Garden Hose Adapter

Posted by Roberts_Clif

|

Garden Hose Adapter October 12, 2018 09:34AM |

Registered: 6 years ago Posts: 1,863 |

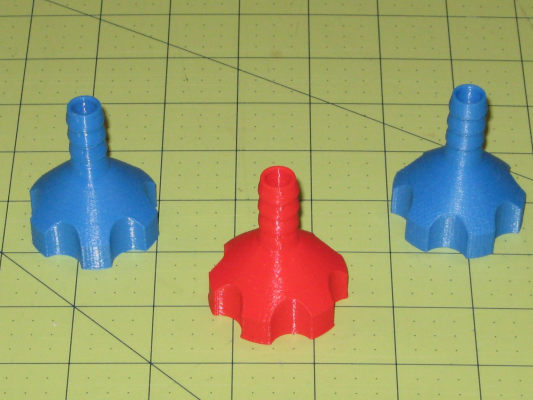

Today I 3D Printed a garden hose adapter. They came out looking good.

The adapter was connected to the outside faucet with no other parts except for a rubber washer to seal the connection.

Though they sprayed water out lots of cracks in-between the seams, which wakes them unusable for water as is.

Is there a special way to print these to make them work or have I found a limit to what can be 3D Printed for use...

Computer Programmer / Electronics Technician

The adapter was connected to the outside faucet with no other parts except for a rubber washer to seal the connection.

Though they sprayed water out lots of cracks in-between the seams, which wakes them unusable for water as is.

Is there a special way to print these to make them work or have I found a limit to what can be 3D Printed for use...

Computer Programmer / Electronics Technician

|

Re: Garden Hose Adapter October 12, 2018 11:38AM |

Registered: 6 years ago Posts: 1,863 |

Decide to change all settings reprint and try again. Better but still not a useful adapter.

To make it clear I am not blaming the Adapter, I am putting the blame on the 3D Printing of the Object.

Edited 3 time(s). Last edit at 10/12/2018 05:31PM by Roberts_Clif.

Computer Programmer / Electronics Technician

To make it clear I am not blaming the Adapter, I am putting the blame on the 3D Printing of the Object.

Edited 3 time(s). Last edit at 10/12/2018 05:31PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Garden Hose Adapter October 12, 2018 03:15PM |

Registered: 9 years ago Posts: 465 |

Interlayer adhesion is a pretty consistent problem with 3D printing. There are things that you can do to make it better, depending on what filament you use.

To make something water tight, the layers have to have really good adhesion.

For PLA or PETG, I'd probably try using a slightly less than solid infill rate, but increase your extrusion multiplier a bit. This will cause the shell layers to squish together. Finding the sweet spot for this will take trial and error. An increase in extrusion temperature can also help with inter layer bonding, preventing those cracks from opening up.With this method, I'd probably actually go for thicker layers, about as much as your nozzle can do well.

For ABS, I'd probably just use acetone vapour to smooth the part surface, and let that take care of sealing the cracks. Print the part with solid infill, and suspend it over some warm acetone until the part is smooth to the touch. (I use a couple of aluminum foil roasters with a dollar store cake cooling rack. Put about 5-10mm of acetone in the bottom, and put the part on the cooling rack, tape the 2 roasters together, and place it on the printer's heated bed, set to about 35-40 deg C for an hour or two. the part will come out smooth to the touch.

In either event, a any sealing coat of something might do the trick as well. A quick covering of clear enamel based spray paint could be all that it needs to be water-proof. This will also help protect the parts from sunlight, since most enamel spray paint is UV resistant.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

To make something water tight, the layers have to have really good adhesion.

For PLA or PETG, I'd probably try using a slightly less than solid infill rate, but increase your extrusion multiplier a bit. This will cause the shell layers to squish together. Finding the sweet spot for this will take trial and error. An increase in extrusion temperature can also help with inter layer bonding, preventing those cracks from opening up.With this method, I'd probably actually go for thicker layers, about as much as your nozzle can do well.

For ABS, I'd probably just use acetone vapour to smooth the part surface, and let that take care of sealing the cracks. Print the part with solid infill, and suspend it over some warm acetone until the part is smooth to the touch. (I use a couple of aluminum foil roasters with a dollar store cake cooling rack. Put about 5-10mm of acetone in the bottom, and put the part on the cooling rack, tape the 2 roasters together, and place it on the printer's heated bed, set to about 35-40 deg C for an hour or two. the part will come out smooth to the touch.

In either event, a any sealing coat of something might do the trick as well. A quick covering of clear enamel based spray paint could be all that it needs to be water-proof. This will also help protect the parts from sunlight, since most enamel spray paint is UV resistant.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: Garden Hose Adapter October 12, 2018 05:35PM |

Registered: 6 years ago Posts: 1,863 |

Sorry, only registered users may post in this forum.