Diagonal lines - troubleshooting, please help

Posted by JanF

|

Diagonal lines - troubleshooting, please help September 20, 2016 02:48AM |

Registered: 7 years ago Posts: 6 |

Hi everyone, Aussie girl here, very new to 3D printing and electronics in general. However l have successfully put together a Prusa i3 and have it printing pretty well - or at least well enough for my needs EXCEPT for one problem I just cannot solve.

Can someone PLEASE tell me why I am getting diagonal missed lines as shown in the pic? I have searched and searched for answers, adjusted belts, screws, calibrated to within an inch of the machine's life (which was going to be VERY short for a while!!) and this problem remains. My 2 cm calibration square is printing perfectly, so I know my steps are good and am assuming it must be mechanical?? It does this on every print and I can watch it skip a line and then move on to fill perfectly until the next skip. Only mod to machine is replaced Z rods with lead screws, but it was doing it both before and after this. Nothing seems loose or wobbly, bed is steady........ Played with voltage to extruder stepper, but not sure if I should have. It's not hot when working, just barely warm.

This pic shows the bottom of the objects but it is also doing it on the top layers - but a little less noticeable.

Grateful for any help

Thanks

Jan

Can someone PLEASE tell me why I am getting diagonal missed lines as shown in the pic? I have searched and searched for answers, adjusted belts, screws, calibrated to within an inch of the machine's life (which was going to be VERY short for a while!!) and this problem remains. My 2 cm calibration square is printing perfectly, so I know my steps are good and am assuming it must be mechanical?? It does this on every print and I can watch it skip a line and then move on to fill perfectly until the next skip. Only mod to machine is replaced Z rods with lead screws, but it was doing it both before and after this. Nothing seems loose or wobbly, bed is steady........ Played with voltage to extruder stepper, but not sure if I should have. It's not hot when working, just barely warm.

This pic shows the bottom of the objects but it is also doing it on the top layers - but a little less noticeable.

Grateful for any help

Thanks

Jan

|

Re: Diagonal lines - troubleshooting, please help September 20, 2016 07:09AM |

Registered: 7 years ago Posts: 6 |

After looking through the sticky "pictorial print issue posts" I believe I may have found my issue here - [www.flickr.com]

"Slipping hob bolt" on the extruder although it seems in my case it was not "guck" stuck in the teeth, but that one of the grub (set) screws was missing. I have now installed a second and am currently printing a test. So far so good!!. So happy....

This was the first time I have seen anything like my problem pictured, despite much research of troubleshooting sites, so much kudos to you guys for doing the research and compiling the results!

Kindest regards

Jan

"Slipping hob bolt" on the extruder although it seems in my case it was not "guck" stuck in the teeth, but that one of the grub (set) screws was missing. I have now installed a second and am currently printing a test. So far so good!!. So happy....

This was the first time I have seen anything like my problem pictured, despite much research of troubleshooting sites, so much kudos to you guys for doing the research and compiling the results!

Kindest regards

Jan

|

Re: Diagonal lines - troubleshooting, please help September 20, 2016 04:59PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Diagonal lines - troubleshooting, please help September 21, 2016 01:14PM |

Registered: 8 years ago Posts: 318 |

Yup! looks like you found the problem yourself. Now there are two causes to the same issue, if it does resurface:

1. The stepper motor itself can be skipping steps. If so, you will hear an audible click when this happens.

2. The hobbed bolt can be stripping on the filament. You will see bits of plastic ground up by the extruder.

Fixes:

1. Increase voltage through stepper driver, maybe loosen tensioner on the idler

2. Tighten your tensioner

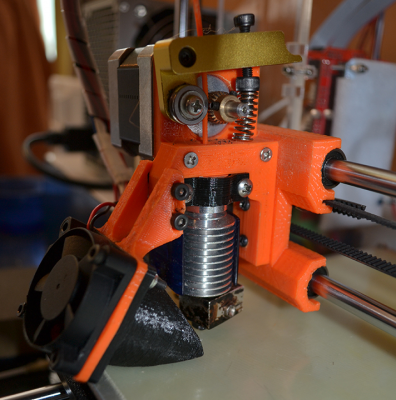

Also, if you have the china hot end and extruder mk8, I would highly suggest getting a better hot end and reusing the extruder like this:

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

1. The stepper motor itself can be skipping steps. If so, you will hear an audible click when this happens.

2. The hobbed bolt can be stripping on the filament. You will see bits of plastic ground up by the extruder.

Fixes:

1. Increase voltage through stepper driver, maybe loosen tensioner on the idler

2. Tighten your tensioner

Also, if you have the china hot end and extruder mk8, I would highly suggest getting a better hot end and reusing the extruder like this:

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

|

Re: Diagonal lines - troubleshooting, please help September 21, 2016 08:56PM |

Registered: 7 years ago Posts: 6 |

Thank you very much for the extra info. Looking further I also found that the teeth on my hob wheel appeared to be a little damaged on one side just in one area (thus the regular, reoccurring issue, every cycle of the wheel?). Maybe it came that way or maybe I did it. Anyway for now I have turned the wheel around and mounted so the filament connects with the undamaged area. Printing beautifully, no diagonal lines missing! Yahhh.... I shall now order another wheel (or 2).

Thanks everyone

Kindest regards

Jan

Thanks everyone

Kindest regards

Jan

|

Re: Diagonal lines - troubleshooting, please help September 21, 2016 08:59PM |

Registered: 7 years ago Posts: 6 |

|

Re: Diagonal lines - troubleshooting, please help September 21, 2016 11:43PM |

Registered: 8 years ago Posts: 318 |

The one in the picture is my preferred hot end of choice, its the E3D v6, all metal so I can print at high temps if I need to use something like nylon. (For reference, some hot ends have a plastic call PTFE inside that makes it have less friction than metal to avoid jams. But this limits your max temp to really only using PLA)

You can buy the real deal name brand E3D, which I would suggest, but a lot of people buy Chinese versions. Some of them are crap, others work as flawless as the originals. You save money, but at your own risk.

Oh, and in my experience, the mk8 has enough torque to push PLA (the most likely to jam in an all metal hot end) through the E3D v6, even when I had it pushing filament in a bowden setup.

And when your new hobbed bolt arrives be prepared to recalibrate your steps/mm or extrusion multiplier. Also, this is a good look into which bolts are the best.

Edited 1 time(s). Last edit at 09/21/2016 11:57PM by DaGameFace.

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

You can buy the real deal name brand E3D, which I would suggest, but a lot of people buy Chinese versions. Some of them are crap, others work as flawless as the originals. You save money, but at your own risk.

Oh, and in my experience, the mk8 has enough torque to push PLA (the most likely to jam in an all metal hot end) through the E3D v6, even when I had it pushing filament in a bowden setup.

And when your new hobbed bolt arrives be prepared to recalibrate your steps/mm or extrusion multiplier. Also, this is a good look into which bolts are the best.

Edited 1 time(s). Last edit at 09/21/2016 11:57PM by DaGameFace.

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

|

Re: Diagonal lines - troubleshooting, please help September 22, 2016 07:21PM |

Registered: 7 years ago Posts: 6 |

|

Re: Diagonal lines - troubleshooting, please help September 24, 2016 06:45AM |

Registered: 11 years ago Posts: 1,592 |

Quote

DaGameFace

snip>> (For reference, some hot ends have a plastic call PTFE inside that makes it have less friction than metal to avoid jams. But this limits your max temp to really only using PLA)<<

It doesn't limit its use to PLA or at least it shouldn't. I have been using my shop made metal hotend with PTFE liner for 3 years or so, almost exclusively with ABS. The liner is cooled by the fins fan anyway so should be useable at even higher temps than that used for ABS.

_______________________________________

Waitaki 3D Printer

|

Re: Diagonal lines - troubleshooting, please help September 24, 2016 07:53AM |

Registered: 9 years ago Posts: 1,873 |

It depends on how far down into the hotend you take the liner. The ideal use case for ptfe is for a pla only hotend where you extend the ptfe all the way in to the heater block to the junction with the nozzle. That way there are no joints in the critical transition zone where the pla gets soft and sticky. The alternative is to have the ptfe stop well above the heatbreak so that the joint is above the transition zone, but that doesn't really give much benefit as the highest friction area is still pla on metal.Quote

wataki

It doesn't limit its use to PLA or at least it shouldn't.

Still, I used a ptfe into the heatblock setup with abs for a few months without the ptfe being destroyed. It probably reduces the lifetime compared to pla temps though. (Assuming pla printed at around 190 vs abs at about 240C).

Sorry, only registered users may post in this forum.