PETG UGH!!

Posted by RC-CnC

|

PETG UGH!! April 07, 2018 03:27PM |

Registered: 10 years ago Posts: 87 |

Been trying to print PETG for past couple days. What a PITA. Took hrs of trail n error just to get it to stick to BuildTak surface

Tried various temps from 235-255 bed temps from 40-80. Using a modified PLA profile in Simplify3D, 255/80 slowed down 1st layer speed to 30% .2 height. Bed leveled with .1mm distance. Adhesion worked the first print but the bottom side is horrible. Been watching videos and reviews on how this is supposed to print easily like PLA BS!!, unless I'm doing something completely wrong.

I had excellent result with ABS, but cant get tall prints to layer bond well.

I'm ready to send all 6 rolls back!!

Edited 1 time(s). Last edit at 04/07/2018 03:28PM by RC-CnC.

Tried various temps from 235-255 bed temps from 40-80. Using a modified PLA profile in Simplify3D, 255/80 slowed down 1st layer speed to 30% .2 height. Bed leveled with .1mm distance. Adhesion worked the first print but the bottom side is horrible. Been watching videos and reviews on how this is supposed to print easily like PLA BS!!, unless I'm doing something completely wrong.

I had excellent result with ABS, but cant get tall prints to layer bond well.

I'm ready to send all 6 rolls back!!

Edited 1 time(s). Last edit at 04/07/2018 03:28PM by RC-CnC.

|

Re: PETG UGH!! April 09, 2018 12:48PM |

Registered: 6 years ago Posts: 262 |

plz attach a pic of your first layer issues. bottom side pic

PETG is (once you get the hang of it) as easy as PLA.

That said its a PITA to get the hang of.... I can print PETG awesome on my old printer, I am still struggling with my new one....

The first layer is crucial, too much squish with too much heat and you need a chisel to get it off.

To much nozzle distance and you have an ugly surface.

I don't know S3D, I tried it and moved on, I use Cura 3.x so any advice I have on settings you have to translate to S3D on your own.

First thing I have to say is you don't want hardly any squish, essentially none.

Hot tip is better for first layer, warm bed, NOT HOT. like 50-60c if your too hot your going to bond y our PETG to the surface and pull parts of of the surface off with the print.

Alot of peeps that print PLA or ABS use squish to fill in the gaps in their first layer, it makes a nice first layer that way. You cant do that with PETG.

You have to increase your line width in another way, Cura has a setting called 'initial layer line width' that can be used to extrude more for the first layer.

So in short what I do is calibrate my printer so Z=0 is touching the build plate then set my first layer to .3 and extrude at 240c with my plate at 50c these are all ISH on temp as your system and filament may vary of course.

Then I do a test first layer to see if I have it sticking well but not too well. I increase my bed by 5c per test until I get my stick right.

Then I boost up my first layer line width percentage until all the gaps close and I have my first layer right.

After this I recommend you reduce the bed temp a little just in case.

It will be worth it I assure you.

Btw, I have never used builtak I use PEI so I have nothing to say on that combo....

oh I print the rest of the layers a 220c fan 70%

Edited 1 time(s). Last edit at 04/09/2018 12:49PM by JustSumGuy.

PETG is (once you get the hang of it) as easy as PLA.

That said its a PITA to get the hang of.... I can print PETG awesome on my old printer, I am still struggling with my new one....

The first layer is crucial, too much squish with too much heat and you need a chisel to get it off.

To much nozzle distance and you have an ugly surface.

I don't know S3D, I tried it and moved on, I use Cura 3.x so any advice I have on settings you have to translate to S3D on your own.

First thing I have to say is you don't want hardly any squish, essentially none.

Hot tip is better for first layer, warm bed, NOT HOT. like 50-60c if your too hot your going to bond y our PETG to the surface and pull parts of of the surface off with the print.

Alot of peeps that print PLA or ABS use squish to fill in the gaps in their first layer, it makes a nice first layer that way. You cant do that with PETG.

You have to increase your line width in another way, Cura has a setting called 'initial layer line width' that can be used to extrude more for the first layer.

So in short what I do is calibrate my printer so Z=0 is touching the build plate then set my first layer to .3 and extrude at 240c with my plate at 50c these are all ISH on temp as your system and filament may vary of course.

Then I do a test first layer to see if I have it sticking well but not too well. I increase my bed by 5c per test until I get my stick right.

Then I boost up my first layer line width percentage until all the gaps close and I have my first layer right.

After this I recommend you reduce the bed temp a little just in case.

It will be worth it I assure you.

Btw, I have never used builtak I use PEI so I have nothing to say on that combo....

oh I print the rest of the layers a 220c fan 70%

Edited 1 time(s). Last edit at 04/09/2018 12:49PM by JustSumGuy.

|

Re: PETG UGH!! April 09, 2018 09:21PM |

Registered: 10 years ago Posts: 87 |

|

Re: PETG UGH!! April 10, 2018 11:20AM |

Registered: 6 years ago Posts: 262 |

|

Re: PETG UGH!! April 10, 2018 09:06PM |

Registered: 10 years ago Posts: 87 |

|

Re: PETG UGH!! April 11, 2018 11:29AM |

Registered: 6 years ago Posts: 262 |

I did a lot of ABS last summer but when the summer heat and dry was gone I could not print ABS if my life depended on it....

I had a cardboard box for my printer and I bought a heater setup for it too, never got the heater installed as I tried PETG first...

I have been doing PETG since mid Sept and while I have several spools of ABS still fresh in packages, I am not likely to go back....

I had a cardboard box for my printer and I bought a heater setup for it too, never got the heater installed as I tried PETG first...

I have been doing PETG since mid Sept and while I have several spools of ABS still fresh in packages, I am not likely to go back....

|

Re: PETG UGH!! April 14, 2018 02:42PM |

Registered: 10 years ago Posts: 87 |

Have some time to mess with PETG today

Based on your settings you posted I got the first layer to sick fairly decent, but it didn't adhere really well.

I adjust z axis to .05 and my first layer height to .25 100% height 106% line width dropped the speed way down to 14%

Still wasn't sticking at this point so I slowly tightened up the height with the bed screws until it did. Curious why the infill looks like this and why the extruder is skipping only on the infill

Based on your settings you posted I got the first layer to sick fairly decent, but it didn't adhere really well.

I adjust z axis to .05 and my first layer height to .25 100% height 106% line width dropped the speed way down to 14%

Still wasn't sticking at this point so I slowly tightened up the height with the bed screws until it did. Curious why the infill looks like this and why the extruder is skipping only on the infill

|

Re: PETG UGH!! April 14, 2018 06:35PM |

Registered: 10 years ago Posts: 87 |

|

Re: PETG UGH!! April 16, 2018 05:11PM |

Registered: 6 years ago Posts: 262 |

PETG likes to string, I suggest 3.5mm retractions at around 45mms speed.

then do fast non print moves.

I print PETG slow around 45mms and my non print moves are 150mms on my duet based hyper cube and 100mms on my marlin based baby cube.

If your I3 type design you are likely to have issues moving your Y axis that fast if your jerk settings are not dialed in well tho.

Essentially as fast as you can without failures to minimize the non print time helps the stringing alot.

of course, print as cold as you can, I bet you have done the temp tower to get that dialed in

then do fast non print moves.

I print PETG slow around 45mms and my non print moves are 150mms on my duet based hyper cube and 100mms on my marlin based baby cube.

If your I3 type design you are likely to have issues moving your Y axis that fast if your jerk settings are not dialed in well tho.

Essentially as fast as you can without failures to minimize the non print time helps the stringing alot.

of course, print as cold as you can, I bet you have done the temp tower to get that dialed in

|

Re: PETG UGH!! April 16, 2018 08:23PM |

Registered: 10 years ago Posts: 87 |

Here is what I came up with. 238/75

Printed quite a few parts today. Only real big issue is getting it to stick without it balling up first, been just pulling the blob away with my ruler

String hasn't been a big issue, there are some, but with time I think it'll get dialed in better.

Printed quite a few parts today. Only real big issue is getting it to stick without it balling up first, been just pulling the blob away with my ruler

String hasn't been a big issue, there are some, but with time I think it'll get dialed in better.

|

Re: PETG UGH!! April 17, 2018 12:07AM |

Registered: 10 years ago Posts: 87 |

Hmm still having poor layer adhesion imo

PSU Cover 2mm sides 70mm tall. Just by chance I squeezed it picking it up with the weight of the mount PSU and it cracked.

Ugh!

I'd really like to make this out of ABS. Tried several times layers always separate even with a blanket over the printer. But I think it's just way to tall???

Might have to build a heated chamber??

Edited 1 time(s). Last edit at 04/17/2018 12:24AM by RC-CnC.

PSU Cover 2mm sides 70mm tall. Just by chance I squeezed it picking it up with the weight of the mount PSU and it cracked.

Ugh!

I'd really like to make this out of ABS. Tried several times layers always separate even with a blanket over the printer. But I think it's just way to tall???

Might have to build a heated chamber??

Edited 1 time(s). Last edit at 04/17/2018 12:24AM by RC-CnC.

|

Re: PETG UGH!! April 17, 2018 12:22PM |

Registered: 6 years ago Posts: 262 |

PETG is quite brittle so thin parts don't work well, If you can redesign maybe make the walls a little thicker. It can make for a very strong part but when it comes to something with a little give ABS is much better for thin stuff. Really need a heated chamber to do ABS right tho....

Layer adhesion is not likely the issue, that's where PETG shines. Maybe slow your extrusion fan a bit, I run mine around 70% but 50% might be in order and go way slower for thin parts. like 30mms

what is your print speed?

edit: I saw now your walls are 2mm thick, how many perimeter walls are you doing? 2? try 3...

Edited 2 time(s). Last edit at 04/17/2018 12:23PM by JustSumGuy.

Layer adhesion is not likely the issue, that's where PETG shines. Maybe slow your extrusion fan a bit, I run mine around 70% but 50% might be in order and go way slower for thin parts. like 30mms

what is your print speed?

edit: I saw now your walls are 2mm thick, how many perimeter walls are you doing? 2? try 3...

Edited 2 time(s). Last edit at 04/17/2018 12:23PM by JustSumGuy.

|

Re: PETG UGH!! April 17, 2018 07:59PM |

Registered: 10 years ago Posts: 87 |

|

Re: PETG UGH!! April 29, 2018 08:09PM |

Registered: 8 years ago Posts: 318 |

|

Re: PETG UGH!! April 29, 2018 09:29PM |

Registered: 11 years ago Posts: 5,780 |

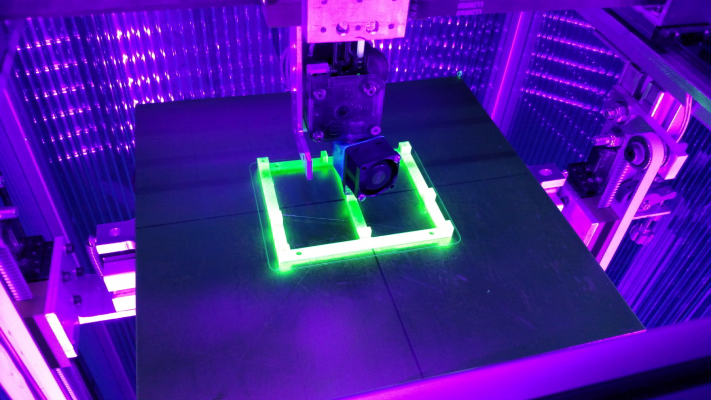

FWIW, I am running my first ever PETG print right now. I got the filament via Amazon: [smile.amazon.com]

I measured in 30 places and it averaged 1.74 mm diameter. The worst measurement was 1.72 mm.

I am printing at 240C/90C and it appears to be sticking to the clean PEI bed just fine, and I see only 1 string among the 10 posts in the print (a bracket to mount a Duet controller board). No print cooling fan... I'm printing at 60 mm/sec with Titan and V6 with volcano heater block..

Oh yeah, it glows nicely under UV lighting.

We'll see what the surface finish looks like when it's done.

... and it's done! While it was printing I noticed a few more very tiny hairs, so I dropped the extruder to 235C and it stopped stringing completely. The surface is shiny and smooth, good interlayer bonding, no lifting of the sharp corners, and it let go of the bed pretty easily once the bed cooled. Very nice!

Edited 2 time(s). Last edit at 04/30/2018 12:25AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I measured in 30 places and it averaged 1.74 mm diameter. The worst measurement was 1.72 mm.

I am printing at 240C/90C and it appears to be sticking to the clean PEI bed just fine, and I see only 1 string among the 10 posts in the print (a bracket to mount a Duet controller board). No print cooling fan... I'm printing at 60 mm/sec with Titan and V6 with volcano heater block..

Oh yeah, it glows nicely under UV lighting.

We'll see what the surface finish looks like when it's done.

... and it's done! While it was printing I noticed a few more very tiny hairs, so I dropped the extruder to 235C and it stopped stringing completely. The surface is shiny and smooth, good interlayer bonding, no lifting of the sharp corners, and it let go of the bed pretty easily once the bed cooled. Very nice!

Edited 2 time(s). Last edit at 04/30/2018 12:25AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: PETG UGH!! June 08, 2018 12:42AM |

Registered: 9 years ago Posts: 383 |

I've recently found out that non-linear extrusion correction appears critical for PETG. I'm running Titan, V6, 0.4 nozzle, and 220C. Without it I was stuct to about 40mm/sec print. With it I did a range of prints from 80-180. These were simple test geometries. Solid parts measuring 35 * 35 * 4mm. I think thermal stress issues maybe exagetrated if you are close to drawing the polymer from the nozzle. With the correction in place it ket my tracks at 0.55mm wide and so no drawing. I posted yesterday's work in the duet forum.

Sorry, only registered users may post in this forum.