Uneven surface problem

Posted by MosfetN

|

Re: Uneven surface problem September 24, 2016 04:48AM |

Registered: 7 years ago Posts: 25 |

Quote

Paul Wanamaker

Doesn't look to me like Z is the problem.

Quote

MosfetN

Yesterday i have changed the whole hotend assembly from genuine E3D V6 to old one peek J-head with 0.5mm nozzle.

Results are surprising the surface is now much smoother.

I'd like to focus on the X/Y movement. Doing a circular object was good to test this.

Looking at the Jhead test, the improved smoothness may just be due to slight differences in temperature or nozzle geometry.

What sticks out (or in) is that big grove near the bottom, and smaller ones near the top.

- Is that a single wall item?

- Is the perimeter pushed towards the inside at those locations? If so then that is very telling.

- What speeds, layer height, temp did you use?

- Is there any play at the hot-end tip?

- With belts disconnected - is the X/Y movement completely smooth or are there any slight hangups or binding?

- Is there more displacement in X or Y direction?

- What exact drivers are you using?

-It is 2 wall item (2 perimeters without infill)

-it's hard to check that but it looks like it is pushed towards the inside at those locations.

-External perimeter's 15mm/s internal 25mm/s infil 40mm/s (i have been trying other speed,s with no effect at all),layer 0.2mm,ABS,hotend temp 235 deg C ,heatbed 80 deg C + dimafix

-There is no play at hotend tip

-Yes it is completely smooth.

-No there isn't . The dimensions of a 20mm cube are 11.99/12/12.05 (XYZ)

-Im using right now A4988 at 1/16 or 1/8 microstepping + 0.9 deg steppers(42BYGHM809).I have been trying other stepper drivers and other motors with no effect.

--> i Switched to direct extruder with no effect too.

Edited 1 time(s). Last edit at 09/24/2016 04:49AM by MosfetN.

|

Re: Uneven surface problem September 24, 2016 07:58AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Uneven surface problem September 24, 2016 08:18AM |

Registered: 11 years ago Posts: 5,780 |

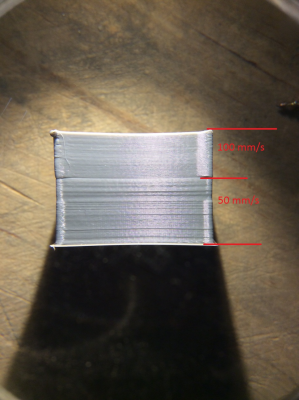

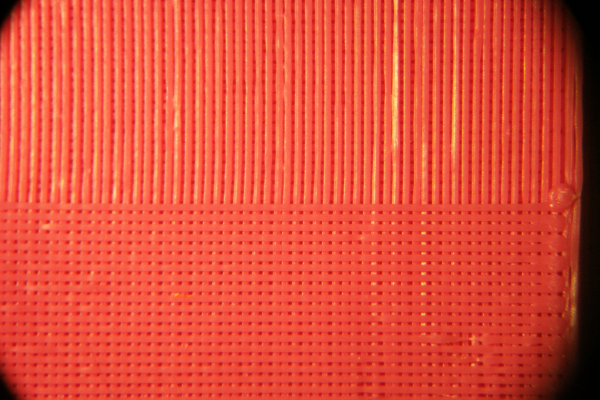

I was recently tuning up extrusion by printing a cube at 95% infill, then adjusting extrusion until I could just see small gaps between the lines. In the first pass I noticed that the gaps varied in width- every other gap was wider. The infill was being printed at 45 degrees to the axes, so I could not isolate the problem, so I resliced with the infill at 0 degrees so the lines would be laid down parallel to the axes. This is the result:

You're looking at two layers of the print. I interrupted the topmost layer so I could see both it and the underlying layer. The bottom half of the image is the X axis parallel lines with spacing controlled by the ball screw driven Y axis, The top half of the image is the Y axis parallel lines with spacing determined by the belt driven X axis.

Maybe you can try something similar to isolate the problem...

Edited 1 time(s). Last edit at 09/24/2016 08:20AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You're looking at two layers of the print. I interrupted the topmost layer so I could see both it and the underlying layer. The bottom half of the image is the X axis parallel lines with spacing controlled by the ball screw driven Y axis, The top half of the image is the Y axis parallel lines with spacing determined by the belt driven X axis.

Maybe you can try something similar to isolate the problem...

Edited 1 time(s). Last edit at 09/24/2016 08:20AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Uneven surface problem September 24, 2016 11:22AM |

Registered: 7 years ago Posts: 25 |

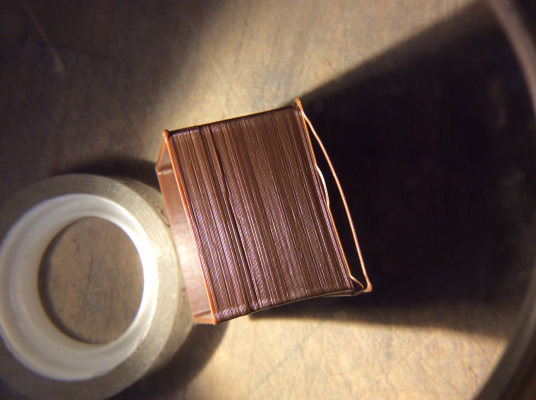

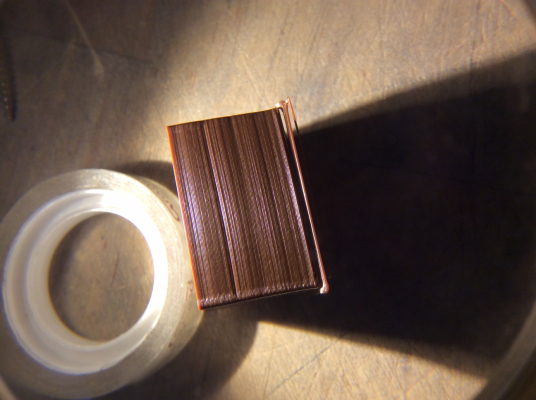

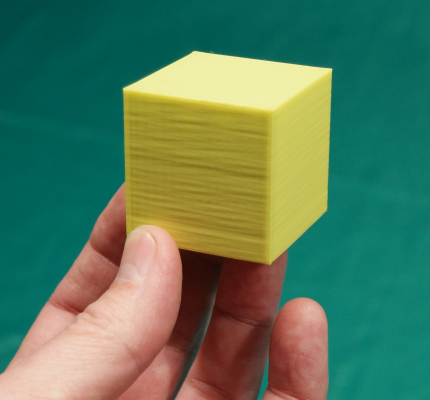

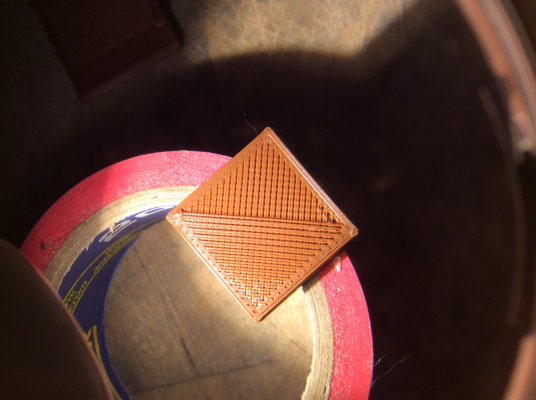

Here is 20mm calibration cube with 95% infill and small gaps between (0 deg parallel to x/y axis ):

The same but 45 deg to x/y axis:

Edited 1 time(s). Last edit at 09/24/2016 11:22AM by MosfetN.

The same but 45 deg to x/y axis:

Edited 1 time(s). Last edit at 09/24/2016 11:22AM by MosfetN.

|

Re: Uneven surface problem September 24, 2016 03:36PM |

Registered: 10 years ago Posts: 580 |

Fascinating.

I have a few possibilities in this mess:

1) Lash in one direction? Looks like what DD described. The lines are parallel, just not spaced correctly. Do you have flats ground on all steppers and shafts where the grub screws contact??? A slight slip there could easily be causing this. Use fingernail polish on the threads of the grub screws too - it functions as a removable form of Loctite.

2) What is the current steps per mm for X and Y?

3) "20mm cube are 11.99/12/12.05 (XYZ)" I note this as odd, but not the reason it's shifted.

4) If you didn't already have a test that clearly shows the issue I would suggest printing a circle with a single wall. It is easier to see if perimeters are shifted.

5) Your speeds are quite low enough, and it looks like acceleration is also low (I see blobs at ends of lines), so also not the issue. Hot end temp is a bit low for my taste for ABS, but not the issue. I don't think it is entirely missing steps, (lines are parallel, no permanent shift). Still could be driver current setting issue.

6) Are you printing from an SD card? You may want to try that.

7) You mention you are using step sticks ( A4988 - that's OK) - but you must be using an 8-bit controller (ugh). That may be the problem - someone else had these same issues (on a delta) even at slow speed. You may need to switch firmware or the controller. (Recommend Smoothie or Duet, not clones).

8) Make sure your stepper wires are not near other wires. Something to check if the above isn't it. There is a link in the WIKI page below.

Edit:

Some of these issues and resolutions can be found in the WIKI page Shifted Layers / Offset Layers / Missed Steps

Edited 1 time(s). Last edit at 09/24/2016 04:05PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I have a few possibilities in this mess:

1) Lash in one direction? Looks like what DD described. The lines are parallel, just not spaced correctly. Do you have flats ground on all steppers and shafts where the grub screws contact??? A slight slip there could easily be causing this. Use fingernail polish on the threads of the grub screws too - it functions as a removable form of Loctite.

2) What is the current steps per mm for X and Y?

3) "20mm cube are 11.99/12/12.05 (XYZ)" I note this as odd, but not the reason it's shifted.

4) If you didn't already have a test that clearly shows the issue I would suggest printing a circle with a single wall. It is easier to see if perimeters are shifted.

5) Your speeds are quite low enough, and it looks like acceleration is also low (I see blobs at ends of lines), so also not the issue. Hot end temp is a bit low for my taste for ABS, but not the issue. I don't think it is entirely missing steps, (lines are parallel, no permanent shift). Still could be driver current setting issue.

6) Are you printing from an SD card? You may want to try that.

7) You mention you are using step sticks ( A4988 - that's OK) - but you must be using an 8-bit controller (ugh). That may be the problem - someone else had these same issues (on a delta) even at slow speed. You may need to switch firmware or the controller. (Recommend Smoothie or Duet, not clones).

8) Make sure your stepper wires are not near other wires. Something to check if the above isn't it. There is a link in the WIKI page below.

Edit:

Some of these issues and resolutions can be found in the WIKI page Shifted Layers / Offset Layers / Missed Steps

Edited 1 time(s). Last edit at 09/24/2016 04:05PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Uneven surface problem September 25, 2016 07:30AM |

Registered: 7 years ago Posts: 25 |

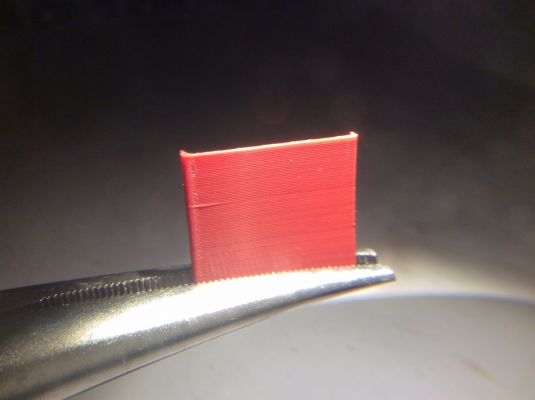

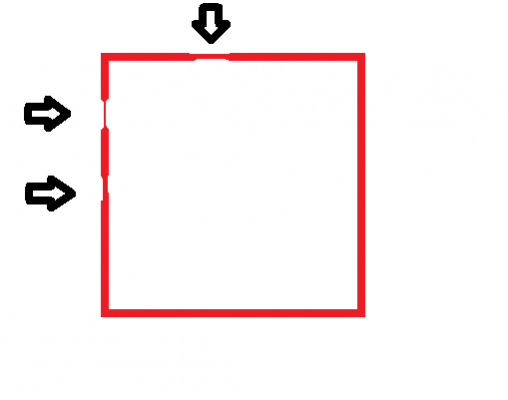

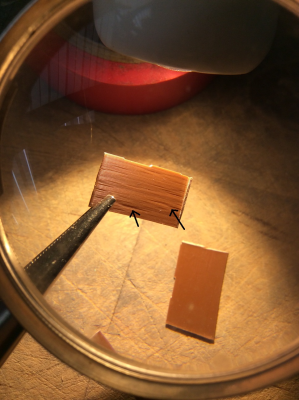

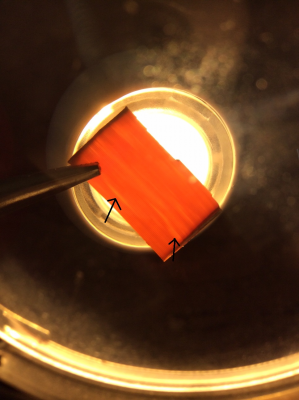

i have printed a one perimeter cube today. I cuted it into single wall pieces and discovered something interesting. The perimeter isn't pushed towards the inside at those locations but it is narrower on both sides (You can see visualization of the perimeter on the graphics):

Under light i can actually see there's less filament in these places:

Edited 1 time(s). Last edit at 09/25/2016 07:39AM by MosfetN.

Under light i can actually see there's less filament in these places:

Edited 1 time(s). Last edit at 09/25/2016 07:39AM by MosfetN.

|

Re: Uneven surface problem September 25, 2016 07:38AM |

Registered: 7 years ago Posts: 25 |

1) This lash could be caused by loosened belts on Y axis (i have done this to test this axis). I 'll tighten them and check this once more.

2) 80 steps for mm on Y and X

4)I have printed the cube with one perimeter above but i'll check the circle too.

5) Im sure it's not the stepper current issue (i have been trying all combinations).

6)Im printing over USB because SD card doesn't work at all. EDIT-> SD card started working after slowing down SPI transmission , shortening the wire and adding a ferrite bead. But after fixing sd card the print looks still the same.

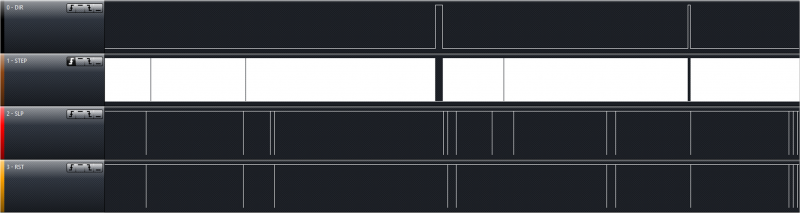

7)Im using MKS Gen 1.4 but i have double checked for missed steps with logic analyzer:

8) Stepper wires are near other wires for eg. in cable carriage but i don't think it is source of the problem. I have disabled checking endstops during print in firmware with no effect.

Edited 1 time(s). Last edit at 09/25/2016 07:43AM by MosfetN.

2) 80 steps for mm on Y and X

4)I have printed the cube with one perimeter above but i'll check the circle too.

5) Im sure it's not the stepper current issue (i have been trying all combinations).

6)Im printing over USB because SD card doesn't work at all. EDIT-> SD card started working after slowing down SPI transmission , shortening the wire and adding a ferrite bead. But after fixing sd card the print looks still the same.

7)Im using MKS Gen 1.4 but i have double checked for missed steps with logic analyzer:

8) Stepper wires are near other wires for eg. in cable carriage but i don't think it is source of the problem. I have disabled checking endstops during print in firmware with no effect.

Edited 1 time(s). Last edit at 09/25/2016 07:43AM by MosfetN.

|

Re: Uneven surface problem September 25, 2016 08:34AM |

Registered: 11 years ago Posts: 5,780 |

The short, thinned areas may be evidence of crud on the extruder drive gear.

I'm not sure what I'm seeing in the 45 degree infill print- it looks like there's a tiny gap down the center of each fill line (i.e. I'm looking at two fill lines really close together) and the wider space every other line. Try deliberately under-extruding by reducing extrusion a bit more to make the effect more pronounced. It should then be obvious if those are single lines with a ridge if the there's an XY motion problem. In the print with 0 degree fill lines the lines seem pretty well spaced in both X and Y. Hmmm.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'm not sure what I'm seeing in the 45 degree infill print- it looks like there's a tiny gap down the center of each fill line (i.e. I'm looking at two fill lines really close together) and the wider space every other line. Try deliberately under-extruding by reducing extrusion a bit more to make the effect more pronounced. It should then be obvious if those are single lines with a ridge if the there's an XY motion problem. In the print with 0 degree fill lines the lines seem pretty well spaced in both X and Y. Hmmm.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Uneven surface problem September 25, 2016 10:33AM |

Registered: 10 years ago Posts: 580 |

Hmmm, indeed. Perhaps more than one issue.

Is your 20 mm test cube really coming out "11.99/12/12.05 (XYZ)"? If so then you need to adjust your steps per mm so it comes out near 20/20/20 before anything else.

I did notice some odd things in the extrusion of the "20mm" test cube. Here I have cropped and sharpened it:

I agree with the DD, there sure does appear to be something odd in subsequent lines. Take a look also at the perimeters on the left and right sides, notice the perimeters on the left are not touching, but they are on the right? Are you sure the grub screws are mating to ground flats everywhere? You can draw a line with a sharpie across the end of the pulley to the shaft to see if there is any slight movement.

Do you notice that the infill starts out very thin and thready in both visible layers, and finally catches up to the thickness it should be? This can be caused by multiple things:

1) Hot end temp too low? For me 235 is at the very bottom for ABS, try bumping it up to 250 and try the infill and single wall item again.

2) There are wide swings in extrusion rates between features. You have "External perimeter's 15mm/s internal 25mm/s infil 40mm/s". So when it goes from the outside perimeter to the infill the extrusion will require a large change in mm3/sec - requiring higher pressure in the nozzle right when it starts the infill to begin printing at the proper width. If you are using auto settings in the slicer, then it may also change the extrusion width at the same time, making even larger swings in extrusion rate than what you would expect. The with a bowden extruder this extra pressure will take time to build up (especially since your slicer isn't doing bowden pressure compensation, none are).

So for your testing you may want to use settings that make all extrusion rates nearly the same. Are you using Slic3r? If you are, you will not want to use auto settings for anything. You could drop the infill speed to 25 (or just set them all to 20 for now), and use the same set extrusion width number (not a percentage) for all features. A safe extrusion width is around nozzle diameter * 1.3, and safe layer height is nozzle diameter * .4 I'm not sure what nozzle diameter you have.

3) Your slicer may still output the infill at twice the mm3/sec you think it is in some cases. If you post your entire gcode file, with comments turned on I can run it through my analyzer and see. But it would be best to try the above first.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Is your 20 mm test cube really coming out "11.99/12/12.05 (XYZ)"? If so then you need to adjust your steps per mm so it comes out near 20/20/20 before anything else.

I did notice some odd things in the extrusion of the "20mm" test cube. Here I have cropped and sharpened it:

I agree with the DD, there sure does appear to be something odd in subsequent lines. Take a look also at the perimeters on the left and right sides, notice the perimeters on the left are not touching, but they are on the right? Are you sure the grub screws are mating to ground flats everywhere? You can draw a line with a sharpie across the end of the pulley to the shaft to see if there is any slight movement.

Do you notice that the infill starts out very thin and thready in both visible layers, and finally catches up to the thickness it should be? This can be caused by multiple things:

1) Hot end temp too low? For me 235 is at the very bottom for ABS, try bumping it up to 250 and try the infill and single wall item again.

2) There are wide swings in extrusion rates between features. You have "External perimeter's 15mm/s internal 25mm/s infil 40mm/s". So when it goes from the outside perimeter to the infill the extrusion will require a large change in mm3/sec - requiring higher pressure in the nozzle right when it starts the infill to begin printing at the proper width. If you are using auto settings in the slicer, then it may also change the extrusion width at the same time, making even larger swings in extrusion rate than what you would expect. The with a bowden extruder this extra pressure will take time to build up (especially since your slicer isn't doing bowden pressure compensation, none are).

So for your testing you may want to use settings that make all extrusion rates nearly the same. Are you using Slic3r? If you are, you will not want to use auto settings for anything. You could drop the infill speed to 25 (or just set them all to 20 for now), and use the same set extrusion width number (not a percentage) for all features. A safe extrusion width is around nozzle diameter * 1.3, and safe layer height is nozzle diameter * .4 I'm not sure what nozzle diameter you have.

3) Your slicer may still output the infill at twice the mm3/sec you think it is in some cases. If you post your entire gcode file, with comments turned on I can run it through my analyzer and see. But it would be best to try the above first.

This is something you may need to consider further. The reason I mentioned it is I have seen a case here where bundled cables caused the extruder to be slightly uneven in just this way.Quote

MosfetN

Stepper wires are near other wires for eg. in cable carriage

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Uneven surface problem September 25, 2016 05:28PM |

Registered: 9 years ago Posts: 1,873 |

Quote

Is your 20 mm test cube really coming out "11.99/12/12.05 (XYZ)"? If so then you need to adjust your steps per mm so it comes out near 20/20/20 before anything else.

Really? I guess I've been too lax in my requirements then, I'd be more than happy with those numbers. (I probably need to invest in better instruments as well, as I'd expect +/- .05 in measurement errors.)

Edit; Doh, well silly me. 20 != 12. I'll just sit here and eat my words for a while...

Edited 2 time(s). Last edit at 09/25/2016 07:00PM by JamesK.

|

Re: Uneven surface problem September 26, 2016 12:16PM |

Registered: 7 years ago Posts: 25 |

|

Re: Uneven surface problem September 26, 2016 01:55PM |

Registered: 10 years ago Posts: 580 |

|

Re: Uneven surface problem September 26, 2016 02:45PM |

Registered: 9 years ago Posts: 21 |

|

Re: Uneven surface problem September 27, 2016 04:40AM |

Registered: 7 years ago Posts: 109 |

I have exactly the same axis configuration as you have, and had no issues. But I had to really tighten everything until the belts on the Y axis were like guitar strings. I also have PU belts with steel core. This helps a lot. I have virtually 0 backlash on X and 0.05mm on Y, almost non noticeable. If I take a better look at your latest test print, it might first seem like a backlash issue, but only on one travel direction ? Why not on both ? Like you would have backlash when changing from left to right, bot not from right to left. That's strange. I would do one thing if I were you: change the controller! You are not the first on this forum that scratches his head and maybe later bangs his head against the wall because of 8 bit PRC clones. Your machine deserves better than this anyway !

|

Re: Uneven surface problem September 30, 2016 02:53AM |

Registered: 7 years ago Posts: 109 |

Ok, I have some updates.

I just added some astrosyn dampers on my steppers to reduce noise, and this introduced backlash in the X and Y axis. The backlash on X is almost non measurable, but it is quite large on the Y axis where the motor has to do a lot more work and the drag from all the belts and linear motion is higher. Now I am getting exactly the same offset between the infill extrusion like in your 20mm test cube: two close together and two apart. So this is definitely a backlash issue on your Y axis, but it does not have anything to do with surface finish! My surface finish remained as smooth as before, no problems there, so your surface finish issue has something to do with extrusion rate not being stable.

I just added some astrosyn dampers on my steppers to reduce noise, and this introduced backlash in the X and Y axis. The backlash on X is almost non measurable, but it is quite large on the Y axis where the motor has to do a lot more work and the drag from all the belts and linear motion is higher. Now I am getting exactly the same offset between the infill extrusion like in your 20mm test cube: two close together and two apart. So this is definitely a backlash issue on your Y axis, but it does not have anything to do with surface finish! My surface finish remained as smooth as before, no problems there, so your surface finish issue has something to do with extrusion rate not being stable.

|

Re: Uneven surface problem September 30, 2016 08:57AM |

Registered: 8 years ago Posts: 318 |

From these new photos, seeing random under extruded spot looks like it has to be from the extruder.

Try replacing your extruder stepper driver?? I've had some that would act weird. One would be able to move steppers but wouldn't hold them in place.

You said your drive gear is clean, but did you look close enough to notice any missing teeth or other weirdness? If you could try a direct drive that would be interesting.

Edited 1 time(s). Last edit at 09/30/2016 09:09AM by DaGameFace.

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

Try replacing your extruder stepper driver?? I've had some that would act weird. One would be able to move steppers but wouldn't hold them in place.

You said your drive gear is clean, but did you look close enough to notice any missing teeth or other weirdness? If you could try a direct drive that would be interesting.

Edited 1 time(s). Last edit at 09/30/2016 09:09AM by DaGameFace.

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

|

Re: Uneven surface problem October 01, 2016 09:54AM |

Registered: 7 years ago Posts: 25 |

I have tightened Y axis belts and backlash is gone now.

I have been replacing stepper drivers for about 4 times (A4988 , DRV8825) with no effect.

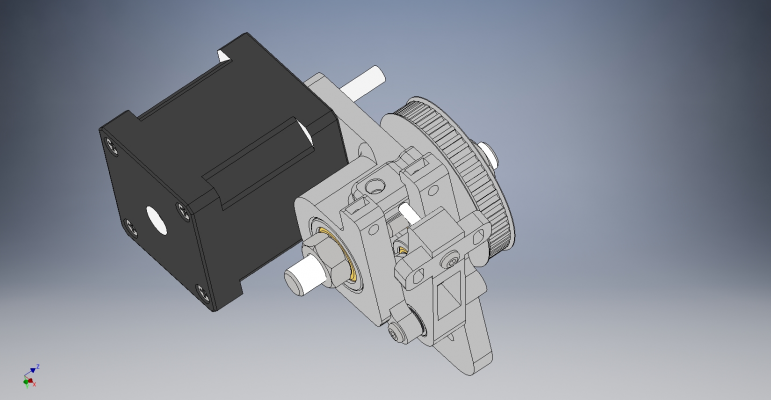

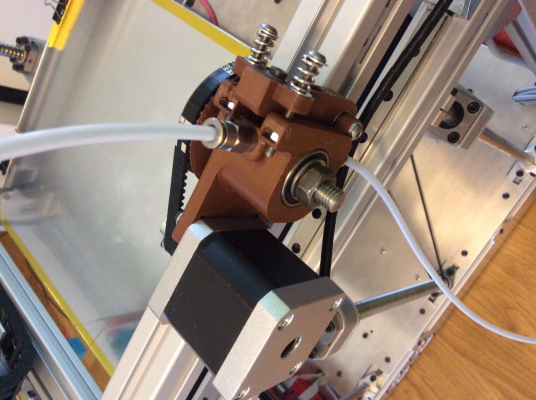

I 'll print a redesigned 4:1 extruder with new hobbed bolt and new bowden connectors today.

Edited 1 time(s). Last edit at 10/01/2016 10:00AM by MosfetN.

I have been replacing stepper drivers for about 4 times (A4988 , DRV8825) with no effect.

I 'll print a redesigned 4:1 extruder with new hobbed bolt and new bowden connectors today.

Edited 1 time(s). Last edit at 10/01/2016 10:00AM by MosfetN.

|

Re: Uneven surface problem October 05, 2016 05:56AM |

Registered: 7 years ago Posts: 25 |

I have changed the extruder assembly to a new one which is already perfect for me (new machined hobbed bolt,new bowden connector and new gears with 4:1 ratio) and shortened bowden tube a little. Quality of the surface slightly increased but still that's not this what i have expected from this printer.

I noticed that bowden tube might be source of the problem. These artifacts are created when i slightly move,bend or twist the bowden tube ,so when X/Y axis moves it is constantly twisting tube and bending it in all directions. I still don't have any idea how to design a light , geared and small direct extruder for this X carriage without moving hotend forward.

I noticed that bowden tube might be source of the problem. These artifacts are created when i slightly move,bend or twist the bowden tube ,so when X/Y axis moves it is constantly twisting tube and bending it in all directions. I still don't have any idea how to design a light , geared and small direct extruder for this X carriage without moving hotend forward.

|

Re: Uneven surface problem October 05, 2016 06:02AM |

Registered: 9 years ago Posts: 104 |

|

Re: Uneven surface problem October 05, 2016 06:30AM |

Registered: 7 years ago Posts: 25 |

|

Re: Uneven surface problem October 05, 2016 06:55AM |

Registered: 7 years ago Posts: 25 |

Small update:

I discovered something interesting :the faster i print the better surface finish i get ! - that's very strange for me.....

I discovered something interesting :the faster i print the better surface finish i get ! - that's very strange for me.....

|

Re: Uneven surface problem November 05, 2016 12:46PM |

Registered: 7 years ago Posts: 25 |

First of all i want to thank everyone for help

Surface quality is much better now but it still isn't perfect (maybe i have too high demands for FDM technology).

Surface quality is much better now but it still isn't perfect (maybe i have too high demands for FDM technology).

|

Re: Uneven surface problem April 03, 2017 06:44PM |

Registered: 9 years ago Posts: 330 |

|

Re: Uneven surface problem April 10, 2017 12:25PM |

Registered: 7 years ago Posts: 25 |

|

Re: Uneven surface problem April 29, 2017 08:03PM |

Registered: 10 years ago Posts: 211 |

|

Re: Uneven surface problem May 05, 2017 11:56AM |

Registered: 8 years ago Posts: 413 |

Im suspicious that the infill overlap doesn't work properly. Don't know what you are using but set it to 0 for now.

Its possible that the hot end is so far from the guide rail bearings and the drive belt you are getting some movement at the nozzle tip. Anything you can do to make the attachment more rigid?

Its possible that the hot end is so far from the guide rail bearings and the drive belt you are getting some movement at the nozzle tip. Anything you can do to make the attachment more rigid?

|

Re: Uneven surface problem June 25, 2017 04:42AM |

Registered: 7 years ago Posts: 25 |

|

Re: Uneven surface problem June 25, 2017 08:17AM |

Registered: 11 years ago Posts: 5,780 |

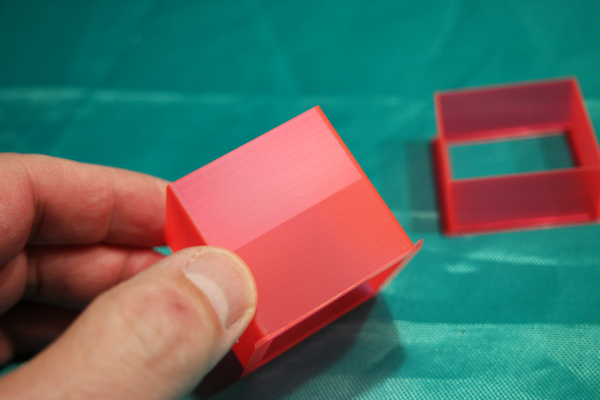

When I first printed on UMMD I was seeing similar surface quality problems.

Before:

After some extruder calibration and belt tightening:

(ignore the file name- those are 0.27 mm (bottom) and 0.18 mm (top) layers.

Which brings up something else. Those odd layer thickness values are used because they are based on full step multiples in the Z axis (89.9999 um/full step). You might want to check that in your printer.

I have no idea why it would matter. The explanation doesn't make any sense to me. The assumption is that by using full step multiples, at each layer position the Z motor will be sitting in one of the full step detents and not relying on the microstepping for position control which could result in variations in the bed's position. But that also assumes that when you home the bed the motor stops in a full step position. If it doesn't, and what are the chances that it will, you're right back to relying on microstepping to position the bed accurately and precisely. And yet, it seems to work. Hmmmm. I would think that if you want full step positioning you'd just run the Z axis with microstepping turned off. That will get you full step positioning at every point on the Z axis every time. The first layer may be a little off from whatever value you set for its thickness but all subsequent layers will be exactly what you set as long as it is whole number multiple of the full step value.

Of course, running the Z axis in full steps isn't a problem during printing, but it will probably be pretty noisy during jogging operations like homing the machine.

Edited 1 time(s). Last edit at 06/25/2017 08:19AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Before:

After some extruder calibration and belt tightening:

(ignore the file name- those are 0.27 mm (bottom) and 0.18 mm (top) layers.

Which brings up something else. Those odd layer thickness values are used because they are based on full step multiples in the Z axis (89.9999 um/full step). You might want to check that in your printer.

I have no idea why it would matter. The explanation doesn't make any sense to me. The assumption is that by using full step multiples, at each layer position the Z motor will be sitting in one of the full step detents and not relying on the microstepping for position control which could result in variations in the bed's position. But that also assumes that when you home the bed the motor stops in a full step position. If it doesn't, and what are the chances that it will, you're right back to relying on microstepping to position the bed accurately and precisely. And yet, it seems to work. Hmmmm. I would think that if you want full step positioning you'd just run the Z axis with microstepping turned off. That will get you full step positioning at every point on the Z axis every time. The first layer may be a little off from whatever value you set for its thickness but all subsequent layers will be exactly what you set as long as it is whole number multiple of the full step value.

Of course, running the Z axis in full steps isn't a problem during printing, but it will probably be pretty noisy during jogging operations like homing the machine.

Edited 1 time(s). Last edit at 06/25/2017 08:19AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Uneven surface problem June 25, 2017 08:56AM |

Registered: 9 years ago Posts: 1,873 |

Quote

DD

The assumption is that by using full step multiples, at each layer position the Z motor will be sitting in one of the full step detents and not relying on the microstepping for position control which could result in variations in the bed's position.

It's not that it sits in a full step position, but that it sits in the same (microstep) position relative to a full step for each layer. The microsteps are not evenly distributed through the angular travel, but a given microstep should be relatively reproducible from step to step. If you were to use a layer thickness that wasn't a simple multiple (uh, maybe divisor?) of the microsteps then successive layers would visit some subset (or possibly all) of the microstep positions and you might see a periodic error in thickness. I must confess, I don't worry too much about using layer heights corresponding to a 1/2 step. It means that alternating layers may have different heights but I haven't noticed it in practice.

|

Re: Uneven surface problem June 25, 2017 09:54AM |

Registered: 11 years ago Posts: 5,780 |

The errors I see don't look periodic, but otherwise it sounds like a reasonable explanation of the effect, and it does seem to clean up the surface quality.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.

I wanted to say the dimensions of 20mm calibration cube are 19.99/20/20.05 mm [XYZ] instead of 11.99/12/12.05.

I wanted to say the dimensions of 20mm calibration cube are 19.99/20/20.05 mm [XYZ] instead of 11.99/12/12.05.