|

weird problem with under-extrusion only on first layers after the first one.. Any ideas? December 07, 2018 01:24PM |

Registered: 5 years ago Posts: 2 |

My setup is Slic3r Prusa with some custom Mendels i redesigned myself (carthesian, marlin 1.1.9, inductive sensor, geared direct extruder, heated bed with blue tape), some have a vulcano clone with 0.6mm nozzle and 5/16 and some have a regular V6 with a 0.4mm.

Im not sure when this started but some time reciently it got worse. The thing is my machines understrude on purpose, i calibrate the extrusion watching the surface finish, that ends up in like 92% of what it should extruse and so far i had no problem, no weak parts, no air gaps, good tolerances etc and printing super fast no problem.

Sometime ago it started extremely understruding on the first 3 layers after the first layer, that would be layers 1, 2, and 3, starting from layer 0, and it tends to coincide with the bottom solid infill layers, and only affects the first layers, after it finishes the solid infill it then extrudes normally, no gaps between perimeters or sparse solid infill. So i get an understruded bottom solid infill and a completely fine and normal top solid infill.

I tried setting the steps/mm so that i have 100% extrusion and it helps a bit but then the rest of the piece ends up completely bloated, the tolerances are horrible and top surface finish is all overextruded and full of drag marks.

So far i made a python program that will read slicer prusa gcode and parse the settings and recalculate the extrusion from layer 1 to 3 (or up the the last layer of bottom solid infill. and it somewhat fixed the issue but not always, and still i cant get consistent perimeters on those first layers on every gcode file.

Also tried reducing the speed to 50% and lowering the temperatures to 220ºC and still same results.

This happened both with cure and slic3r prusa, on both mi machines with V6 `+ THSL screw and Vulcano + 5/16 rods.

Does anyone have any idea of what am i doing wrong? Is this hardware, software? I seriously searched everywhere and found nothing simillar

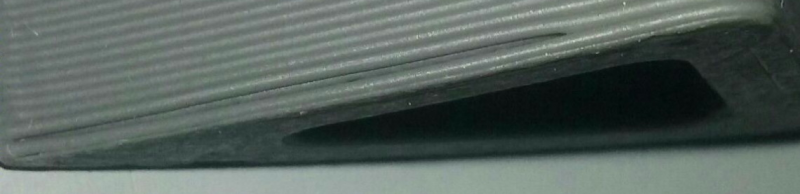

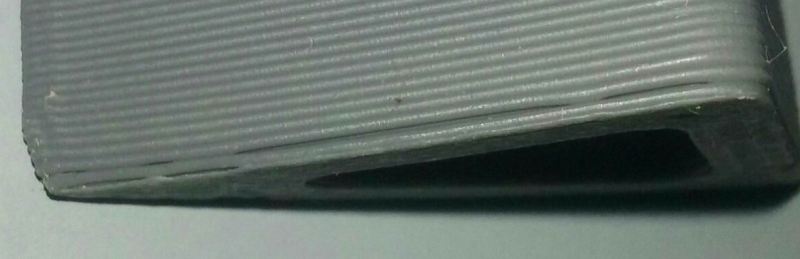

(the pictures: 0.5mm layer, 0.6mm nozzle, 0.675 Ext. Width, 22mm^3/s perimeters)

Im not sure when this started but some time reciently it got worse. The thing is my machines understrude on purpose, i calibrate the extrusion watching the surface finish, that ends up in like 92% of what it should extruse and so far i had no problem, no weak parts, no air gaps, good tolerances etc and printing super fast no problem.

Sometime ago it started extremely understruding on the first 3 layers after the first layer, that would be layers 1, 2, and 3, starting from layer 0, and it tends to coincide with the bottom solid infill layers, and only affects the first layers, after it finishes the solid infill it then extrudes normally, no gaps between perimeters or sparse solid infill. So i get an understruded bottom solid infill and a completely fine and normal top solid infill.

I tried setting the steps/mm so that i have 100% extrusion and it helps a bit but then the rest of the piece ends up completely bloated, the tolerances are horrible and top surface finish is all overextruded and full of drag marks.

So far i made a python program that will read slicer prusa gcode and parse the settings and recalculate the extrusion from layer 1 to 3 (or up the the last layer of bottom solid infill. and it somewhat fixed the issue but not always, and still i cant get consistent perimeters on those first layers on every gcode file.

Also tried reducing the speed to 50% and lowering the temperatures to 220ºC and still same results.

This happened both with cure and slic3r prusa, on both mi machines with V6 `+ THSL screw and Vulcano + 5/16 rods.

Does anyone have any idea of what am i doing wrong? Is this hardware, software? I seriously searched everywhere and found nothing simillar

(the pictures: 0.5mm layer, 0.6mm nozzle, 0.675 Ext. Width, 22mm^3/s perimeters)

|

Re: weird problem with under-extrusion only on first layers after the first one.. Any ideas? December 07, 2018 02:47PM |

Registered: 7 years ago Posts: 558 |

I've experienced some issues with 0.6 nozzles compared to 0.4 nozzles and it seems to miss some sections and creates gaps. I'm still working to figure out the exact cause, but I suspect neither Slic3r or Cura work well with anything beyond 0.4 nozzles. It's almost like the tooling paths are setup and designed for 0.4, and just increasing the nozzle size causes some "errors" to happen around certain features. In my case I could see a direct issue between 0.4 nozzles and 0.6, as a print would be perfect at 0.4, but re-sliced at 0.6 would result in some gaps around certain features. I'm still testing, but I plan to see what a 0.8 nozzle does and with it being a multiple of 0.4 if its better than a 0.6.

I did have some success on certain parts setting my extrusion width or nozzle size to 0.58 instead of 0.6 and that did seem to correct some of those gap issues.

Edited 1 time(s). Last edit at 12/07/2018 02:48PM by PDBeal.

I did have some success on certain parts setting my extrusion width or nozzle size to 0.58 instead of 0.6 and that did seem to correct some of those gap issues.

Edited 1 time(s). Last edit at 12/07/2018 02:48PM by PDBeal.

|

Re: weird problem with under-extrusion only on first layers after the first one.. Any ideas? December 07, 2018 03:52PM |

Registered: 5 years ago Posts: 2 |

I also had issues with the 0.6mm nozzle and noticed the same you say but as slic3r prusa kept updating the problems kind of went away.

In any case this also happens to me in my e3D V6/0.4mm machine, whats more, that was the machine that made me take a look into this issue because it started making parts that were unusable that would have the bottom layers completely detach from the rest by just pushing my nail inbetween without much effort. Thats why its so confusing, its happening in all my machines, new and old ones and changing software didnt fix it, so i cant pinpoint it to whats causing it, hardware, software or what!

In any case this also happens to me in my e3D V6/0.4mm machine, whats more, that was the machine that made me take a look into this issue because it started making parts that were unusable that would have the bottom layers completely detach from the rest by just pushing my nail inbetween without much effort. Thats why its so confusing, its happening in all my machines, new and old ones and changing software didnt fix it, so i cant pinpoint it to whats causing it, hardware, software or what!

|

Re: weird problem with under-extrusion only on first layers after the first one.. Any ideas? January 08, 2019 07:20PM |

Registered: 7 years ago Posts: 619 |

Quote

PDBeal

I've experienced some issues with 0.6 nozzles compared to 0.4 nozzles and it seems to miss some sections and creates gaps. I'm still working to figure out the exact cause, but I suspect neither Slic3r or Cura work well with anything beyond 0.4 nozzles. It's almost like the tooling paths are setup and designed for 0.4, and just increasing the nozzle size causes some "errors" to happen around certain features. In my case I could see a direct issue between 0.4 nozzles and 0.6, as a print would be perfect at 0.4, but re-sliced at 0.6 would result in some gaps around certain features. I'm still testing, but I plan to see what a 0.8 nozzle does and with it being a multiple of 0.4 if its better than a 0.6.

I did have some success on certain parts setting my extrusion width or nozzle size to 0.58 instead of 0.6 and that did seem to correct some of those gap issues.

I use CURA and Simplify3D on a custom printer with a .6mm nozzle. I have found that unless you have a "Volcano" with your .6mm nozzle you have to slow down a little because the heater just can't melt the filament fast enough. I print at 60mm/s and either .25 or .3mm print heights and line widths of .5 to .6mm. I print "less pretty" models out 2x or 3x faster with this setup than a .4mm nozzle. I use this printer to make large cases for stuff where I don't have any fine detail, so I don't care.

DLC

|

Re: weird problem with under-extrusion only on first layers after the first one.. Any ideas? January 09, 2019 08:16AM |

Registered: 8 years ago Posts: 413 |

I would check your Z steps per mm. And you may aswell check the extruder aswell.

Check the Z offset for the 1st layer.

You can have an error in the z offset that can caus a good squished 1st layer but the error causes issues on the 2nd layer, and possibly the 3rd. After that all the layers are the same.

From the picture you have a very thin 1st layer then a large 2nd layer so i think the z calibration is your issue.

Check the Z offset for the 1st layer.

You can have an error in the z offset that can caus a good squished 1st layer but the error causes issues on the 2nd layer, and possibly the 3rd. After that all the layers are the same.

From the picture you have a very thin 1st layer then a large 2nd layer so i think the z calibration is your issue.

|

Re: weird problem with under-extrusion only on first layers after the first one.. Any ideas? January 09, 2019 09:34AM |

Registered: 6 years ago Posts: 1,863 |

I read somewhere that you should never print a layer height of more than 80percent of the nozzle size.

If this is correct then with a .6 nozzle * 80 % the largest layer should be only 0.48 Myself 70-75% make for better layer adhesion.

Looking at the above prints the layers look almost round you might be able to reduce the gaps enough with a 0.46 - 0.48 layer height.

Preheat the hot-end allowing for and even heat saturation before Printing begins, Print a skirt with a couple wraps.

It only takes a test print with 3 or 4 layers to determine the best settings.

Edited 4 time(s). Last edit at 01/09/2019 11:58AM by Roberts_Clif.

Computer Programmer / Electronics Technician

If this is correct then with a .6 nozzle * 80 % the largest layer should be only 0.48 Myself 70-75% make for better layer adhesion.

Looking at the above prints the layers look almost round you might be able to reduce the gaps enough with a 0.46 - 0.48 layer height.

Quote

pomponX

weird problem with under-extrusion only on first layers after the first one

Preheat the hot-end allowing for and even heat saturation before Printing begins, Print a skirt with a couple wraps.

It only takes a test print with 3 or 4 layers to determine the best settings.

Edited 4 time(s). Last edit at 01/09/2019 11:58AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Sorry, only registered users may post in this forum.