lowering the temp a little until the ooze is under control and see if it helps.Edit: What layer height are you using?

Edited 1 time(s). Last edit at 04/09/2016 08:31AM by JamesK.

|

Re: Bulging corners April 09, 2016 12:07PM |

Registered: 8 years ago Posts: 35 |

Ok, I tried to drop the temps 5C at a time till it was at 170C at which point Pronterface prevented cold extrusion. The bulge in the one corner just wont go away. It got alittle better, but I really don't think the problem is printing too hot.

I also tried a different filament which I know works because I use it on my other printer and get good results. I don't get it. Is it crappy hot end?

I have the Replikeo Prusa i3. They don't specify the model on their site, but it looks like this.

I'm printing at 0.2mm layer height.

I also tried a different filament which I know works because I use it on my other printer and get good results. I don't get it. Is it crappy hot end?

I have the Replikeo Prusa i3. They don't specify the model on their site, but it looks like this.

I'm printing at 0.2mm layer height.

|

Re: Bulging corners April 09, 2016 01:19PM |

Registered: 9 years ago Posts: 1,873 |

I wouldn't have thought it was the hot end - why would it only affect the one corner, with the rest of your perimeter looking very good. Seems odd. If you wiggle the hot end is anything loose? Just wondering if the extra movement in that corner would cause a physical displacement if the hot end wasn't tight in the carriage perhaps? Grasping at straws I know...

|

Re: Bulging corners April 09, 2016 01:48PM |

Registered: 11 years ago Posts: 5,780 |

That part is small and the time it takes to print a layer is short. That doesn't allow time for the previous layer to cool/harden before the nozzle comes by and heats everything up again. You're printing on mushy layers and they're getting squished out by the fresh, hot plastic from the nozzle.

Try printing two or three of those at once separated by a few inches on the bed and you'll see a drastic improvement in quality.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Try printing two or three of those at once separated by a few inches on the bed and you'll see a drastic improvement in quality.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Bulging corners April 09, 2016 02:14PM |

Registered: 8 years ago Posts: 35 |

Quote

the_digital_dentist

That part is small and the time it takes to print a layer is short. That doesn't allow time for the previous layer to cool/harden before the nozzle comes by and heats everything up again. You're printing on mushy layers and they're getting squished out by the fresh, hot plastic from the nozzle.

Try printing two or three of those at once separated by a few inches on the bed and you'll see a drastic improvement in quality.

Tried that, but didn't really make a difference. I have a table fan blowing on the print so it should cool down in a matter of seconds.

|

Re: Bulging corners April 09, 2016 02:16PM |

Registered: 8 years ago Posts: 35 |

Quote

JamesK

I wouldn't have thought it was the hot end - why would it only affect the one corner, with the rest of your perimeter looking very good. Seems odd. If you wiggle the hot end is anything loose? Just wondering if the extra movement in that corner would cause a physical displacement if the hot end wasn't tight in the carriage perhaps? Grasping at straws I know...

I have checked all screw on the extruder. Everything is tight.

|

Re: Bulging corners April 09, 2016 02:49PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Bulging corners April 10, 2016 05:27PM |

Registered: 8 years ago Posts: 35 |

Is it backlash or some hysteresis? Do you have belt tensioners in your x and y axis? Are your belts reasonably tight?

I would try lower speed and lower x and y axis acceleration and see if it makes it go away. You can change those things temporarily by adding M203 and M204 commands to your starup G-Code section of Slic3r. Mine are set to 200 and 1000 right now.

M203 X200 ; max feed rate

M202 X1000 ; max acceleration

I would try lower speed and lower x and y axis acceleration and see if it makes it go away. You can change those things temporarily by adding M203 and M204 commands to your starup G-Code section of Slic3r. Mine are set to 200 and 1000 right now.

M203 X200 ; max feed rate

M202 X1000 ; max acceleration

|

Re: Bulging corners April 11, 2016 10:09AM |

Registered: 8 years ago Posts: 35 |

Quote

CTCHunter1

Is it backlash or some hysteresis? Do you have belt tensioners in your x and y axis? Are your belts reasonably tight?

I would try lower speed and lower x and y axis acceleration and see if it makes it go away. You can change those things temporarily by adding M203 and M204 commands to your starup G-Code section of Slic3r. Mine are set to 200 and 1000 right now.

M203 X200 ; max feed rate

M202 X1000 ; max acceleration

If it's backlash shouldn't I see similar result on other corners?

I don't have a belt tensioner on the X axis. I alreary tightened it and I feels good, but I can try tightening it a bit more.

About the max feed rates. Print speed is set to 50mm / s in slic3r and external perimeters at 50%. Acceleration is at 500, so it's quite slow.

|

Re: Bulging corners April 11, 2016 10:41AM |

Registered: 8 years ago Posts: 183 |

If its just in one corner, then probably leaking when changing layers. Maybe disable any retracts-upon-z-change?

Not letting the nozzle idle is key- you want a constant flow of plastic to make sure that no areas get too much, and as a result, that no areas get too little.

Master Tinkerer

Not letting the nozzle idle is key- you want a constant flow of plastic to make sure that no areas get too much, and as a result, that no areas get too little.

Master Tinkerer

|

Re: Bulging corners April 11, 2016 10:46AM |

Registered: 8 years ago Posts: 35 |

Quote

Montiey

If its just in one corner, then probably leaking when changing layers. Maybe disable any retracts-upon-z-change?

Not letting the nozzle idle is key- you want a constant flow of plastic to make sure that no areas get too much, and as a result, that no areas get too little.

Layer changes don't happen in that corner, but perimeter changes do. Layer changes happen in the infill so they don't effect the corners.

|

Re: Bulging corners April 11, 2016 11:11AM |

Registered: 8 years ago Posts: 183 |

|

Re: Bulging corners April 11, 2016 11:17AM |

Registered: 8 years ago Posts: 35 |

Quote

Montiey

Set your infill to 0 to see if it is actually the infill. If not, the. it's a mechanical problem because it should be happening in the others corners.

Not sure what you mean. I've printed with and without infill. Both have the bulge, but with infill I can know for sure that it's not the layer change thats causing it, because layer changes happen in the infill.

|

Re: Bulging corners April 12, 2016 07:32AM |

Registered: 8 years ago Posts: 413 |

You sure you are not just chasing the shrinkage. The walls typically shrink more than the corners so the walls "pull in". This is why the infill affects the outside as it can reduce the shrinkage.

The corners will be thicker with increasing nozzle size so a 0.5 nozzle will be more of a problem than a 0.4mm.

The order of printing the perimeter should have an influence. As the 1st perimeter printed can cool/shrink before the next perimeter is extruded.

Don't forget your fan will affect the cooling rate and hence the distortion. Sounds like your bulging corner is the one nearest the fan.

The corners will be thicker with increasing nozzle size so a 0.5 nozzle will be more of a problem than a 0.4mm.

The order of printing the perimeter should have an influence. As the 1st perimeter printed can cool/shrink before the next perimeter is extruded.

Don't forget your fan will affect the cooling rate and hence the distortion. Sounds like your bulging corner is the one nearest the fan.

|

Re: Bulging corners April 12, 2016 11:45AM |

Registered: 8 years ago Posts: 35 |

Quote

MCcarman

You sure you are not just chasing the shrinkage. The walls typically shrink more than the corners so the walls "pull in". This is why the infill affects the outside as it can reduce the shrinkage.

The corners will be thicker with increasing nozzle size so a 0.5 nozzle will be more of a problem than a 0.4mm.

The order of printing the perimeter should have an influence. As the 1st perimeter printed can cool/shrink before the next perimeter is extruded.

Don't forget your fan will affect the cooling rate and hence the distortion. Sounds like your bulging corner is the one nearest the fan.

I don't think it shrinkage. I should see the same result on all sides?

I've been tinkering and tuning my printer many hours. Checked that everyhting is square. I found a 0.5mm difference on the base and tried to get it as perfect as possible.

I've been trying different XY Jerk setting and accelerations. I see some improvement, but theres still some bulging in the corner. I tried to print with out a fan and I think this made it a bit better. (the fan was nearest to the lower right corner, not the one thats bulging)

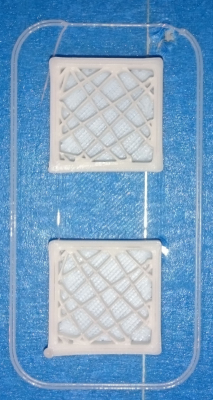

Now when I measure from the middle of the cube I get 19.8mm. Measuring at the corners it's 20mm. It's only a .2mm difference, at some point t was 0.5mm.

I know the printer is capable of doing a square under .1mm tolerance, it's just a matter of tuning. I'm just running out of ideas what to try....well I have one upgrade coming that should take care all the slack in the Y axis. Just waiting for the linear bearings to arrive.

Here the latest. I switched to 5 perimeters. 200C

|

Re: Bulging corners July 05, 2017 11:50AM |

Registered: 7 years ago Posts: 34 |

|

Re: Bulging corners July 05, 2017 01:08PM |

Registered: 8 years ago Posts: 35 |

Quote

saintofinternet

sorry to wake this topic after one year...

did you get the improvement? i am building a printer and facing the same problem??

inputs will be highly appreciated.

Hey,

Believe it or not It's still pretty much at the same stage. I kinda lost interest for a year and just now started tinkering with it again. Added a nice cooling fan, changed the standard bearings (LM8UU) to some plastic Drylin RJ4JP-01-08 which people were praising.

Changed some of the rods because they weren't straight. I printed new x-axis parts with belt tensioner. Double and triple checked everything is square. Still no go. I haven't been focusing on the "cube bulge", but just general quality in the prints. It prints ok with large stuff, but anything with small detail is crap. Look at Buddha batmans ears.

I think it's all due to the mechanical parts. Theres just too much slack everywhere that It's hard to get good prints with this.

I'm not done with this though. I'll keep trying and fix when I got nothing better to do. Trying to make this thing work has become my hobby now.

Sorry, only registered users may post in this forum.