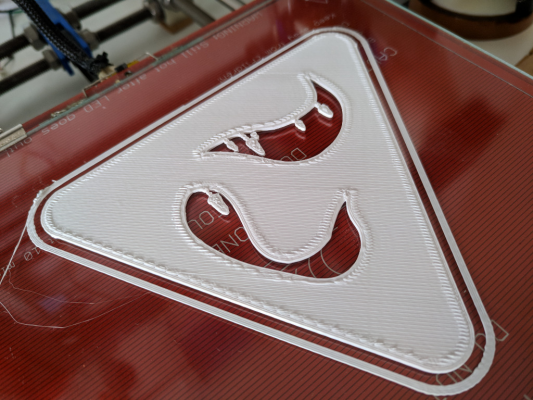

i3, excess material near infill borders

Posted by luismanson

|

i3, excess material near infill borders November 14, 2018 09:59AM |

Registered: 10 years ago Posts: 371 |

Hello, i have this issue which i never was able to readuce 100%, its like near the end of an inflill line, it pushes a bit of excess material to a side from the previous line, reducing extrusion multiplier does not seem to be the right fix, since it also causes small gaps between infill lines. Im using a 0.5mm nozzle, near 70mm/s top speed, slicing with simplify3d

|

Re: i3, excess material near infill borders November 14, 2018 10:23AM |

Registered: 9 years ago Posts: 465 |

What controller/firmware?

Looks like [marlinfw.org] or [duet3d.dozuki.com]

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

Looks like [marlinfw.org] or [duet3d.dozuki.com]

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: i3, excess material near infill borders November 14, 2018 10:29AM |

Registered: 10 years ago Posts: 371 |

|

Re: i3, excess material near infill borders November 15, 2018 04:16PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: i3, excess material near infill borders November 15, 2018 05:31PM |

Registered: 9 years ago Posts: 752 |

Try bumping up acceleration until loosing steps then back it off a bit until stable, then try bumping up the jerk setting. That worked for me.

It's basically due to nozzle pressure not being able to adjust rapidly enough to account for slowing down due to direction changes and how fast it can do 180 degrees turns, which is what solid infill is. So to fix this you can try making the nozzle spend as little time doing cornering, at as close to the speed you're doing infill.

To a lesser degree the way the bed is mechanically mounted can also play a role. When mounted on springs, any back and forth motion will dip and rise the bed slightly and bounce as you can see in the extrusion lines. Replacing the springs by shims will help to some extend. The i3 mechanics aren't really good for higher speeds than 40mm/s tops.

As mentioned, the new default setting for infill overlap is 25%. It used to be 15%. When I dropped down to 15% it improved a lot though some gaps may start appearing if there's too much compliance/backlash. Even without compliance gaps may appear.

At higher speeds filament tends to cut corners too, so the too of 'hearpin' corners may draw together, bunching them up.

The bigger the nozzle the higher the tendency to ooze and leak. Try 0.4mm nozzle and see if that improves it.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

It's basically due to nozzle pressure not being able to adjust rapidly enough to account for slowing down due to direction changes and how fast it can do 180 degrees turns, which is what solid infill is. So to fix this you can try making the nozzle spend as little time doing cornering, at as close to the speed you're doing infill.

To a lesser degree the way the bed is mechanically mounted can also play a role. When mounted on springs, any back and forth motion will dip and rise the bed slightly and bounce as you can see in the extrusion lines. Replacing the springs by shims will help to some extend. The i3 mechanics aren't really good for higher speeds than 40mm/s tops.

As mentioned, the new default setting for infill overlap is 25%. It used to be 15%. When I dropped down to 15% it improved a lot though some gaps may start appearing if there's too much compliance/backlash. Even without compliance gaps may appear.

At higher speeds filament tends to cut corners too, so the too of 'hearpin' corners may draw together, bunching them up.

The bigger the nozzle the higher the tendency to ooze and leak. Try 0.4mm nozzle and see if that improves it.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: i3, excess material near infill borders November 16, 2018 10:40AM |

Registered: 10 years ago Posts: 371 |

|

Re: i3, excess material near infill borders November 19, 2018 11:13AM |

Registered: 7 years ago Posts: 619 |

Maybe it is just me, but...

I notice that you're using white filament. I have used three different, good quality manufacturers' filament and whenever I use a white filament my surfaces look like crap. Swap out the white for another color and all is perfect...

Has anyone else ever noticed that white PLA prints poorly? What is the secret for printing white PLA?

Thanks,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

I notice that you're using white filament. I have used three different, good quality manufacturers' filament and whenever I use a white filament my surfaces look like crap. Swap out the white for another color and all is perfect...

Has anyone else ever noticed that white PLA prints poorly? What is the secret for printing white PLA?

Thanks,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: i3, excess material near infill borders November 21, 2018 05:07AM |

Registered: 7 years ago Posts: 154 |

@ luismanson: check your slicer - parameter infill overlap --> this defines how much infill and perimeter do overlap. Usually I use about 15% - seems like your overlap is set to high.

@dlc60: strange. I used a spool of white PLA filament a while ago - was no different to the other colors (I nearly only use PLA, only very seldom PETG/TPU/PA6.66)

Edited 1 time(s). Last edit at 11/21/2018 05:08AM by Dancer.

@dlc60: strange. I used a spool of white PLA filament a while ago - was no different to the other colors (I nearly only use PLA, only very seldom PETG/TPU/PA6.66)

Edited 1 time(s). Last edit at 11/21/2018 05:08AM by Dancer.

|

Re: i3, excess material near infill borders November 21, 2018 08:24AM |

Registered: 10 years ago Posts: 371 |

|

Re: i3, excess material near infill borders November 21, 2018 09:37AM |

Registered: 7 years ago Posts: 154 |

|

Re: i3, excess material near infill borders November 21, 2018 02:06PM |

Registered: 10 years ago Posts: 371 |

Sorry, only registered users may post in this forum.