ABS warping, what am I doing wrong?

Posted by kodde

ABS warping, what am I doing wrong? June 20, 2016 04:26AM |

Registered: 10 years ago Posts: 28 |

Hey guys,

Sorry if this is already covered here. Tried finding a similar thread with this issue but didn't manage to find anything.

Anyway. I own a Nophead Mendel90 and I have been able to print ABS right when I got the printer and a while after. But for a year or so I've always been having the print failing due to the base warping and breaking off the print bed. I've tried ABS slurry, kapton tape, painters tape and recently 3DLac spray. I use Slic3r to generate the G code. A while back I build a proper enclosure for the printer.

With my last attempt I used 3DLac on a brand new mirror surface. I used raft for the print and as far as I can tell the raft seemed to stick quite well to the glass surface. However the print seemed to break from the raft about 60% through.

Any ideas what I'm doing wrong? Thanks!

Sorry if this is already covered here. Tried finding a similar thread with this issue but didn't manage to find anything.

Anyway. I own a Nophead Mendel90 and I have been able to print ABS right when I got the printer and a while after. But for a year or so I've always been having the print failing due to the base warping and breaking off the print bed. I've tried ABS slurry, kapton tape, painters tape and recently 3DLac spray. I use Slic3r to generate the G code. A while back I build a proper enclosure for the printer.

With my last attempt I used 3DLac on a brand new mirror surface. I used raft for the print and as far as I can tell the raft seemed to stick quite well to the glass surface. However the print seemed to break from the raft about 60% through.

Any ideas what I'm doing wrong? Thanks!

Re: ABS warping, what am I doing wrong? June 20, 2016 04:48AM |

Registered: 8 years ago Posts: 310 |

Abs is very easy to warp from the bed. Best thing is use abs juice or wolfbite, are you running a heated bed?

I been tackling abs for almost a year now as well and about 2mm on each corner warping from bed is the best I got so far with only pva glue and bed at 110c, I did however got a couple prints with no warp on krapton tape enclosed build chamber and bed at 120c

Edited 1 time(s). Last edit at 06/20/2016 04:49AM by deaconfrost.

Prusa i3 upgraded with some of my own parts and E3D v6 hardened steel nozzle, large 400mm3 enclosed printer in to revision 3

I been tackling abs for almost a year now as well and about 2mm on each corner warping from bed is the best I got so far with only pva glue and bed at 110c, I did however got a couple prints with no warp on krapton tape enclosed build chamber and bed at 120c

Edited 1 time(s). Last edit at 06/20/2016 04:49AM by deaconfrost.

Prusa i3 upgraded with some of my own parts and E3D v6 hardened steel nozzle, large 400mm3 enclosed printer in to revision 3

Re: ABS warping, what am I doing wrong? June 20, 2016 04:56AM |

Registered: 10 years ago Posts: 28 |

Re: ABS warping, what am I doing wrong? June 20, 2016 05:02AM |

Registered: 8 years ago Posts: 310 |

Definitely not enough heat on the bed, it's recommended 100c plus for abs, give that a try and see if it improves, and turn off print fan or reduce to below 50% fan speed but no fan for first 20 to 30 layers for sure. Because abs shrinkage is very bad when it gets cool down to quickly, most people print with no fan on, I use 30% to 40% after about 20 layers or so but only when I have my printer enclosed

If the bed drops below 100c during print it can warp aswell. Happened to me before I built the enclosure

Edited 2 time(s). Last edit at 06/20/2016 05:07AM by deaconfrost.

If the bed drops below 100c during print it can warp aswell. Happened to me before I built the enclosure

Edited 2 time(s). Last edit at 06/20/2016 05:07AM by deaconfrost.

Re: ABS warping, what am I doing wrong? June 20, 2016 05:08AM |

Registered: 10 years ago Posts: 28 |

Re: ABS warping, what am I doing wrong? June 20, 2016 05:47AM |

Registered: 8 years ago Posts: 310 |

Re: ABS warping, what am I doing wrong? June 20, 2016 07:16AM |

Registered: 10 years ago Posts: 28 |

Re: ABS warping, what am I doing wrong? June 20, 2016 08:00AM |

Registered: 9 years ago Posts: 60 |

Your mirror shouldn't be so clean as you show on picture. It should be dirty because 3Dlac ( it is just hair spray without fragance)

Since English is not my mother language... I will post picture of my mirror on a heatbed ( I use Nelly hair spray extra hold ).

No, I'm not a "dirty guy", You need that kind of rugosity to make ABS glue on the mirror. A clean mirror makes difficult to ABS to glue on in.

Do you see these hair spray waves?

Don't clean your mirror after a print, just add more 3Dlac. I think that mirro is so dirty after 10 printed pieces, I won't clean yet.

Mirror and glass may deform with high temperature, so you should check the distance from nozzle to heatbed once heatbed is at 80ºC. I do that with a paper between nozzle and heatbed on the corners, and the center of the bed. If you see that a paper gets between nozzle and heatbed at the corners, but you can NOT introduce it at the center of the bed, yeah! your deformed mirror is causing warp!

Another factor is perfect bed leveling: Once first layer is printed, you should check the color of the layer, more transparency tells you the nozzle is too near of the bed. If layer if solid, it tell you the nozzle is far away from bed (worst adhesion). Think about it, paper between nozzle and heatbed makes 0.1 mm of distance; the first layer height should be 0.2 mm to make squash ABS and enhanced adhesion. First layer transparence should be equal on the whole layer.

Hope you could understand me.

Edited 2 time(s). Last edit at 06/20/2016 08:05AM by Lepes.

Since English is not my mother language... I will post picture of my mirror on a heatbed ( I use Nelly hair spray extra hold ).

No, I'm not a "dirty guy", You need that kind of rugosity to make ABS glue on the mirror. A clean mirror makes difficult to ABS to glue on in.

Do you see these hair spray waves?

Don't clean your mirror after a print, just add more 3Dlac. I think that mirro is so dirty after 10 printed pieces, I won't clean yet.

Mirror and glass may deform with high temperature, so you should check the distance from nozzle to heatbed once heatbed is at 80ºC. I do that with a paper between nozzle and heatbed on the corners, and the center of the bed. If you see that a paper gets between nozzle and heatbed at the corners, but you can NOT introduce it at the center of the bed, yeah! your deformed mirror is causing warp!

Another factor is perfect bed leveling: Once first layer is printed, you should check the color of the layer, more transparency tells you the nozzle is too near of the bed. If layer if solid, it tell you the nozzle is far away from bed (worst adhesion). Think about it, paper between nozzle and heatbed makes 0.1 mm of distance; the first layer height should be 0.2 mm to make squash ABS and enhanced adhesion. First layer transparence should be equal on the whole layer.

Hope you could understand me.

Edited 2 time(s). Last edit at 06/20/2016 08:05AM by Lepes.

Re: ABS warping, what am I doing wrong? June 20, 2016 08:16AM |

Registered: 10 years ago Posts: 28 |

Hello Lepes,

I see what you mean with the amount of 3DLac/Hair spray. There is a layer on the glass, although quite thin.

I think I understood you with the bed leveling and transparency. I'll check out these factors as well.

One thing though. My last print wasn't an issue with the raft releasing from the glass surface. It was the model releasing from the raft midprint. Mirror/glass surface was never used so I'm thinking it shouldn't be that warped/curved yet. I'm thinking it's more of a temperature issue rather than adhesion, leveling or curved print surface?

Thanks.

I see what you mean with the amount of 3DLac/Hair spray. There is a layer on the glass, although quite thin.

I think I understood you with the bed leveling and transparency. I'll check out these factors as well.

One thing though. My last print wasn't an issue with the raft releasing from the glass surface. It was the model releasing from the raft midprint. Mirror/glass surface was never used so I'm thinking it shouldn't be that warped/curved yet. I'm thinking it's more of a temperature issue rather than adhesion, leveling or curved print surface?

Thanks.

Re: ABS warping, what am I doing wrong? June 20, 2016 08:44AM |

Registered: 11 years ago Posts: 5,780 |

I've been printing ABS almost exclusively for about 3 years. Here's what you need:

1) flat, level, evenly heated bed at 105C (ABS glass transition)

2) a "grippy surface" - kapton tape works well.

3) a warm enclosure- 45-50C

4) no cooling fan for the print

Your first layer is sticking OK on the glass by using hairspray. Now your problem is the part warping free of the raft. Do you need the raft? Turn the bed temperature up to 105C. That will help. Shut off the print cooling fan. Put a box over the printer- it will help retain heat, but may not get warm enough to prevent delamination. Be careful about enclosing the printer- electronics and heat are a bad combo- try to keep the power supply and controller board away from the heat. You may have to add additional heat to the enclosure.

You can try reducing the air gap between the raft and the first layer of the print to bond the two more tightly, but it will be harder to separate when the print is finished.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

1) flat, level, evenly heated bed at 105C (ABS glass transition)

2) a "grippy surface" - kapton tape works well.

3) a warm enclosure- 45-50C

4) no cooling fan for the print

Your first layer is sticking OK on the glass by using hairspray. Now your problem is the part warping free of the raft. Do you need the raft? Turn the bed temperature up to 105C. That will help. Shut off the print cooling fan. Put a box over the printer- it will help retain heat, but may not get warm enough to prevent delamination. Be careful about enclosing the printer- electronics and heat are a bad combo- try to keep the power supply and controller board away from the heat. You may have to add additional heat to the enclosure.

You can try reducing the air gap between the raft and the first layer of the print to bond the two more tightly, but it will be harder to separate when the print is finished.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: ABS warping, what am I doing wrong? June 20, 2016 08:49AM |

Registered: 10 years ago Posts: 28 |

Thanks for the suggestions the_digital_dentist.

No the raft is not a deal breaker. I think I will try without it for my next print. I've already got my custom built enclosure so I'm going to put a thermometer there and see what temperatures I get.

To-do for next print: Up the bed temperature from 80 -> 105C, check bed leveling when bed is hot, disable the fan altogether and skip the raft.

No the raft is not a deal breaker. I think I will try without it for my next print. I've already got my custom built enclosure so I'm going to put a thermometer there and see what temperatures I get.

To-do for next print: Up the bed temperature from 80 -> 105C, check bed leveling when bed is hot, disable the fan altogether and skip the raft.

Re: ABS warping, what am I doing wrong? June 20, 2016 09:40PM |

Registered: 8 years ago Posts: 430 |

Have you tried a brim? I always need to use a brim to get it to stay down. I use aquanet and a brim. I have now been making the brim two layers since I got simplify3d since sometimes I had the part break away from the brim.

I think it's worth finding something that will work I think abs is better than pla in every other respect.

Newbie with Folgertech 2020 i3.

I think it's worth finding something that will work I think abs is better than pla in every other respect.

Newbie with Folgertech 2020 i3.

Re: ABS warping, what am I doing wrong? June 21, 2016 12:38AM |

Registered: 10 years ago Posts: 28 |

I haven't tried brim yet.

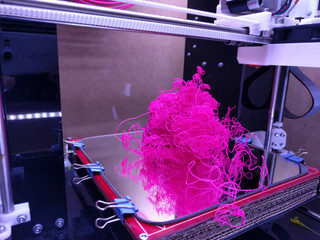

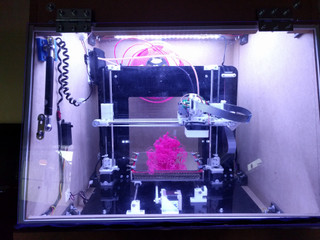

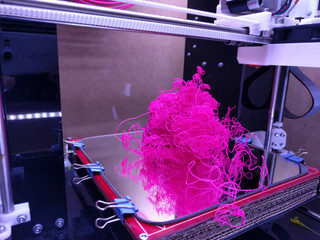

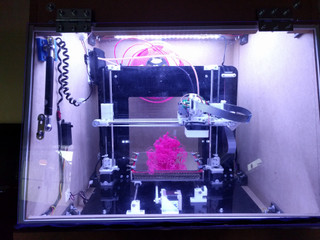

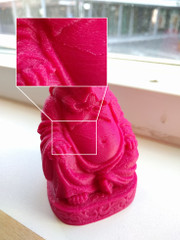

So here's last nights results. Great success! My first successful ABS in a long time. Unfortunately I had managed to some how enable autogenerated supports in Slic3r. I'll try some more prints with these new settings. Thanks everyone!

Edited 1 time(s). Last edit at 06/21/2016 02:07AM by kodde.

So here's last nights results. Great success! My first successful ABS in a long time. Unfortunately I had managed to some how enable autogenerated supports in Slic3r. I'll try some more prints with these new settings. Thanks everyone!

Edited 1 time(s). Last edit at 06/21/2016 02:07AM by kodde.

Re: ABS warping, what am I doing wrong? June 21, 2016 02:19AM |

Registered: 10 years ago Posts: 28 |

Here's some more pics of last nights results.

I really leveled the bed close to the hotend nozzle to really squash it. Seems like it produced a really flat and glossy bottom. This is good right? Was no signs or warping/lifting at the base edges. The first layers have some issues with excess material(?). I'm guessing this is due to the squashed layer evening out over a few layers and the excess materials is pushed outwards as a result? Maybe not have the nozzle quite as close to the bed? Or maybe back up on first layer height (currently 0.35mm)?

Also, at the top of the head I'm getting some holes. Any ideas? More infill and maybe more top layers? Enable fan with really low speed?

Thanks guys.

I really leveled the bed close to the hotend nozzle to really squash it. Seems like it produced a really flat and glossy bottom. This is good right? Was no signs or warping/lifting at the base edges. The first layers have some issues with excess material(?). I'm guessing this is due to the squashed layer evening out over a few layers and the excess materials is pushed outwards as a result? Maybe not have the nozzle quite as close to the bed? Or maybe back up on first layer height (currently 0.35mm)?

Also, at the top of the head I'm getting some holes. Any ideas? More infill and maybe more top layers? Enable fan with really low speed?

Thanks guys.

Re: ABS warping, what am I doing wrong? June 21, 2016 06:43AM |

Registered: 8 years ago Posts: 310 |

Re: ABS warping, what am I doing wrong? June 21, 2016 07:25AM |

Registered: 10 years ago Posts: 28 |

Re: ABS warping, what am I doing wrong? June 21, 2016 07:51AM |

Registered: 8 years ago Posts: 310 |

extrusion width I meant for the first layer  it puts the lines down a bit wider and still flatten it at the same height, I have mine set up 200% for ABS 180% for PET and 150% for PLA my first layer height is 0.3mm

it puts the lines down a bit wider and still flatten it at the same height, I have mine set up 200% for ABS 180% for PET and 150% for PLA my first layer height is 0.3mm

Here's my first layer with pla

its all trial and error, try different settings and adjust if needed to get your desire result

Edited 3 time(s). Last edit at 06/21/2016 07:56AM by deaconfrost.

it puts the lines down a bit wider and still flatten it at the same height, I have mine set up 200% for ABS 180% for PET and 150% for PLA my first layer height is 0.3mm

it puts the lines down a bit wider and still flatten it at the same height, I have mine set up 200% for ABS 180% for PET and 150% for PLA my first layer height is 0.3mmHere's my first layer with pla

its all trial and error, try different settings and adjust if needed to get your desire result

Edited 3 time(s). Last edit at 06/21/2016 07:56AM by deaconfrost.

Re: ABS warping, what am I doing wrong? June 21, 2016 10:51AM |

Registered: 10 years ago Posts: 28 |

Ahhh...

Found it. Was in advanced settings where I rarely venture. It seems default is 200% which I haven't changed so I think I'm running the same settings you just mentioned for ABS.

Like you mentioned from here on it it's going to be a lot of trial and error with small setting increments. Thanks.

Found it. Was in advanced settings where I rarely venture. It seems default is 200% which I haven't changed so I think I'm running the same settings you just mentioned for ABS.

Like you mentioned from here on it it's going to be a lot of trial and error with small setting increments. Thanks.

Re: ABS warping, what am I doing wrong? June 22, 2016 02:31AM |

Registered: 10 years ago Posts: 28 |

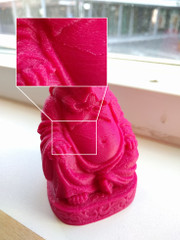

So right after that first successful print I did another one with same settings except for disabling the auto-generated support material. Turned out pretty nice except for the print having an even bigger hole on the top of the head. I'm doing 6 top layers and infill level is at 10%. My PLA versions of this model has managed to fill that hole nicely.

Could this be failing bridging perhaps? In absence of underlying infill structure to rely on I'm guessing this boils down to how well bridging works. What settings should I be tweaking for better bridging?

Maybe a bit OT, but I tried acetone treating that first print just to see how this ABS would turn out. I love it! Gives a bit darker pink color which makes the reflections "pop" well. Lovely!

Edited 2 time(s). Last edit at 06/22/2016 02:31AM by kodde.

Could this be failing bridging perhaps? In absence of underlying infill structure to rely on I'm guessing this boils down to how well bridging works. What settings should I be tweaking for better bridging?

Maybe a bit OT, but I tried acetone treating that first print just to see how this ABS would turn out. I love it! Gives a bit darker pink color which makes the reflections "pop" well. Lovely!

Edited 2 time(s). Last edit at 06/22/2016 02:31AM by kodde.

Re: ABS warping, what am I doing wrong? June 22, 2016 03:25AM |

Registered: 10 years ago Posts: 28 |

Re: ABS warping, what am I doing wrong? June 23, 2016 02:47AM |

Registered: 10 years ago Posts: 28 |

Here's yet another print, this time with the intention of fixing the hole at the top of the head.

Changes since last print:

Top & bottom infill layers: 6 -> 12

Automatic fan speed: 0% - 40% when layer time 15s - 5s

As you can see the hole in the head is gone

But... general surface quality has gotten quite a lot worse, looks like excess material. I am guessing the change in fast speed only kicks in at top of the head and the surface quality is worse overall. Which leads me to think the doubled amount of top/bottom layers are the cause. Anyone have any experience or knowledge on this?

Right now I'm doing another print with same fan speed settings but top/bottom layers 12 -> 8.

Thanks for the feedback!

Changes since last print:

Top & bottom infill layers: 6 -> 12

Automatic fan speed: 0% - 40% when layer time 15s - 5s

As you can see the hole in the head is gone

But... general surface quality has gotten quite a lot worse, looks like excess material. I am guessing the change in fast speed only kicks in at top of the head and the surface quality is worse overall. Which leads me to think the doubled amount of top/bottom layers are the cause. Anyone have any experience or knowledge on this?

Right now I'm doing another print with same fan speed settings but top/bottom layers 12 -> 8.

Thanks for the feedback!

Re: ABS warping, what am I doing wrong? June 27, 2016 06:21PM |

Registered: 10 years ago Posts: 231 |

Definitely your bridging settings have to be in order. I've found by printing Triffid Hunter's bridge torture test, I have to slow down my speed to 12mm/s and my bridge flow ratio to .87. It took a lot of trial and error to come up with that. A fan might help as well, but I don't have a fan.

The bridging settings have really slowed down my print times because at least Slic3r considers the first solid layer over infill as bridging and slows the speed accordingly. On a big part, it takes forever to do those first solid layers. Also, the head might come out better if you use a lower layer height. .35 might be a little too much to get a smooth curve on the top. Slic3r has a nice feature if you use their Plater tab to allow you to adjust the layer height for only certain parts of the print. So you could say print at .35 for almost the entire thing, then switch to .20 for the top of the head.

As far as the warping, I just started a thread on printing on PEI which so far looks promising. But before that, I found that using Elmer's purple glue stick and pointing 2 100W incandescent bulbs at the build platform helped with my warping issues a lot. I start with the bed temp at 115C for the first layer, then drop it down to 85C for the rest of the layers. The only time I would get some warping would be after fully cleaning the glass of all the glue stick and putting down a fresh coat. That first print in that case would seem to be troublesome. But after that as the glue stick builds up on the plate, it worked well even though it looked ugly.

The bridging settings have really slowed down my print times because at least Slic3r considers the first solid layer over infill as bridging and slows the speed accordingly. On a big part, it takes forever to do those first solid layers. Also, the head might come out better if you use a lower layer height. .35 might be a little too much to get a smooth curve on the top. Slic3r has a nice feature if you use their Plater tab to allow you to adjust the layer height for only certain parts of the print. So you could say print at .35 for almost the entire thing, then switch to .20 for the top of the head.

As far as the warping, I just started a thread on printing on PEI which so far looks promising. But before that, I found that using Elmer's purple glue stick and pointing 2 100W incandescent bulbs at the build platform helped with my warping issues a lot. I start with the bed temp at 115C for the first layer, then drop it down to 85C for the rest of the layers. The only time I would get some warping would be after fully cleaning the glass of all the glue stick and putting down a fresh coat. That first print in that case would seem to be troublesome. But after that as the glue stick builds up on the plate, it worked well even though it looked ugly.

Re: ABS warping, what am I doing wrong? June 29, 2016 03:20AM |

Registered: 10 years ago Posts: 28 |

Thanks for the feedback brucehvn. I'm going to try out lowering the speed and the flow ratio. That torture test seems useful.

I've had good results with the 3DLac so far for both ABS and also PLA. Printing on IKEA Sörli mirrors. So I'll stick to that for the time being. Might check out PEI if the 3DLac starts to fail though.

I've had good results with the 3DLac so far for both ABS and also PLA. Printing on IKEA Sörli mirrors. So I'll stick to that for the time being. Might check out PEI if the 3DLac starts to fail though.

Sorry, only registered users may post in this forum.