Can't get proper dimensional accuracy.

Posted by Alex_1234

|

Can't get proper dimensional accuracy. April 20, 2018 10:51PM |

Registered: 6 years ago Posts: 27 |

I have had a Anycubic Kossel delta printer for about 6 months now and have recently been printing parts that need accurate parts. The first thing I noticed the problem with was a NEMA 23 that I modeled with ~1mm larger clearances that was printer at 105% scale and still was too small for the motor to fit. I tried different extrusion multipliers, nozzle sizes, line widths, and delta rod length but parts still come out 0.5mm too big on the outside and 0.5mm to small in holes. I have tried everything I can think of and looked online but nothing has worked.

If anyone has any advice in would be greatly appreciated.

If anyone has any advice in would be greatly appreciated.

|

Re: Can't get proper dimensional accuracy. April 20, 2018 11:33PM |

Admin Registered: 13 years ago Posts: 7,001 |

3d printers cannot print accurate holes... You have to over size them in the CAD.

See [gilesbathgate.com] as to why and the math needed to correct for it.

See [gilesbathgate.com] as to why and the math needed to correct for it.

|

Re: Can't get proper dimensional accuracy. April 21, 2018 12:25AM |

Registered: 6 years ago Posts: 27 |

Quote

Dust

3d printers cannot print accurate holes... You have to over size them in the CAD.

See [gilesbathgate.com] as to why and the math needed to correct for it.

I understand that, but it's not just holes that are too small, on the bracket I included a picture for the distance between holes in also too short.

|

Re: Can't get proper dimensional accuracy. April 21, 2018 01:38AM |

Admin Registered: 13 years ago Posts: 7,001 |

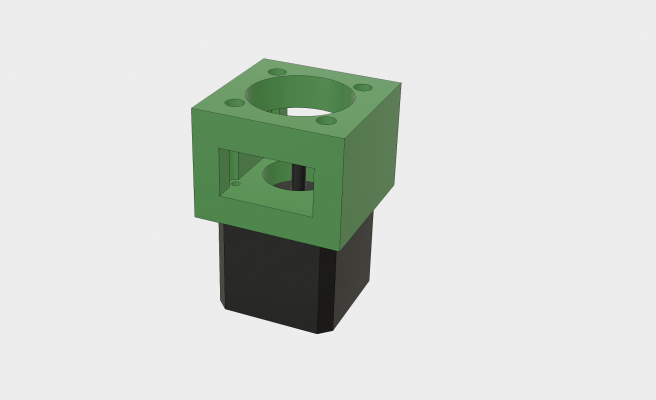

Your picture is of a stepper motor and the plastics is barely part of the picture!!

You haven't included your models.. so we have no idea is its design error or what

Even just the stl would help...

But basically your saying that machine is not calibrated.

So what firmware is it running, did they provide source so it can be edited?

You haven't included your models.. so we have no idea is its design error or what

Even just the stl would help...

But basically your saying that machine is not calibrated.

So what firmware is it running, did they provide source so it can be edited?

|

Re: Can't get proper dimensional accuracy. April 21, 2018 08:36AM |

Registered: 11 years ago Posts: 5,780 |

I don't know how to fix the problem with your printer, but I can tell you that that motor mount is going to be completely unsatisfactory if the motor is moving any kind of load. That type of design is the first thing that comes to mind because you see them made of steel. The problem is we're not using steel. Plastic is flexible. Another thing to consider: that's a large motor and will probably operate with a lot of current and generate a lot of heat. The motor mount will soften. The combo of heat and load will distort it beyond recognition.

If I were trying to mount a motor like that using a printed plastic mount, I'd design it like a block that covers the shaft, then remove just enough material for the shaft and pulley or coupler or whatever is going to attach to the shaft, and then add some screw holes to mount it. Sort of like this NEMA-17 example:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If I were trying to mount a motor like that using a printed plastic mount, I'd design it like a block that covers the shaft, then remove just enough material for the shaft and pulley or coupler or whatever is going to attach to the shaft, and then add some screw holes to mount it. Sort of like this NEMA-17 example:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Can't get proper dimensional accuracy. April 21, 2018 01:19PM |

Registered: 6 years ago Posts: 27 |

Quote

Dust

Your picture is of a stepper motor and the plastics is barely part of the picture!!

You haven't included your models.. so we have no idea is its design error or what

Even just the stl would help...

But basically your saying that machine is not calibrated.

So what firmware is it running, did they provide source so it can be edited?

I am running the version of marlin that the printer came with and I have the source.

|

Re: Can't get proper dimensional accuracy. April 21, 2018 01:39PM |

Registered: 6 years ago Posts: 27 |

Quote

the_digital_dentist

I don't know how to fix the problem with your printer, but I can tell you that that motor mount is going to be completely unsatisfactory if the motor is moving any kind of load. That type of design is the first thing that comes to mind because you see them made of steel. The problem is we're not using steel. Plastic is flexible. Another thing to consider: that's a large motor and will probably operate with a lot of current and generate a lot of heat. The motor mount will soften. The combo of heat and load will distort it beyond recognition.

If I were trying to mount a motor like that using a printed plastic mount, I'd design it like a block that covers the shaft, then remove just enough material for the shaft and pulley or coupler or whatever is going to attach to the shaft, and then add some screw holes to mount it. Sort of like this NEMA-17 example:

[attachment 104483 motormountdesignideav2.png]

I've seen motors mounted on printed parts like this before, so I assumed it was adequate. I'll redesign them more like your example.

|

Re: Can't get proper dimensional accuracy. April 21, 2018 06:54PM |

Registered: 6 years ago Posts: 54 |

I think you should check your printer's calibration the "dirty way"

Deltas' x0,y0 is in the center, right? Ok, lets go.

1. Pull up a terminal

2. g0 x-50 y0 z5

3. Mark the nozzle spot with a pencil on the table

4. g0 x50

5. Measure the distance between the dot and the current nozzle position

6. If it's not 100mm then you have a calibration problem

7. You can do the same for Y

a. g0 x0 y-50 z5

b. Mark the spot

c. g0 y50

d. Measure the distance

8. With Z it is simpler

9. g0 x0 y0 z100

10. Measure distance from table to nozzle

11. Correct me if I am wrong

PS. dat corner warping is something you should troubleshoot also, maybe print with 5mm brim?

Proud owner and maker of build from scratch FDM 3D printer [forums.reprap.org]

Deltas' x0,y0 is in the center, right? Ok, lets go.

1. Pull up a terminal

2. g0 x-50 y0 z5

3. Mark the nozzle spot with a pencil on the table

4. g0 x50

5. Measure the distance between the dot and the current nozzle position

6. If it's not 100mm then you have a calibration problem

7. You can do the same for Y

a. g0 x0 y-50 z5

b. Mark the spot

c. g0 y50

d. Measure the distance

8. With Z it is simpler

9. g0 x0 y0 z100

10. Measure distance from table to nozzle

11. Correct me if I am wrong

PS. dat corner warping is something you should troubleshoot also, maybe print with 5mm brim?

Proud owner and maker of build from scratch FDM 3D printer [forums.reprap.org]

|

Re: Can't get proper dimensional accuracy. April 22, 2018 04:34AM |

Registered: 12 years ago Posts: 799 |

Quote

Alex_1234

I have had a Anycubic Kossel delta printer for about 6 months now and have recently been printing parts that need accurate parts. The first thing I noticed the problem with was a NEMA 23 that I modeled with ~1mm larger clearances that was printer at 105% scale and still was too small for the motor to fit. I tried different extrusion multipliers, nozzle sizes, line widths, and delta rod length but parts still come out 0.5mm too big on the outside and 0.5mm to small in holes. I have tried everything I can think of and looked online but nothing has worked.

If anyone has any advice in would be greatly appreciated.

Yeah, you never get 100% accurate parts with 3D printer,s but 1mm is too much.

Outer dimensions with unter 0,1mm fit and wholes with 0,1-0,2mm should be easy reachable, even mor with more effort / knowledge.

The general too small parts sound like wrong calibration, try what Rossos wrote,

The second problem basicly sounds like you print Inside perimeter first

Mechanical Parts should always be printed "outside perimeters" first.

can please you upload your gcode file for check.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: Can't get proper dimensional accuracy. April 22, 2018 10:08AM |

Registered: 6 years ago Posts: 6 |

3D printers may not always be 100% accurate, but if you have a dimensional accuracy problem, here is how to solve it.

1: print a calibration cube to see the exact widths/lengths of the object compared to the CAD model. Start with your Z axis. If it isn’t exactly the same measurement, then you need to adjust your steps/mm in the firmware or lcd.

2. Check your x/y measurements. These, if they are off, can be fixed with DELTA_DIAGONAL_ROD in the marlin firmware. Inncrease this value to make your x/y axis smaller, and decrease this to make them bigger. Print several test cubes of different values and try to determine the right one.

If your firmware values do not transfer over to the printer (if you flash the firmware but the prints are still the same) open up a command prompt (like repeiter or pronterface) and send M500 followed by M502 to save the hard coded firmware to your eeprom.

1: print a calibration cube to see the exact widths/lengths of the object compared to the CAD model. Start with your Z axis. If it isn’t exactly the same measurement, then you need to adjust your steps/mm in the firmware or lcd.

2. Check your x/y measurements. These, if they are off, can be fixed with DELTA_DIAGONAL_ROD in the marlin firmware. Inncrease this value to make your x/y axis smaller, and decrease this to make them bigger. Print several test cubes of different values and try to determine the right one.

If your firmware values do not transfer over to the printer (if you flash the firmware but the prints are still the same) open up a command prompt (like repeiter or pronterface) and send M500 followed by M502 to save the hard coded firmware to your eeprom.

|

Re: Can't get proper dimensional accuracy. March 29, 2019 11:46AM |

Registered: 5 years ago Posts: 3 |

I realize this post has a bit of age to it, but I am experiencing the same issue.. The Z-height is spot on but X and Y are a little larger than they should be, dimension wise.. The post above said to adjust the DELTA_DIAGONAL_ROD in the firmware.. I have an Anycubic Kossel with Marlin firmware 1.1.0... Where do I find these settings?

I am a beginner when it comes to 3D printers but I am willing to learn..

Thank you

Edited 1 time(s). Last edit at 03/29/2019 11:48AM by Mikejn1.

I am a beginner when it comes to 3D printers but I am willing to learn..

Thank you

Edited 1 time(s). Last edit at 03/29/2019 11:48AM by Mikejn1.

|

Re: Can't get proper dimensional accuracy. April 01, 2019 04:46PM |

Registered: 7 years ago Posts: 619 |

Quote

Mikejn1

I realize this post has a bit of age to it, but I am experiencing the same issue.. The Z-height is spot on but X and Y are a little larger than they should be, dimension wise.. The post above said to adjust the DELTA_DIAGONAL_ROD in the firmware.. I have an Anycubic Kossel with Marlin firmware 1.1.0... Where do I find these settings?

I am a beginner when it comes to 3D printers but I am willing to learn..

Thank you

You will find it in configuration.h.

DLC

Sorry, only registered users may post in this forum.