My experience with printing ABS on PEI

Posted by brucehvn

|

My experience with printing ABS on PEI June 27, 2016 03:24AM |

Registered: 10 years ago Posts: 231 |

I've just decided to try printing using a PEI sheet on my build surface. Thought I would document my results and findings.

I have an i3 derivative that I built about 2+ years ago. I've printed only ABS in that time.

What I had settled on that worked pretty much about 95% of the time without warping is:

About the only time I would see the chance of warping was if I had just cleaned the build plate of all the glue stick and put down a fresh layer of glue stick. Printing a fairly large item in that situation would show warping, but re-applying the glue stick and re-printing would usually be fine. Seems that it liked to have some buildup of glue stick besides putting down a fresh coat on every print. Since I don't have an enclosed print area, the two light bulbs seemed to be effectively heating the surface enough to also prevent warping. I don't know if every item on that list was necessary, but the combination of them worked pretty well for me.

After reading some great things about printing on PEI, I decided I wanted to try it. I purchased an 8" x 8" .08mm thick sheet from eBay and it arrived a couple days ago. I was pretty anxious to try it out as the thought of never having to worry about glue stick anymore was very enticing.

Since the sheet is very thin and flexible, I could see it was going to take some more bulldog clips to hold it to my mirror tile tightly and securely. I'm using a total of 8 clips now, 2 on each side.

The sheet I got was glossy on one side and more of a matte finish on the other. Based on what I'd seen posted in various places, I opted to use the matte side for printing.

It was my hope that I would be able to do away with the heat lamps as well since they make the machine look cluttered and it would clear a lot of space at the front.

Ok, so let's get started...

I have an i3 derivative that I built about 2+ years ago. I've printed only ABS in that time.

What I had settled on that worked pretty much about 95% of the time without warping is:

- Bed surface is home depot mirror tiles cut to fit the standard heated bed. Tile held down with 2 bulldog clips, one on each side.

- Bed temp 115 for first layer, 85 for subsequent layers.

- Elmers purple glue stick.

- 2 - 100W incandescent bulbs pointed at the build plate during printing.

About the only time I would see the chance of warping was if I had just cleaned the build plate of all the glue stick and put down a fresh layer of glue stick. Printing a fairly large item in that situation would show warping, but re-applying the glue stick and re-printing would usually be fine. Seems that it liked to have some buildup of glue stick besides putting down a fresh coat on every print. Since I don't have an enclosed print area, the two light bulbs seemed to be effectively heating the surface enough to also prevent warping. I don't know if every item on that list was necessary, but the combination of them worked pretty well for me.

After reading some great things about printing on PEI, I decided I wanted to try it. I purchased an 8" x 8" .08mm thick sheet from eBay and it arrived a couple days ago. I was pretty anxious to try it out as the thought of never having to worry about glue stick anymore was very enticing.

Since the sheet is very thin and flexible, I could see it was going to take some more bulldog clips to hold it to my mirror tile tightly and securely. I'm using a total of 8 clips now, 2 on each side.

The sheet I got was glossy on one side and more of a matte finish on the other. Based on what I'd seen posted in various places, I opted to use the matte side for printing.

It was my hope that I would be able to do away with the heat lamps as well since they make the machine look cluttered and it would clear a lot of space at the front.

Ok, so let's get started...

|

Re: My experience with printing ABS on PEI June 27, 2016 03:36AM |

Registered: 10 years ago Posts: 231 |

I had to re-calibrate my z-probe offset for the new material. Up until about 3 weeks ago, I was using the standard servo controlled micro switch based probing arm for ABL, but then switched out to an Omrom EE-SPY402 optical sensor that is fixed to try and gain more accuracy. I could do a whole other posting on that and probably will at some point. So because there is a difference in the reflectivity of the PEI vs. the raw mirror tile, I had to adjust my z offset again, but got that dialed in.

So I had seen from the Wiki and other sources that people were finding success printing ABS on PEI with bed temperatures from 80-100C. I decided I would start out at 90. As per other information I read, I would clean the surface of the PEI with 91% rubbing alcohol between each print session. The first few items I tested were small pieces. I found they had no problem with adhesion and came off with no problem once the bed was cooled. I was also not using the heat lamps at this point, just to see how well it would work. I was amazed at how smooth the bottom of the printed object was. Having rough layers of old glue stick caused the bottoms of my prints to always be a little rough.

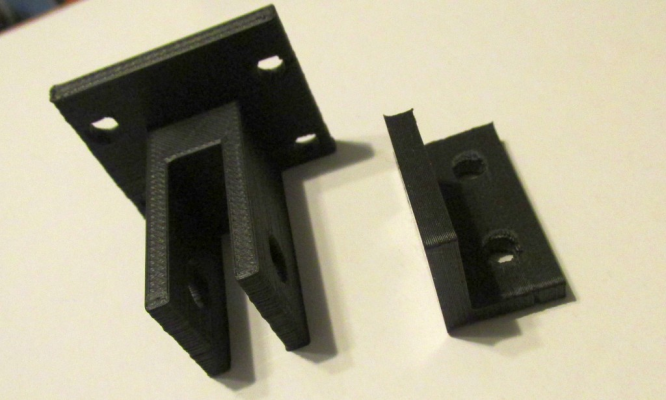

So far so good. Now to try something a little bigger. I'm about to get some parts from OpenBuilds and want to rebuild the Y axis of my printer using v-slot and their wheels for the linear motion. So I've been designing and printing some various parts to adapt to the new frame.

First up was the rear motor mount...

So I had seen from the Wiki and other sources that people were finding success printing ABS on PEI with bed temperatures from 80-100C. I decided I would start out at 90. As per other information I read, I would clean the surface of the PEI with 91% rubbing alcohol between each print session. The first few items I tested were small pieces. I found they had no problem with adhesion and came off with no problem once the bed was cooled. I was also not using the heat lamps at this point, just to see how well it would work. I was amazed at how smooth the bottom of the printed object was. Having rough layers of old glue stick caused the bottoms of my prints to always be a little rough.

So far so good. Now to try something a little bigger. I'm about to get some parts from OpenBuilds and want to rebuild the Y axis of my printer using v-slot and their wheels for the linear motion. So I've been designing and printing some various parts to adapt to the new frame.

First up was the rear motor mount...

|

Re: My experience with printing ABS on PEI June 27, 2016 03:48AM |

Registered: 10 years ago Posts: 231 |

The new motor mount has two arms that attach to the motor in sort of a horse shoe fashion. Feeling cocky about the small pieces I had printed on the PEI up until now, I started this printing only to get OOPS

Ok, well that knocked me off my high horse. Reading some other users experiences, it seemed when they had problems with warping, they would try increasing the bed temp. I decided to try and increase my temp to 100C.

Next is the same object printed at that temp...

Ok, well that knocked me off my high horse. Reading some other users experiences, it seemed when they had problems with warping, they would try increasing the bed temp. I decided to try and increase my temp to 100C.

Next is the same object printed at that temp...

|

Re: My experience with printing ABS on PEI June 27, 2016 04:03AM |

Registered: 10 years ago Posts: 231 |

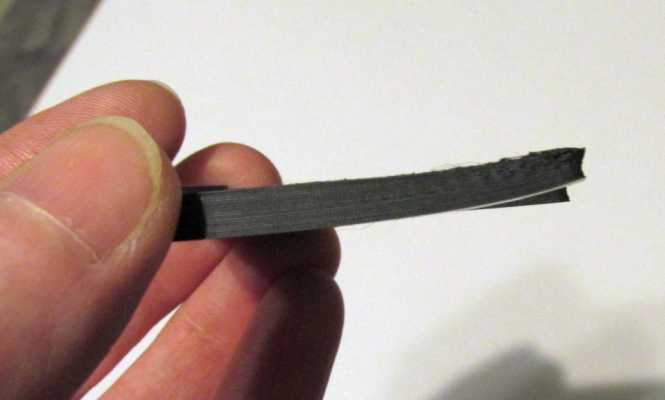

With the bed temp turned up to 100C, I attempted to print out the motor mount piece again. This time it turned out much better and at first glance showed no signs of warping.

However, because the bottom of the print is so smooth, you can actually see any imperfections. Looking at the bottom of the print we can see this:

So, there actually was a slight warping, but in looking at the profile view of the part, you really have to look for it and it certainly does not ruin the part. I can still use it. You probably can't even see it in the photo above. One thing to note is that there does seem to be a temperature differential between the reading from the thermistor and the build plate surface. Checking the temp with an infared thermometer showed the surface about 8-10 degrees C lower than what was being read by the printer. This is probably due to the fact that PEI is an insulator and the thermistor is reading from the bottom of the mirror plate. So while I'm setting the bed temperature to 100, I might really only be getting 90 at the surface.

Next up is the pulley bracket. I decided to print this at the same settings to see how that would work...

Edited 1 time(s). Last edit at 06/27/2016 04:26AM by brucehvn.

However, because the bottom of the print is so smooth, you can actually see any imperfections. Looking at the bottom of the print we can see this:

So, there actually was a slight warping, but in looking at the profile view of the part, you really have to look for it and it certainly does not ruin the part. I can still use it. You probably can't even see it in the photo above. One thing to note is that there does seem to be a temperature differential between the reading from the thermistor and the build plate surface. Checking the temp with an infared thermometer showed the surface about 8-10 degrees C lower than what was being read by the printer. This is probably due to the fact that PEI is an insulator and the thermistor is reading from the bottom of the mirror plate. So while I'm setting the bed temperature to 100, I might really only be getting 90 at the surface.

Next up is the pulley bracket. I decided to print this at the same settings to see how that would work...

Edited 1 time(s). Last edit at 06/27/2016 04:26AM by brucehvn.

|

Re: My experience with printing ABS on PEI June 27, 2016 04:11AM |

Registered: 10 years ago Posts: 231 |

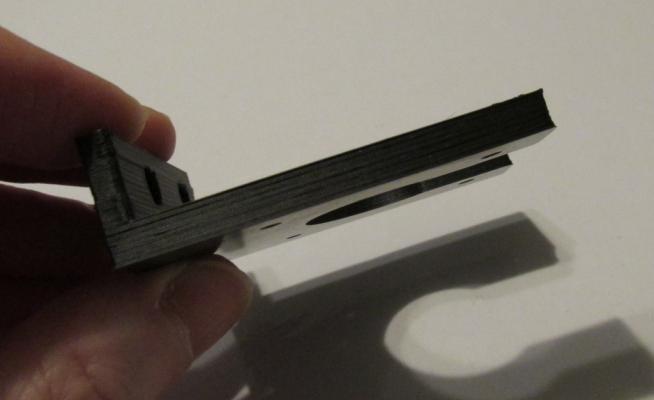

Printing the pulley bracket at the same settings of 100C for the bed temperature again resulted in a part that at first glance looked fine. However, inspecting the underside of the part, we can again see some minor warping:

On this part, looking at the profile view, it's a little easier to see the warping, but again not a deal breaker for using the part.

Sigh. So the next step is to try turning on the heat lamps again during printing. I could try and increase the bed temperature as well, but I like the fact that I can be printing much faster by only heating to 100C. 90C was even better, but alas, that doesn't work well at all.

Next up, a redesigned pulley bracket and one corner plate...

On this part, looking at the profile view, it's a little easier to see the warping, but again not a deal breaker for using the part.

Sigh. So the next step is to try turning on the heat lamps again during printing. I could try and increase the bed temperature as well, but I like the fact that I can be printing much faster by only heating to 100C. 90C was even better, but alas, that doesn't work well at all.

Next up, a redesigned pulley bracket and one corner plate...

|

Re: My experience with printing ABS on PEI June 27, 2016 04:20AM |

Registered: 10 years ago Posts: 231 |

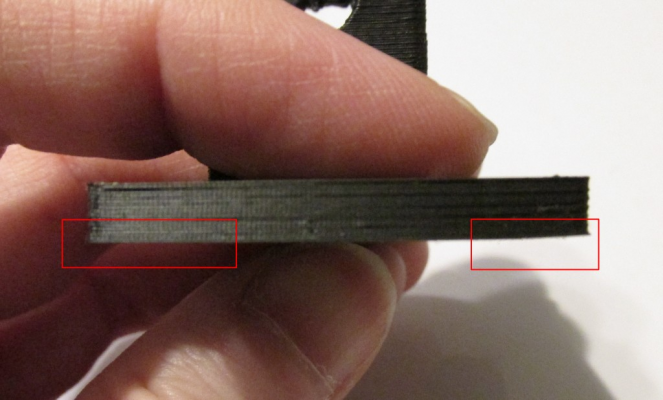

Ok, so here are the next parts I printed on the PEI. This time I kept with my 100C bed temperature, but also used the 100W bulbs to heat the platform from the top.

These two pieces printed really good except for one minor glitch. If we look at the bottom of the pulley bracket, we see on the end of one of the arms, we got just a smidge of warping.

Seeing this in the profile view, it is easily seen, but it's not going to affect usage of the part.

So that's where I'm at so far. Hopefully this info might be helpful to others. As I keep printing more with the PEI surface, I'll post some more results.

These two pieces printed really good except for one minor glitch. If we look at the bottom of the pulley bracket, we see on the end of one of the arms, we got just a smidge of warping.

Seeing this in the profile view, it is easily seen, but it's not going to affect usage of the part.

So that's where I'm at so far. Hopefully this info might be helpful to others. As I keep printing more with the PEI surface, I'll post some more results.

|

Re: My experience with printing ABS on PEI June 30, 2016 02:34PM |

Registered: 10 years ago Posts: 231 |

Since my last post, I've printed probably about 30 different parts, the biggest of which was 120mm x 65mm and I've had absolutely no warping using the last thing I was trying, which is the bed at 100C and light bulbs pointed at the build surface.

I clean the PEI with alcohol after every print and I see no signs of any buildup or residue. Once the bed cools, the parts just come right off, rarely are they even stuck to the bed at that point.

So, overall, I'm pretty jazzed about this print surface and thinking I should have done this a long time ago.

I clean the PEI with alcohol after every print and I see no signs of any buildup or residue. Once the bed cools, the parts just come right off, rarely are they even stuck to the bed at that point.

So, overall, I'm pretty jazzed about this print surface and thinking I should have done this a long time ago.

|

Re: My experience with printing ABS on PEI July 01, 2016 11:13AM |

Registered: 10 years ago Posts: 293 |

|

Re: My experience with printing ABS on PEI July 02, 2016 02:30AM |

Registered: 11 years ago Posts: 1,171 |

I print on PEI and I set my bed to 110c for the first 2 layers then down to 95c.

Having a perfectly level bed is important with PEI, also you can hit it with very fine sandpaper (400 - 1200 grit) to get it to bite a little more, clean it with a little isopropyl alcohol. Also with ABS you really do need a heated build chamber to keep the part warm thought the print to prevent warping. It's well worth it to build a good one.

I love my PEI, Rarely have warps, parts remove fairly easy.

Having a perfectly level bed is important with PEI, also you can hit it with very fine sandpaper (400 - 1200 grit) to get it to bite a little more, clean it with a little isopropyl alcohol. Also with ABS you really do need a heated build chamber to keep the part warm thought the print to prevent warping. It's well worth it to build a good one.

I love my PEI, Rarely have warps, parts remove fairly easy.

|

Re: My experience with printing ABS on PEI July 04, 2016 03:41AM |

Registered: 10 years ago Posts: 231 |

Quote

WZ9V

I you might want to put a thermometer on the PEI plate because you may not be getting the entire 100C at the surface. I like to use a multimeter thermocouple to see what my actual surface temp is and then adjust accordingly.

Based on readings with an infrared thermometor, the surface is about 8-10 degrees cooler than the reported thermistor temperature. I think that's why some people say they print at 90, some at 100, etc. There's a lot of variation in what people's bed surfaces are and they just figure out what thermistor reading to print at.

|

Re: My experience with printing ABS on PEI July 05, 2016 04:12AM |

Registered: 8 years ago Posts: 916 |

|

Re: My experience with printing ABS on PEI October 06, 2016 08:04PM |

Registered: 8 years ago Posts: 108 |

I never clean mine  and works all the time, I use 110C for ABS and 50C for PLA, you need to make sure the temperature on top of PEI is over 100C because the temp sensor is on the actual bed and the heat needs to go through glass and then PEI and believe me a lot of heat is lost. Anyway I started using this material when at my school where I work I setup a Lulzbot printer and I was surprised for the fact we don't need to use glue or blue tape.

and works all the time, I use 110C for ABS and 50C for PLA, you need to make sure the temperature on top of PEI is over 100C because the temp sensor is on the actual bed and the heat needs to go through glass and then PEI and believe me a lot of heat is lost. Anyway I started using this material when at my school where I work I setup a Lulzbot printer and I was surprised for the fact we don't need to use glue or blue tape.

and works all the time, I use 110C for ABS and 50C for PLA, you need to make sure the temperature on top of PEI is over 100C because the temp sensor is on the actual bed and the heat needs to go through glass and then PEI and believe me a lot of heat is lost. Anyway I started using this material when at my school where I work I setup a Lulzbot printer and I was surprised for the fact we don't need to use glue or blue tape.

and works all the time, I use 110C for ABS and 50C for PLA, you need to make sure the temperature on top of PEI is over 100C because the temp sensor is on the actual bed and the heat needs to go through glass and then PEI and believe me a lot of heat is lost. Anyway I started using this material when at my school where I work I setup a Lulzbot printer and I was surprised for the fact we don't need to use glue or blue tape.

|

Re: My experience with printing ABS on PEI March 23, 2019 04:53AM |

Registered: 5 years ago Posts: 11 |

|

Re: My experience with printing ABS on PEI March 23, 2019 07:49AM |

Registered: 11 years ago Posts: 5,780 |

3 year old thread, but OK.

What size are your magic ABS prints? Can you post a few photos?

It has been my experience that you can print small ABS parts, or even large single walled vases without a warm enclosure, but a print cooling fan will absolutely destroy the print.

Guess which one was printed in a warm enclosure and which was on an open machine:

Edited 1 time(s). Last edit at 03/23/2019 07:49AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

What size are your magic ABS prints? Can you post a few photos?

It has been my experience that you can print small ABS parts, or even large single walled vases without a warm enclosure, but a print cooling fan will absolutely destroy the print.

Guess which one was printed in a warm enclosure and which was on an open machine:

Edited 1 time(s). Last edit at 03/23/2019 07:49AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.