|

Bonding between perimeter lines, holes - fill, fill to perimeter January 05, 2019 06:06PM |

Registered: 5 years ago Posts: 7 |

Slic3R rev 1.3.1-dev

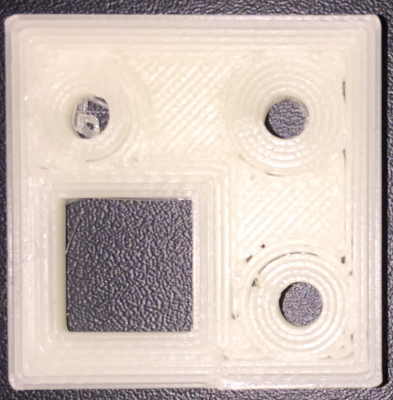

I've played around for a bit understanding how to get decent results for various parts. My latest part has holes in it that support other items. With little effort they snap right out of the body. The attached photo shows why, .

This happens even in the perimeter layers, and between perimeter/ the infill. I've tried for quite some time to resolve the issue.

Please respond with suggestions.

Slice 3R Config Files

Printer- PLAconfig.ini

Filament - PLAconfigHotterby5.ini

Print Settings - PLAconfig.ini

I've played around for a bit understanding how to get decent results for various parts. My latest part has holes in it that support other items. With little effort they snap right out of the body. The attached photo shows why, .

This happens even in the perimeter layers, and between perimeter/ the infill. I've tried for quite some time to resolve the issue.

Please respond with suggestions.

Slice 3R Config Files

Printer- PLAconfig.ini

Filament - PLAconfigHotterby5.ini

Print Settings - PLAconfig.ini

|

Re: Bonding between perimeter lines, holes - fill, fill to perimeter January 06, 2019 06:52PM |

Registered: 5 years ago Posts: 7 |

The issue appeared to be the amount of extruded material. Changing the Slic3R Extrusion Filament Multiplier from 1.0 to 1.10 improved the print a lot, near perfect infill to perimeter and line to line. Increasing it to 1.20 now makes a very solid part.

Given the small printed part I am unsure what the effect would be on a large fill area or thick wall. May cause warping if there is too much filament being printed.

Given the small printed part I am unsure what the effect would be on a large fill area or thick wall. May cause warping if there is too much filament being printed.

|

Re: Bonding between perimeter lines, holes - fill, fill to perimeter January 09, 2019 12:46PM |

Registered: 5 years ago Posts: 7 |

|

Re: Bonding between perimeter lines, holes - fill, fill to perimeter January 09, 2019 07:48PM |

Registered: 7 years ago Posts: 558 |

Sorry, only registered users may post in this forum.