I'm not getting good print quality when increasing speed.

Posted by kd6hq

|

I'm not getting good print quality when increasing speed. February 16, 2018 03:02PM |

Registered: 9 years ago Posts: 223 |

Up to now I've mostly just printed small parts. I did this at a slow speed and did not care about the time. Now I would like to print some bigger parts but am running into some issues that I have not been able to figure out.

In picture SP-20 the inner is not fully connected to the infill.

In pictures SP-40 and SP-60 are the same part just at faster speeds.

When I print a circle it is slightly off so this might account for the inner wall not being fully connected.

In pictures 40 & 60 the settings are off and I am not sure what to change to get better prints. I tried several things but I just have not found the correct combination yet

SP = 20 mm / s, 40mm / s and 60 mm / s.

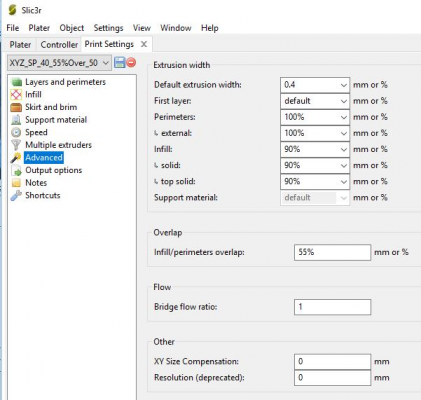

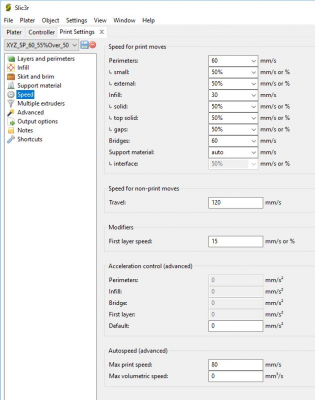

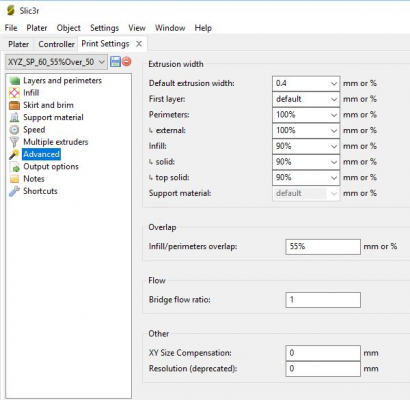

Setting images are attached.

Your help would be appreciated.

In picture SP-20 the inner is not fully connected to the infill.

In pictures SP-40 and SP-60 are the same part just at faster speeds.

When I print a circle it is slightly off so this might account for the inner wall not being fully connected.

In pictures 40 & 60 the settings are off and I am not sure what to change to get better prints. I tried several things but I just have not found the correct combination yet

SP = 20 mm / s, 40mm / s and 60 mm / s.

Setting images are attached.

Your help would be appreciated.

|

Re: I'm not getting good print quality when increasing speed. February 17, 2018 02:59AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: I'm not getting good print quality when increasing speed. February 17, 2018 07:33AM |

Registered: 11 years ago Posts: 5,780 |

What printer, what slicer, and which speeds are you setting to 20, 40 and 60 mm/sec?

Have you calibrated the extruder? Are the belts tight? Have you calibrated steps/mm of the X.,Y, and Z mechanism?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Have you calibrated the extruder? Are the belts tight? Have you calibrated steps/mm of the X.,Y, and Z mechanism?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: I'm not getting good print quality when increasing speed. February 17, 2018 10:28AM |

Registered: 9 years ago Posts: 223 |

Thank you o lampe, the digital dentist for the response.

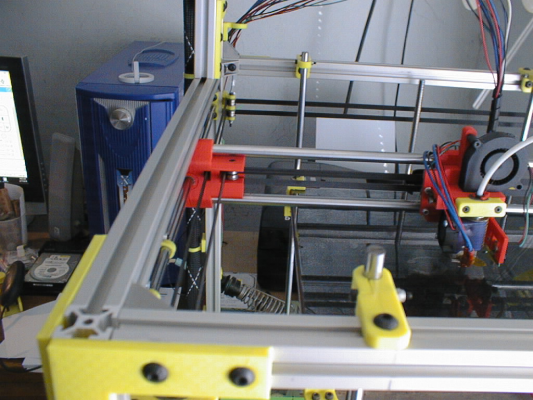

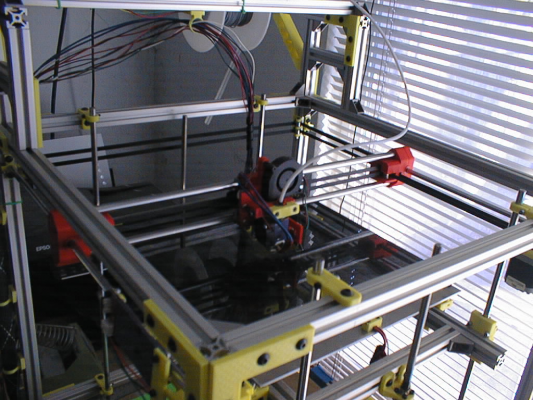

The machine is a CoreXY

Belts tight - yes

Calibrated steps / mm X, Y, Z - yes

Slicer - (Repetier-Host) - Slic3r

Ok, I adjusted the Perimeters: is set to 40 mm/s. Infill to 20 mm/s all the rest to 50% as can be seen in the attachments.

I changed the number of Perimeters from 3 to 6.

Infill overlap is set to 55%. .

Infill amount is set to 50% for all speeds.

Although the print for the speed of 60 is an improvement it needs more work.

6 perimeters sounds high to me, is it, or is there something else I should be adjusting?

The machine is a CoreXY

Belts tight - yes

Calibrated steps / mm X, Y, Z - yes

Slicer - (Repetier-Host) - Slic3r

Ok, I adjusted the Perimeters: is set to 40 mm/s. Infill to 20 mm/s all the rest to 50% as can be seen in the attachments.

I changed the number of Perimeters from 3 to 6.

Infill overlap is set to 55%. .

Infill amount is set to 50% for all speeds.

Although the print for the speed of 60 is an improvement it needs more work.

6 perimeters sounds high to me, is it, or is there something else I should be adjusting?

|

Re: I'm not getting good print quality when increasing speed. February 17, 2018 11:06AM |

Registered: 11 years ago Posts: 5,780 |

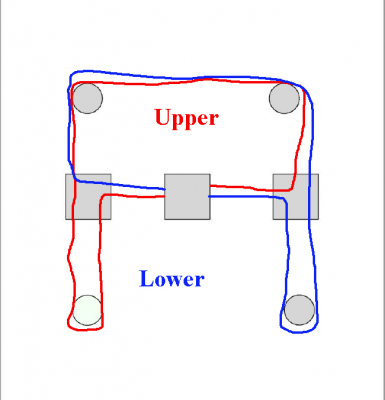

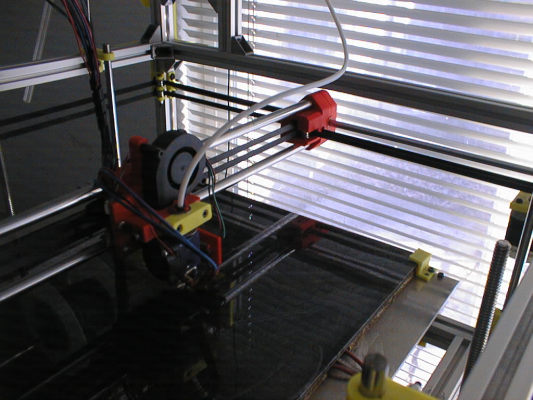

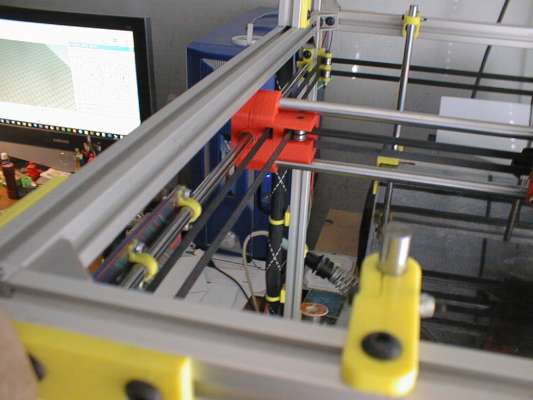

You shouldn't need all that. Perimeters overlap at 15% should be plenty. 3 perimeters should hide infill at any speed. Post a picture of the machine showing the belt paths.

I have had problems with slic3r in the past where it would try to print lines narrower than the nozzle diameter. That sort of behavior may have been fixed in recent releases, but I don't trust it. I set all the speed and line width parameters myself so I know exactly how the printer is going to behave. I would start by setting all those options manually, and go from there.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I have had problems with slic3r in the past where it would try to print lines narrower than the nozzle diameter. That sort of behavior may have been fixed in recent releases, but I don't trust it. I set all the speed and line width parameters myself so I know exactly how the printer is going to behave. I would start by setting all those options manually, and go from there.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: I'm not getting good print quality when increasing speed. February 17, 2018 11:33AM |

Registered: 9 years ago Posts: 223 |

|

Re: I'm not getting good print quality when increasing speed. February 17, 2018 11:45AM |

Registered: 11 years ago Posts: 5,780 |

I know what a coreXY belt path is supposed to look like. Post a photo...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: I'm not getting good print quality when increasing speed. February 17, 2018 11:54AM |

Registered: 9 years ago Posts: 223 |

|

Re: I'm not getting good print quality when increasing speed. February 17, 2018 12:14PM |

Registered: 9 years ago Posts: 223 |

|

Re: I'm not getting good print quality when increasing speed. February 17, 2018 01:44PM |

Registered: 11 years ago Posts: 5,780 |

It looks like the belts are parallel to the rails from what I can see, so at least that isn't an issue. What material are you printing and at what temperature? Have you checked the sides of the print with a square or measured the diagonals? If the diagonals don't match the X and Y axes aren't square- adjusting belt tension can square them up if they aren't too far out of alignment. Check for play at the extruder carriage- grab it like Trump would grab a p**sy and try to wiggle it. It should resist any attempt to move it in any direction the same way the p**sy would resist Trump. Have you calibrated the extruder?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: I'm not getting good print quality when increasing speed. February 17, 2018 02:17PM |

Registered: 9 years ago Posts: 223 |

I'm just printing with good old PLA, head is at 200 and bed is at 75.

You mentioned that you have had problems with slic3r, the only other choices I have are

Cura, Skeinforge and Slic3r Prusa Edition. What do you use for a slicer and program to run the printer?

I have not check with a square or measured but I will.

There is very little play in the extruder mount. I've checked that before and modified it to tighten it up.

It has been a while since I've verified the X, Y, and Z. But I will do that also.

I've been at this for about 10 hours now, time for a break for now and when I come back to it latter tonight I will check stuff.

You mentioned that you have had problems with slic3r, the only other choices I have are

Cura, Skeinforge and Slic3r Prusa Edition. What do you use for a slicer and program to run the printer?

I have not check with a square or measured but I will.

There is very little play in the extruder mount. I've checked that before and modified it to tighten it up.

It has been a while since I've verified the X, Y, and Z. But I will do that also.

I've been at this for about 10 hours now, time for a break for now and when I come back to it latter tonight I will check stuff.

|

Re: I'm not getting good print quality when increasing speed. February 17, 2018 04:11PM |

Registered: 11 years ago Posts: 5,780 |

Slic3r is fine, just don't let it select speeds or extrusion widths. I had problems with that in the past- it may be fixed now, but don't leave things to chance while you're troubleshooting. I don't use host software- I print from SD cards. In my experience, SD cards are far more reliable than a USB connection.

At 200C PLA may be a little thick to print at 60 mm/sec. Try turning the temperature up a bit, especially if you hear any clicking coming from the extruder.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

At 200C PLA may be a little thick to print at 60 mm/sec. Try turning the temperature up a bit, especially if you hear any clicking coming from the extruder.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: I'm not getting good print quality when increasing speed. February 18, 2018 03:02AM |

Registered: 8 years ago Posts: 5,232 |

I agree with DD, 55% infill overlap is too much.

Infill at 20mm/s should end up with the same result, no matter how fast you print the perimeters. So maybe the extruder isn't up to the speed and the perimeters are bad?

My gut feeling tells me, the smooth rods are too small or soft for their length. Do you see the same behaviour, when printing in a corner of the bed, where the rods would be stiffer than in the middle?

Infill at 20mm/s should end up with the same result, no matter how fast you print the perimeters. So maybe the extruder isn't up to the speed and the perimeters are bad?

My gut feeling tells me, the smooth rods are too small or soft for their length. Do you see the same behaviour, when printing in a corner of the bed, where the rods would be stiffer than in the middle?

|

Re: I'm not getting good print quality when increasing speed. February 18, 2018 07:51AM |

Registered: 9 years ago Posts: 223 |

|

Re: I'm not getting good print quality when increasing speed. February 19, 2018 07:50AM |

Registered: 8 years ago Posts: 413 |

Can someone with knowledge coment on the speed limit settings in the firmware.

The slicer will generate the gcode with the speeds you specify but the firmware will limit these to the values set in the config file. And i believe some of them use the lowest value set for all of them.

So if you just increase the speeds in slicer these will apear in the Gcode but not be delivered if its limited by the firmware.

I raise this here as it looks like under extrusion at your higher speeds. it may be that your movements in X and Y have increased but the extruder is limited by its firmware settings and can't keep up.

The slicer will generate the gcode with the speeds you specify but the firmware will limit these to the values set in the config file. And i believe some of them use the lowest value set for all of them.

So if you just increase the speeds in slicer these will apear in the Gcode but not be delivered if its limited by the firmware.

I raise this here as it looks like under extrusion at your higher speeds. it may be that your movements in X and Y have increased but the extruder is limited by its firmware settings and can't keep up.

|

Re: I'm not getting good print quality when increasing speed. February 19, 2018 10:36AM |

Registered: 9 years ago Posts: 223 |

Well so far I have not found the correct combination. Placing the object in different parts of the print bed does not seem to matter.

The prints looked virtually identical when I tried that. So I've been varying the values in the Advance section of the settings.

Those having to do with Extrusion width, Perimeters and infill. I did switch from percentages to actual values. Starting with 0.1 up to 0.5

I was trying to make the perimeter walls thicker, which worked but at the same time it seemed that the infill would shrink.

So at this point I think I need to do some more reading and perhaps try to find an examples to try. Unless someone has some examples to try?

The prints looked virtually identical when I tried that. So I've been varying the values in the Advance section of the settings.

Those having to do with Extrusion width, Perimeters and infill. I did switch from percentages to actual values. Starting with 0.1 up to 0.5

I was trying to make the perimeter walls thicker, which worked but at the same time it seemed that the infill would shrink.

So at this point I think I need to do some more reading and perhaps try to find an examples to try. Unless someone has some examples to try?

|

Re: I'm not getting good print quality when increasing speed. February 19, 2018 11:14AM |

Registered: 9 years ago Posts: 175 |

|

Re: I'm not getting good print quality when increasing speed. February 19, 2018 11:50AM |

Registered: 9 years ago Posts: 223 |

|

Re: I'm not getting good print quality when increasing speed. February 19, 2018 01:04PM |

Registered: 9 years ago Posts: 175 |

Well, that's one of the most important test you should perform on a printer before even start to print with it..!

Don't know were to find it in Slic3r, ....can someone help here please..?

Point is that this test will see to it that the width of a perimeter(single strand) is correct(or not).

Draw a cube, print it 'Vase Modus' and measure the thickness of the walls of that single perimeter cube and adjust accordingly with the 'Extrusion multiplier' parameter in your slicer. The thickness of printed walls should be the same as the nozzle's diameter. I always make them a few hunderst thicker. So with a nozzle of 0.4 see to it that the walls are 0.42 to 0.44mm thick.

You should perform this test for all different filaments you're using.

Don't know were to find it in Slic3r, ....can someone help here please..?

Point is that this test will see to it that the width of a perimeter(single strand) is correct(or not).

Draw a cube, print it 'Vase Modus' and measure the thickness of the walls of that single perimeter cube and adjust accordingly with the 'Extrusion multiplier' parameter in your slicer. The thickness of printed walls should be the same as the nozzle's diameter. I always make them a few hunderst thicker. So with a nozzle of 0.4 see to it that the walls are 0.42 to 0.44mm thick.

You should perform this test for all different filaments you're using.

|

Re: I'm not getting good print quality when increasing speed. February 19, 2018 01:08PM |

Registered: 9 years ago Posts: 175 |

|

Re: I'm not getting good print quality when increasing speed. February 19, 2018 09:46PM |

Registered: 9 years ago Posts: 223 |

I found something called "Spiral vase" I suspect it may be what you are talking about.

So I drew a cube and started to print it. Then something strange happened. Both my

hot end and heat bed shut down by about 1/2 thru the first perimeter. So I reset everything

and tried again but the same thing happened. I have not idea why !

So I drew a cube and started to print it. Then something strange happened. Both my

hot end and heat bed shut down by about 1/2 thru the first perimeter. So I reset everything

and tried again but the same thing happened. I have not idea why !

|

Re: I'm not getting good print quality when increasing speed. February 20, 2018 06:29AM |

Registered: 9 years ago Posts: 175 |

That is coincidence, 'Spiral Vase' printing has nothing to do with that shutting down of both the heaters.

You should first find out what causes that shutting down.

These are only a few guesses :

You have reached the max temp according to the settings in the firmware. So the mainboard is powering down the heaters. But both at the same time is not likely to happen.

Or maybe, just maybe, one of the polyfuses (in the powerunit) was activated and shut down the powerunit (and heaters).

The 12V main cable toward the RAMPS is broke/loose.

And one last possible cause is that the 12V input connector for the heater (on the RAMPS board) is broke.( Got to hot). You should look for discoloration(brown-isch) of the RAMPS at that location. It is even possible the plastic connector on the RAMPS is molten(a bit).

(Just found out that Slicer call it 'Spiral Vase' and some others call it 'Vase mode'.)

You should first find out what causes that shutting down.

These are only a few guesses :

You have reached the max temp according to the settings in the firmware. So the mainboard is powering down the heaters. But both at the same time is not likely to happen.

Or maybe, just maybe, one of the polyfuses (in the powerunit) was activated and shut down the powerunit (and heaters).

The 12V main cable toward the RAMPS is broke/loose.

And one last possible cause is that the 12V input connector for the heater (on the RAMPS board) is broke.( Got to hot). You should look for discoloration(brown-isch) of the RAMPS at that location. It is even possible the plastic connector on the RAMPS is molten(a bit).

(Just found out that Slicer call it 'Spiral Vase' and some others call it 'Vase mode'.)

|

Re: I'm not getting good print quality when increasing speed. February 20, 2018 07:38AM |

Registered: 8 years ago Posts: 413 |

Some of the settings seem strange to me.

Default width I would have left on Auto or 20% over nozle size = 0.48.

All the infill has the width set to 90% . Why ? That should under extrude. If it looks Ok that may indicate your extruder calibration is wrong.

Note that if there is an issue with the extruder not being able to keep up then the calibration will be afected by the speed. So check the calibration at different speeds. The root cause is still why can't the extruder keep up. That may be an issue with the hot end restricting the flow so check temperatures, maybe run a bit hoter.

The top layer quality seems to vary. That makes me think its temperature cycling afecting the flow rate.

I run my infill faster than perimeters as i am more concerned about perimeter quality than the infill. That also saves a lot of time.

Default width I would have left on Auto or 20% over nozle size = 0.48.

All the infill has the width set to 90% . Why ? That should under extrude. If it looks Ok that may indicate your extruder calibration is wrong.

Note that if there is an issue with the extruder not being able to keep up then the calibration will be afected by the speed. So check the calibration at different speeds. The root cause is still why can't the extruder keep up. That may be an issue with the hot end restricting the flow so check temperatures, maybe run a bit hoter.

The top layer quality seems to vary. That makes me think its temperature cycling afecting the flow rate.

I run my infill faster than perimeters as i am more concerned about perimeter quality than the infill. That also saves a lot of time.

|

Re: I'm not getting good print quality when increasing speed. February 20, 2018 10:05AM |

Registered: 9 years ago Posts: 223 |

chriske

The simple answer is no to all the above. The only thing the main controller board does is to heat up the hot end, provide connections for fan 1 & 2 and sensors. The small stuff. All other heavy current functions are handled by an external fused relay pcb that I built. The mosfet (60A) that handles the heated bed also has it's own pcb. So the heaviest load the controller board handles it the hot end. All this was done from the beginning because I knew that the rumba / ramps board would not handle the 18A that the heated bed pulls. So only signal level voltages / amperage is needed. Additionally this is the only time this has ever happened in the last year or so. So I suspect that there may be a setting in the firmware that I did not know about when using the Spiral Vase command (well could be anyway).

MCcarman

I'm not surprised that some of the settings seem strange. For the last year or so I have only been printing small parts and did not care about how long it took. So printing at a speed of 10 or 20 was not a big deal. Now I would like to print a part that at the speed of 10 is estimated to take 38+ hours. So I decided see if I could speed things up. So all these settings are just a starting point. With no particular reasons for any of them. I would be happy to try any suggestions you may have. In fact if you would provide a screen shot I would duplicate the just to see what happens. I will check on the calibration at speed as you suggest. Recently I raised the temperature from 200 to 210. The filament is PLA. With no difference being noted so I suspect that 200 was probably ok. Temperature cycling may be a factor as the hotend varies about 2° +/- and the bed a bit more. Just for the record I'm using Repetier-Host V2.0.5 with Slic3r as the slicer.

Thanks all for the help and commits.

The simple answer is no to all the above. The only thing the main controller board does is to heat up the hot end, provide connections for fan 1 & 2 and sensors. The small stuff. All other heavy current functions are handled by an external fused relay pcb that I built. The mosfet (60A) that handles the heated bed also has it's own pcb. So the heaviest load the controller board handles it the hot end. All this was done from the beginning because I knew that the rumba / ramps board would not handle the 18A that the heated bed pulls. So only signal level voltages / amperage is needed. Additionally this is the only time this has ever happened in the last year or so. So I suspect that there may be a setting in the firmware that I did not know about when using the Spiral Vase command (well could be anyway).

MCcarman

I'm not surprised that some of the settings seem strange. For the last year or so I have only been printing small parts and did not care about how long it took. So printing at a speed of 10 or 20 was not a big deal. Now I would like to print a part that at the speed of 10 is estimated to take 38+ hours. So I decided see if I could speed things up. So all these settings are just a starting point. With no particular reasons for any of them. I would be happy to try any suggestions you may have. In fact if you would provide a screen shot I would duplicate the just to see what happens. I will check on the calibration at speed as you suggest. Recently I raised the temperature from 200 to 210. The filament is PLA. With no difference being noted so I suspect that 200 was probably ok. Temperature cycling may be a factor as the hotend varies about 2° +/- and the bed a bit more. Just for the record I'm using Repetier-Host V2.0.5 with Slic3r as the slicer.

Thanks all for the help and commits.

|

Re: I'm not getting good print quality when increasing speed. February 20, 2018 11:31AM |

Registered: 9 years ago Posts: 175 |

Best is someone could export and send you a slicer file.

I would, but I do not use Slic3r.

Import and adjust for your printer. It would start you up very quickly.

See what happens.

Depending on the printer you're using you should be able to print at 75 to 90mm/s(PLA) Don't know yet with PETG, busy testing. This very moment busy @ 60mm/s. Looking good.

I would, but I do not use Slic3r.

Import and adjust for your printer. It would start you up very quickly.

See what happens.

Depending on the printer you're using you should be able to print at 75 to 90mm/s(PLA) Don't know yet with PETG, busy testing. This very moment busy @ 60mm/s. Looking good.

|

Re: I'm not getting good print quality when increasing speed. February 20, 2018 11:49AM |

Registered: 9 years ago Posts: 223 |

From what I've read PETG seems to need to be a little slower than PLA, but of course you get a better part (depending on your view point).

The printer is a core XY, modeled after one call HyperCibe. Modeled because I built it bigger.

What software / slicer are you using? Maybe it's time to change.

The printer is a core XY, modeled after one call HyperCibe. Modeled because I built it bigger.

What software / slicer are you using? Maybe it's time to change.

|

Re: I'm not getting good print quality when increasing speed. February 20, 2018 12:54PM |

Registered: 9 years ago Posts: 175 |

|

Re: I'm not getting good print quality when increasing speed. February 20, 2018 01:02PM |

Registered: 9 years ago Posts: 175 |

|

Re: I'm not getting good print quality when increasing speed. February 21, 2018 07:41AM |

Registered: 8 years ago Posts: 413 |

If you tried with higher temperature and your variation is only +/- 2degrees then its not temperature related (assuming the thermistor reads correctly).

Its a fairly long bowden tube. Have a good look at how that works - no sharp edges or bad alignment of fittings.

If you do a print are the X and Y dimensions the same. If you print a square is it square. If you print a 45deg traingle is it 45 degrees.

Ive forgoten the permutations for core X-Y but if the motors don't sync you can get misalignment issues. Could be that under high load (read high speed) one motor/driver is strugling. I supose they are both set to the same steps and jumper settings on the RAMPS.

Its a fairly long bowden tube. Have a good look at how that works - no sharp edges or bad alignment of fittings.

If you do a print are the X and Y dimensions the same. If you print a square is it square. If you print a 45deg traingle is it 45 degrees.

Ive forgoten the permutations for core X-Y but if the motors don't sync you can get misalignment issues. Could be that under high load (read high speed) one motor/driver is strugling. I supose they are both set to the same steps and jumper settings on the RAMPS.

|

Re: I'm not getting good print quality when increasing speed. February 22, 2018 09:44AM |

Registered: 6 years ago Posts: 109 |

My two cents.

E3Dv6 or clone, all metal? Reduce the retraction to 1.5-2mm NOT 5mm. E3dv6 clone I have is terrible at the repriming, and I have a pretty short bowden setup. At 4mm mine would jam up halfway thru a complex part and then I get a 10% filled part.

Get a simple retraction test from thingiverse and run it.

200C seems too cool to me, try 210 then 220 to see. I run PLA at 215, but this varies of course by manufacturer. I use 3DSolutech and Hatchbox.

Again on a all metal E3D clone, more heat can work against you, causing ever faster jams, as the upper ares warms faster.

So far my one clone is all I have, but I will soon have another slightly different one up and running(it seems to have an even shorter heatbrake.

3 perimeters should be plenty.

Finally get a copy of the old Cura 14, its lightening fast and great for tests like this, less worrying about how goofy the slicer is.

E3Dv6 or clone, all metal? Reduce the retraction to 1.5-2mm NOT 5mm. E3dv6 clone I have is terrible at the repriming, and I have a pretty short bowden setup. At 4mm mine would jam up halfway thru a complex part and then I get a 10% filled part.

Get a simple retraction test from thingiverse and run it.

200C seems too cool to me, try 210 then 220 to see. I run PLA at 215, but this varies of course by manufacturer. I use 3DSolutech and Hatchbox.

Again on a all metal E3D clone, more heat can work against you, causing ever faster jams, as the upper ares warms faster.

So far my one clone is all I have, but I will soon have another slightly different one up and running(it seems to have an even shorter heatbrake.

3 perimeters should be plenty.

Finally get a copy of the old Cura 14, its lightening fast and great for tests like this, less worrying about how goofy the slicer is.

Sorry, only registered users may post in this forum.