Uneven surface problem

Posted by MosfetN

|

Uneven surface problem September 17, 2016 01:20PM |

Registered: 7 years ago Posts: 25 |

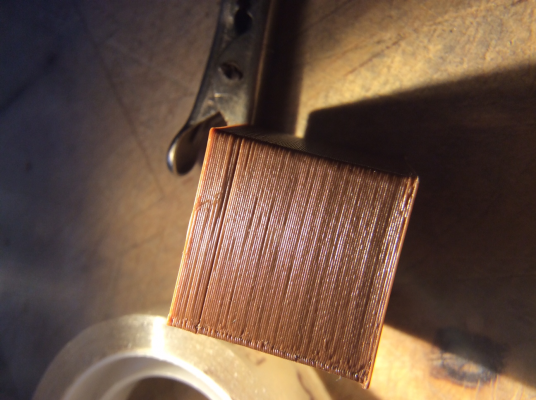

Surface of the print is not smooth . I don't know what could cause this problem .

That's what i have tried to do/change with no results:

- replace standard Mk7 extruder to geared one (belt driven 3:1)

- microsteps

- motor current

- belt tension

- feedrate

- extrusion multiplier

- extrusion width

- bowden tube shortening

- hotend temperature

- different filaments

- replacing PTFE tube connector for one without looseness

- acceleration

- XY jerk

- changing stepsticks

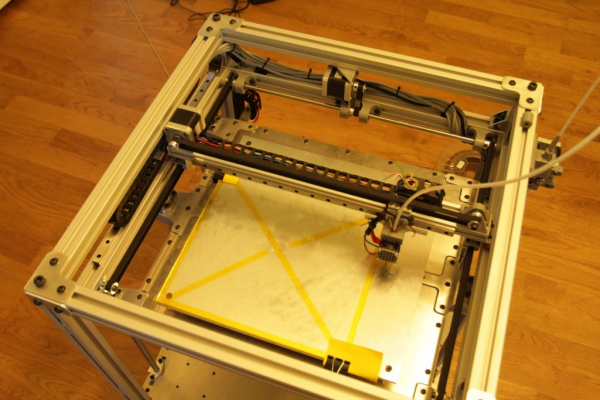

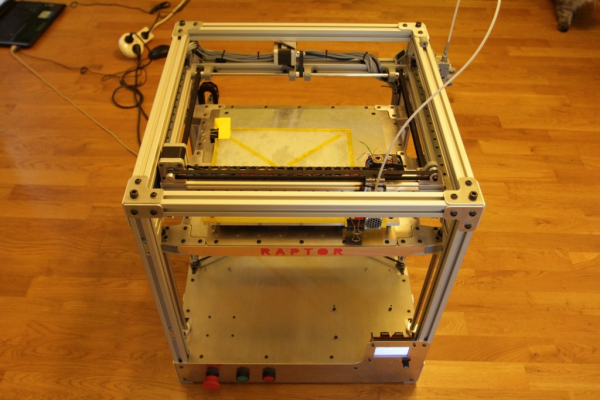

Printer is made from aluminium extrusion and HIWIN rail,s and its very rigid.

Edited 1 time(s). Last edit at 09/18/2016 08:56AM by MosfetN.

That's what i have tried to do/change with no results:

- replace standard Mk7 extruder to geared one (belt driven 3:1)

- microsteps

- motor current

- belt tension

- feedrate

- extrusion multiplier

- extrusion width

- bowden tube shortening

- hotend temperature

- different filaments

- replacing PTFE tube connector for one without looseness

- acceleration

- XY jerk

- changing stepsticks

Printer is made from aluminium extrusion and HIWIN rail,s and its very rigid.

Edited 1 time(s). Last edit at 09/18/2016 08:56AM by MosfetN.

|

Re: Uneven surface problem September 17, 2016 01:42PM |

Registered: 11 years ago Posts: 5,780 |

Which surface are you complaining about, top, bottom, or sides?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Uneven surface problem September 17, 2016 02:47PM |

Registered: 7 years ago Posts: 45 |

|

Re: Uneven surface problem September 17, 2016 03:47PM |

Registered: 7 years ago Posts: 25 |

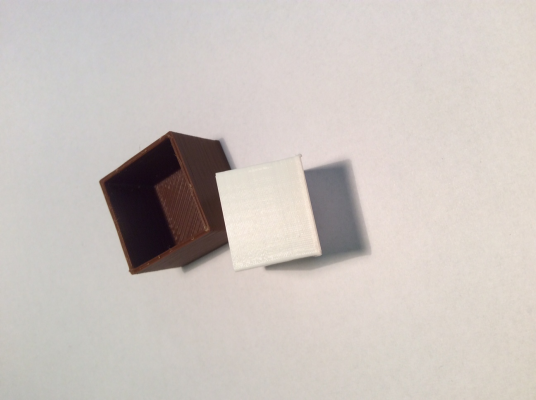

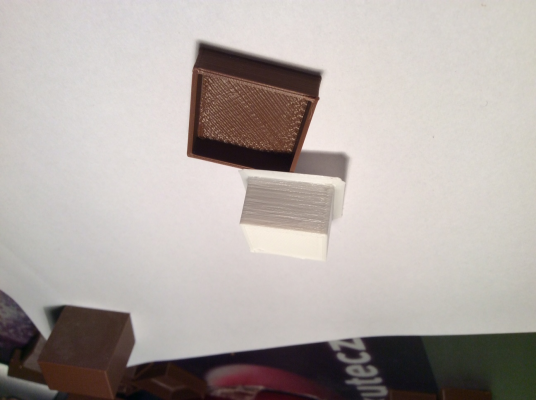

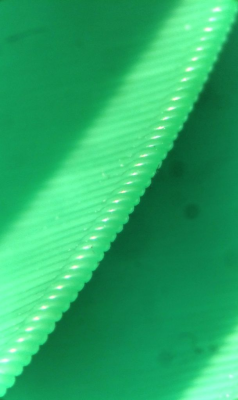

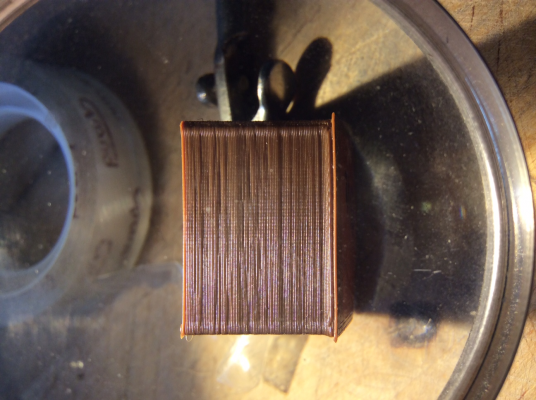

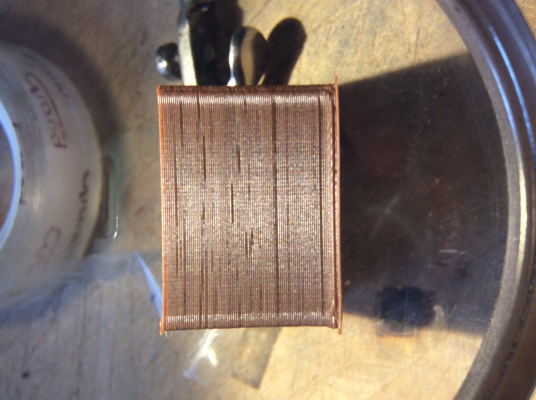

Im complaining about sides of the print (0.3mm layers look very good but 0.2 or less are very uneven like on the photo). Im 100% sure that it isn't over extrusion (measurements in one of the photos). Perimeters that should have 0.8 (2x0.4mm) actually have 0.79mm or 0.8. Acceleration or X/Y jerk doesn't make any changes to print quality. Im printing with ABS + dimafix + heatbed at 80 degree C.

Edited 1 time(s). Last edit at 09/17/2016 03:48PM by MosfetN.

Edited 1 time(s). Last edit at 09/17/2016 03:48PM by MosfetN.

|

Re: Uneven surface problem September 17, 2016 05:53PM |

Registered: 11 years ago Posts: 5,780 |

I'd say that those sides look pretty good, actually. You can check layer registration by looking at the square corners. From what I can see, they look like they are lined up pretty well. If they look worse at 200 um than at 300 um, maybe the Z axis isn't behaving itself. The tiny error you're chasing could be variation in layer thickness caused by the Z axis bouncing or tilting slightly. It could also be in the frame rigidity, though speeding up the printer will probably make that worse. Even temperature variation in the bed and/or hot end could cause this small level of error. Rerun the PID tuning, check the Z axis (is it cantilevered?).

Do you have a microscope? I have found it very useful for critical print analysis. You can buy clip on microscope lenses for cell phone cameras for <$10 if you don't have access to a real microscope. This is the sort of stuff you can see:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Do you have a microscope? I have found it very useful for critical print analysis. You can buy clip on microscope lenses for cell phone cameras for <$10 if you don't have access to a real microscope. This is the sort of stuff you can see:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Uneven surface problem September 18, 2016 08:27AM |

Registered: 8 years ago Posts: 318 |

my money would be on the z axis, but it actually isnt that bad. Could be a bent threaded rod? though that would probably manifest itself more noticeably. You buy cheap filament? if so, that could easily be variations in diameter.

On another note, make sure you are basing you microsteps/extrusion on getting a perfect 2cm cube. This is something that some people do but it is not the way to get the most accurate prints. (wouldnt cause the problem you are having though)

Edited 1 time(s). Last edit at 09/18/2016 08:30AM by DaGameFace.

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

On another note, make sure you are basing you microsteps/extrusion on getting a perfect 2cm cube. This is something that some people do but it is not the way to get the most accurate prints. (wouldnt cause the problem you are having though)

Edited 1 time(s). Last edit at 09/18/2016 08:30AM by DaGameFace.

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

|

Re: Uneven surface problem September 18, 2016 08:47AM |

Registered: 7 years ago Posts: 25 |

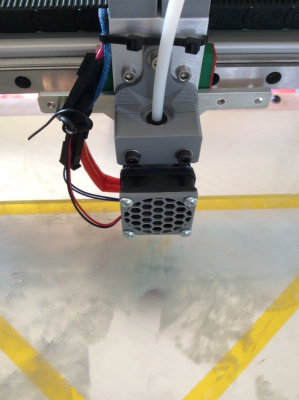

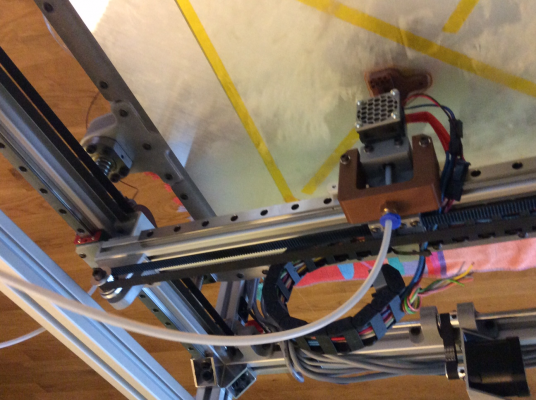

I don't think that is caused by Z axis anyway i ll check that with Clock Dial Test Indicator. I have 2 1605 Ballscrews on Z axis with endless belt and one motor (1/4 microstepping) supported o both sides . Even if that would be Z axis the stripes would go all way around cube , but they actually don't. In attachment there are some zoomed photos . I have done PID tuning 2 times with no effect. Today i 'll change my hotend from my new e3d v6 (with thermistor cartdrige) to an old one j-hed peak heotend. Maybe there's something wrong with it. If i speed up print everything looks the same (15mm/s to 80mm/s). I use bowden with belt driven geared extruder. I switched to direct with no effect.Printer is quite large printing dimensions are : 362.6mm x 342.6mm x 350mm. I have 9mm GT2 belt and 20 tooth pulley,s and MKS GEN 1.4 electronics -> maybe there is a problem.My filament haves very good diameter and roundness stability , it isn't the cheap one.

Edited 1 time(s). Last edit at 09/18/2016 08:53AM by MosfetN.

Edited 1 time(s). Last edit at 09/18/2016 08:53AM by MosfetN.

|

Re: Uneven surface problem September 18, 2016 09:05AM |

Registered: 11 years ago Posts: 5,780 |

How many sides exhibit that roughness? If it is on just one side, I'd say the problem is probably mechanical. Look for flex in the motor and or pulley mounts. Do the belts run without interference, parallel to their guide rails?

Have you tried a different slicer? After many hours of chasing variations in print quality I have found that some, occasionally even gross variations, are attributable to variations in slicers. Even with settings as close to identical as possible, there will be differences. I've had some parts print perfectly with one slicer and come out awful with another. I keep S3D, Slic3r, and Cura handy. I will often slice in all three then select the one that looks best on-screen to print.

Try printing multiple objects at once and see if it improves. Sometimes it's just a matter of letting the previous layer cool a bit before putting down the next one. When I am trying to print small parts, I either print multiples of the part or I add a sacrificial cylinder to the bed to keep the extruder busy while the print cools between layers.

The standard 20mm cube is much too small for calibration of steps/mm, unless you only print very small objects. There is always error in your measurement. If you use a 20 mm cube to set steps/mm, when you print a larger object the error in that 20 mm measurement will multiply. If you calibrate with a larger object, say 100 mm square, when you print smaller objects the error in the 100 mm measurement will divide. If you have a really big caliper that is accurate, print the largest possible object to calibrate your printer's steps/mm.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Have you tried a different slicer? After many hours of chasing variations in print quality I have found that some, occasionally even gross variations, are attributable to variations in slicers. Even with settings as close to identical as possible, there will be differences. I've had some parts print perfectly with one slicer and come out awful with another. I keep S3D, Slic3r, and Cura handy. I will often slice in all three then select the one that looks best on-screen to print.

Try printing multiple objects at once and see if it improves. Sometimes it's just a matter of letting the previous layer cool a bit before putting down the next one. When I am trying to print small parts, I either print multiples of the part or I add a sacrificial cylinder to the bed to keep the extruder busy while the print cools between layers.

The standard 20mm cube is much too small for calibration of steps/mm, unless you only print very small objects. There is always error in your measurement. If you use a 20 mm cube to set steps/mm, when you print a larger object the error in that 20 mm measurement will multiply. If you calibrate with a larger object, say 100 mm square, when you print smaller objects the error in the 100 mm measurement will divide. If you have a really big caliper that is accurate, print the largest possible object to calibrate your printer's steps/mm.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Uneven surface problem September 18, 2016 10:20AM |

Registered: 7 years ago Posts: 25 |

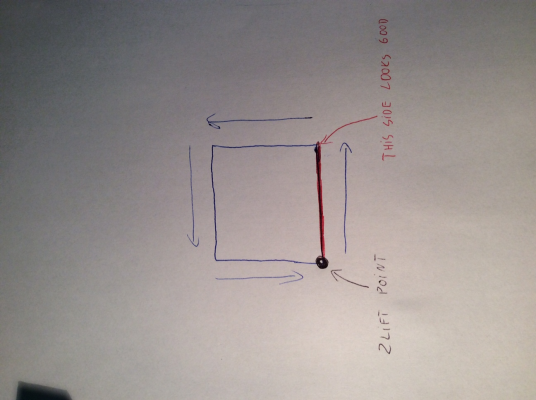

All 4 sides have this roughness but one of them is different (smoother) it is the first one after Z lift.

Short video of 3d printer running

https://youtu.be/J8MFaaJ-r84

Belts run smooth paralel to rail,s

I ll try different slicer today.

Edited 1 time(s). Last edit at 09/18/2016 10:25AM by MosfetN.

Short video of 3d printer running

https://youtu.be/J8MFaaJ-r84

Belts run smooth paralel to rail,s

I ll try different slicer today.

Edited 1 time(s). Last edit at 09/18/2016 10:25AM by MosfetN.

|

Re: Uneven surface problem September 18, 2016 01:10PM |

Registered: 8 years ago Posts: 318 |

EDIT: post removed, it was originally marked a robot spam so I got a duplicate

Edited 1 time(s). Last edit at 09/18/2016 10:51PM by DaGameFace.

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

Edited 1 time(s). Last edit at 09/18/2016 10:51PM by DaGameFace.

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

|

Re: Uneven surface problem September 18, 2016 01:15PM |

Registered: 8 years ago Posts: 318 |

|

Re: Uneven surface problem September 18, 2016 03:43PM |

Registered: 7 years ago Posts: 25 |

|

Re: Uneven surface problem September 18, 2016 08:01PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Uneven surface problem September 19, 2016 03:14AM |

Registered: 11 years ago Posts: 973 |

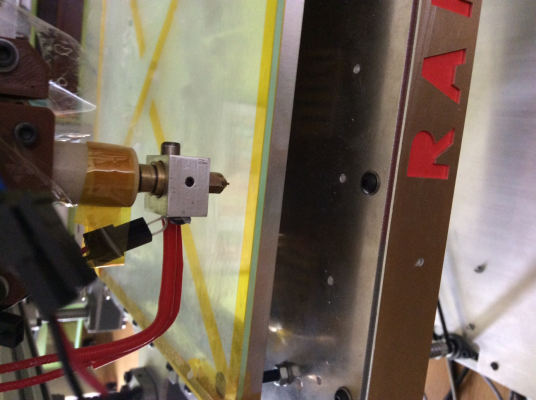

i would say nozzle one of the pictures shows that in misses part of the layer. also what material you printing if pla make sure fan hitting on the layer

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: Uneven surface problem September 19, 2016 09:31AM |

Registered: 8 years ago Posts: 318 |

The more I look at this the more I think that it has to be wobble in the mechanics. Not the frame, that printer looks extremely well built. But, you have so many belts, that I there is bound to be lash in them. Not to mention your x axis, looks like it would be likely to have a tiny bit more give than traditional smooth rails and bearings.

This would explain why one of the faces is fine, it is just after a z layer change meaning that during the change the belts all stop and the lash goes away, it gets moved in one direction which it does fine. But then when it needs to change direction its momentum effects the perimeter because the belts have tiny amounts of play in them. Thereby leaving imperfections in the other 3 sides.

I find it kinda funny, that a machine as well built as that can suffer from outer perimeter problems while my really wobbly i3 acrylic frame prints beautiful parts. (though they can't be nearly as square and true as anything your machine produces)

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

This would explain why one of the faces is fine, it is just after a z layer change meaning that during the change the belts all stop and the lash goes away, it gets moved in one direction which it does fine. But then when it needs to change direction its momentum effects the perimeter because the belts have tiny amounts of play in them. Thereby leaving imperfections in the other 3 sides.

I find it kinda funny, that a machine as well built as that can suffer from outer perimeter problems while my really wobbly i3 acrylic frame prints beautiful parts. (though they can't be nearly as square and true as anything your machine produces)

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

|

Re: Uneven surface problem September 19, 2016 09:58AM |

Registered: 11 years ago Posts: 5,780 |

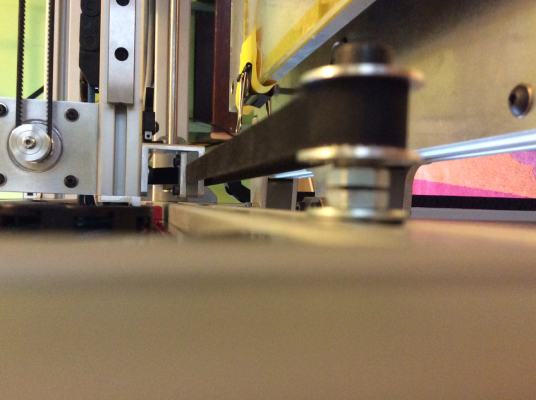

You've apparently never used linear guides. There's absolutely no play in those bearings. The rail is attached to a piece of 2020 or tubing which makes it even stiffer than it normally is. The X axis is very rigid and uses a single relatively short belt that appears to be 9 mm wide. It is the last place I'd expect to see a problem in this build. The Y axis uses a shaft to drive both ends of the X axis. That shaft is belt driven. Maybe there's some play/stretch in the belts or twist in the shaft that drives the axis. Maybe the two Y axis belts at the ends of the X axis are not equally tensioned allowing one side to lag the other slightly.

I still think the problem is most likely in the Z axis.

Or in the slicer.

Or...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I still think the problem is most likely in the Z axis.

Or in the slicer.

Or...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Uneven surface problem September 19, 2016 11:35AM |

Registered: 10 years ago Posts: 651 |

Would you also post pics of your machine?

Edit: After watching the youtube video. I'd second Dentist's last suggestion about equal belt tension on the Y

Also for the Z, you have 4 linear rods, with 2 lead screws at the center on both sides. Does the bed seesaw at all?

Edited 3 time(s). Last edit at 09/19/2016 11:49AM by FA-MAS.

Edit: After watching the youtube video. I'd second Dentist's last suggestion about equal belt tension on the Y

Also for the Z, you have 4 linear rods, with 2 lead screws at the center on both sides. Does the bed seesaw at all?

Edited 3 time(s). Last edit at 09/19/2016 11:49AM by FA-MAS.

|

Re: Uneven surface problem September 19, 2016 02:54PM |

Registered: 8 years ago Posts: 318 |

Quote

the_digital_dentist

You've apparently never used linear guides. There's absolutely no play in those bearings. The rail is attached to a piece of 2020 or tubing which makes it even stiffer than it normally is. The X axis is very rigid and uses a single relatively short belt that appears to be 9 mm wide. It is the last place I'd expect to see a problem in this build. The Y axis uses a shaft to drive both ends of the X axis. That shaft is belt driven. Maybe there's some play/stretch in the belts or twist in the shaft that drives the axis. Maybe the two Y axis belts at the ends of the X axis are not equally tensioned allowing one side to lag the other slightly.

Yeah it was the Y that really caught my attention, a long fairly thin shaft can twist, plus 3 belts? sounds like a likely source of lash. And yeah, I was indeed unfamiliar with linear guides.

SO, the x axis is out, Y, Maybe? I thought that Z axis was insanely overbuilt, would surprise me if that is where his problems lay. Just for the hell of it could you print a 20x20 cylinder? (with the circular base as the bottom and top layer)

|

Re: Uneven surface problem September 20, 2016 02:06PM |

Registered: 7 years ago Posts: 25 |

Quote

JamesK

Is the Z dimension of your test-cube what you expect it to be? Having just spent the weekend fighting my Z axis I have missed steps on my mind. On X and Y missed steps are immediately obvious, not so much on Z. It can sneak up on you and causes artefacts not unlike those you show.

Yes it is what i expect to be. I ll check the Z step accuracy with Clock Dial Test Indicator when it arrives.

Quote

chris33

i would say nozzle one of the pictures shows that in misses part of the layer. also what material you printing if pla make sure fan hitting on the layer

I ll try to change the whole hotend to a j-head peek one.

Quote

DaGameFace

The more I look at this the more I think that it has to be wobble in the mechanics. Not the frame, that printer looks extremely well built. But, you have so many belts, that I there is bound to be lash in them. Not to mention your x axis, looks like it would be likely to have a tiny bit more give than traditional smooth rails and bearings.

This would explain why one of the faces is fine, it is just after a z layer change meaning that during the change the belts all stop and the lash goes away, it gets moved in one direction which it does fine. But then when it needs to change direction its momentum effects the perimeter because the belts have tiny amounts of play in them. Thereby leaving imperfections in the other 3 sides.

I find it kinda funny, that a machine as well built as that can suffer from outer perimeter problems while my really wobbly i3 acrylic frame prints beautiful parts. (though they can't be nearly as square and true as anything your machine produces)

I ll reassembly and check all belts, I found that the toothed idlers are a little wobbly. i ll change them to flanged bearings.(I know that i should't do this with GT2 belts but its worth checking)

Quote

the_digital_dentist

You've apparently never used linear guides. There's absolutely no play in those bearings. The rail is attached to a piece of 2020 or tubing which makes it even stiffer than it normally is. The X axis is very rigid and uses a single relatively short belt that appears to be 9 mm wide. It is the last place I'd expect to see a problem in this build. The Y axis uses a shaft to drive both ends of the X axis. That shaft is belt driven. Maybe there's some play/stretch in the belts or twist in the shaft that drives the axis. Maybe the two Y axis belts at the ends of the X axis are not equally tensioned allowing one side to lag the other slightly.

I would say that the X axis is almost bulletproof like the Z axis and the whole frame. Everything is made from aluminium and steel. The X axis rail is bolted to 20x40mm aluminium extrusion so it is rock solid. Whole printer weights about 15-20Kg and X assembly with stepper less than 1Kg.

Quote

FA-MAS

Would you also post pics of your machine?

Edit: After watching the youtube video. I'd second Dentist's last suggestion about equal belt tension on the Y

Also for the Z, you have 4 linear rods, with 2 lead screws at the center on both sides. Does the bed seesaw at all?

Heated Bed is made from 8mm thick precision aluminium plate machined on CNC. Z axis platform is almost 28 mm thick (structural design made of 20x20 extrusions and sheets of laser cut aluminium and it uses 1605 ball screws and 12mm linear shafts ) and there is absolutely no looseness. You can place 1Kg weight on one of its corners and it wouldn't move or seesaw.

I 'll post more pics of my printer later:

Quote

DaGameFace

Yeah it was the Y that really caught my attention, a long fairly thin shaft can twist, plus 3 belts? sounds like a likely source of lash. And yeah, I was indeed unfamiliar with linear guides.

SO, the x axis is out, Y, Maybe? I thought that Z axis was insanely overbuilt, would surprise me if that is where his problems lay. Just for the hell of it could you print a 20x20 cylinder? (with the circular base as the bottom and top layer)

I think that this 8mm linear shaft can't twist it is only 450mm long also the accelerations are not high .

The most possible is that there might be something wrong with Y and X belts or steppers or electronics.

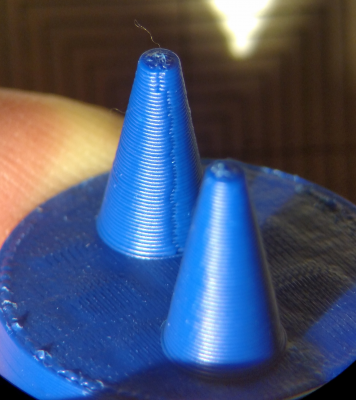

There it is 20mm dia cylinder and 20mm height, 0.2mm layer ,ABS,Simplifiy 3D,0.45mm extrusin width:

List of things to do /check:

-Pulley,s

-Change idlers to bearings

-Check Z axis for missed steps

-Change belts to MXL from old printer

-Change hotend

-Double Check Y axis belt tension

-...........

Edited 2 time(s). Last edit at 09/20/2016 02:23PM by MosfetN.

|

Re: Uneven surface problem September 20, 2016 02:09PM |

Registered: 11 years ago Posts: 5,780 |

Make sure the extruder drive gear is clean.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Uneven surface problem September 20, 2016 02:45PM |

Registered: 9 years ago Posts: 1,873 |

Yes, as per DD's comment, given the general solidness of your build, I'm starting to suspect the extruder and that long bowden setup. I wonder if it would be possible to test for even extrusion by printing line segments a single layer thick? It would be nice to have a test that separated out possible extruder issues from possible Z axis issues.

Very nice looking build - I'm sure you'll get this worked out.

Very nice looking build - I'm sure you'll get this worked out.

|

Re: Uneven surface problem September 20, 2016 05:25PM |

Registered: 8 years ago Posts: 318 |

8mm rod? yeah that shouldn't be nearly as bad as I thought, looked like 5mm at a glance.

okay, my theory behind the cylinder was that a constant change in direction wouldn't produce the ugliness that a sudden change would like the corners in the cube if it were indeed play in the rods and belts.

okay, my theory behind the cylinder was that a constant change in direction wouldn't produce the ugliness that a sudden change would like the corners in the cube if it were indeed play in the rods and belts.

|

Re: Uneven surface problem September 20, 2016 05:41PM |

Registered: 7 years ago Posts: 558 |

|

Re: Uneven surface problem September 23, 2016 08:31AM |

Registered: 7 years ago Posts: 25 |

Im sure the drive gear is clean.

I disabled retraction and there are no results.

Yesterday i have changed the whole hotend assembly from genuine E3D V6 to old one peek J-head with 0.5mm nozzle.

Results are surprising the surface is now much smoother.

I think there must be something wrong with extruder/bowden/hotend assembly.

I disabled retraction and there are no results.

Yesterday i have changed the whole hotend assembly from genuine E3D V6 to old one peek J-head with 0.5mm nozzle.

Results are surprising the surface is now much smoother.

I think there must be something wrong with extruder/bowden/hotend assembly.

|

Re: Uneven surface problem September 23, 2016 01:16PM |

Registered: 7 years ago Posts: 25 |

I have tested My Z axis today here are results of 0.1mm move measurement . Max error i see over there is +/- 0.02mm.

https://youtu.be/mkLbKHYwql0

Edited 1 time(s). Last edit at 09/23/2016 01:17PM by MosfetN.

https://youtu.be/mkLbKHYwql0

Edited 1 time(s). Last edit at 09/23/2016 01:17PM by MosfetN.

|

Re: Uneven surface problem September 23, 2016 01:23PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Uneven surface problem September 23, 2016 01:56PM |

Registered: 7 years ago Posts: 25 |

Yes it goes back in the same position with +/- 0.01mm accuracy - it surprised me .It moved up and down 10 times so the travel is 200 mm. I think Z axis is very precise comparing to my old priusa i3 style 3d printer.

There is vid of end of the test it should go back to 20 (where the indicator is at the beginning).

https://youtu.be/ZKytWFC9xQY

The most annoying is that everything looks good and works as expected but the surface of the print still looks bad.

Edited 2 time(s). Last edit at 09/23/2016 02:00PM by MosfetN.

There is vid of end of the test it should go back to 20 (where the indicator is at the beginning).

https://youtu.be/ZKytWFC9xQY

The most annoying is that everything looks good and works as expected but the surface of the print still looks bad.

Edited 2 time(s). Last edit at 09/23/2016 02:00PM by MosfetN.

|

Re: Uneven surface problem September 23, 2016 02:04PM |

Registered: 7 years ago Posts: 25 |

And there is Z axis platform "seesaw" test as you can see it moves only - 0.04mm when i push it down with my hand.

https://youtu.be/P5BJhhQBQas

https://youtu.be/P5BJhhQBQas

|

Re: Uneven surface problem September 23, 2016 04:05PM |

Registered: 10 years ago Posts: 580 |

Doesn't look to me like Z is the problem.

I'd like to focus on the X/Y movement. Doing a circular object was good to test this.

Looking at the Jhead test, the improved smoothness may just be due to slight differences in temperature or nozzle geometry.

What sticks out (or in) is that big grove near the bottom, and smaller ones near the top.

- Is that a single wall item?

- Is the perimeter pushed towards the inside at those locations? If so then that is very telling.

- What speeds, layer height, temp did you use?

- Is there any play at the hot-end tip?

- With belts disconnected - is the X/Y movement completely smooth or are there any slight hangups or binding?

- Is there more displacement in X or Y direction?

- What exact drivers are you using?

Edited 1 time(s). Last edit at 09/23/2016 11:40PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Quote

MosfetN

Yesterday i have changed the whole hotend assembly from genuine E3D V6 to old one peek J-head with 0.5mm nozzle.

Results are surprising the surface is now much smoother.

I'd like to focus on the X/Y movement. Doing a circular object was good to test this.

Looking at the Jhead test, the improved smoothness may just be due to slight differences in temperature or nozzle geometry.

What sticks out (or in) is that big grove near the bottom, and smaller ones near the top.

- Is that a single wall item?

- Is the perimeter pushed towards the inside at those locations? If so then that is very telling.

- What speeds, layer height, temp did you use?

- Is there any play at the hot-end tip?

- With belts disconnected - is the X/Y movement completely smooth or are there any slight hangups or binding?

- Is there more displacement in X or Y direction?

- What exact drivers are you using?

Edited 1 time(s). Last edit at 09/23/2016 11:40PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Uneven surface problem September 23, 2016 05:01PM |

Registered: 9 years ago Posts: 1,873 |

Really excellent. I wish my build was anywhere near as rigid as that. Well, I think those experiments lead us back to the extruder side of things. I'm afraid I don't have any experience with bowden systems, so I'm out of my depth there. Have you considered experimenting with a direct extruder just to try and rule out one set of possibilities?

[edit: Cross posted with Paul's excellent suggestions, didn't want it to look like I was disagreeing with anything he'd said]

Edited 1 time(s). Last edit at 09/23/2016 05:10PM by JamesK.

[edit: Cross posted with Paul's excellent suggestions, didn't want it to look like I was disagreeing with anything he'd said]

Edited 1 time(s). Last edit at 09/23/2016 05:10PM by JamesK.

Sorry, only registered users may post in this forum.