Successful 1st ABS Print

Posted by Roberts_Clif

|

Successful 1st ABS Print September 14, 2018 10:16PM |

Registered: 6 years ago Posts: 1,863 |

I have been printing PLA now for 2 years very Successfully.

So 1 week ago I ordered 3 Rolls of ABS and to my surprise today they kind of arrived. (Picture below)

You will note that out of an order of 3 rolls of filament only Red and Blue are ABS the Black was actually the most important for my needs.

And you will note in the picture this one roll of filament that I needed the most is not ABS it is PLA now this is just my luck!

And after trying to print on my Vinyl Transfer Paper with No luck I went to Blue Tape, only to find it was not the tape at all.

I had a little problem getting the Proximity Sensor slide mount to adjusted to the lower height I ran out of screw threads.

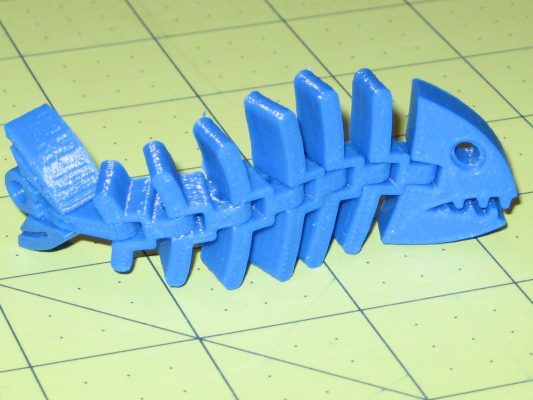

Well I wanted the first ABS print to be an average test, So I selected the Fossil Fish Key ring.

With tight corners, bridging a quick print time this was my selection for the first test print.

Setting the nozzle temperature to 230C the bed temperature to 96C fan speed to 58% started my first ABS Print.

Total print time 55 minutes.

Checking the Z-Axis and Proximity sensor reviled that the Sensor locking screw had become loose messing with the Z-Axis calibrations.

Edited 2 time(s). Last edit at 09/16/2018 07:51AM by Roberts_Clif.

Computer Programmer / Electronics Technician

So 1 week ago I ordered 3 Rolls of ABS and to my surprise today they kind of arrived. (Picture below)

You will note that out of an order of 3 rolls of filament only Red and Blue are ABS the Black was actually the most important for my needs.

And you will note in the picture this one roll of filament that I needed the most is not ABS it is PLA now this is just my luck!

And after trying to print on my Vinyl Transfer Paper with No luck I went to Blue Tape, only to find it was not the tape at all.

I had a little problem getting the Proximity Sensor slide mount to adjusted to the lower height I ran out of screw threads.

Well I wanted the first ABS print to be an average test, So I selected the Fossil Fish Key ring.

With tight corners, bridging a quick print time this was my selection for the first test print.

Setting the nozzle temperature to 230C the bed temperature to 96C fan speed to 58% started my first ABS Print.

Total print time 55 minutes.

Checking the Z-Axis and Proximity sensor reviled that the Sensor locking screw had become loose messing with the Z-Axis calibrations.

Edited 2 time(s). Last edit at 09/16/2018 07:51AM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Successful 1st ABS Print September 16, 2018 07:49AM |

Registered: 5 years ago Posts: 26 |

Hi Roberts,

Congratulations for your printed part, it really looks amazing!!

From our own experience, blue tape will work for smaller parts, things begin to get tricky when the parts are bigger, larger, and taller (and it depends on the part itself, how lateral tensions are created within the part + infill).

The nozzle temperature (130 C) seems a bit too low for ABS...

George Gal

DustnPrint Evangelist

www.dustnprint.com/blog

Congratulations for your printed part, it really looks amazing!!

From our own experience, blue tape will work for smaller parts, things begin to get tricky when the parts are bigger, larger, and taller (and it depends on the part itself, how lateral tensions are created within the part + infill).

The nozzle temperature (130 C) seems a bit too low for ABS...

George Gal

DustnPrint Evangelist

www.dustnprint.com/blog

|

Re: Successful 1st ABS Print September 16, 2018 07:51AM |

Registered: 6 years ago Posts: 1,863 |

Corrected the above missed the 2 and hit a 1.

The correct temperature should have been 230C Nozzle and 96C Bed.

Fingers missed the correct key.

When I find more time I will test a larger Print using the Vinyl Transfer Paper Tape ('Similar to Blue Tape') and what ever these Hictop Bed Build surfaces are made.

Edited 4 time(s). Last edit at 09/16/2018 08:09AM by Roberts_Clif.

Computer Programmer / Electronics Technician

The correct temperature should have been 230C Nozzle and 96C Bed.

Fingers missed the correct key.

When I find more time I will test a larger Print using the Vinyl Transfer Paper Tape ('Similar to Blue Tape') and what ever these Hictop Bed Build surfaces are made.

Edited 4 time(s). Last edit at 09/16/2018 08:09AM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Successful 1st ABS Print September 20, 2018 05:41AM |

Registered: 12 years ago Posts: 2,470 |

The fan will be a problem with most prints, cooling ABS during printing is not necessary and often problematic. It behaves very differently than PLA. For bigger parts try to prevent draught, depending on the shape of your printer try to enclose it. Often enough covering it with a mylar foil can improve prints hugely.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Successful 1st ABS Print September 20, 2018 09:13AM |

Registered: 6 years ago Posts: 1,863 |

Quote

Srek

The fan will be a problem with most prints, cooling ABS during printing is not necessary and often problematic. It behaves very differently than PLA. For bigger parts try to prevent draught, depending on the shape of your printer try to enclose it. Often enough covering it with a mylar foil can improve prints hugely.

I understand though my printer is inside a heated chamber so in fact am blowing the chambers heated air on to the Part, would this make a difference.

However the chamber air temperature is around 40C. The above Fossil Fish I printed was one of the Better models I have printed though not the Best.

The bridging was almost perfect as it was removed with very little pressure what so ever and the hinges functioned the second the part was removed.

Computer Programmer / Electronics Technician

|

Re: Successful 1st ABS Print September 25, 2018 01:07PM |

Registered: 7 years ago Posts: 619 |

Quote

Roberts_Clif

Quote

Srek

The fan will be a problem with most prints, cooling ABS during printing is not necessary and often problematic. It behaves very differently than PLA. For bigger parts try to prevent draught, depending on the shape of your printer try to enclose it. Often enough covering it with a mylar foil can improve prints hugely.

I understand though my printer is inside a heated chamber so in fact am blowing the chambers heated air on to the Part, would this make a difference.

However the chamber air temperature is around 40C. The above Fossil Fish I printed was one of the Better models I have printed though not the Best.

The bridging was almost perfect as it was removed with very little pressure what so ever and the hinges functioned the second the part was removed.

Whatever you did, keep doing it. That ABS print is as close to perfect as any that I have seen. I use this part as a tuning test for a setup.

DLC

|

Re: Successful 1st ABS Print September 28, 2018 03:02PM |

Registered: 12 years ago Posts: 2,470 |

You will see that the problems come and increase with the size of the printed objects. The fish consists of small, flat and disconnected parts, close to the most uncritical thing you can print with ABS.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Successful 1st ABS Print September 29, 2018 12:02PM |

Registered: 9 years ago Posts: 752 |

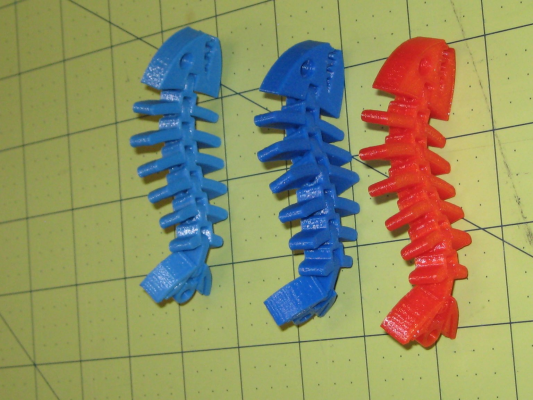

It looks very shiny, a bit too shiny to be pure abs. Are you sure it's pure ABS or is it a hybrid, maybe mixed with PLA? I got such a roll of filament. It needed about 230 degrees nozzle temperature and printed a bit more shiny than regular ABS. My pure ABS filament prints at 258 degrees (give or take 5 degrees, using a k type thermocouple). It's called 'Dutch ABS'.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Successful 1st ABS Print October 01, 2018 02:43PM |

Registered: 6 years ago Posts: 1,863 |

I believe what you are seeing is the camera flash.

I have a three the center one is ABS the outer ones are PLA, not really as shinny until the flash hit it...

The First three ABS Colors I purchased two have a Temperature range of 210 - 240 the third was a mistaken PLA, was discounted $5.00 to keep.

The Second three ABS Colors I purchased One has Temperature range of 210 - 240 two have Temperature range of 230 - 260. These may require 20C more heat have not printed them as of this date.

Have not received the last six ABS colors as of this date.

Even though I have verified my hot-end Temperature with a Multi-meter Thermal Probe it still could be off and the temperature hotter than measurement shown.

Multi-meter Thermal Probe accuracy is not that perfect with the measurement taken on the outside of the hot-end. Will re-post when I print with the higher temp ABS filaments as to there Print temperature.

Computer Programmer / Electronics Technician

I have a three the center one is ABS the outer ones are PLA, not really as shinny until the flash hit it...

The First three ABS Colors I purchased two have a Temperature range of 210 - 240 the third was a mistaken PLA, was discounted $5.00 to keep.

The Second three ABS Colors I purchased One has Temperature range of 210 - 240 two have Temperature range of 230 - 260. These may require 20C more heat have not printed them as of this date.

Have not received the last six ABS colors as of this date.

Even though I have verified my hot-end Temperature with a Multi-meter Thermal Probe it still could be off and the temperature hotter than measurement shown.

Multi-meter Thermal Probe accuracy is not that perfect with the measurement taken on the outside of the hot-end. Will re-post when I print with the higher temp ABS filaments as to there Print temperature.

Computer Programmer / Electronics Technician

|

Re: Successful 1st ABS Print October 01, 2018 03:10PM |

Registered: 9 years ago Posts: 752 |

Can you notice the smell? I've got a roll of filament in the past that smelled like abs mixed with pla, the pla smell was a bit stronger. Then downside was that it clogged the nozzle more often, probably the pla burning up loosing its viscosity. 210 is definitely too low for ABS printing, so I think it's a mixed filament.

Looking at the picture the ABS is almost as shiny as the pla. The ABS I use now is more diffused even in flash light.

It'll be interesting to see the 260C abs next to these 3

Edited 1 time(s). Last edit at 10/01/2018 03:10PM by imqqmi.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

Looking at the picture the ABS is almost as shiny as the pla. The ABS I use now is more diffused even in flash light.

It'll be interesting to see the 260C abs next to these 3

Edited 1 time(s). Last edit at 10/01/2018 03:10PM by imqqmi.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Successful 1st ABS Print October 01, 2018 04:54PM |

Registered: 6 years ago Posts: 1,863 |

Well I decide to start the Next type ABS 230-260 temp range, started the first prints at 230C it was looking well then the Vinyl Transfer Paper Tape came off the 96C Hotbed.

Started the Second ABS print 230C on my Build Surface which is like brand new because I have always used the Vinyl Transfer Paper Tape seem to adhere to to build surface.

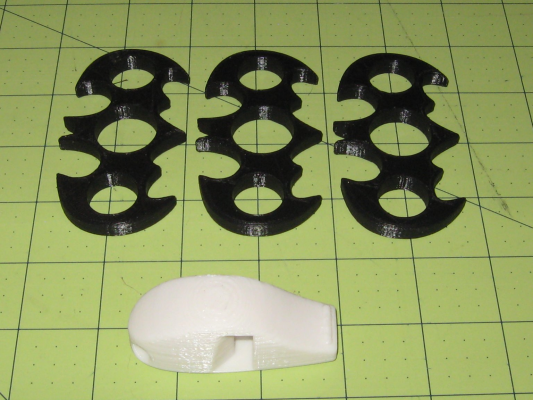

Printing three Bat-o-Rangs in black on 1st 3D Printer Blu and Printing a small G29 Whistle in white on 2nd 3D Printer ABS Red both at 230C.

I did note that the ABS smell is their have not noticed PLA smell yet because the ABS smell is overwhelming?

And it does have the tendency to want to warp if it does not have good adhesion to the bed as in the first print on the tape warped quite a bit.

It seem to want to print at a slower rate this could be because I am printing at the lower end of the melting point.

Might be that if the print speed was to increase it would require the higher temperature and have a more pungent ABS Aroma.

Will note this too on another print test. Will print at the higher temperature with a faster print speed, may even need to increase the hot-bed and chamber temperatures.

Not sure hot much this Chinese 3D Printer will handle, However I did add a cooling fan and heat sinks on all high power components.

However I am under the impression the higher the filament temperature the more likely the chances of warping. So try to stay at the lowest printable temperature.

Was not sure I could reach 96C hot bed temp though it was easily obtainable.

Post the Photo results this evening.

Edited 4 time(s). Last edit at 10/01/2018 05:21PM by Roberts_Clif.

Computer Programmer / Electronics Technician

Started the Second ABS print 230C on my Build Surface which is like brand new because I have always used the Vinyl Transfer Paper Tape seem to adhere to to build surface.

Printing three Bat-o-Rangs in black on 1st 3D Printer Blu and Printing a small G29 Whistle in white on 2nd 3D Printer ABS Red both at 230C.

I did note that the ABS smell is their have not noticed PLA smell yet because the ABS smell is overwhelming?

And it does have the tendency to want to warp if it does not have good adhesion to the bed as in the first print on the tape warped quite a bit.

It seem to want to print at a slower rate this could be because I am printing at the lower end of the melting point.

Might be that if the print speed was to increase it would require the higher temperature and have a more pungent ABS Aroma.

Will note this too on another print test. Will print at the higher temperature with a faster print speed, may even need to increase the hot-bed and chamber temperatures.

Not sure hot much this Chinese 3D Printer will handle, However I did add a cooling fan and heat sinks on all high power components.

However I am under the impression the higher the filament temperature the more likely the chances of warping. So try to stay at the lowest printable temperature.

Was not sure I could reach 96C hot bed temp though it was easily obtainable.

Post the Photo results this evening.

Edited 4 time(s). Last edit at 10/01/2018 05:21PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Successful 1st ABS Print October 01, 2018 07:34PM |

Registered: 6 years ago Posts: 1,863 |

The Image of the 3 Bat-o-Rangs and the whistle all in ABS printed at 230C lowest Temperature on the ABS filament Roll (230-260C).

Same as the First ABS Print however the ABS on that roll temperature was 210-240C. All part are as they came off the bed no cleanup.

As I was in a hurry the printed item were a little to high so all did not lay perfectly flat on the bed, they all experienced a little edge curving about 2 layer worth in total warp .56mm.

Not to bad for a really fast Z-Axis Height adjustment, on a bed surface material I rarely use to print on.

Edited 2 time(s). Last edit at 10/01/2018 07:42PM by Roberts_Clif.

Computer Programmer / Electronics Technician

Same as the First ABS Print however the ABS on that roll temperature was 210-240C. All part are as they came off the bed no cleanup.

As I was in a hurry the printed item were a little to high so all did not lay perfectly flat on the bed, they all experienced a little edge curving about 2 layer worth in total warp .56mm.

Not to bad for a really fast Z-Axis Height adjustment, on a bed surface material I rarely use to print on.

Edited 2 time(s). Last edit at 10/01/2018 07:42PM by Roberts_Clif.

Computer Programmer / Electronics Technician

Sorry, only registered users may post in this forum.