Wild randomness on a generally good print

Posted by leadinglights

|

Wild randomness on a generally good print June 22, 2018 05:36AM |

Registered: 12 years ago Posts: 1,450 |

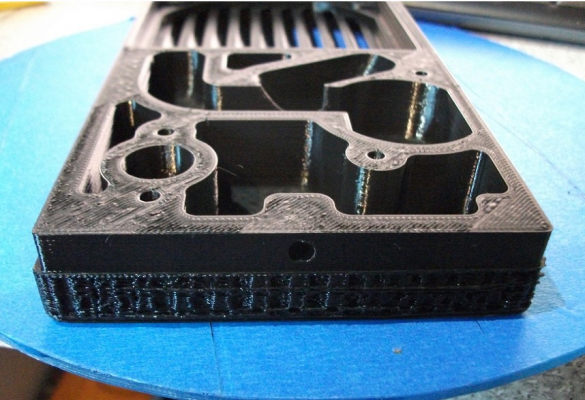

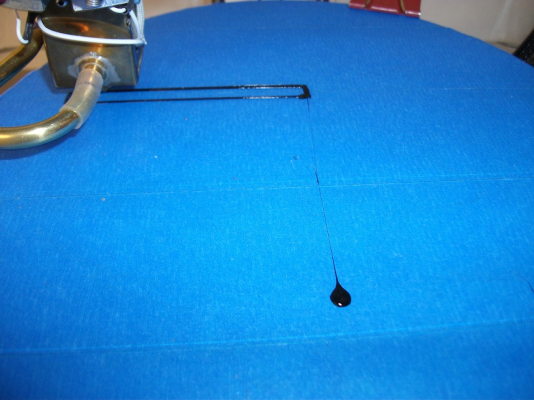

I have had a problem that I haven't seen before on a printer that is normally trouble free. I have attached some photos below showing the effect in the hope that somebody recognises this. The problem did not exist on the first 10 or so layers and disappeared completely when the length of the print reduced from 183mm to 180mm for the last 40 layers.

Printer is a Delta to the Rostock pattern with control by an Arduino/Ramps running Repetier firmware.

Filament is Polymaker true black PLA 1.7mm

Sliced with Slic3r 1.2.9 under Repetier Host V2.0.1

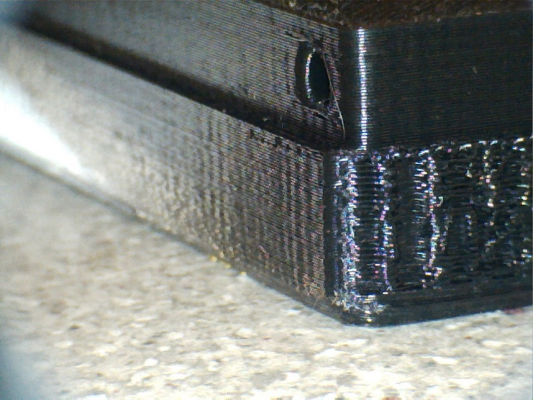

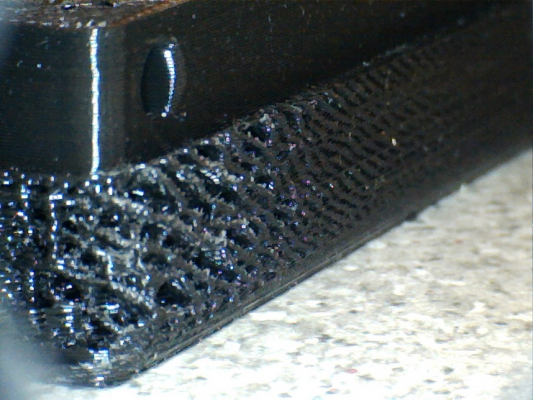

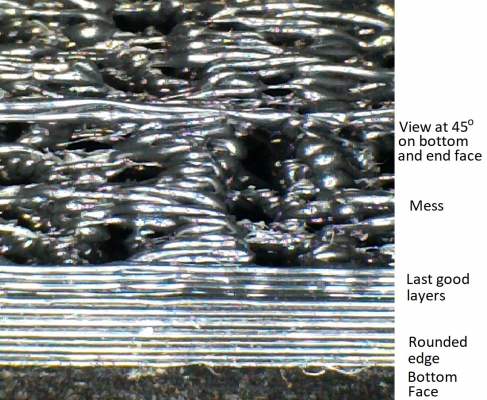

The printer produces reliable and accurate prints of a good to excellent surface finish. Post mortem checks on this prints showed only that there was an under-extrusion of 3% to 4% - not normally enough to give any problem. Photos show one end with a very random mess and the other end with a repetitive wave repeating every 6.8mm. On entry to the ends the print is clean and on exit returns to a smooth print after about 25mm of decreasing random rubbish. There is very little ghosting on the holes visible in the photos.

Thanks for any enlightenment,

Mike

Printer is a Delta to the Rostock pattern with control by an Arduino/Ramps running Repetier firmware.

Filament is Polymaker true black PLA 1.7mm

Sliced with Slic3r 1.2.9 under Repetier Host V2.0.1

The printer produces reliable and accurate prints of a good to excellent surface finish. Post mortem checks on this prints showed only that there was an under-extrusion of 3% to 4% - not normally enough to give any problem. Photos show one end with a very random mess and the other end with a repetitive wave repeating every 6.8mm. On entry to the ends the print is clean and on exit returns to a smooth print after about 25mm of decreasing random rubbish. There is very little ghosting on the holes visible in the photos.

Thanks for any enlightenment,

Mike

|

Re: Wild randomness on a generally good print June 22, 2018 10:13AM |

Registered: 12 years ago Posts: 1,450 |

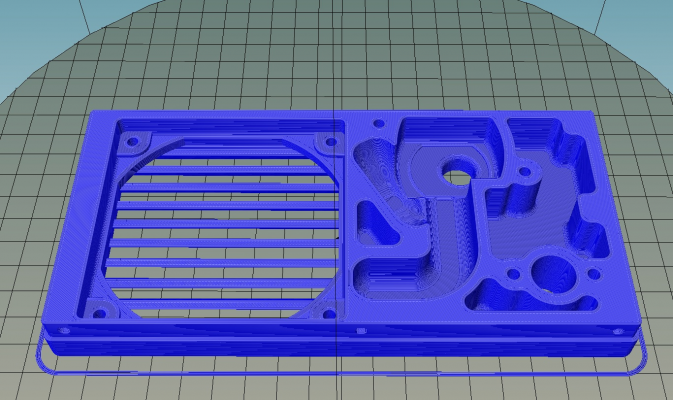

O.K., now it starts getting really weird. A new STL file run through Netfabb basic to clean it up and sliced as before. The preview distinctly shows a three loop skirt as shown in screen-dump below, but the print ignores the skirt and purges out some filament before going straight on to the body print.

The filament purge is obviously intentional - possibly a false "Resume Print"????

I have checked that the skirt size does not exceed any limits in either the firmware or the host software and that I haven't accidentally switced on something like vase mode but all looks good.

Any thoughts?

Mike

The filament purge is obviously intentional - possibly a false "Resume Print"????

I have checked that the skirt size does not exceed any limits in either the firmware or the host software and that I haven't accidentally switced on something like vase mode but all looks good.

Any thoughts?

Mike

|

Re: Wild randomness on a generally good print June 22, 2018 12:17PM |

Registered: 12 years ago Posts: 1,450 |

On very careful observation and looking at the extruder stepper during a print, the areas where the print is all messed up coincide with no extruder movement - a mark on the end of the shaft can clearly be seen turning but stops completely when it is printing with X >90mm or X< -90mm. I still haven't seen anything in the host or EEPROM settings but will now look at the Arduino config files to see if it is there.

Mike

Mike

|

Re: Wild randomness on a generally good print June 22, 2018 10:55PM |

Registered: 11 years ago Posts: 5,780 |

You might want to check the cable leading to the extruder motor. I once had extruder motor wires fail because I was using a too-small bending radius with a drag chain. The wires can break inside their insulation due to excessive flexing, so they look fine, and they will connect and work for a while and quit at seemingly odd times, usually related to the extruder coordinates. An intermittent cable can kill a motor driver chip, so even after replacing the cable you may still have some problems driving the motor.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Wild randomness on a generally good print June 23, 2018 02:52AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Wild randomness on a generally good print June 23, 2018 06:02AM |

Registered: 12 years ago Posts: 1,450 |

@the_digital_dentist,

As it is a delta printer the extruder is stationary but I have just checked for connection problems and all is well

@o_lampe,

both feeding with the Repetier host manual controls and manually pushing filament through the extruder there is no discernible change in resistance.

The biggest clue is the failure of the printer to even try to print the skirt (which is clearly visible in both the print preview and in the gcode) The nozzle purge blob has to be a deliberate function replacement to get the nozzle primed.

Subsequent to the initial failure I replaced the nozzle and cleaned the plastic path and started a second print: This is where I noticed that the extruder motor stopped turning when doing the end parts.

A third try with the total length shortened by 4mm printed without problem.

Examining the configurable part of the EEPROM the only parts which seem to be of interest are:-

X min pos: 0

Y min pos: 0

X max length 200

Y max length 200

max printable radius 200

Looking at the Repetier firmware configuration.h there again is the same sort of thing:

#define X_MAX_LENGTH 200

#define Y_MAX_LENGTH 200

#define Z_MAX_LENGTH 300

#define X_MIN_POS 0

#define Y_MIN_POS 0

#define Z_MIN_POS 0

There seems to be nothing in the extruder section to tell it not to extrude beyond any limit and I have run out of other areas to look for the cause.

Mike

As it is a delta printer the extruder is stationary but I have just checked for connection problems and all is well

@o_lampe,

both feeding with the Repetier host manual controls and manually pushing filament through the extruder there is no discernible change in resistance.

The biggest clue is the failure of the printer to even try to print the skirt (which is clearly visible in both the print preview and in the gcode) The nozzle purge blob has to be a deliberate function replacement to get the nozzle primed.

Subsequent to the initial failure I replaced the nozzle and cleaned the plastic path and started a second print: This is where I noticed that the extruder motor stopped turning when doing the end parts.

A third try with the total length shortened by 4mm printed without problem.

Examining the configurable part of the EEPROM the only parts which seem to be of interest are:-

X min pos: 0

Y min pos: 0

X max length 200

Y max length 200

max printable radius 200

Looking at the Repetier firmware configuration.h there again is the same sort of thing:

#define X_MAX_LENGTH 200

#define Y_MAX_LENGTH 200

#define Z_MAX_LENGTH 300

#define X_MIN_POS 0

#define Y_MIN_POS 0

#define Z_MIN_POS 0

There seems to be nothing in the extruder section to tell it not to extrude beyond any limit and I have run out of other areas to look for the cause.

Mike

|

Re: Wild randomness on a generally good print June 24, 2018 01:12AM |

Registered: 8 years ago Posts: 5,232 |

Just wild guessing, but maybe 8bit Marlin is too busy managing to print at the outer edge, that there's no time for the planner to squeeze in e-steps.

There is at least one tower stepper zipping around at 'insane' speed, when you print at the edge....

At the moment you made it shorter ( read: part further in the middle ) the symptom is gone.

There is at least one tower stepper zipping around at 'insane' speed, when you print at the edge....

At the moment you made it shorter ( read: part further in the middle ) the symptom is gone.

|

Re: Wild randomness on a generally good print June 24, 2018 05:24AM |

Registered: 12 years ago Posts: 1,450 |

I am pretty sure that it is something to do with the ability of the firmware (Repetier) to keep up, but I think it more likely that it is a limit built into a setting - one that is not accessible in the configuration.h file. The question becomes "what triggered it?" My guess it that if a ratio of the delta arm length to the requested print diameter > some figure then stop extruding. The fact that there is no warning makes me think it is legacy software.

Mike

Edited 1 time(s). Last edit at 06/24/2018 05:24AM by leadinglights.

Mike

Edited 1 time(s). Last edit at 06/24/2018 05:24AM by leadinglights.

|

Re: Wild randomness on a generally good print June 24, 2018 08:27AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Wild randomness on a generally good print June 24, 2018 12:23PM |

Registered: 12 years ago Posts: 1,450 |

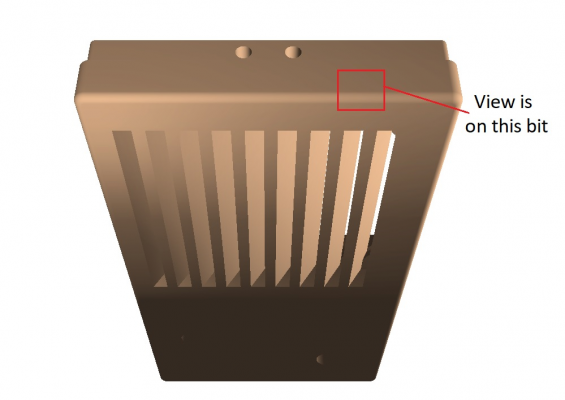

Picture shows that it starts going messy about 12 layers up. Bottom solid shell requested is 3 layers, 0.3mm for first layer then 0.2mm. Viewed through a microscope the 4 layers before it gets really messy do seem to be a little uneven though. I have added a rendering to show where we are looking.

I have no idea why the first few layers are O.K.

Mike

Edited 1 time(s). Last edit at 06/24/2018 12:25PM by leadinglights.

I have no idea why the first few layers are O.K.

Mike

Edited 1 time(s). Last edit at 06/24/2018 12:25PM by leadinglights.

|

Re: Wild randomness on a generally good print June 24, 2018 04:57PM |

Registered: 7 years ago Posts: 154 |

As I can see on the first picture, the object you want to print is nearly filling up your print plate.

In your last post I see, that bottom edge is rounded.

Somewhere in the middle you tell us

Well...

1.) Why does a Delta have min set to Zero?

Both of my Deltas have Zero in the middle - so if Printbed is 200mm in diameter I have

Xmin = -100

Xmax = 100

2.) If max printable radius is 200mm does not match with Xmin=0/Xmax=200

printable radius would be 100 (see above)

3.) If you calculate distance from your parts center to the edges, I think they will be below 100mm at the rounded edges, but more than 100mm when the edge has rounded out.

4.) If your part is 183mm long, and already nearly at the limits of printable radius, skirt is outside of printable radius - your printer will simply refuse to travel to this coordinates - so it might spit out some filament at the position it is starting at.

My hint would be to increase printable area in the firmware and then try printing again.

5.) I had great problems with Slicer 1.2.9 - Now I use Slicer Prusa Edition 1.40.0

[github.com]

Edited 1 time(s). Last edit at 06/24/2018 05:00PM by Dancer.

In your last post I see, that bottom edge is rounded.

Somewhere in the middle you tell us

Quote

leadinglights

Examining the configurable part of the EEPROM the only parts which seem to be of interest are:-

X min pos: 0

Y min pos: 0

X max length 200

Y max length 200

max printable radius 200

Looking at the Repetier firmware configuration.h there again is the same sort of thing:

#define X_MAX_LENGTH 200

#define Y_MAX_LENGTH 200

#define Z_MAX_LENGTH 300

#define X_MIN_POS 0

#define Y_MIN_POS 0

#define Z_MIN_POS 0

There seems to be nothing in the extruder section to tell it not to extrude beyond any limit and I have run out of other areas to look for the cause.

Mike

Well...

1.) Why does a Delta have min set to Zero?

Both of my Deltas have Zero in the middle - so if Printbed is 200mm in diameter I have

Xmin = -100

Xmax = 100

2.) If max printable radius is 200mm does not match with Xmin=0/Xmax=200

printable radius would be 100 (see above)

3.) If you calculate distance from your parts center to the edges, I think they will be below 100mm at the rounded edges, but more than 100mm when the edge has rounded out.

4.) If your part is 183mm long, and already nearly at the limits of printable radius, skirt is outside of printable radius - your printer will simply refuse to travel to this coordinates - so it might spit out some filament at the position it is starting at.

My hint would be to increase printable area in the firmware and then try printing again.

5.) I had great problems with Slicer 1.2.9 - Now I use Slicer Prusa Edition 1.40.0

[github.com]

Edited 1 time(s). Last edit at 06/24/2018 05:00PM by Dancer.

|

Re: Wild randomness on a generally good print June 25, 2018 01:44AM |

Registered: 12 years ago Posts: 1,450 |

|

Re: Wild randomness on a generally good print June 25, 2018 02:00AM |

Registered: 7 years ago Posts: 154 |

Well....

Why printable radius of 144? - I know 100×sqrt(2)=approx 141.

But: which diameter is your printbed? - printable radius is half of it (approximately, not thinking of mounting brackets)

[www.calculatorsoup.com]

141mm is the diagonal line of a square with sides of 100mm

[www.calculatorsoup.com]

Or maybe I just misunderstood you now (english is not my native language)...

Why printable radius of 144? - I know 100×sqrt(2)=approx 141.

But: which diameter is your printbed? - printable radius is half of it (approximately, not thinking of mounting brackets)

[www.calculatorsoup.com]

141mm is the diagonal line of a square with sides of 100mm

[www.calculatorsoup.com]

Or maybe I just misunderstood you now (english is not my native language)...

|

Re: Wild randomness on a generally good print June 25, 2018 02:55AM |

Registered: 12 years ago Posts: 1,450 |

|

Re: Wild randomness on a generally good print June 25, 2018 03:48AM |

Registered: 7 years ago Posts: 154 |

OK

So if you have printable radius of 100mm and your object is 100.6 from center to edge, it is clear why your printer behaves so strange.

It is ignoring every coordinate outside this radius.

I assume you are using relative E-Distances.

So if there is a long side to print, but destination coordinates are outside, this move is ignored.

Next move is from your round corners - so just a segment of a small arc. --> E-Distance is very short, but absolut movement is the distance from the ignored move + the new move - you are simply underextruding extremely - therefore your outside walls look that strange.

I do not exactly know, why the upper layers look good again - maybe it has something to do with the sideway holes - so you have coordinates inbetween, which are inside printable area.

I would increase X, Y and printable Radius to 220 and try again.

If you have mounting brackets inside this radius, you could simply draw your printable area (printbed without mounting) in openscad, save as stl, and in Slicer import a custom printbed in the rightmost tab. (I think printer settings)

(I'll be at my printer again today afternoon if you need more hints)

Edited 1 time(s). Last edit at 06/25/2018 03:56AM by Dancer.

So if you have printable radius of 100mm and your object is 100.6 from center to edge, it is clear why your printer behaves so strange.

It is ignoring every coordinate outside this radius.

I assume you are using relative E-Distances.

So if there is a long side to print, but destination coordinates are outside, this move is ignored.

Next move is from your round corners - so just a segment of a small arc. --> E-Distance is very short, but absolut movement is the distance from the ignored move + the new move - you are simply underextruding extremely - therefore your outside walls look that strange.

I do not exactly know, why the upper layers look good again - maybe it has something to do with the sideway holes - so you have coordinates inbetween, which are inside printable area.

I would increase X, Y and printable Radius to 220 and try again.

If you have mounting brackets inside this radius, you could simply draw your printable area (printbed without mounting) in openscad, save as stl, and in Slicer import a custom printbed in the rightmost tab. (I think printer settings)

(I'll be at my printer again today afternoon if you need more hints)

Edited 1 time(s). Last edit at 06/25/2018 03:56AM by Dancer.

|

Re: Wild randomness on a generally good print June 25, 2018 05:00AM |

Registered: 12 years ago Posts: 1,450 |

Now that my brain has had enough caffeine and the shock of a dental filling in the morning to wake it up - on with the excuses for my failure to see the obvious. I suspect one brain cell knew what was happening but couldn't be heard over the chorus of WTF??? from the others.

From memory my settings in the past have been X and Y min -110, X and Y length 220 and printable radius 135 (No, I don't know why not 110mm). I think that when Repetier changed to the auto configuraor I just filled in something that worked - then left it as "F*** it it's good enough". I must admit I was happier with the manual configuration as it forced me to think.

The only questions left are academic only - like "Why did the skirt dump out plastic while the end of the print did not?" and "How come the configuration of X and Y min = 0 even let it print anything on the left front of the print?"

Still, I guess if I understood everything i would be President.

Mike

Or why this was rejected on first submission and now appears twice WTF??????

Edited 1 time(s). Last edit at 06/25/2018 05:07AM by leadinglights.

From memory my settings in the past have been X and Y min -110, X and Y length 220 and printable radius 135 (No, I don't know why not 110mm). I think that when Repetier changed to the auto configuraor I just filled in something that worked - then left it as "F*** it it's good enough". I must admit I was happier with the manual configuration as it forced me to think.

The only questions left are academic only - like "Why did the skirt dump out plastic while the end of the print did not?" and "How come the configuration of X and Y min = 0 even let it print anything on the left front of the print?"

Still, I guess if I understood everything i would be President.

Mike

Or why this was rejected on first submission and now appears twice WTF??????

Edited 1 time(s). Last edit at 06/25/2018 05:07AM by leadinglights.

|

Re: Wild randomness on a generally good print June 25, 2018 05:05AM |

Registered: 12 years ago Posts: 1,450 |

Now that my brain has had enough caffeine and the shock of a dental filling in the morning to wake it up - on with the excuses for my failure to see the obvious. I suspect one brain cell knew what was happening but couldn't be heard over the chorus of WTF??? from the others.

From memory my settings in the past have been X and Y min -110, X and Y length 220 and printable radius 135 (No, I don't know why not 110mm). I think that when Repetier changed to the auto configuraor I just filled in something that worked. I must admit I was happier with the manual configuration as it forced me to think.

The only questions left are academic only - like "Why did the skirt dump out plastic while the end of the print did not?" and "How come the configuration of X and Y min = 0 even let it print anything on the left front of the print?"

Still, I guess if I understood everything i would be President.

Mike

From memory my settings in the past have been X and Y min -110, X and Y length 220 and printable radius 135 (No, I don't know why not 110mm). I think that when Repetier changed to the auto configuraor I just filled in something that worked. I must admit I was happier with the manual configuration as it forced me to think.

The only questions left are academic only - like "Why did the skirt dump out plastic while the end of the print did not?" and "How come the configuration of X and Y min = 0 even let it print anything on the left front of the print?"

Still, I guess if I understood everything i would be President.

Mike

|

Re: Wild randomness on a generally good print June 25, 2018 05:15AM |

Registered: 7 years ago Posts: 154 |

I'm glad we found out what was wrong - nothing damaged - only misconfiguration.

I was never happy with Repetier configurator, and could never get Repetier to print on my Delta, therefore I only use Marlin (1.1.6 and 1.1.8) on my machines - and there is no configurator - you have to do everything by hand and fully use your brain.

Sorry, only registered users may post in this forum.