Gaps in exterior after change to Volcano 0.6 from E3D 0.4

Posted by PDBeal

|

Gaps in exterior after change to Volcano 0.6 from E3D 0.4 September 16, 2018 08:35PM |

Registered: 7 years ago Posts: 558 |

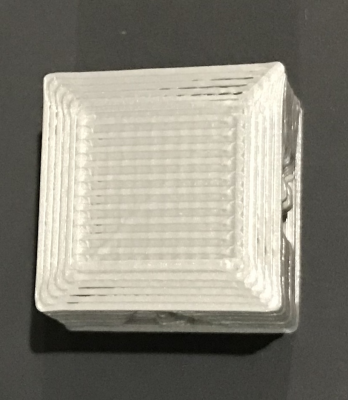

So over the weekend, I changed out my Titan E3D 0.4 setup to a Titan E3D Volcano 0.6 setup. I adjusted my z-height and also changed my slicer to use the 0.6 nozzle instead of the 0.4. On the first few test prints, I’m seeing a strange gap on some of the top layers. It shows up in two different places, but the rest of the top surface is almost perfect. I’m sort of at a loss for where to start to attempt to close this gap. The only change was to the volcano setup, and it didn’t have this gap before. It’s still using the same Titan extruder it had before. The print was at 45 mm/s on my CoreXY at 205C using eSun PLA Pro.

I don’t think it’s under extrusion because of the rest of the part feels smooth and doesn’t have any rough gaps anywhere else, only on these two corners. And the part was printed at an orientation of 45 to the bed.

Any thoughts or opinions?

I don’t think it’s under extrusion because of the rest of the part feels smooth and doesn’t have any rough gaps anywhere else, only on these two corners. And the part was printed at an orientation of 45 to the bed.

Any thoughts or opinions?

|

Re: Gaps in exterior after change to Volcano 0.6 from E3D 0.4 September 17, 2018 12:45AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Gaps in exterior after change to Volcano 0.6 from E3D 0.4 September 17, 2018 07:29AM |

Registered: 11 years ago Posts: 5,780 |

Good luck with the 0.6 nozzle/volcano. I have spent months trying to tune those things up for consistent and accurate extrusion and have never been able to make it work well with either Slic3r or Cura. It only gets worse if you go to larger nozzles. I have found I can tweak for a few hours and get it to work reasonably well with one print, but if I try to print multiple objects on the build plate or change to a different print, all bets are off. It frequently leaves gaps at the start of a layer after a retraction at the end of the previous layer, and after travel moves on the same layer even without a retraction. If you can keep the filament flowing forward through the extruder it is OK- spiral vases work fine, but as soon as you interrupt the forward flow of plastic, you get gaps.

Cura has a plugin that varies the extra prime length based of the distance traveled, which seems to help a little. Look for "scalable extra prime".

If you manage to find that magic combo of settings that work, please post your results.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Cura has a plugin that varies the extra prime length based of the distance traveled, which seems to help a little. Look for "scalable extra prime".

If you manage to find that magic combo of settings that work, please post your results.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Gaps in exterior after change to Volcano 0.6 from E3D 0.4 September 22, 2018 07:31PM |

Registered: 7 years ago Posts: 558 |

There isn't any noticeable movement in my hotend mount. Even if I grab it and pull it doesn't want to move. Primarily because the hotend is direct mounted in the E3D Titan, and my stepper motor bracket that holds the motor and titan is substantially thick.

Preliminary results are looking better if I tell Cura to use line width 0.57 on a 0.6 nozzle. It's closed up the holes from the print pictured, and everything is still dimensionally correct on the finished part. Makes we wonder if the volcano nozzle is a true 0.6, or the standard 0.4 nozzles aren't 0.4 but slightly larger like 0.42 or 0.43.

I'll continue to try other settings, but setting my line width to 0.57 has produced the best results so far.

Further testing improves if I use a 0.57 nozzle size and the line width 0.57 in Cura despite the nozzle being a 0.6. This leads me back to my initial thoughts that a 0.6 isn't 0.6 or a 0.4 is larger than 0.4.

Edited 2 time(s). Last edit at 09/22/2018 08:14PM by PDBeal.

Preliminary results are looking better if I tell Cura to use line width 0.57 on a 0.6 nozzle. It's closed up the holes from the print pictured, and everything is still dimensionally correct on the finished part. Makes we wonder if the volcano nozzle is a true 0.6, or the standard 0.4 nozzles aren't 0.4 but slightly larger like 0.42 or 0.43.

I'll continue to try other settings, but setting my line width to 0.57 has produced the best results so far.

Further testing improves if I use a 0.57 nozzle size and the line width 0.57 in Cura despite the nozzle being a 0.6. This leads me back to my initial thoughts that a 0.6 isn't 0.6 or a 0.4 is larger than 0.4.

Edited 2 time(s). Last edit at 09/22/2018 08:14PM by PDBeal.

|

Re: Gaps in exterior after change to Volcano 0.6 from E3D 0.4 September 24, 2018 01:31AM |

Registered: 10 years ago Posts: 11 |

Hi. Not E3D - but possible similar problem.

I try to use an 0,6mm Nozzle for te 1730 system. (Works fine since many months with a 1730 - 0,4mm )

I have no success that 0,6 er to run over a complete part.

If I push the filament (1,75 er) continously the materal flow, but if I stop (with small retraction [1mm or so]) for more than 10 second the filament is blocked.

After retraction from round about 10 mm the filament continous to flow.

In real print mode a so big amout of retract is not useable.

Sevreral trials to get a tip from the supplier was not successfull.

There is no reaction to my mails.

JoRo

I try to use an 0,6mm Nozzle for te 1730 system. (Works fine since many months with a 1730 - 0,4mm )

I have no success that 0,6 er to run over a complete part.

If I push the filament (1,75 er) continously the materal flow, but if I stop (with small retraction [1mm or so]) for more than 10 second the filament is blocked.

After retraction from round about 10 mm the filament continous to flow.

In real print mode a so big amout of retract is not useable.

Sevreral trials to get a tip from the supplier was not successfull.

There is no reaction to my mails.

JoRo

Sorry, only registered users may post in this forum.