BullDog XL and E3D v6 jam!

Posted by the_digital_dentist

|

BullDog XL and E3D v6 jam! May 21, 2016 10:30AM |

Registered: 11 years ago Posts: 5,780 |

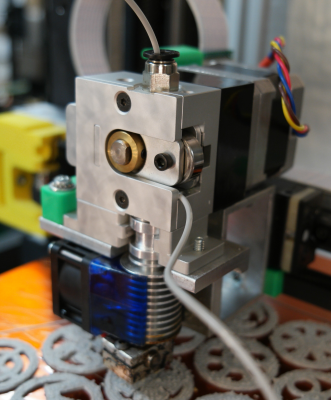

Back in January, after at least a year of almost daily operation, I had my first-ever extruder jam with the BullDog XL and E3D v6. Here's what I found inside the hot end when I pulled the filament:

About a week ago I had the second ever problem with the combo. The filament somehow got kinked and started coming out next to the pinchwheel. It was doing this for quite a while before anyone noticed and killed the machine. When I pulled the filament out I found no evidence of a hot-end jam- the filament came out clean and a new piece went in and extruded perfectly. I suspect I had the pinch wheel pressure set a little too high and it may have crushed the filament and squeezed it out to the side of the pinchwheel.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

About a week ago I had the second ever problem with the combo. The filament somehow got kinked and started coming out next to the pinchwheel. It was doing this for quite a while before anyone noticed and killed the machine. When I pulled the filament out I found no evidence of a hot-end jam- the filament came out clean and a new piece went in and extruded perfectly. I suspect I had the pinch wheel pressure set a little too high and it may have crushed the filament and squeezed it out to the side of the pinchwheel.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: BullDog XL and E3D v6 jam! May 21, 2016 02:03PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: BullDog XL and E3D v6 jam! May 21, 2016 03:34PM |

Registered: 11 years ago Posts: 5,780 |

I don't think there's any way to know whether the object came into the extruder from within the filament or was dragged in from outside along with the filament. I have printed about 15 kg of filament from this manufacturer and never had anything like this happen before, but if it makes you happy, the green filament was made by Coex3D.

I will continue to use their stuff.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I will continue to use their stuff.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: BullDog XL and E3D v6 jam! May 22, 2016 02:55AM |

Registered: 9 years ago Posts: 294 |

i got terrified now for two reasons . The first one is that i always found dirt in my filaments but the one to blame is me, as i am not very carefull during the production of the filament. So most of the time the dirt gets out with the extruded filament and no harm is done. But sometimes my quick set nozzle clogs and i was hoping that the e3d v6 i am waiting would be better than that .

After all they say the better a machine is the more forgiven.

Offtopic. at what speeds was that print on the photo dentist ?

Delta Printer

Duet 0.8.5 firmware 1.19

After all they say the better a machine is the more forgiven.

Offtopic. at what speeds was that print on the photo dentist ?

Delta Printer

Duet 0.8.5 firmware 1.19

|

Re: BullDog XL and E3D v6 jam! May 22, 2016 05:42AM |

Registered: 9 years ago Posts: 330 |

|

Re: BullDog XL and E3D v6 jam! May 22, 2016 06:37AM |

Registered: 8 years ago Posts: 778 |

When I experimented with recycling plastic for my printer I learned two things quite quickly:

a) It is next to impossible to re-use any PLA as it becomes far too brittle.

b) Even with the best extruder at hand you need fine screens to filter out the contaminents from the plastic.

is a bit hard when it comes to fine nozzles as at least I was struggling to ensure the plastic going in would be still of a good enough quality.

is a bit hard when it comes to fine nozzles as at least I was struggling to ensure the plastic going in would be still of a good enough quality.

Keep in mind that plastizisers are used and that most of it already evaporated during the initial print, so the re-used material will certainly show different properties to the filament initially used.

a) It is next to impossible to re-use any PLA as it becomes far too brittle.

b) Even with the best extruder at hand you need fine screens to filter out the contaminents from the plastic.

is a bit hard when it comes to fine nozzles as at least I was struggling to ensure the plastic going in would be still of a good enough quality.

is a bit hard when it comes to fine nozzles as at least I was struggling to ensure the plastic going in would be still of a good enough quality.Keep in mind that plastizisers are used and that most of it already evaporated during the initial print, so the re-used material will certainly show different properties to the filament initially used.

|

Re: BullDog XL and E3D v6 jam! May 22, 2016 07:01AM |

Registered: 11 years ago Posts: 5,780 |

Quote

Gaou

i was hoping that the e3d v6 i am waiting would be better than that .

After all they say the better a machine is the more forgiven.

Offtopic. at what speeds was that print on the photo dentist ?

It doesn't matter what hot-end you use, or how good your printer is. If the object is larger than the hole in the nozzle, it's going to jam. The print was running at 40 mm/sec or 50 mm/sec.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: BullDog XL and E3D v6 jam! May 22, 2016 07:35AM |

Registered: 11 years ago Posts: 5,780 |

The programmer's saying "garbage in - garbage out" is especially apropos to 3D printing. You can't get a high quality print from poor quality filament. I don't think I'll ever attempt to make my own filament, especially not from recycled prints. Mixed plastics, foreign objects, moisture, and diameter control are all problems with no good solutions for DIY filament making.

Folks who think they are being "green" by making their own filament, especially by recycling old prints, are kidding themselves. 3D printing isn't a "green" activity. The stuff these machines churn out will be around for hundreds, if not thousands of years. PLA may be degradable if it is left exposed to sun and rain, but bury it in the ground and it will sit there unchanged forever.

My only effort at being "green" is to make my prints as high quality as possible so they will stay functional/attractive for as long as possible. That will keep them out of the landfill for a while, at least. I also put my old prints and scrap in a recycling bin and they get incinerated or melted and reused on an industrial scale with all the other plastics I put in the bin. I don't think it's possible to be more "green" than that and still pursue 3D printing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Folks who think they are being "green" by making their own filament, especially by recycling old prints, are kidding themselves. 3D printing isn't a "green" activity. The stuff these machines churn out will be around for hundreds, if not thousands of years. PLA may be degradable if it is left exposed to sun and rain, but bury it in the ground and it will sit there unchanged forever.

My only effort at being "green" is to make my prints as high quality as possible so they will stay functional/attractive for as long as possible. That will keep them out of the landfill for a while, at least. I also put my old prints and scrap in a recycling bin and they get incinerated or melted and reused on an industrial scale with all the other plastics I put in the bin. I don't think it's possible to be more "green" than that and still pursue 3D printing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: BullDog XL and E3D v6 jam! May 22, 2016 07:39AM |

Registered: 9 years ago Posts: 294 |

|

Re: BullDog XL and E3D v6 jam! May 25, 2016 02:56PM |

Registered: 11 years ago Posts: 5,780 |

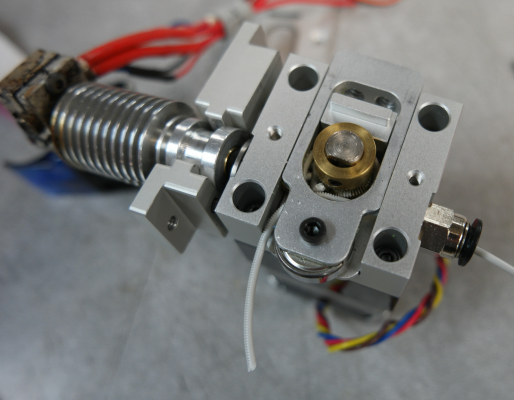

It did it again.

This time I carefully examined the filament and the extruder and figured out exactly what caused the problem. There were three issues contributing to it:

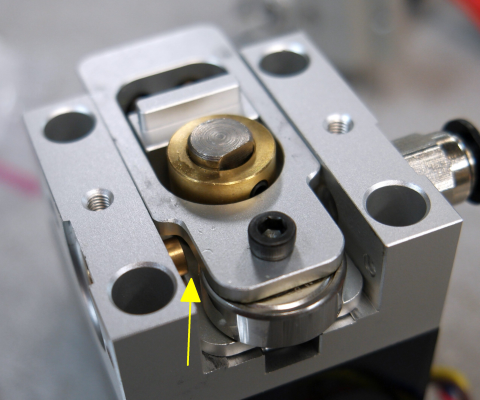

1) Pinch wheel pressure on the filament was set too high and it was flattening the filament, making it easy to bend. This is a picture of the filament I pulled out of the hot-end. I noticed that it was flattened so I measured it.

2) I set the slicer for volumetric extrusion (filament diameter 1.128379 mm) and enter the filament diameter at print start-up. That allows me to use the same gcode for different colors of filament which will come from different spools that have different diameters. The person who started the printer in the two failed jobs wasn't aware of this and didn't enter a filament diameter at print time, resulting in heavy over extrusion- see the printed parts in the first picture. The machine thought the filament diameter was 1.128379 mm but it was actually 1.793 mm.

3) The extruder design has a gap of about 5 or 6 mm between the filament drive gear/pinch wheel contact point and the entry to the guide that sends the filament down to the hot-end. That leaves room for the filament to buckle.

While it was printing, the hot-end couldn't keep up with the over extrusion but the extruder kept trying to push the filament anyway. Eventually, the filament buckled in the space between the guide tube and the drive gear and that was the end of printing. The filament actually got wrapped around the drive gear before it broke and then the free end found its way out below the pinch wheel.

The guide tube is a screw-in brass part that should have been made about 5 or 6 mm longer to prevent the filament from buckling. This extruder probably won't do too well with really flexible filament, though I have successfully printed TPU with it. I am going to look into making a new guide tube so that there won't be such a large gap.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

This time I carefully examined the filament and the extruder and figured out exactly what caused the problem. There were three issues contributing to it:

1) Pinch wheel pressure on the filament was set too high and it was flattening the filament, making it easy to bend. This is a picture of the filament I pulled out of the hot-end. I noticed that it was flattened so I measured it.

2) I set the slicer for volumetric extrusion (filament diameter 1.128379 mm) and enter the filament diameter at print start-up. That allows me to use the same gcode for different colors of filament which will come from different spools that have different diameters. The person who started the printer in the two failed jobs wasn't aware of this and didn't enter a filament diameter at print time, resulting in heavy over extrusion- see the printed parts in the first picture. The machine thought the filament diameter was 1.128379 mm but it was actually 1.793 mm.

3) The extruder design has a gap of about 5 or 6 mm between the filament drive gear/pinch wheel contact point and the entry to the guide that sends the filament down to the hot-end. That leaves room for the filament to buckle.

While it was printing, the hot-end couldn't keep up with the over extrusion but the extruder kept trying to push the filament anyway. Eventually, the filament buckled in the space between the guide tube and the drive gear and that was the end of printing. The filament actually got wrapped around the drive gear before it broke and then the free end found its way out below the pinch wheel.

The guide tube is a screw-in brass part that should have been made about 5 or 6 mm longer to prevent the filament from buckling. This extruder probably won't do too well with really flexible filament, though I have successfully printed TPU with it. I am going to look into making a new guide tube so that there won't be such a large gap.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: BullDog XL and E3D v6 jam! May 25, 2016 07:22PM |

Registered: 9 years ago Posts: 1,873 |

Nice analysis. Any thoughts on the cause of that dark band around the filament tip? A small amount of a previously used dark filament that had remained in the hotend?

The amount of filament distortion you measured doesn't look too bad to me. I suspect the hotend would have coped ok with that if it wasn't for the dramatic over extrusion. I think the E3D throat bore for 1.75mm filament is 2mm, so getting tight but probably still good.

The amount of filament distortion you measured doesn't look too bad to me. I suspect the hotend would have coped ok with that if it wasn't for the dramatic over extrusion. I think the E3D throat bore for 1.75mm filament is 2mm, so getting tight but probably still good.

|

Re: BullDog XL and E3D v6 jam! May 26, 2016 12:20AM |

Registered: 9 years ago Posts: 294 |

|

Re: BullDog XL and E3D v6 jam! May 26, 2016 01:04AM |

Registered: 11 years ago Posts: 5,780 |

I think it was just some charred crud from inside the hot-end. Maybe PLA from the last time I printed with it a couple months ago.

It looks like the gap between the edge of the brass feeder tube and the pinch wheel is only about 2 mm or so, so it won't be possible to use a longer feeder tube in the extruder. I haven't had any problems with it before, including printing TPU, so it's probably no big deal as long as I remember to enter the filament diameter at print start up.

Edited 1 time(s). Last edit at 05/26/2016 01:09AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It looks like the gap between the edge of the brass feeder tube and the pinch wheel is only about 2 mm or so, so it won't be possible to use a longer feeder tube in the extruder. I haven't had any problems with it before, including printing TPU, so it's probably no big deal as long as I remember to enter the filament diameter at print start up.

Edited 1 time(s). Last edit at 05/26/2016 01:09AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.