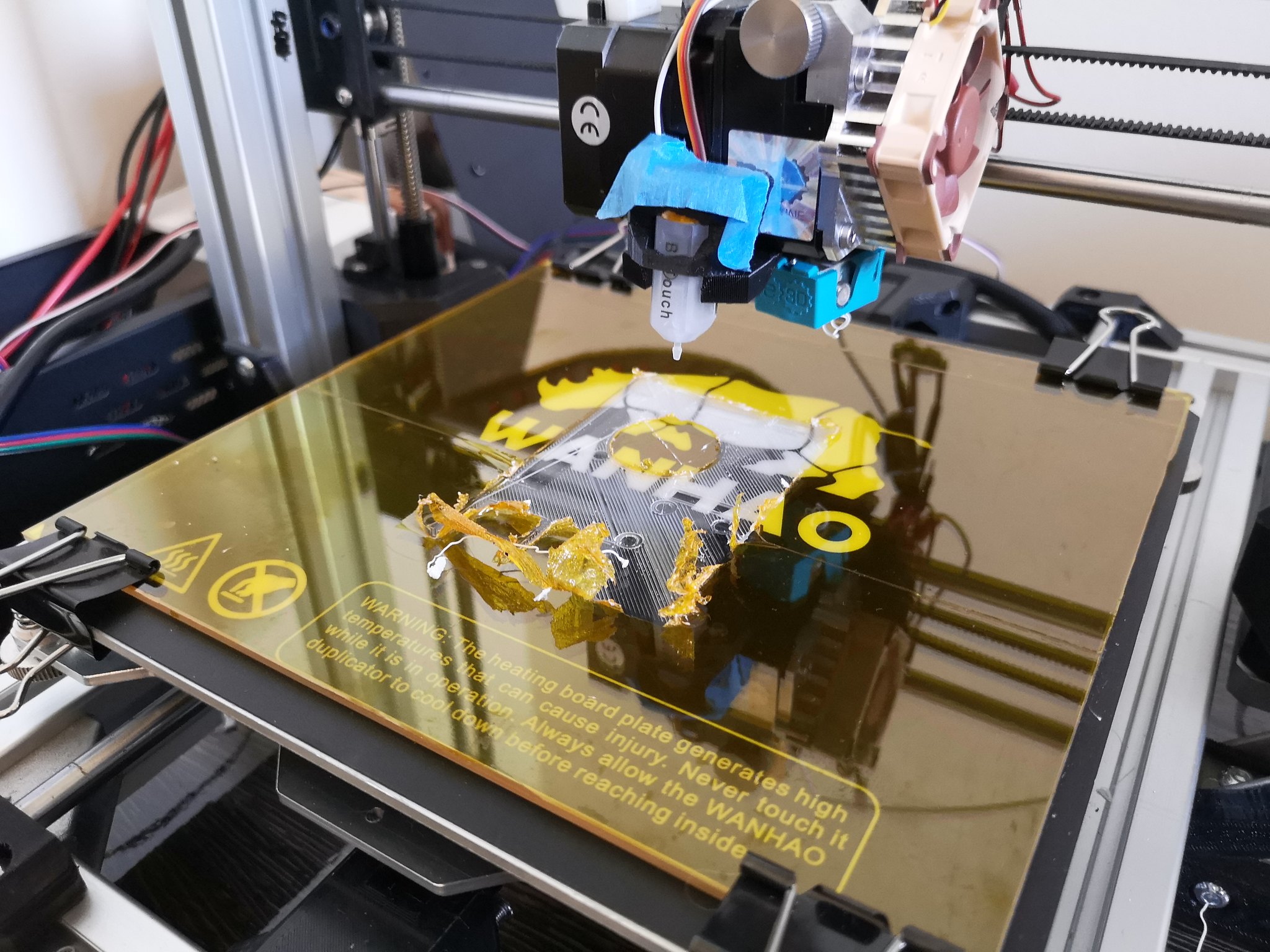

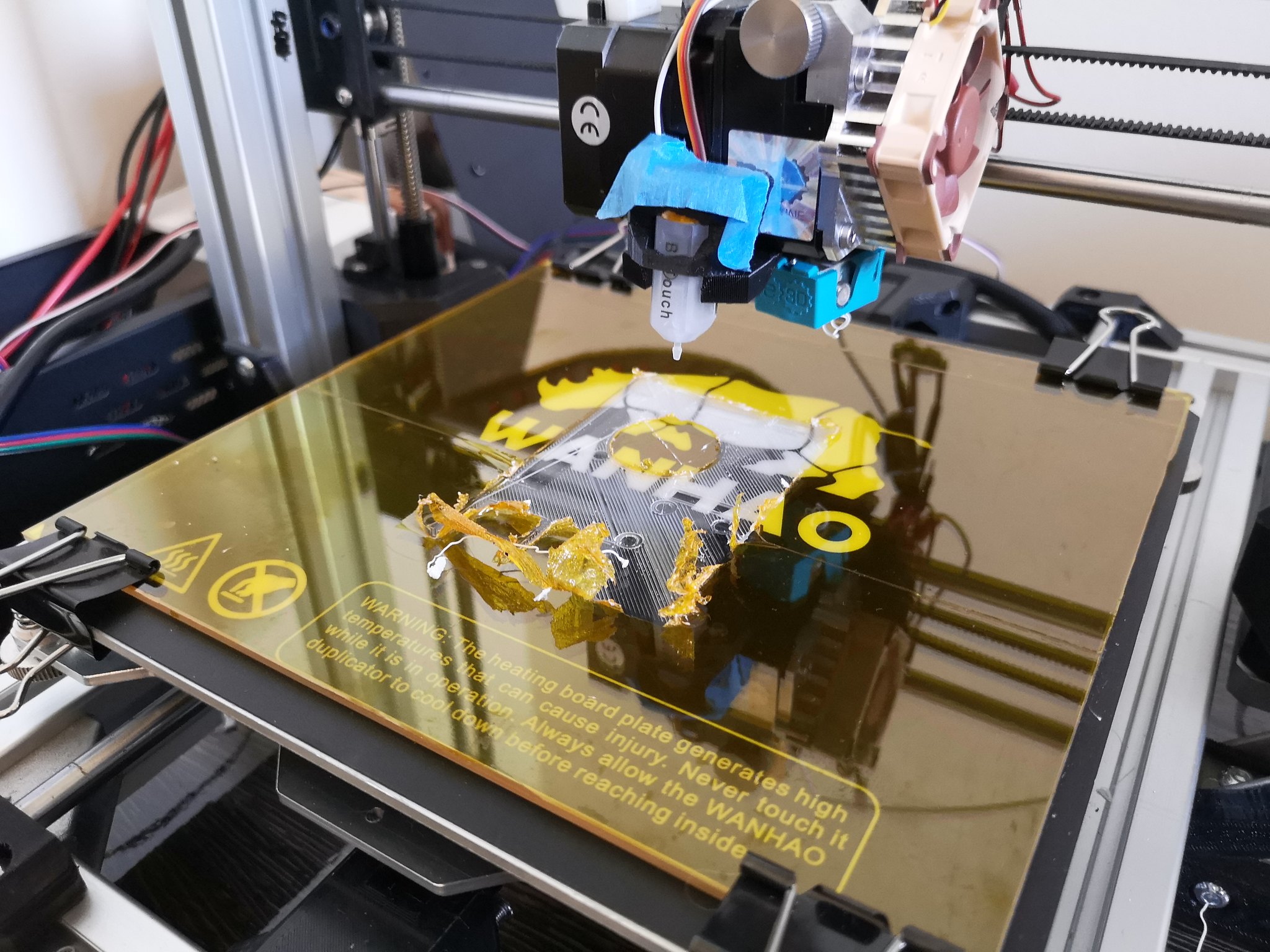

Ripped up kepton tape! why???

Posted by Gaz83

|

Ripped up kepton tape! why??? August 06, 2018 03:33AM |

Registered: 5 years ago Posts: 25 |

I have recently rebuilt my printer and at the moment it feels like the worse thing ever todo.

I printer a few items in PLA to make sure everything was working ok and then I switched over to PETG and start calibrating etc.

Got a few things printing and was happy with my cura settings. Yesterday I noticed that the lines on each layer started showing gaps. I added something like .2 mm to the Z offset and stll no joy.

I put a spirit level on the X axis and noticed it was not level, so I adjusted one of the Z-axis motors and turned it until it was level.

Back to printing and now the PETG was squishing so I dialed the zaxis offset back to where it was. Started a print off and the first 3/4 lines of the brim was looking perfect.

I went away for about 40 mins and came back to this (minus the print as I removed it).

How can this happen? Haven't changed any settings in my printing.

Firmware is Marlin and I print with Octopi.

I printer a few items in PLA to make sure everything was working ok and then I switched over to PETG and start calibrating etc.

Got a few things printing and was happy with my cura settings. Yesterday I noticed that the lines on each layer started showing gaps. I added something like .2 mm to the Z offset and stll no joy.

I put a spirit level on the X axis and noticed it was not level, so I adjusted one of the Z-axis motors and turned it until it was level.

Back to printing and now the PETG was squishing so I dialed the zaxis offset back to where it was. Started a print off and the first 3/4 lines of the brim was looking perfect.

I went away for about 40 mins and came back to this (minus the print as I removed it).

How can this happen? Haven't changed any settings in my printing.

Firmware is Marlin and I print with Octopi.

|

Re: Ripped up kepton tape! why??? August 06, 2018 07:54AM |

Registered: 11 years ago Posts: 5,780 |

Was the nozzle dragging on the kapton?

The kapton tape sold for 3D printing is too thin (usually 0.001") and fragile. I used to use 5 mil thick tape and one application would last for 6 months of daily printing. I switched to PEI a few years ago and would never go back to putting tape on a bed. On a printer at the makerspace, we have a 0.06" (about 0.7mm) thick piece of PEI and it has been on the machine and working fine for about 3 years of daily abuse by rank amateur printers.

Dual motors in the Z axis will get out of sync which tilts the X axis. Prusa machines solve the problem by running the X axis up to the top of the Z axis and beyond, which forces the X axis to be perpendicular to Z, the motors stall, and when you lower the X axis again, it comes down level with the motors in sync. It's a pretty simple piece of gcode (G1 Zxxx F600 where xxx is the machines Z axis length t+ about 5 mm) you can use to drive the Z axis beyond the maximum and then just use the homing operation to bring it back down.

Edited 1 time(s). Last edit at 08/06/2018 07:59AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The kapton tape sold for 3D printing is too thin (usually 0.001") and fragile. I used to use 5 mil thick tape and one application would last for 6 months of daily printing. I switched to PEI a few years ago and would never go back to putting tape on a bed. On a printer at the makerspace, we have a 0.06" (about 0.7mm) thick piece of PEI and it has been on the machine and working fine for about 3 years of daily abuse by rank amateur printers.

Dual motors in the Z axis will get out of sync which tilts the X axis. Prusa machines solve the problem by running the X axis up to the top of the Z axis and beyond, which forces the X axis to be perpendicular to Z, the motors stall, and when you lower the X axis again, it comes down level with the motors in sync. It's a pretty simple piece of gcode (G1 Zxxx F600 where xxx is the machines Z axis length t+ about 5 mm) you can use to drive the Z axis beyond the maximum and then just use the homing operation to bring it back down.

Edited 1 time(s). Last edit at 08/06/2018 07:59AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Ripped up kepton tape! why??? August 06, 2018 10:45AM |

Registered: 5 years ago Posts: 25 |

Thanks for the info on the Z axis.

In regards to the nozzle, I can only assume it wasn't. 1) because I had printed about 10 prints over a few days before and it had a nice first layer on all. 2) When I left it, it was printing the brim nicely, as I mentioned. If this was scraping I would have imagined I would have seen a squished lines or even no lines at all.

In regards to the nozzle, I can only assume it wasn't. 1) because I had printed about 10 prints over a few days before and it had a nice first layer on all. 2) When I left it, it was printing the brim nicely, as I mentioned. If this was scraping I would have imagined I would have seen a squished lines or even no lines at all.

|

Re: Ripped up kepton tape! why??? August 06, 2018 10:55AM |

Registered: 11 years ago Posts: 5,780 |

The lines on the glass sure look like it was tearing up the kapton and trying to print on the glass...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Ripped up kepton tape! why??? August 06, 2018 11:23AM |

Registered: 5 years ago Posts: 25 |

|

Re: Ripped up kepton tape! why??? August 06, 2018 11:48AM |

Registered: 8 years ago Posts: 318 |

|

Re: Ripped up kepton tape! why??? August 06, 2018 11:54AM |

Registered: 5 years ago Posts: 25 |

|

Re: Ripped up kepton tape! why??? August 06, 2018 03:40PM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.