Possible bug in slic3r?

Posted by nikola50

|

Possible bug in slic3r? November 29, 2018 04:13PM |

Registered: 5 years ago Posts: 3 |

Hej there! First to introduce myself, im new on this forum, but not in any mean new to 3d printing, worked with many models and even industrial 3d printers, but now im having some problem which i cannot solve

I updated slic3r, and since last update, it started to work bit strange. Infill is looking really thin, fragile and bad, and i cannot change width of infill lines. It change density of lines, but not amount of plastic which is extruded for infill. What am I missing? I altered extrusion multiplier, temperature, even lowered fan, but amount of plastic is same, it only alters density and distance between walls of infill and perimeter walls. As attachment im adding this picture, and there you can see how it behave on change of settings. How i simply i can make it extrude more plastic on infill?

I updated slic3r, and since last update, it started to work bit strange. Infill is looking really thin, fragile and bad, and i cannot change width of infill lines. It change density of lines, but not amount of plastic which is extruded for infill. What am I missing? I altered extrusion multiplier, temperature, even lowered fan, but amount of plastic is same, it only alters density and distance between walls of infill and perimeter walls. As attachment im adding this picture, and there you can see how it behave on change of settings. How i simply i can make it extrude more plastic on infill?

|

Re: Possible bug in slic3r? November 29, 2018 05:08PM |

Admin Registered: 16 years ago Posts: 13,884 |

... infill greater 100% should give "strange" results by design ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Possible bug in slic3r? November 29, 2018 05:13PM |

Registered: 9 years ago Posts: 752 |

You can't increase the flow for infill specifically as far as I know, only the extrusion factor and filament diameter for all extrusions.

If you think you need a different extrusion flow rate for infill from petimeter chances are there are other problems. Maybe the infill speed is too great or you may be using a long bowden tube that doesn't keep up with the required pressure changes.

You could try slic3r prusa edition which has a star infill pattern which will put down a layer on top of every layer, instead of every other layer cross hatched which makes it much stronger.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

If you think you need a different extrusion flow rate for infill from petimeter chances are there are other problems. Maybe the infill speed is too great or you may be using a long bowden tube that doesn't keep up with the required pressure changes.

You could try slic3r prusa edition which has a star infill pattern which will put down a layer on top of every layer, instead of every other layer cross hatched which makes it much stronger.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Possible bug in slic3r? November 29, 2018 05:27PM |

Registered: 11 years ago Posts: 5,780 |

I suggest that instead of using percentages you manually set line widths in mm, and set all of them equal to the nozzle diameter or only slightly larger, never smaller.

I never understood the point of using percentages for those settings. % of what? It just adds an extra layer of obfuscation to an already complex process.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I never understood the point of using percentages for those settings. % of what? It just adds an extra layer of obfuscation to an already complex process.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Possible bug in slic3r? November 29, 2018 05:37PM |

Registered: 5 years ago Posts: 3 |

I tried also that, to set widths in mm, but without sucess, as i said, it only change density of infill, not amount of actuall plastic. Its direct drive extruder, its tevo black widow, to be precise. I tried altering speeds, but still, infill is just too thin.

Thing is that i did not change any hardware, only updated slic3r. Now i started to use s3d, but im still puzzled what setting i missed with slic3r.

Thing is that i did not change any hardware, only updated slic3r. Now i started to use s3d, but im still puzzled what setting i missed with slic3r.

|

Re: Possible bug in slic3r? November 29, 2018 06:12PM |

Admin Registered: 16 years ago Posts: 13,884 |

... the percentage of infill is meant for a complete dense layer with parallel lines at 100% infill ... then 50% will calculate half density ...

For more infill you have to change the extrusion or flow rate, change speed or layer height, or overlap ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

For more infill you have to change the extrusion or flow rate, change speed or layer height, or overlap ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Possible bug in slic3r? November 29, 2018 09:04PM |

Registered: 9 years ago Posts: 383 |

I think the standard infill is using bridging parameters and so bridge flow has an effect. I found it was a pain to get infill good at layer thicknesses lower than 0.3mm for a 0.5mm nozzle. Petimeters and non bridging infill worked fine at 0.1mm. As others have suggested swapping to in infill style that avoids bridging will help. Prusa edition not essential for that.

Edited 1 time(s). Last edit at 11/29/2018 09:05PM by WesBrooks.

Edited 1 time(s). Last edit at 11/29/2018 09:05PM by WesBrooks.

|

Re: Possible bug in slic3r? December 02, 2018 02:59PM |

Registered: 5 years ago Posts: 10 |

unfortunately its a "bug" in both s3d and slic3r . you cannot choose infill thickness more then a single extrusion line . you can increase infill extrusion in s3d , but it is still a single extrusion .

i cant believe this issue exist for so long without anybody to care .

those single extrusion infills are weak and pointless , the only reason for them to exist is to support the top layers , they add almost nothing to parts rigidity .

thats why most of the time i design my parts with the infill in the cad software and then print with 100% infill.

you can use a simple trick in s3d to make a 3 layer thick infill ,but only with honeycomb .

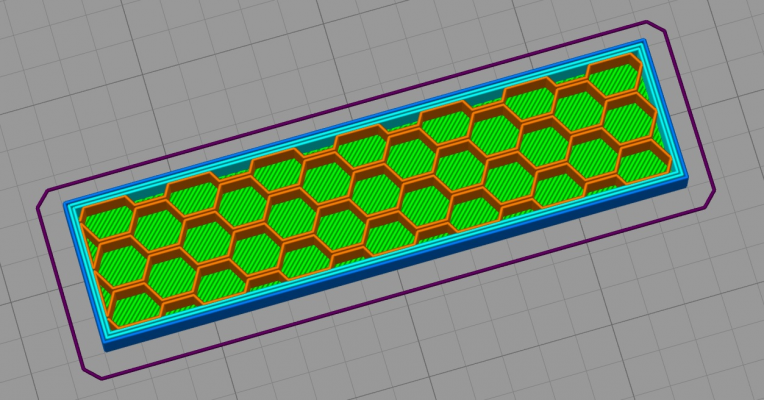

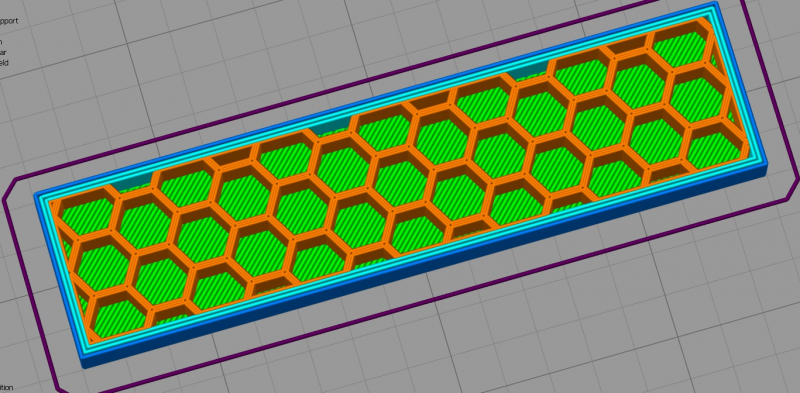

for example this is 20% infill full honeycomb

this infill is weak , wont add any structural advantage .

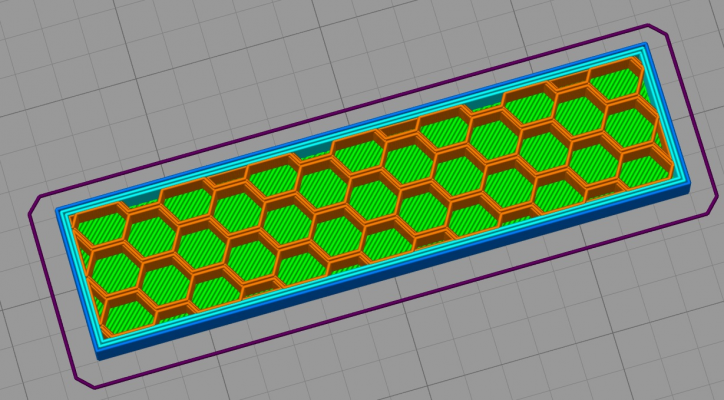

now here's the same 20% with another infill angle added (was 0 , added 120)

now the same infill has 2 line thickness , but not all the lines printed each layer .

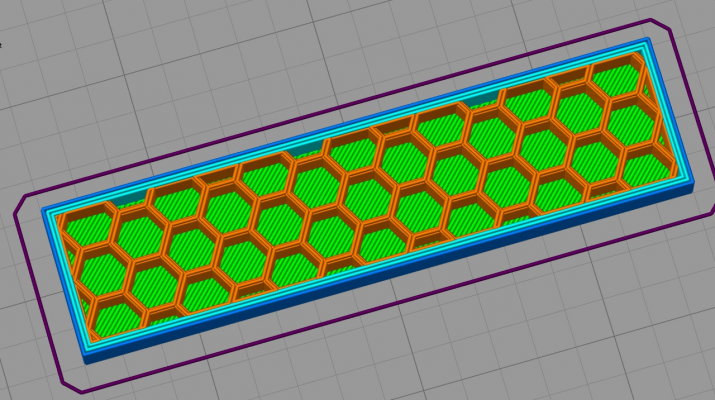

and last one with another angle added (240)

3 layers but not everything printed each layer

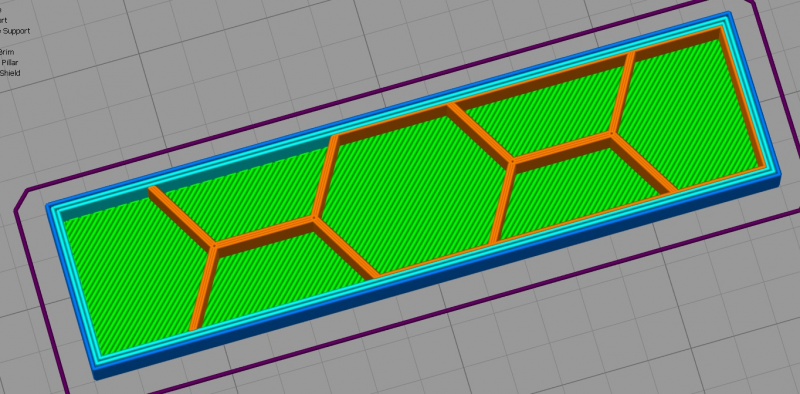

now if i mark the checkbox to print each angle every layer there's a bug that will do this :

to fix it need to choose 60% infill (its still around 20%), and this is the result

i dont know why those slicers wont just add an option to choose the infill layer width , same way they do with perimeters.

the infill in the last pic i added will create much stronger parts then those printed with single extrusion infill even with 80% infill

i cant believe this issue exist for so long without anybody to care .

those single extrusion infills are weak and pointless , the only reason for them to exist is to support the top layers , they add almost nothing to parts rigidity .

thats why most of the time i design my parts with the infill in the cad software and then print with 100% infill.

you can use a simple trick in s3d to make a 3 layer thick infill ,but only with honeycomb .

for example this is 20% infill full honeycomb

this infill is weak , wont add any structural advantage .

now here's the same 20% with another infill angle added (was 0 , added 120)

now the same infill has 2 line thickness , but not all the lines printed each layer .

and last one with another angle added (240)

3 layers but not everything printed each layer

now if i mark the checkbox to print each angle every layer there's a bug that will do this :

to fix it need to choose 60% infill (its still around 20%), and this is the result

i dont know why those slicers wont just add an option to choose the infill layer width , same way they do with perimeters.

the infill in the last pic i added will create much stronger parts then those printed with single extrusion infill even with 80% infill

|

Re: Possible bug in slic3r? December 02, 2018 05:07PM |

Registered: 5 years ago Posts: 3 |

Thing is that i dont need double walls, i just need to set amount of extruded plastic. Somehow, since last update, regardless that i didnt change any settings, both on slic3r or printer itself, it just started to make infill so thin that i need to keep fan on 40% all the time only to keep it of not stringing and ungluing from layers. Im not sure what happened, i even recalled backup settings (always have thoose) and still, its just fragile, thin, almost like sponge.

|

Re: Possible bug in slic3r? December 02, 2018 06:33PM |

Registered: 11 years ago Posts: 5,780 |

Try reinstalling?

Regarding hex infill... I think it's great if you are selling 3D printers and need to take some cool photos for your marketing materials, but practically speaking it's awful. All motion in the printer is subject to acceleration/deceleration. All those short segments in varying directions that make up the honeycomb pattern print slow and shake the crap out of the printer while they are printing. I've never seen any demo of any advantage to hex infill over any other pattern. If you want strong infill that prints quickly and won't beat up your printer, use the grid pattern.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Regarding hex infill... I think it's great if you are selling 3D printers and need to take some cool photos for your marketing materials, but practically speaking it's awful. All motion in the printer is subject to acceleration/deceleration. All those short segments in varying directions that make up the honeycomb pattern print slow and shake the crap out of the printer while they are printing. I've never seen any demo of any advantage to hex infill over any other pattern. If you want strong infill that prints quickly and won't beat up your printer, use the grid pattern.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Possible bug in slic3r? December 03, 2018 04:00AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Possible bug in slic3r? December 03, 2018 04:27AM |

Registered: 9 years ago Posts: 383 |

Quote

MKSA

Gee, so many infill choices, parameters ... so I used to select honeycomb. Now I discover most are useless gimmicks.

They don't make 'em like the used to do they? All this fancy GUI, only need a terminal! ;-)

To be fair I stick with rectilinear myself but did come away wishing the infill could be 0.3mm layers and the perimeter on 0.1. May well be a possibility but the couple of parameters that I though may have given this didn't seem to.

The rectilinear (90 degree alternating grid with big spacing!) is indeed the fastest, unless you have tuned you machine with one axis faster than the other and in this case the single orientation infill may be slightly quicker.

I can see a few potential benefits of the alternate options but have no time to investigate. You can often see witness marks on the outside of the part which correspond to the infill pattern on the inside. In these cases the option to chose a slower wavey pattern may be advantageous as if the thermal stress in the infill is distorting the perimeter (rather than just pushing it away a bit) then the infill would have a bit of give in it when contracting imparting less force on the perimeter. Also when it comes to printing on the infill if the infill alignment is equal to the solid infill alignment then a wave scan could directly support more of the deposited lines, whereas there would be a number that fall between infill lines with no support other than start and finish.

Edit: Honeycomb is indeed a rattly thing but uses less data than the wavey patterns.

Edited 1 time(s). Last edit at 12/03/2018 04:34AM by WesBrooks.

|

Re: Possible bug in slic3r? December 03, 2018 04:42AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Possible bug in slic3r? December 03, 2018 04:44AM |

Registered: 9 years ago Posts: 383 |

|

Re: Possible bug in slic3r? December 03, 2018 06:18AM |

Registered: 5 years ago Posts: 10 |

I showed honeycomb because thats the only infill that can do 3 layer thickness, not because its the best one.

You can use higher thickness lines in s3d by increasing infill extrusion to 200 or 300% for any type of infill.

But i still prefer multi line width fill to just thicker single line, so i continue using 100 fill and generate the infill in cad for amy structural design.

You can use higher thickness lines in s3d by increasing infill extrusion to 200 or 300% for any type of infill.

But i still prefer multi line width fill to just thicker single line, so i continue using 100 fill and generate the infill in cad for amy structural design.

|

Re: Possible bug in slic3r? December 03, 2018 07:21AM |

Registered: 11 years ago Posts: 5,780 |

The reason rectilinear is fast is because it is a series of long straight lines- the mechanism only changes direction when it has finished a line and needs to start a new one. It isn't terribly strong because the lines run in alternating directions on every other layer. That means each layer infill is bridging the previous layer infill (and I believe the bridging speed setting in slic3r applies), so the only point of contact is where the infill lines cross. If you want very strong infill that still prints pretty fast, use the grid pattern. It looks like rectilinear but the difference is that it lays down plastic in both directions on every layer so there's no bridging. The triangle pattern works like the grid pattern and produces very strong infill.

If you're seeing the infill in the surface of the print, use more perimeters. I have found that 3 seems to be the magic number that hides the infill in almost every case. Likewise the top fill- the first layer of the top fill is bridging on the infill, and usually comes out rough. The second layer looks a lot better, and a third layer usually comes out perfect. Of course, it depends a bit on how sparse the infill is. If you're using 5% infill, you may need more top layers to make the top look good.

I suspect a lot of those "interesting" infill patterns are there because some programmer thought "I wonder if I can make it do xxx". I've seen some videos where people try to compare the strength of different infill patterns- it usually involves some "scientific" testing like standing on the print, or throwing it on the ground. Comparisons are very difficult to make. If you compare 10% fill hexagon and grid, maybe the hexagon is stronger. But what if you compare 10% hexagon to 15% grid? Grid prints so much faster without shaking the machine apart...

The Hilbert curve, and octagram spiral sometimes make nice looking top/bottom fill pattern. Cura has a "fuzzy" pattern (that may not be the correct name for it) that can be applied to the surface of the print where it dithers the nozzle position as it prints each outer perimeter layer and produces a rough surface texture.

Infill can be thicker than outer perimeters if you use Slic3r. For example, slice in 100 um layers and in the infill section, under "Reduce printing time" select "combine infill every" and set it to 3 layers. You'll get 100 um perimeters and 300 um infill (assuming you have an appropriate sized nozzle in the extruder). Cura can probably do this, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you're seeing the infill in the surface of the print, use more perimeters. I have found that 3 seems to be the magic number that hides the infill in almost every case. Likewise the top fill- the first layer of the top fill is bridging on the infill, and usually comes out rough. The second layer looks a lot better, and a third layer usually comes out perfect. Of course, it depends a bit on how sparse the infill is. If you're using 5% infill, you may need more top layers to make the top look good.

I suspect a lot of those "interesting" infill patterns are there because some programmer thought "I wonder if I can make it do xxx". I've seen some videos where people try to compare the strength of different infill patterns- it usually involves some "scientific" testing like standing on the print, or throwing it on the ground. Comparisons are very difficult to make. If you compare 10% fill hexagon and grid, maybe the hexagon is stronger. But what if you compare 10% hexagon to 15% grid? Grid prints so much faster without shaking the machine apart...

The Hilbert curve, and octagram spiral sometimes make nice looking top/bottom fill pattern. Cura has a "fuzzy" pattern (that may not be the correct name for it) that can be applied to the surface of the print where it dithers the nozzle position as it prints each outer perimeter layer and produces a rough surface texture.

Infill can be thicker than outer perimeters if you use Slic3r. For example, slice in 100 um layers and in the infill section, under "Reduce printing time" select "combine infill every" and set it to 3 layers. You'll get 100 um perimeters and 300 um infill (assuming you have an appropriate sized nozzle in the extruder). Cura can probably do this, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Possible bug in slic3r? December 03, 2018 07:24AM |

Registered: 9 years ago Posts: 383 |

Quote

the_digital_dentist

Infill can be thicker than outer perimeters if you use Slic3r. For example, slice in 100 um layers and in the infill section, under "Reduce printing time" select "combine infill every" and set it to 3 layers. You'll get 100 um perimeters and 300 um infill (assuming you have an appropriate sized nozzle in the extruder). Cura can probably do this, too.

Thanks, I'll have another poke at that at some point soon! Not an issue when working at 0.3 layers but infill doesn't print nice with rectilinear and 0.1 layers with a 0.5mm nozzle!

Sorry, only registered users may post in this forum.