z-ribbing on one corner less than others?

Posted by siderala

|

z-ribbing on one corner less than others? April 21, 2016 02:20PM |

Registered: 8 years ago Posts: 32 |

Hello all,

my mendel i2 was running very well. I built an enclosure for it recently and now I have created a large Z-wobble. I printed some z constraints with bearings [www.thingiverse.com] i put them on just the free hanging end of the rod and still had the wobble. i put them on the top by the coupling as well, then all hell broke loose, one side started going up and down faster than the other.

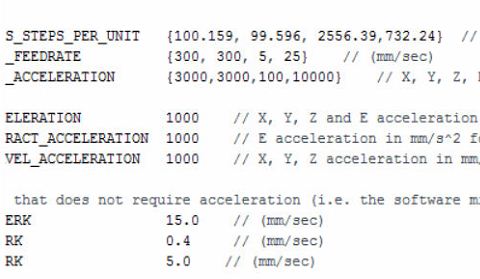

I took all the restraints off and just got it back to where I started. I started trying to adjust the z smooth rods to be straighter and parralel with the z threaded rods. I lowered my jerk setting in marlin to see if that would do anything. I also tightened my bed springs so there was no play in the heatbed at all. here are my settings in marlin:

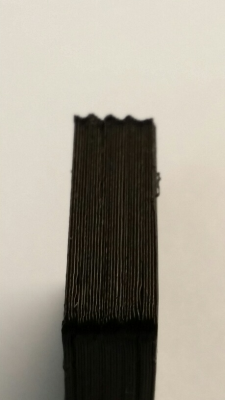

I started the next cube and noticed that one edge was receiving significantly less z ribbing than the other three corners.

does anyone have suggestions or ways to figure out the best solution to get my corners straight again!!

thanks in advance.

Luke

my mendel i2 was running very well. I built an enclosure for it recently and now I have created a large Z-wobble. I printed some z constraints with bearings [www.thingiverse.com] i put them on just the free hanging end of the rod and still had the wobble. i put them on the top by the coupling as well, then all hell broke loose, one side started going up and down faster than the other.

I took all the restraints off and just got it back to where I started. I started trying to adjust the z smooth rods to be straighter and parralel with the z threaded rods. I lowered my jerk setting in marlin to see if that would do anything. I also tightened my bed springs so there was no play in the heatbed at all. here are my settings in marlin:

I started the next cube and noticed that one edge was receiving significantly less z ribbing than the other three corners.

does anyone have suggestions or ways to figure out the best solution to get my corners straight again!!

thanks in advance.

Luke

|

Re: z-ribbing on one corner less than others? April 21, 2016 03:10PM |

Registered: 10 years ago Posts: 1,401 |

Constraining the Z threaded rods the way you did, might have damaged your X carriage, specially were the Z nut fit in the carriage creating a play that will affect your prints. unless you use precision lead screws, constraining the ends of a standard threaded rod is calling for disaster.

your settings look good, so my advice to you is to either re-print your X carriages (friend or purchase) or fix the current ones gluing the nut firmly to the carriage and then print new ones if possible and purchase new threaded rods (try to get the most straight ones) or improve to T8 lead screws (cheaper than ball type).

your settings look good, so my advice to you is to either re-print your X carriages (friend or purchase) or fix the current ones gluing the nut firmly to the carriage and then print new ones if possible and purchase new threaded rods (try to get the most straight ones) or improve to T8 lead screws (cheaper than ball type).

|

Re: z-ribbing on one corner less than others? April 22, 2016 07:16AM |

Registered: 8 years ago Posts: 413 |

Coupe of thoughts:-

Make sure the threaded Z screws are not constrained - they are only there to provide the Z change.

Check the couplings between the threaded rod and the motor - it needs to be concentric.

Ensure the extruder hot end is not loose or the bearings rocking on the guide shafts.

Make sure the threaded Z screws are not constrained - they are only there to provide the Z change.

Check the couplings between the threaded rod and the motor - it needs to be concentric.

Ensure the extruder hot end is not loose or the bearings rocking on the guide shafts.

Sorry, only registered users may post in this forum.