Issues with printing larger objects

Posted by A_Designs

|

Re: Issues with printing larger objects April 25, 2017 07:31AM |

Registered: 7 years ago Posts: 49 |

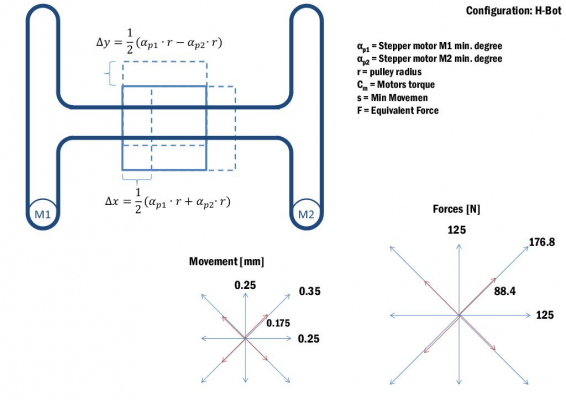

My acceleration is down to 20mm/s2 now, it's much lower than what it was, but it still drifts. H-Bot and Corexy are the same as far as the electronics and software is concerned, corexy just has an additional belt and more pulleys.Quote

the_digital_dentist

In a corexy mechanism diagonal lines are produced when only one motor is turning. I don't know if h-bot works the same way. In a corexy machine that torque-slips on the 45/135 degree lines, I'd turn down the acceleration until it stops slipping.

This kind of slip could be caused if one motor was to stop turning while the other continued, but I haven't noticed any such desync at the time of drift. It just finishes printing the infill, then goes to corner to start printing, except that it starts printing at 2-3mm diagonally towards 0,0, rather than the corner itself.

|

Re: Issues with printing larger objects April 25, 2017 07:35AM |

Registered: 11 years ago Posts: 5,780 |

In that case it sounds like a mechanism binding problem. Things may move smoothly and easily without the belts in place but belt tension can cause things to flex out of alignment. Can you post some pictures of the machine?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Issues with printing larger objects April 25, 2017 08:06AM |

Registered: 7 years ago Posts: 49 |

Quote

the_digital_dentist

In that case it sounds like a mechanism binding problem. Things may move smoothly and easily without the belts in place but belt tension can cause things to flex out of alignment. Can you post some pictures of the machine?

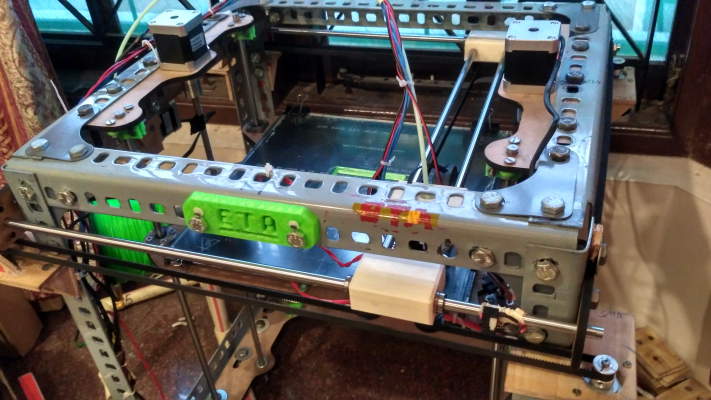

That is a possibility, as my mechanism does have a bit of racking, my test cubes are slightly the shape of quadrilaterals when looked at from above. Here are some photos of my printer,

I'm making an additional collar to help stiffen the Y carriages, which are made with ABS 40% infill. Besides my drifting issues, I also need to solve the racking problem, any suggestions to do so without milling the carriages from aluminum?

Edited 1 time(s). Last edit at 04/25/2017 08:08AM by A_Designs.

|

Re: Issues with printing larger objects June 26, 2017 12:46PM |

Registered: 7 years ago Posts: 49 |

Right, so I've converted my printer from a HBOT to a CoreXY, replaced the belts, got new bearings so both axes run smoothly through their entire travel, got a new hot end mount printed, got brand new stepper motors for the X & Y axes, ensured there are no wires running parallel, re-tuned stepper currents, tried 3 different slicers and checked my horoscope. Regardless, it still has the same staircase-like misalignment issue... The offset is about the same except that instead of the direction was towards Xmin Ymin, and now it's towards Xmax Ymin, likely due to the new belt system.

After the Hbot to CoreXY conversion, it printed a 40mm cube it was having the misalignment issue with earlier, but then when I tried printing a larger object it got misaligned again. I've really run out of ideas to try out, short of homing between every single layer...

Any last ditch efforts I should attempt?

After the Hbot to CoreXY conversion, it printed a 40mm cube it was having the misalignment issue with earlier, but then when I tried printing a larger object it got misaligned again. I've really run out of ideas to try out, short of homing between every single layer...

Any last ditch efforts I should attempt?

|

Re: Issues with printing larger objects June 26, 2017 07:33PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Issues with printing larger objects June 27, 2017 01:31AM |

Registered: 7 years ago Posts: 49 |

Quote

JamesK

Everything you describe is consistent with too little drive current. Please could you describe again how you calibrated the current?

Initially, I calculated the current as per pololu's website, [www.pololu.com] and measured vref with a multimeter. When I started getting this layer misalignment issue, I slowly increased the current and then ran it at the max for my drivers, but the layer drift still happened, and the only difference was that the drivers and steppers were very warm to the touch (I have heatsinks and active cooling on the entire RAMPS board). My steppers are listed as 5.5kgcm 1.5A per phase.

However, last night while I was browsing the reprap wiki, I found out that the drivers I had were stepsticks, not Polulo drivers as I had originally thought. Step sticks have only a 1a limit, right? So even if I was running them at max current, they would still fall short of the optimal current requirements of the stepper motors. I read that the DRV8825 boards have greater current limits, but are also susceptible to a host of other issues, so I'm steering clear of those.

Are there any RAMPS compatible driver boards with greater current limits other than the polulo A4988 and the DRV8825 boards?

|

Re: Issues with printing larger objects June 27, 2017 10:14PM |

Registered: 9 years ago Posts: 1,873 |

Ah, ok. If you've had it so the motors were running hot then we can probably rule out lack of current as the cause. The DRV8825 aren't that bad, at least not for cartesian printers. They are prone to creating surface artifacts because they don't handle the first few microsteps very well when there is a large difference between the supply voltage and the target voltage needed for the microstep current, but that's a detail compared to the problems you currently have.

Given the low price you could try a set of drv8825, but it doesn't sound like that's your problem now. The fact that it's always the same diagonal suggests that only one motor is being affected. If you manually move each motor you should be able to see which one moves on that diagonal. You might then want to try running a spare set of wires from the electronics to that motor to test for an intermittent wiring problem, and if possible, swap the motor for a spare (and apologies if you've already tried that). You said you had witness marks on the pulleys which is good, and you have the speeds well down, so we shouldn't be getting anywhere near the max steps/s limit of the processor. It's quite the mystery you have there!

Given the low price you could try a set of drv8825, but it doesn't sound like that's your problem now. The fact that it's always the same diagonal suggests that only one motor is being affected. If you manually move each motor you should be able to see which one moves on that diagonal. You might then want to try running a spare set of wires from the electronics to that motor to test for an intermittent wiring problem, and if possible, swap the motor for a spare (and apologies if you've already tried that). You said you had witness marks on the pulleys which is good, and you have the speeds well down, so we shouldn't be getting anywhere near the max steps/s limit of the processor. It's quite the mystery you have there!

|

Re: Issues with printing larger objects June 28, 2017 03:05AM |

Registered: 7 years ago Posts: 49 |

Quote

JamesK

Ah, ok. If you've had it so the motors were running hot then we can probably rule out lack of current as the cause. The DRV8825 aren't that bad, at least not for cartesian printers. They are prone to creating surface artifacts because they don't handle the first few microsteps very well when there is a large difference between the supply voltage and the target voltage needed for the microstep current, but that's a detail compared to the problems you currently have.

Given the low price you could try a set of drv8825, but it doesn't sound like that's your problem now. The fact that it's always the same diagonal suggests that only one motor is being affected. If you manually move each motor you should be able to see which one moves on that diagonal. You might then want to try running a spare set of wires from the electronics to that motor to test for an intermittent wiring problem, and if possible, swap the motor for a spare (and apologies if you've already tried that). You said you had witness marks on the pulleys which is good, and you have the speeds well down, so we shouldn't be getting anywhere near the max steps/s limit of the processor. It's quite the mystery you have there!

I know which motor moves the diagonal, but I can't quite tell what's the problem with it. I initially had two 1.7a 4.4kgcm motors, and I tried swapping them, but the drift towards xmin ymin was still there.

Day before yesterday, I tried a brand new pair of 1.5a 5.5kgcm motors, and ran them at different current levels, with no difference in the drift. Both sets of motors had D shafts with witness marks, and I've tried both high speeds and low speeds and acceleration, but the drift remains.

The only thing that changed the drift was the swap from hbot to corexy. When it was a hbot, the drift was towards xmin ymin, but after the new belts and pulleys were added, the offset went to xMAX ymin. I reckon this is due to the fact that the motors had to rotate in the opposite direction to move the head in the same direction as before, because of the differences between the belt systems.

This was my original belt path

The drift was to the lower left, which is also home

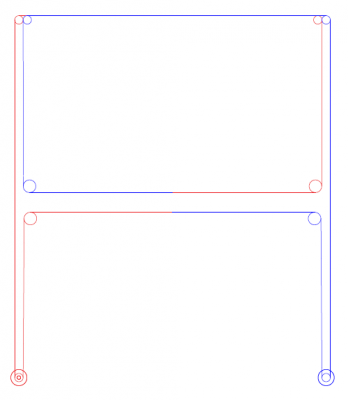

This was my new belt path, requiring two belts on two planes (yay for no crossed belts), and 4 idlers, but significantly cutting down on the racking caused by my bearings.

The drift is now towards the lower right, which is XMAX YMin.

The drift is perfectly diagonal, so probably caused by something afflicting one motor. However, I've tried swapping and replacing the motors, drivers, firmware (marlin and repetier) and swapping the entire ramps board with a friend's, but none of those did anything to the drift. Is there any way to check if it's due to EM interference?

My frame is steel, and I have a 12v 30a heated bed (I think it draws less 30a though), but I made sure none of the wires run parallel, and all endstops use NC contacts and their wires are twisted together.

|

Re: Issues with printing larger objects June 28, 2017 09:14AM |

Registered: 7 years ago Posts: 49 |

#crazytheorytime

I'm just short of buying an Ouija board or a deck of tarot cards to attempt to communicate with the spirit possessing my printer, but I decided to wave a compass on it instead.

My frame is cold rolled steel slotted L profiles, the kind used in making cheap shelving (check the images). Likely due to all the wires running all over it, as well as the presence of strong magnets inside the stepper, the entire frame is slightly magnetic. The magnetism is super weak, it can't even attract a small m1 screw to it, but is there a possibility that a stronger field could be induced as the printer is running, and that that field could somehow interfere with the cabling/steppers?

I'm shooting in the dark, or plain crazy, but I'm just trying to get my printer functional so I can print stuff without finding that my sentry tower print became the leaning tower of Pisa when I wasn't looking.

I'm just short of buying an Ouija board or a deck of tarot cards to attempt to communicate with the spirit possessing my printer, but I decided to wave a compass on it instead.

My frame is cold rolled steel slotted L profiles, the kind used in making cheap shelving (check the images). Likely due to all the wires running all over it, as well as the presence of strong magnets inside the stepper, the entire frame is slightly magnetic. The magnetism is super weak, it can't even attract a small m1 screw to it, but is there a possibility that a stronger field could be induced as the printer is running, and that that field could somehow interfere with the cabling/steppers?

I'm shooting in the dark, or plain crazy, but I'm just trying to get my printer functional so I can print stuff without finding that my sentry tower print became the leaning tower of Pisa when I wasn't looking.

|

Re: Issues with printing larger objects June 29, 2017 09:03AM |

Registered: 7 years ago Posts: 49 |

Ok, I made a test object of a 200mm hollow cube with 2mm thick walls, and printed it in vase mode (so no roof or floor) with 0.32 layers. My prior failed prints were much smaller at around 80-120mm across at most. However, the thin walls continued printing fine for more than 1cm, at which point I stopped it, but the smaller, more detailed models all failed as early as 5mm up.

This suggests that the problem might stem from objects with infill or a lot of internal details, but I can't figure out how to solve it, as I've tried lowering speed down to 20mm/s, acceleration to 150mm/s2 (it's 3000 by default in marlin and worked for sometime in that range for me), and XY jerk to 20mm/s. Still no luck, only a large pile of wasted prints.

This suggests that the problem might stem from objects with infill or a lot of internal details, but I can't figure out how to solve it, as I've tried lowering speed down to 20mm/s, acceleration to 150mm/s2 (it's 3000 by default in marlin and worked for sometime in that range for me), and XY jerk to 20mm/s. Still no luck, only a large pile of wasted prints.

|

Re: Issues with printing larger objects June 29, 2017 09:15AM |

Registered: 9 years ago Posts: 1,873 |

Oh. Jerk sounds high. Try taking that way down, just in case (e.g. start at 1 and see what happens). What's your moving mass like? Hmm, doesn't look too bad, and doesn't explain why the problem only affects one motor. Still feels like a possible wiring problem at the moment - did you try running a second set of wires for the motors to rule that out?

emf/magnetics are unlikely to affect the motor wires as those are high current. You can get cross-talk into sensor wiring (end-stops and temperature), but I think you ruled out the end-stops, and temperature isn't really our main concern right now.

Are you printing from SD card or from a host via usb? Whichever, maybe worth trying the other

emf/magnetics are unlikely to affect the motor wires as those are high current. You can get cross-talk into sensor wiring (end-stops and temperature), but I think you ruled out the end-stops, and temperature isn't really our main concern right now.

Are you printing from SD card or from a host via usb? Whichever, maybe worth trying the other

|

Re: Issues with printing larger objects June 29, 2017 09:46AM |

Registered: 7 years ago Posts: 49 |

I tried two pairs of motors, the first had thinner wires, the second (currently installed) have nice thick wires. Wiggling the connectors and cables at various points did not result in any irregularity of motor movement, so I don't think it's a loose contact or solder joint. My kinematics is CoreXY with a bowden extruder, so the moving mass is two carriages, a pair of smooth rods, bearings, another carriage, and a hotend + fans, so comparatively light, I suppose.Quote

JamesK

Oh. Jerk sounds high. Try taking that way down, just in case (e.g. start at 1 and see what happens). What's your moving mass like? Hmm, doesn't look too bad, and doesn't explain why the problem only affects one motor. Still feels like a possible wiring problem at the moment - did you try running a second set of wires for the motors to rule that out?

emf/magnetics are unlikely to affect the motor wires as those are high current. You can get cross-talk into sensor wiring (end-stops and temperature), but I think you ruled out the end-stops, and temperature isn't really our main concern right now.

Are you printing from SD card or from a host via usb? Whichever, maybe worth trying the other

I'm running a test print at 1mm/s jerk now, and I can already tell my printer hates me from the sound it makes while stuttering around the corners. Strangely enough these settings don't afflict calibration cubes.

On a side note, has anyone else had pauses of about 0.2-4s occur while printing gcode made with the latest version of cura? I didn't have these before, and these look like the kind of pause brought on by the microcontroller struggling to keep up with calculations (mega 2560), which seems very strange. The latest version also seems to have some other issues, like tweak at z failwhaling again.

|

Re: Issues with printing larger objects June 29, 2017 10:59AM |

Registered: 8 years ago Posts: 413 |

I really wish I could help you.

We know one drive is out of sync with the other hence the diagonal shift.

The shift is progressive in one direction. So its not just something loose or it would be variable.

The shifts are less than belt pitch so its not jumping teeth.

The motors have D shafts so the gears can't slip progressively round the motor.

The motors are different but they have been swapped to no effect.

The motors turn in opposite directions. Don't know the electrical significance of this. (Just thinking about inverse driver output + reverse wired motors + software setting to invert motor signal........)

Wires to the motors are different but has been investigated and should not be significant.

Drivers are different. I haven't followed if you swapped the drivers.

Missing steps is still an option but seems like you have addressed the current and any jamming/resistance issues.

Don't know if this works:- If you home the printer. Go to a point (e.g. 50,50) mark (tippex) in a line the motor+gear+belt for each do a print with an issue. Go back the original point. Do you get one motor still aligned and one not?

I suppose you could mount one of the motors the other way up with some spacers just so they both turn the same way - would have to adjust the direction settings.

We know one drive is out of sync with the other hence the diagonal shift.

The shift is progressive in one direction. So its not just something loose or it would be variable.

The shifts are less than belt pitch so its not jumping teeth.

The motors have D shafts so the gears can't slip progressively round the motor.

The motors are different but they have been swapped to no effect.

The motors turn in opposite directions. Don't know the electrical significance of this. (Just thinking about inverse driver output + reverse wired motors + software setting to invert motor signal........)

Wires to the motors are different but has been investigated and should not be significant.

Drivers are different. I haven't followed if you swapped the drivers.

Missing steps is still an option but seems like you have addressed the current and any jamming/resistance issues.

Don't know if this works:- If you home the printer. Go to a point (e.g. 50,50) mark (tippex) in a line the motor+gear+belt for each do a print with an issue. Go back the original point. Do you get one motor still aligned and one not?

I suppose you could mount one of the motors the other way up with some spacers just so they both turn the same way - would have to adjust the direction settings.

|

Re: Issues with printing larger objects June 29, 2017 11:20AM |

Registered: 7 years ago Posts: 49 |

Quote

MCcarman

I really wish I could help you.

We know one drive is out of sync with the other hence the diagonal shift.

The shift is progressive in one direction. So its not just something loose or it would be variable.

The shifts are less than belt pitch so its not jumping teeth.

The motors have D shafts so the gears can't slip progressively round the motor.

The motors are different but they have been swapped to no effect.

The motors turn in opposite directions. Don't know the electrical significance of this. (Just thinking about inverse driver output + reverse wired motors + software setting to invert motor signal........)

Wires to the motors are different but has been investigated and should not be significant.

Drivers are different. I haven't followed if you swapped the drivers.

Missing steps is still an option but seems like you have addressed the current and any jamming/resistance issues.

Don't know if this works:- If you home the printer. Go to a point (e.g. 50,50) mark (tippex) in a line the motor+gear+belt for each do a print with an issue. Go back the original point. Do you get one motor still aligned and one not?

I suppose you could mount one of the motors the other way up with some spacers just so they both turn the same way - would have to adjust the direction settings.

@JamesK

Ok, I tried printing at 1mm/s jerk, and it failed because the PVA glue on the heatbed was worn, so I replaced the coating and then started a print at 2mm/s. It went well until about 6mm up, then it got the usual drift again. I paused it and tried to force the stepper back into alignment, but the torque is too strong for me to turn it when the motors are holding. Also, I used to print via pronterface, but after a crashed computer had my hotend stewing in a pool of plastic, I switched to a 2gb SD card. Last week, as part of extended troubleshooting, I also tried a literally fresh out of the packing 16gb sandisk microsd, but no avail, it still drifted.

@MCcarman I've tried pretty much everything you mentioned. My motors are from the same manufacturer and lot, and mounted in the same fashion and level. The drivers are the same, and I've also made sure to swap and replace all motors and drivers, but it didn't fix anything. Both motors control the XY axes simultaneously by using a pair of belts hooked up to the hotend through several idler pulleys, so the direction they turn in influences the direction the head moves. There's a few diagrams up in the thread.

I'll try out marking the belts and pulleys and seeing if the belt is somehow ninja slipping, just to eliminate all possibilities. If this keeps up, I'm going to rename my printer from "ETA" to "DK", for Drift King.

Edited 1 time(s). Last edit at 06/29/2017 11:23AM by A_Designs.

|

Re: Issues with printing larger objects June 29, 2017 12:59PM |

Registered: 7 years ago Posts: 49 |

Ok, Good news, I just ran Drift King at 1mm/s, and as expected, it drifted. Practically a ridiculous 5 degree overhang to the plate, though there was indeed a bit of bearding on the bottom.

I think I've isolated the problem, I marked both pulleys and belts, but when I came back and found it had drifted severely, I observed two things. One, the Y motor responsible for moving the diagonal parallel to the drift was superhot, and the pulley-belt mark on it did NOT align when I homed my printer. It aligned on the X motor pulley just fine, and this motor was warm, but not enough to burn. The Y motor appears to be the source of the problem, as that motor was so hot that it would burn my hand if I held it for more than 2s. Both stepper drivers were set to the same values, and felt the same temperature under forced airflow.

Somehow, it appears that the Y motor pulley has been skipping steps without me noticing, so I'll take it apart and examine the belt for any damage that would result in silent skipping, maybe even setup a camera to record the Y pulley again.

I think I've isolated the problem, I marked both pulleys and belts, but when I came back and found it had drifted severely, I observed two things. One, the Y motor responsible for moving the diagonal parallel to the drift was superhot, and the pulley-belt mark on it did NOT align when I homed my printer. It aligned on the X motor pulley just fine, and this motor was warm, but not enough to burn. The Y motor appears to be the source of the problem, as that motor was so hot that it would burn my hand if I held it for more than 2s. Both stepper drivers were set to the same values, and felt the same temperature under forced airflow.

Somehow, it appears that the Y motor pulley has been skipping steps without me noticing, so I'll take it apart and examine the belt for any damage that would result in silent skipping, maybe even setup a camera to record the Y pulley again.

|

Re: Issues with printing larger objects June 29, 2017 01:21PM |

Registered: 9 years ago Posts: 1,873 |

Interesting. A hot motor might lead us back towards binding as a possibility. One of the issues with H-bot/coreXY is that the belt tension pulls the sides together across what is conventionally the X axis, but looks like the Y axis in your build. I see you don't have a structural member bracing that axis in your build, so you are potentially vulnerable to the rods flexing and changing the separation of the bearings. I know you've said that the mechanism is smooth and free, but you might want to just double check that. Moving the print to different locations on the bed might also be interesting. Centre is potentially worse case for rod flex, so shifting out to the corners might be worth a go. Are those 8mm rods? How long? I've more or less come to the conclusion that 8mm rods have no place on a printer with a span more than 200mm.

Edit: just a quick thought for others that may come across this thread later; there's been several mentions of the lack of noise associated with the offset as an indication of it not being cause by missed steps. Missed steps can be noisy, e.g. when the extruder can't overcome the back-pressure or the carriage hits the end of it's travel, but many other cases of missed steps are completely silent in my experience, making the occurrence of the problem really difficult to detect and diagnose. This includes cases of exceeding the maximum step rate of the processor and the maximum acceleration achievable by the motor.

Edited 1 time(s). Last edit at 06/29/2017 01:30PM by JamesK.

Edit: just a quick thought for others that may come across this thread later; there's been several mentions of the lack of noise associated with the offset as an indication of it not being cause by missed steps. Missed steps can be noisy, e.g. when the extruder can't overcome the back-pressure or the carriage hits the end of it's travel, but many other cases of missed steps are completely silent in my experience, making the occurrence of the problem really difficult to detect and diagnose. This includes cases of exceeding the maximum step rate of the processor and the maximum acceleration achievable by the motor.

Edited 1 time(s). Last edit at 06/29/2017 01:30PM by JamesK.

|

Re: Issues with printing larger objects June 30, 2017 02:35AM |

Registered: 7 years ago Posts: 49 |

Quote

JamesK

Interesting. A hot motor might lead us back towards binding as a possibility. One of the issues with H-bot/coreXY is that the belt tension pulls the sides together across what is conventionally the X axis, but looks like the Y axis in your build. I see you don't have a structural member bracing that axis in your build, so you are potentially vulnerable to the rods flexing and changing the separation of the bearings. I know you've said that the mechanism is smooth and free, but you might want to just double check that. Moving the print to different locations on the bed might also be interesting. Centre is potentially worse case for rod flex, so shifting out to the corners might be worth a go. Are those 8mm rods? How long? I've more or less come to the conclusion that 8mm rods have no place on a printer with a span more than 200mm.

Edit: just a quick thought for others that may come across this thread later; there's been several mentions of the lack of noise associated with the offset as an indication of it not being cause by missed steps. Missed steps can be noisy, e.g. when the extruder can't overcome the back-pressure or the carriage hits the end of it's travel, but many other cases of missed steps are completely silent in my experience, making the occurrence of the problem really difficult to detect and diagnose. This includes cases of exceeding the maximum step rate of the processor and the maximum acceleration achievable by the motor.

In my build, the X axis rods are carried by the Y axis's carriage, the X axis rods are about 8mm x 400mm long and the Y axis rods are 8mm x 500mm long. I generally print either in the center of the bed, or in one of the four quadrants, to avoid wearing out the PVA coating on the bed, and printing in different parts of the bed had no discernible influence on the drift. I haven't used the rods for very long, but I've had them for about a year now, while I was waiting on parts and building my printer. They are pretty good quality, accuracy greater than <0.01mm, and there's no wear or grooves on them. I can't check if they're bent, but they weren't when I got them, I tested them against a pane of plate glass.

If I ever go insane and decide to build another printer, it'll probably use linear rails instead though

Whenever I've had any belts slip or motors skip, they'd produce a rather distinctive sound, so it may because I've gotten so used to hearing those sounds that I may have missed another sound of belt skipping. Now that I know the belt is slipping on the pulley, I'll try readjusting how taut it is. Is it a good idea to use belt tightener springs, or do they just cause rippling?

|

Re: Issues with printing larger objects June 30, 2017 07:23AM |

Registered: 9 years ago Posts: 1,873 |

Quote

A_Designs

In my build, the X axis rods are carried by the Y axis's carriage, the X axis rods are about 8mm x 400mm long and the Y axis rods are 8mm x 500mm long. I generally print either in the center of the bed, or in one of the four quadrants, to avoid wearing out the PVA coating on the bed, and printing in different parts of the bed had no discernible influence on the drift. I haven't used the rods for very long, but I've had them for about a year now, while I was waiting on parts and building my printer. They are pretty good quality, accuracy greater than <0.01mm, and there's no wear or grooves on them. I can't check if they're bent, but they weren't when I got them, I tested them against a pane of plate glass.

If I ever go insane and decide to build another printer, it'll probably use linear rails instead though

Whenever I've had any belts slip or motors skip, they'd produce a rather distinctive sound, so it may because I've gotten so used to hearing those sounds that I may have missed another sound of belt skipping. Now that I know the belt is slipping on the pulley, I'll try readjusting how taut it is. Is it a good idea to use belt tightener springs, or do they just cause rippling?

My issue with 8mm rods is the amount of flexibility. If I put the carriage in the middle of the x-axis I can displace the nozzle by +/- 5mm with relatively little effort, with the majority of the travel being due to twisting of the carriage by displacing the two x rods. I'm partly at fault for implementing the x-carriage such that the nozzle sits a long way from the rods, amplifying the movement, but the inherent flex in the rods is a lot more than I was expecting. I lucked into some high-end linear rails for my next build and the difference is dramatic. Even the cheap linear rail that I needed for the long axis is far better than working with unsupported rods.

I missed the part where you identified the belt was slipping, it hadn't occurred to me that that was particularly easy to do. I haven't tried the springs that look like they came from a clothes peg and fit on the belt. They don't look like they would do anything very useful to me. I have a screw down adjuster, either on the belt anchor for the X axis, or on the pulley for the Y that I use to set the belt tension. I prefer the belt tension to be high enough that you get a musical note when twanging the belt. If I was more musical I'd give you the pitch, but it's going to depend on belt length anyway. I'd say mine are somewhere in the octave below middle C, but couldn't be more specific than that

The belts are spec'd to run at quite high tensions, but most printer's structure are not. With the 180 degree belt-pulley contact typical of hbot/corexy designs you shouldn't need to go too high on belt tension to eliminate slipping, but you definitely don't want any sort of slack.

The belts are spec'd to run at quite high tensions, but most printer's structure are not. With the 180 degree belt-pulley contact typical of hbot/corexy designs you shouldn't need to go too high on belt tension to eliminate slipping, but you definitely don't want any sort of slack.

|

Re: Issues with printing larger objects June 30, 2017 11:11AM |

Registered: 7 years ago Posts: 49 |

I'm so done right about now. I've found the problem.

So, the linchpin that's been a pain in my neck for the last few months, the constant sword of Damocles over my prints, has been isolated to number 4.1 on the shifted layers page on the reprap wiki. That refers to cheap chinese pulleys which aren't machined to a sufficient depth to properly grasp the teeth of the belt. Mine were aluminium, and fairly deep, so that wasn't the problem I faced.

However, it turns out that my pulley was ever so slightly oblique, by less than a millimeter. That mild eccentricity was sufficient for it to skip teeth when moving the head back and forth on a large detailed object. I only realized it myself when I stared at the pulley in question very intently, and thought that the minute wobble may be the issue. I had noticed it earlier, but I'd dismissed it as the belt just stretching mildly as the strain on it went from one side to another.

Right now, I just swapped it out with one of my toothed idler pulleys, and it's working like a charm so far. No other changes, tweaks, nothing. I'm printing on regular acceleration and jerk settings, and I can't see any wobble in the new pulley. Just goes to show, that sometimes, the parts you consider too minor to replace or worry about could end up being your Achilles' O-Ring.

Can someone edit the wiki's Shifted Layers page and add point number 4.2 "Cheap chinese pulleys may be machined irregularly/eccentrically which leads to belts skipping silently. Ensure there is no wobble on the belt as it goes over the pulley, as wobble is an indicator of oblique pulleys."

Thank you all so much for your help, I couldn't have done it without each and every one of you guys.

So, the linchpin that's been a pain in my neck for the last few months, the constant sword of Damocles over my prints, has been isolated to number 4.1 on the shifted layers page on the reprap wiki. That refers to cheap chinese pulleys which aren't machined to a sufficient depth to properly grasp the teeth of the belt. Mine were aluminium, and fairly deep, so that wasn't the problem I faced.

However, it turns out that my pulley was ever so slightly oblique, by less than a millimeter. That mild eccentricity was sufficient for it to skip teeth when moving the head back and forth on a large detailed object. I only realized it myself when I stared at the pulley in question very intently, and thought that the minute wobble may be the issue. I had noticed it earlier, but I'd dismissed it as the belt just stretching mildly as the strain on it went from one side to another.

Right now, I just swapped it out with one of my toothed idler pulleys, and it's working like a charm so far. No other changes, tweaks, nothing. I'm printing on regular acceleration and jerk settings, and I can't see any wobble in the new pulley. Just goes to show, that sometimes, the parts you consider too minor to replace or worry about could end up being your Achilles' O-Ring.

Can someone edit the wiki's Shifted Layers page and add point number 4.2 "Cheap chinese pulleys may be machined irregularly/eccentrically which leads to belts skipping silently. Ensure there is no wobble on the belt as it goes over the pulley, as wobble is an indicator of oblique pulleys."

Thank you all so much for your help, I couldn't have done it without each and every one of you guys.

|

Re: Issues with printing larger objects June 30, 2017 11:18AM |

Registered: 9 years ago Posts: 1,873 |

That's great news - congratulations! I haven't come across that cause before, I'll have to keep it in mind as I have a fair collection of cheap pulleys. Sorry, I don't have editor rights on the wiki, but hopefully some-one else will add the info.

Enjoy your printing again

Edited 1 time(s). Last edit at 06/30/2017 11:18AM by JamesK.

Enjoy your printing again

Edited 1 time(s). Last edit at 06/30/2017 11:18AM by JamesK.

Sorry, only registered users may post in this forum.