ABS infill issue

Posted by h4nc

|

ABS infill issue April 09, 2017 08:18AM |

Registered: 7 years ago Posts: 48 |

Hi,

I'm still new to printing with ABS and have problems with the infill (picture attached) and even bridges.

It seems that the first infill layer doesn't adhere good enough to the layer below. This creates small gaps and the next infill layer does not build up as it should, because of the gap below and the bad bridging behavior.

Can someone help?

I'm still new to printing with ABS and have problems with the infill (picture attached) and even bridges.

It seems that the first infill layer doesn't adhere good enough to the layer below. This creates small gaps and the next infill layer does not build up as it should, because of the gap below and the bad bridging behavior.

Can someone help?

|

Re: ABS infill issue April 09, 2017 08:38AM |

Registered: 7 years ago Posts: 201 |

|

Re: ABS infill issue April 09, 2017 09:58AM |

Registered: 7 years ago Posts: 48 |

|

Re: ABS infill issue April 09, 2017 10:05AM |

Registered: 7 years ago Posts: 201 |

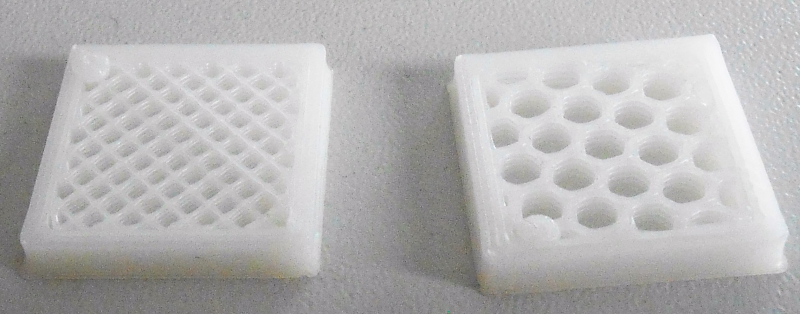

Looks like rectangular infill. Slic3r does hex infill by default. This is slower and very noisy, but more solid. The rectangular infill I know from Cura likes to collapse if there's too much air between the lines, that's why I assumed Cura. What's the size of the Z cube? Looks like 20mm, and then the infill looks like 15% - only guessing by the pic.

|

Re: ABS infill issue April 09, 2017 10:08AM |

Registered: 7 years ago Posts: 48 |

|

Re: ABS infill issue April 09, 2017 02:23PM |

Registered: 7 years ago Posts: 48 |

The 25% does not show the problem good in a picture so I did one with 15% (honeycomb). See picture.

If you look close enough you can see stringing between the intersection. It looks like there is to less material. This also effects briding.

I want to print the digital sun dial but the details are not possible. [www.thingiverse.com]

If you look close enough you can see stringing between the intersection. It looks like there is to less material. This also effects briding.

I want to print the digital sun dial but the details are not possible. [www.thingiverse.com]

|

Re: ABS infill issue April 11, 2017 03:19AM |

Registered: 7 years ago Posts: 201 |

Your cube looks quite good, I don't se (much) stringing. Maybe you can doo a higher res pic?

Next guess: the parts of the infill, where there is too less material, is the infill directly after traveling moves? This is what my nozzle does: While traveling it oozes a bit, sometimes making warts. This is no big deal, but the material that oozed out during travel is missing when extruding the next 3 or 5 mm. I didn't find any good countermeasure for this. Coasting should help, from what I read - this is something like reducing the extraction & travel speed before the end of an extraction is reached, prior to the travel move. But my Cura & Slic3r don't have this.

Next guess: the parts of the infill, where there is too less material, is the infill directly after traveling moves? This is what my nozzle does: While traveling it oozes a bit, sometimes making warts. This is no big deal, but the material that oozed out during travel is missing when extruding the next 3 or 5 mm. I didn't find any good countermeasure for this. Coasting should help, from what I read - this is something like reducing the extraction & travel speed before the end of an extraction is reached, prior to the travel move. But my Cura & Slic3r don't have this.

|

Re: ABS infill issue April 19, 2017 10:34AM |

Registered: 7 years ago Posts: 48 |

|

Re: ABS infill issue April 20, 2017 04:16AM |

Registered: 7 years ago Posts: 201 |

Yes, I can see it, but unfortunately I can't tell you much because I never did rectlnear infill with Slic3r. I switched to Cura a while ago, because of the hole handling. But I remember my Slic3r honeycomb infills looked quite good with a Mendel90, printing ABS at 80mm/s. Without knowing if it helps, maybe you could try the honeycomb.

|

Re: ABS infill issue April 20, 2017 05:25AM |

Registered: 7 years ago Posts: 48 |

|

Re: ABS infill issue April 21, 2017 02:07AM |

Registered: 7 years ago Posts: 201 |

|

Re: ABS infill issue April 21, 2017 04:50AM |

Registered: 7 years ago Posts: 48 |

|

Re: ABS infill issue April 24, 2017 03:43AM |

Registered: 7 years ago Posts: 201 |

|

Re: ABS infill issue April 26, 2017 03:23AM |

Registered: 7 years ago Posts: 48 |

|

Re: ABS infill issue April 30, 2017 02:18AM |

Registered: 7 years ago Posts: 201 |

My car is back home, a part of the cludge is broken. Unfortunately I can't print it ;-) The part is about 50 or 80 €, but replacing will be some hundred. I'm off for the weekend, and in Germany May 1st is a holiday. I'll prepare my Cura now, create a 20mm cube with 30% infill gcodes and probably print it on tuesday, with a 0.5mm nozzle in 0.2 & 0.3mm in white or grey ABS, and manually kill the print to make some pics of the infill.

|

Re: ABS infill issue May 03, 2017 07:23AM |

Registered: 7 years ago Posts: 201 |

I took your settings, changed to my speed and temperature values, and sliced it with Slic3r, 30% infill (one rectlinear, one honeycomb), 0.2mm layer height. Printed both, and in my eyes they look perfect - despite of a little elephant foot, I think I have to adjust my Z heigth a bit. The photo isn't the best, if needed I can make high detail pics with my USB microscope. Anyway I ran out of ideas. My speed settings are a bit higher than yours, and my temp is noticeable higher - IIRC 240 extruder, 130 bed (is in fact 90-95 deg C at the glass surface). I may try 10% infill this evening. Anyway I can't see anything in your Slic3r settings causing bad infill.

Last resorts would be increasing the flowrate, and playing around with temp & speed.. Although I don't see any signs of under extrusion at your parts.

Last resorts would be increasing the flowrate, and playing around with temp & speed.. Although I don't see any signs of under extrusion at your parts.

|

Re: ABS infill issue May 04, 2017 05:39AM |

Registered: 7 years ago Posts: 201 |

|

Re: ABS infill issue May 05, 2017 06:26AM |

Registered: 7 years ago Posts: 48 |

Hi

sry for my late reply.

Your cubes really look good. Thank you.

Maybe its a problem with the filament. But than this would also happen to the perimeters.

I printed a lot of pla parts the last days withour any problem. All came out perfect.

I actually use a chinese e3d clone. Again PLA perfect, but maybe there are some problems with ABS and this clone.

Thank you again!

sry for my late reply.

Your cubes really look good. Thank you.

Maybe its a problem with the filament. But than this would also happen to the perimeters.

I printed a lot of pla parts the last days withour any problem. All came out perfect.

I actually use a chinese e3d clone. Again PLA perfect, but maybe there are some problems with ABS and this clone.

Thank you again!

|

Re: ABS infill issue May 05, 2017 12:19PM |

Registered: 8 years ago Posts: 413 |

|

Re: ABS infill issue May 07, 2017 03:55AM |

Registered: 7 years ago Posts: 201 |

|

Re: ABS infill issue May 08, 2017 05:07AM |

Registered: 7 years ago Posts: 48 |

Thanks for your help. I will try less retraction.

I never understood why the standard setting in slicer for the different flow settings is set automatic. Why should the software be able to change the width while the hardware isn't able too?

I set all those values to 0.4 because one time I printed a thin wall calibration print (0.4 walls). In automatic mode the walls got much thicker. Settings them all to 0,4 helped. Also parts fitted much bettet after that.

Isn't changing those values to 0.48 the same as I set the extrusion multiplier to 1.2 (of course this would effect all)? This would mean that parts will get thicker, holes smaller etc.

Or so you mean that I should only change the infill flow rate?

I never understood why the standard setting in slicer for the different flow settings is set automatic. Why should the software be able to change the width while the hardware isn't able too?

I set all those values to 0.4 because one time I printed a thin wall calibration print (0.4 walls). In automatic mode the walls got much thicker. Settings them all to 0,4 helped. Also parts fitted much bettet after that.

Isn't changing those values to 0.48 the same as I set the extrusion multiplier to 1.2 (of course this would effect all)? This would mean that parts will get thicker, holes smaller etc.

Or so you mean that I should only change the infill flow rate?

|

Re: ABS infill issue May 08, 2017 09:53AM |

Registered: 7 years ago Posts: 201 |

0.4mm nozzle diameter is the hot plastic coming out of the extruder. The printer will squeeze this onto the bed or the lower layers, so the actual extrusion width is larger than the nozzle diameter. Some smart people made some formular to get the smallest possible extrusion width, but it's definitely wider than the nozzle. So extracting 0.4mm with a 0.4mm nozzle will surely not work. The extrusion multiplier is the flowrate (AFAIR), this is for decompensating wrong E steps - if you extrude 100mm, but your filament actually travels 91mm, you'd set this to 1.1 or 110% - approximately. The firmware then will multiply all extruding numbers by 1.1, so extruding 100mm then would result in real 1.1 * 91mm = 100.1mm extraction - very close to 100mm.

With my 0.5mm nozzle I usually sliced to 0.6mm extrusion width, and on the first layer 0.9mm when using Sl1c3r. Cura doesn't have such a setting, but from my eyes it looks similar, probably the lowest layer is even wider.

Too the infill: I don't think you need to adjust the flowrate. You should (maybe) increase the feedrate for the infill. Feed = speed, flowrate = how many plastic will come out. You can set the infill speed without touching the perimeter & travel speed. In Slicer mine is 80mm/s, in Cura 100mm/s.

If you're printing a 20mm test cube you will probably need no retract at all.

Edited 1 time(s). Last edit at 05/08/2017 09:54AM by Inhumierer.

With my 0.5mm nozzle I usually sliced to 0.6mm extrusion width, and on the first layer 0.9mm when using Sl1c3r. Cura doesn't have such a setting, but from my eyes it looks similar, probably the lowest layer is even wider.

Too the infill: I don't think you need to adjust the flowrate. You should (maybe) increase the feedrate for the infill. Feed = speed, flowrate = how many plastic will come out. You can set the infill speed without touching the perimeter & travel speed. In Slicer mine is 80mm/s, in Cura 100mm/s.

If you're printing a 20mm test cube you will probably need no retract at all.

Edited 1 time(s). Last edit at 05/08/2017 09:54AM by Inhumierer.

|

Re: ABS infill issue May 08, 2017 10:09AM |

Registered: 7 years ago Posts: 48 |

|

Re: ABS infill issue May 08, 2017 02:14PM |

Registered: 7 years ago Posts: 48 |

Hi,

I played with the width settings. I tried 0.4, 0.44, 0.48 and automatic. All other settings stood the same. Honeycomb 20% infill. See picture attached.

The 0.48 and the automatic look good to me.

The question about what exactly the automatic mode does is still open to me. It says that it depends on the layer height. For me that is to less information to figure out how calculates the width.

Also it is interessting to see that the automatic honeycomb looks so different too the others. So the holes are bigger because it generates a bigger witdh, which means using more plastic. Right?

Edit: I recognized a gap between the perimeters and the infill for the automatic mode? Does someone know why there is a gap?

Edited 1 time(s). Last edit at 05/09/2017 04:27AM by h4nc.

I played with the width settings. I tried 0.4, 0.44, 0.48 and automatic. All other settings stood the same. Honeycomb 20% infill. See picture attached.

The 0.48 and the automatic look good to me.

The question about what exactly the automatic mode does is still open to me. It says that it depends on the layer height. For me that is to less information to figure out how calculates the width.

Also it is interessting to see that the automatic honeycomb looks so different too the others. So the holes are bigger because it generates a bigger witdh, which means using more plastic. Right?

Edit: I recognized a gap between the perimeters and the infill for the automatic mode? Does someone know why there is a gap?

Edited 1 time(s). Last edit at 05/09/2017 04:27AM by h4nc.

|

Re: ABS infill issue May 09, 2017 04:54AM |

Registered: 7 years ago Posts: 201 |

I never printed PLA, so I'm unsure why you can print 0.4mm extr width with a 0.4mm nozzle and the parts are good. Maybe it's because PLA is more like rubber when hot, ABS is more like honey, less flexible. When you press hot plastic through a 0.4mm hole, the extruded line is cylindric, and a bit thicker than 0.4mm - it depends on the material, the surface tension (Oberflächenspannung), on the temperature and on the speed. But it's never thinner than the nozzle width. This sausage is pressed down to the bed or the lower layer, so it gets a bit flatter (layer heigth in ideal case) and wider. That's why you normally extrude a bit wider than your nozzle actually is. If extrusion width is too small you get a bad connection between the extrusions.

On your picture the auto looks best, in my eyes. Maybe increase the infill overlap a bit, looks like a small gap on top and bottom. I remember Slicer 1.29 was said to have a bug when setting auto width, although I never had a problem with auto setting. 20% infill normaly says that 1cm^3 infill is made out of 0.2cm^3 plastic. If the infill "walls" get thicker when the extrusion width increases, the distances between the walls must increase, too. So the infill honeycombs get bigger. I'm glad that at least you get a pretty good infill right now. :-)

At the beginning I used Slicer, but I had some troubles with holes, especially small ones. In Slicer you can control a lot of things, way more than in Cura, but at least with my printer, holes are much better when the STL is made by Cura. In Slicer I used extrusion width a bit more than my nozzle, or auto, both worked good. In Cura I can set a nozzle diameter, but I can't set the extrusion width, AFAIR. To be honest, I don't care too much, as long as my parts look good. I have a leaky 0.5mm nozzle, and I have some small issues when material leaks out during travel moves, and I have some ghosting artefacts, but the overall extrusion works quite nice. I'll try a 0.3mm nozzle direct extruder, and a 0.4mm nozzle bowden type to reduce the weight of my Y carriage to get less ghosting, when I find some spare time.

I'd like to have a slicer setting to implement coasting, which slows down head movement and extrusion before travel moves to counter leaking, and something to slow down movement before perimeter edges to counter ghosting and ringing, but I fear I have to wait some time before this comes. 3D printing is learning every day...

On your picture the auto looks best, in my eyes. Maybe increase the infill overlap a bit, looks like a small gap on top and bottom. I remember Slicer 1.29 was said to have a bug when setting auto width, although I never had a problem with auto setting. 20% infill normaly says that 1cm^3 infill is made out of 0.2cm^3 plastic. If the infill "walls" get thicker when the extrusion width increases, the distances between the walls must increase, too. So the infill honeycombs get bigger. I'm glad that at least you get a pretty good infill right now. :-)

At the beginning I used Slicer, but I had some troubles with holes, especially small ones. In Slicer you can control a lot of things, way more than in Cura, but at least with my printer, holes are much better when the STL is made by Cura. In Slicer I used extrusion width a bit more than my nozzle, or auto, both worked good. In Cura I can set a nozzle diameter, but I can't set the extrusion width, AFAIR. To be honest, I don't care too much, as long as my parts look good. I have a leaky 0.5mm nozzle, and I have some small issues when material leaks out during travel moves, and I have some ghosting artefacts, but the overall extrusion works quite nice. I'll try a 0.3mm nozzle direct extruder, and a 0.4mm nozzle bowden type to reduce the weight of my Y carriage to get less ghosting, when I find some spare time.

I'd like to have a slicer setting to implement coasting, which slows down head movement and extrusion before travel moves to counter leaking, and something to slow down movement before perimeter edges to counter ghosting and ringing, but I fear I have to wait some time before this comes. 3D printing is learning every day...

|

Re: ABS infill issue May 09, 2017 09:15AM |

Registered: 7 years ago Posts: 48 |

Thanks you! Could you explain ghosting and ringing?

The whole thing is about printing the populat sundial. So after all of your help I tried it again (with auto mode).

The infill looks much better now, but I still face problems with short bridging (see picture).

I looks like the extruded filament doesn't stick to the starting point.

But maybe it's underextrusion again, it could be that the automode uses 0.4 width for the thin lines. How low does the automode go? Or does it "know" that 0.4 is to less?

Edited 1 time(s). Last edit at 05/09/2017 09:28AM by h4nc.

The whole thing is about printing the populat sundial. So after all of your help I tried it again (with auto mode).

The infill looks much better now, but I still face problems with short bridging (see picture).

I looks like the extruded filament doesn't stick to the starting point.

But maybe it's underextrusion again, it could be that the automode uses 0.4 width for the thin lines. How low does the automode go? Or does it "know" that 0.4 is to less?

Edited 1 time(s). Last edit at 05/09/2017 09:28AM by h4nc.

|

Re: ABS infill issue May 11, 2017 10:25AM |

Registered: 7 years ago Posts: 48 |

Hi,

are you able so close wider infills (4mm holes) with one abs layer? I can't. And this influences the next layer. Four top layers in the picuteres attached.

And I think this is my (hopefully) last bigger problem with ABS.

The top layer cracks while printing and gets gaps and holes, because its not able to bridge between those small distances. I tried to reduce the hotend temperature, but that didn't help.

Thx

are you able so close wider infills (4mm holes) with one abs layer? I can't. And this influences the next layer. Four top layers in the picuteres attached.

And I think this is my (hopefully) last bigger problem with ABS.

The top layer cracks while printing and gets gaps and holes, because its not able to bridge between those small distances. I tried to reduce the hotend temperature, but that didn't help.

Thx

|

Re: ABS infill issue May 12, 2017 04:06AM |

Registered: 7 years ago Posts: 201 |

Ghosting or ringing is when the Y carriage makes a "hard" change of movement, f.ex. if you print a box, or you have a wall in x direction and there are some vertical things like holes, letters or similar. The carriage swings a bit, and you get an echo of the movement beside the structure. Goggle for "3d print ringing", you'll see what it is. Hundreds of pictures.

In Sl1c3r there are extra bridging settings. I played around with lots of them, and I can print good bridges up to app. 30 or 40mm. I increased the speed of the bridge strings and lowered my temp a little, and AFAIR I reduced extrusion during bridging to 95%. In Cura the bridges don't get very good, and in general I try to avoid bridges and overhangs > 50 degrees. Oh, and you won't get nice bridges if your layer height is very different to your nozzle diameter. With my 0.5mm nozzle I get good results with 0.3mm layer height, 0.2mm does not come out well. I didn't try 0.25mm or 0.4mm layer heigth, anyway.

To your photos: Just a feeling, it looks like you're printing too hot. And the digital sundial is probably a very difficult thing to print. What layer heigth did you use to print the nozzle holder? Maybe you can try 0.25mm, and 5 or 8 degrees colder?

In Sl1c3r there are extra bridging settings. I played around with lots of them, and I can print good bridges up to app. 30 or 40mm. I increased the speed of the bridge strings and lowered my temp a little, and AFAIR I reduced extrusion during bridging to 95%. In Cura the bridges don't get very good, and in general I try to avoid bridges and overhangs > 50 degrees. Oh, and you won't get nice bridges if your layer height is very different to your nozzle diameter. With my 0.5mm nozzle I get good results with 0.3mm layer height, 0.2mm does not come out well. I didn't try 0.25mm or 0.4mm layer heigth, anyway.

To your photos: Just a feeling, it looks like you're printing too hot. And the digital sundial is probably a very difficult thing to print. What layer heigth did you use to print the nozzle holder? Maybe you can try 0.25mm, and 5 or 8 degrees colder?

|

Re: ABS infill issue May 15, 2017 04:37AM |

Registered: 7 years ago Posts: 48 |

|

Re: ABS infill issue May 19, 2017 07:52AM |

Registered: 11 years ago Posts: 1,592 |

Sorry, only registered users may post in this forum.